ASTM D3164M-03

(Test Method)Standard Test Method for Strength Properties of Adhesively Bonded Plastic Lap-Shear Sandwich Joints in Shear by Tension Loading (Withdrawn 2012)

Standard Test Method for Strength Properties of Adhesively Bonded Plastic Lap-Shear Sandwich Joints in Shear by Tension Loading (Withdrawn 2012)

SCOPE

1.1 This test method is intended to complement Test Method D 1002 and D 3163 and extend its application to single-lap-shear adhesive joints employing plastic adherends. The test method is useful for generating comparative shear strength data for joints made from a number of plastics. It can also provide a means by which several plastics surface treatments can be compared.

1.2 The values stated in SI units are to be regarded as the standard.

Note 1—A soft metric (conversion from English) companion to Test Method D 3164M has been developed - D 3164.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method is intended to complement Test Method D1002 and Test Method D3163 and extend its application to single-lap-shear adhesive joints employing plastic adherends. The test method is useful for generating comparative shear strength data for joints made from a number of plastics. It can also provide a means by which several plastics surface treatments can be compared.

Formerly under the jurisdiction of Committee D14 on Adhesives, this test method was withdrawn in January 2012 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3164M–03

Standard Test Method for

Strength Properties of Adhesively Bonded Plastic Lap-Shear

1

Sandwich Joints in Shear by Tension Loading

This standard is issued under the fixed designation D3164M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* sively Bonded Rigid Plastic Lap-Shear Joints in Shear by

Tension Loading

1.1 ThistestmethodisintendedtocomplementTestMethod

D3164 Test Method for Strength Properties of Adhesively

D1002 and D3163 and extend its application to single-lap-

Bonded Plastic Lap-Shear Sandwich Joints in Shear by

shear adhesive joints employing plastic adherends. The test

Tension Loading

methodisusefulforgeneratingcomparativeshearstrengthdata

D4896 Guide for Use ofAdhesive-Bonded Single Lap-Joint

for joints made from a number of plastics. It can also provide

Specimen Test Results

a means by which several plastics surface treatments can be

E4 Practices for Force Verification of Testing Machines

compared.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard.

3.1 Definitions—Many terms in this test method are defined

NOTE 1—A soft metric (conversion from English) companion to Test

in Terminology D907.

Method D3164M has been developed - D3164.

4. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Due to the increased use of adhesively bonded plastics

responsibility of the user of this standard to establish appro- asaresultoftheinherentadvantagesaffordedbybondedrather

priate safety and health practices and determine the applica-

than mechanically fastened joints, particularly the alleviation

bility of regulatory limitations prior to use. of stress risers and stress cracking, there is a need for standard

tests by which joints of various substrates and adhesives can be

2. Referenced Documents

compared. This test method is intended to meet such a need.

2

2.1 ASTM Standards:

4.2 This test method is limited to test temperatures below

D907 Terminology of Adhesives

the softening point of the subject adherends, and is not

D1002 Test Method forApparent Shear Strength of Single-

intended for use on anisotropic adherends such as reinforced

Lap-Joint Adhesively Bonded Metal Specimens by Ten-

plastic laminates.

sion Loading (Metal-to-Metal)

4.3 The misuse of strength values obtained from this test

D2093 Practice for Preparation of Surfaces of Plastics Prior

method as design stress allowable values for structural joints

to Adhesive Bonding

could lead to product failure, property damage, and human

D2651 Guide for Preparation of Metal Surfaces for Adhe-

injury.

sive Bonding

4.4 The apparent shear strength of an adhesive obtained

D3163 Test Method for Determining Strength of Adhe-

from a given small single-lap specimen may differ from that

obtained from a joint made with different adherends or by a

different bonding process. The normal variation of temperature

1

This test method is under the jurisdiction of ASTM Committee D14 on and moisture in the service environment causes the adherends

AdhesivesandisthedirectresponsibilityofSubcommitteeD14.40onAdhesivesfor

and the adhesive to swell and shrink. The adherends and

Plastics

adhesive are likely to have different thermal and moisture

Current edition approved Aug. 10, 2003. Published September 2003. Originally

coefficients of expansion.

approved in 1998. Last previous edition approved in 1998 as D3164M - 98. DOI:

10.1520/D3164M-03.

4.5 Even in small specimens, short-term environmental

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

changes can induce internal stresses or chemical changes in the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

adhesive that permanently affect the apparent strength and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

other mechanical properties of the adhesive. The problem of

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3164M–03

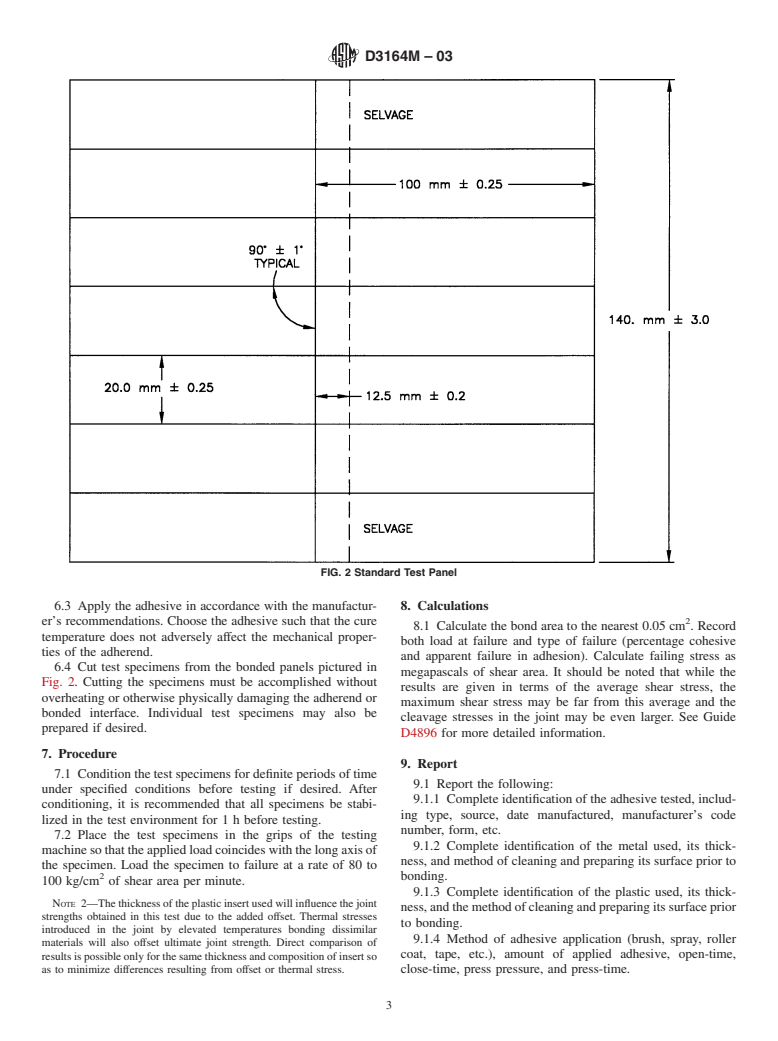

predicting joint behavior in a changing environment is even 5.2 Temperature and Relative Humidity Controlling Equip-

more difficult if a different type of adherend is used in a larger ment, capable of maintaining the test temperature to 63°C and

structural joint than was used in the small specimen.

therelativehumidityto 63 %.Ifambientlaboratoryconditions

4.6 The appa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.