ASTM A960/A960M-14a

(Specification)Standard Specification for Common Requirements for Wrought Steel Piping Fittings

Standard Specification for Common Requirements for Wrought Steel Piping Fittings

ABSTRACT

This specification covers the common requirements that shall apply to wrought steel piping fittings. The material shall consist of forgings, bars, plates, and seamless or welded tubular products. Ferritic steels shall be fully killed. Hollow cylindrically shaped parts up to and including NPS 4 may be machined from bar or seamless tubular material. Elbows, return bends, tees, and header tees shall not be machined directly from bar stock. The following procedures shall be done for heat treatment: full annealing, solution annealing, isothermal annealing, normalizing, tempering and post-weld heat treatment, stress relieving, and quench and temper. Chemical analysis, heat analysis, and product analysis shall also be done. The chemical requirements shall conform to the required compositions of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, vanadium, columbium, titanium, aluminum, lead, and copper. The following tests shall be done for the mechanical requirements: tension, hardness, impact, and hydrostatic tests.

SCOPE

1.1 This specification covers a group of common requirements that shall apply to wrought steel piping fittings covered in any of the following individual product specifications or any other ASTM specification that invokes this specification or portions thereof:

Title of Specification

ASTM

Designation

Specification for Piping Fittings of Wrought

Carbon Steel and Alloy Steel for Moderate and

Elevated Temperatures

A234/A234M

Specification for Wrought Austenitic Stainless

Steel Piping Fittings

A403/A403M

Specification for Piping Fittings of Wrought Carbon

Steel and Alloy Steel for Low-Temperature Service

A420/A420M

Specification for Butt-Welding, Wrought-Carbon

Steel, Piping Fittings with Improved Notch Toughness

A758/A758M

Specification for As-Welded Wrought Austenitic

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate Temperatures

A774/A774M

Specification for Wrought Ferritic, Ferritic/Austenitic,

and Martensitic Stainless Steel Piping Fittings

A815/A815M

Specification for Heat-Treated Carbon Steel

Fittings for Low-Temperature and Corrosive Service

A858/A858M

Specification for Wrought High-Strength

Low-Alloy Steel Butt-Welded Fittings

A860/A860M

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.3 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (See 4.1.8). The acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the order as agreed upon by the purchaser and supplier.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text and the tables, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. The inch-pound units shall apply unless the “M” designation [SI] of the product specification is specified in the order.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A960/A960M −14a

StandardSpecification for

Common Requirements for Wrought Steel Piping Fittings

This standard is issued under the fixed designationA960/A960M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* in each system may not be exact equivalents; therefore each

system shall be used independently of the other. Combining

1.1 This specification covers a group of common require-

values from the two systems may result in non-conformance

ments that shall apply to wrought steel piping fittings covered

with the specification. The inch-pound units shall apply unless

in any of the following individual product specifications or any

the “M” designation [SI] of the product specification is

other ASTM specification that invokes this specification or

specified in the order.

portions thereof:

Title of Specification ASTM

2. Referenced Documents

Designation

Specification for Piping Fittings of Wrought A234/A234M

2.1 ASTM Standards:

Carbon Steel andAlloy Steel for Moderate and

A29/A29M SpecificationforGeneralRequirementsforSteel

Elevated Temperatures

Specification for WroughtAustenitic Stainless A403/A403M

Bars, Carbon and Alloy, Hot-Wrought

Steel Piping Fittings

A234/A234M Specification for Piping Fittings of Wrought

Specification for Piping Fittings of Wrought Carbon A420/A420M

Carbon Steel and Alloy Steel for Moderate and High

Steel andAlloy Steel for Low-Temperature Service

Specification for Butt-Welding, Wrought-Carbon A758/A758M Temperature Service

Steel, Piping Fittings with Improved Notch Toughness

A262 Practices for Detecting Susceptibility to Intergranular

Specification forAs-Welded WroughtAustenitic A774/A774M

Attack in Austenitic Stainless Steels

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate Temperatures

A370 Test Methods and Definitions for Mechanical Testing

Specification for Wrought Ferritic, Ferritic/Austenitic, A815/A815M

of Steel Products

and Martensitic Stainless Steel Piping Fittings

A388/A388M Practice for Ultrasonic Examination of Steel

Specification for Heat-Treated Carbon Steel A858/A858M

Fittings for Low-Temperature and Corrosive Service

Forgings

Specification for Wrought High-Strength A860/A860M

A403/A403M SpecificationforWroughtAusteniticStainless

Low-Alloy Steel Butt-Welded Fittings

Steel Piping Fittings

1.2 In case of conflict between a requirement of the indi-

A420/A420M Specification for Piping Fittings of Wrought

vidual product specification and a requirement of this general

Carbon Steel and Alloy Steel for Low-Temperature Ser-

requirement specification, the requirements of the individual

vice

product specification shall prevail over those of this specifica-

A700 Guide for Packaging, Marking, and Loading Methods

tion.

for Steel Products for Shipment

1.3 By mutual agreement between the purchaser and the

A751 Test Methods, Practices, and Terminology for Chemi-

supplier, additional requirements may be specified (See 4.1.8).

cal Analysis of Steel Products

The acceptance of any such additional requirements shall be

A758/A758M Specification for Wrought-Carbon Steel Butt-

dependent on negotiations with the supplier and must be

Welding Piping Fittings with Improved Notch Toughness

included in the order as agreed upon by the purchaser and

A763 Practices for Detecting Susceptibility to Intergranular

supplier.

Attack in Ferritic Stainless Steels

A774/A774M Specification for As-Welded Wrought Auste-

1.4 The values stated in either SI units or inch-pound units

niticStainlessSteelFittingsforGeneralCorrosiveService

are to be regarded separately as standard. Within the text and

at Low and Moderate Temperatures

the tables, the SI units are shown in brackets.The values stated

A815/A815M Specification for Wrought Ferritic, Ferritic/

Austenitic, and Martensitic Stainless Steel Piping Fittings

A858/A858M Specification for Heat-Treated Carbon Steel

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting

Materials for Piping and Special Purpose Applications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2014 as A960/A960M–14. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0960_A0960M-14A. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

A960/A960M−14a

Fittings for Low-Temperature and Corrosive Service 3.1.4 flange—a component for bolted joints used in piping

A860/A860M Specification for Wrought High-Strength Fer- systems and pressure vessels.

ritic Steel Butt-Welding Fittings

3.1.5 forging—the product of a substantially compressive

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

hot or cold plastic working operation that consolidates the

Alloys, and Ferroalloys

material and produces the required shape.

A967 Specification for Chemical Passivation Treatments for

3.1.6 Discussion—The plastic working must be performed

Stainless Steel Parts

by a forging machine, such as a hammer, press, or ring rolling

A1058 Test Methods for Mechanical Testing of Steel

machine and must deform the material to produce an essen-

Products—Metric

tially wrought structure throughout the material cross section.

E165 Practice for Liquid Penetrant Examination for General

3.2 Definitions—For definitions of other terms used in this

Industry

specification, refer to Terminology A941.

E213 Practice for Ultrasonic Testing of Metal Pipe and

Tubing

4. Ordering Information

E709 Guide for Magnetic Particle Testing

E1916 Guide for Identification of Mixed Lots of Metals

4.1 It is the purchaser’s responsibility to specify in the

2.2 Manufacturer’s Standardization Society Standards: purchase order all ordering information necessary to purchase

MSS-SP-25 The Standard Marking System of Valves,

the needed material. Examples of such information include but

Fittings, Flanges and Unions are not limited to the following:

MSS-SP-43 Standard Practice for Light Weight Stainless

4.1.1 Quantity,

Steel Butt-Welding Fittings 4.1.2 Description of fitting and nominal dimensions (stan-

MSS-SP-75 Specification for High Test Wrought Butt-

dard or special),

Welding Fittings 4.1.3 Steel composition by grade and class designation,

MSS-SP-79 Socket Welding Reducer Inserts

4.1.4 Construction, seamless or welded (unless seamless or

MSS-SP-83 Class 3000 Steel Pipe Unions, Socket Welding welded construction is specified by the purchaser, either may

and Threaded

be furnished at the option of the supplier),

MSS-SP-95 Swage(d) Nipples and Bull Plugs 4.1.5 Specification number (including the year/date of

MSS-SP-97 Integrally Reinforced Forged Branch Outlet

issue),

Fittings—Socket Welding, Threaded and Buttwelding 4.1.6 Choice of testing track from the options listed in Test

Ends

Methods A1058 when material is ordered to an M suffix (SI

units) product standard. If the choice of test track is not

2.3 American Society of Nondestructive Testing:

specified in the order, then the default ASTM track shall be

SNT-TC-1A Recommended Practice for Nondestructive

used as noted in Test Methods A1058.

Testing Personnel Qualification and Certification

5 4.1.7 Supplementary requirements, and

2.4 ASME Standards:

4.1.8 Additional requirements.

B16.9 Steel Butt-Welding Fittings

B16.11 Forged Steel Fittings, Socket Welding and Threaded

5. Material

Boiler and Pressure Vessel Code Section IX

5.1 The material for fittings shall consist of forgings, bars,

3. Terminology

plates and seamless or welded tubular products.

3.1 Definitions of Terms Specific to This Standard:

5.2 The steel shall conform to the chemical requirements of

3.1.1 bar—a solid section that is long in relationship to its

theindividualproductspecificationandmaybemadefromany

cross sectional dimensions, with a relatively constant cross

process.

section throughout its length. (See Specification A29/A29M

5.3 Ferritic steels shall be fully killed.

for definitions relating to the production of hot wrought and

5.4 If secondary melting is employed, the heat shall be

cold finished bars.)

defined as all ingots remelted from a primary heat.

3.1.2 certifying organization—the company or association

responsible for the conformance of, the marking of, and the

6. Manufacture

certification of the product to the specification requirements.

6.1 Forging or shaping operations may be performed by any

3.1.3 fitting—a component for non-bolted joints used in

ofthemethodsincludedintheindividualproductspecification.

piping systems and pressure vessels.

6.2 Hollow cylindrically shaped parts up to and including

NPS 4 may be machined from bar or seamless tubular material

AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

provided the axial length of the part is approximately parallel

Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

to the axial length of the fitting. Elbows, return bends, tees and

hq.com.

header tees shall not be machined directly from bar stock.

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

6.3 Fittings, after forming at an elevated temperature, shall

Available from American Society of Mechanical Engineers (ASME), ASME

be cooled to a temperature below the critical range under

International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org. suitable conditions to prevent injury by cooling too rapidly.

A960/A960M−14a

6.4 All classes of fittings shall have the welders, welding conforms to the requirements of another grade for which that

operators, and welding procedures qualified under the provi- element is a specified element having a required minimum

sion of Section IX of the ASME Boiler and Pressure Vessel content. For this requirement, a grade is defined as an alloy

Code except that welds from the original pipe manufacturer described individually and identified by its own UNS or grade

made without the addition of filler metal do not require such designation in a table of chemical requirements within any

qualification. specification listed within the scope as being covered by this

specification.

7. Heat Treatment

8.3 Product Analysis—If a product analysis is performed it

7.1 Fittings requiring heat treatment shall be treated as

shall be in accordance with Test Methods, Practices, and

specified in the individual product specification using the

TerminologyA751.Thechemicalcompositionthusdetermined

following procedures:

shall conform to limits of the product specification, within the

7.1.1 Full Annealing—Fittings shall be uniformly reheated

permissible variations of Table 1 or Table 2 of this

to a temperature above the transformation range and, after

specification, as appropriate for the grade being supplied.

holding for a sufficient time at this temperature, cooled slowly

to a temperature below the transformation range.

7.1.2 Solution Annealing—Fittings shall be heated to a

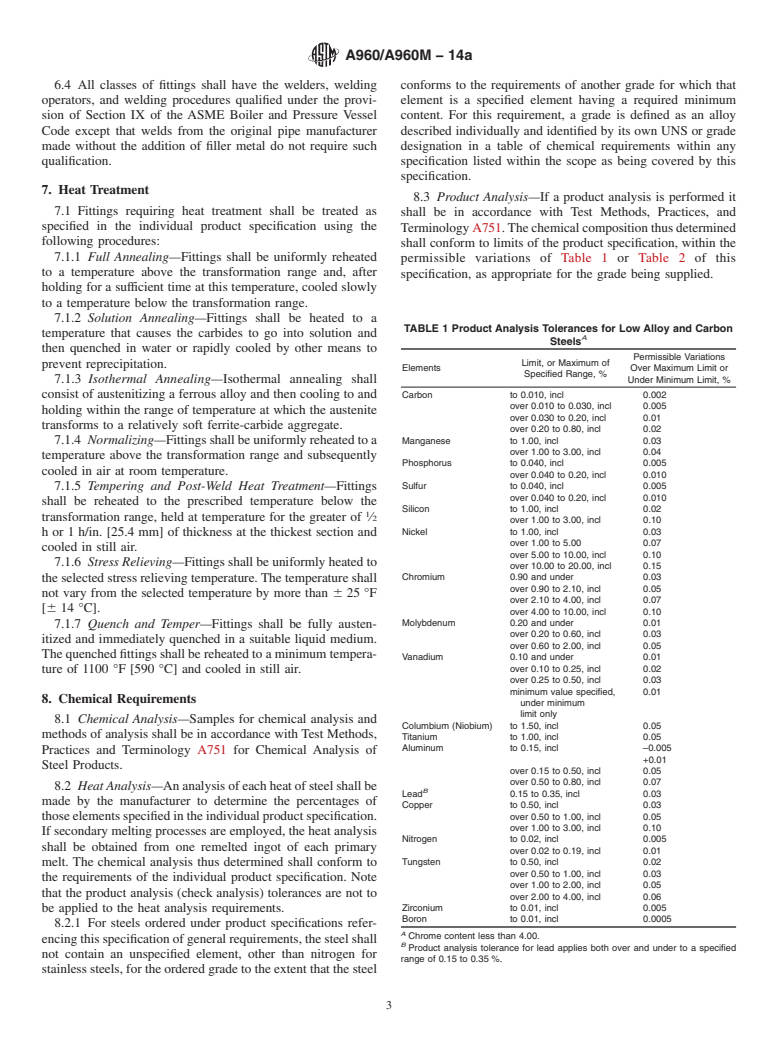

TABLE 1 Product Analysis Tolerances for Low Alloy and Carbon

temperature that causes the carbides to go into solution and

A

Steels

then quenched in water or rapidly cooled by other means to

Permissible Variations

Limit, or Maximum of

prevent reprecipitation.

Elements Over Maximum Limit or

Specified Range, %

7.1.3 Isothermal Annealing—Isothermal annealing shall Under Minimum Limit, %

Carbon to 0.010, incl 0.002

consist of austenitizing a ferrous alloy and then cooling to and

over 0.010 to 0.030, incl 0.005

holding within the range of temperature at which the austenite

over 0.030 to 0.20, incl 0.01

transforms to a relatively soft ferrite-carbide aggregate.

over 0.20 to 0.80, incl 0.02

7.1.4 Normalizing—Fittingsshallbeuniformlyreheatedtoa Manganese to 1.00, incl 0.03

over 1.00 to 3.00, incl 0.04

temperature above the transformation range and subsequently

Phosphorus to 0.040, incl 0.005

cooled in air at room temperature.

over 0.040 to 0.20, incl 0.010

7.1.5 Tempering and Post-Weld Heat Treatment—Fittings Sulfur to 0.040, incl 0.005

over 0.040 to 0.20, incl 0.010

shall be reheated to the prescribed temperature below the

Silicon to 1.00, incl 0.02

transformation range, held at temperature for the greater of ⁄2

over 1.00 to 3.00, incl 0.10

Nickel to 1.00, incl 0.03

h or 1 h/in. [25.4 mm] of thickness at the thickest section and

over 1.00 to 5.00 0.07

cooled in still air.

over 5.00 to 10.00, incl 0.10

7.1.6 Stress Relieving—Fittings shall be uniformly heated to

over 10.00 to 20.00, incl 0.15

Chromium 0.90 and under 0.03

the selected stress relieving temperature.The temperature shall

over 0.90 to 2.10, incl 0.05

not vary from the selected temperature by more than 6 25 °F

over 2.10 to 4.00, incl 0.07

[6 14 °C].

over 4.00 to 10.00, incl 0.10

Molybdenum 0.20 and under 0.01

7.1.7 Quench and Temper—Fittings shall be fully austen-

over 0.20 to 0.60, incl 0.03

itized and immediately quenched in a suitable liquid medium.

over 0.60 to 2.00, incl 0.05

Thequenchedfittingsshallbereheatedtoaminimumtempera-

Vanadium 0.10 and under 0.01

over 0.10 to 0.25, incl 0.02

ture of 1100 °F [590 °C] and cooled in still air.

over 0.25 to 0.50, incl 0.03

minimum value specified, 0.01

8. Chemical Requirements

under minimum

limit only

8.1 Chemical Analysis—Samples for chemical analysis and

Columbium (Niobium) to 1.50, incl 0.05

methods of analysis shall be in accordance with Test Methods,

Titanium to 1.00, incl 0.05

Aluminum to 0.15, incl –0.005

Practices and Terminology A751 for Chemical Analysis of

+0.01

Steel Products.

over 0.15 to 0.50, incl 0.05

over 0.50 to 0.80, incl 0.07

8.2 Heat Analysis—Ananalysisofeachheatofsteelshallbe

B

Lead 0.15 to 0.35, incl 0.03

made by the manufacturer to determine the percentages of

Copper to 0.50, incl 0.03

thoseelementsspecifiedintheindividualproductspecification. over 0.50 to 1.00, incl 0.05

over 1.00 to 3.00, incl 0.10

If secondary melting processes are employed, the heat analysis

Nitrogen to 0.02, incl 0.005

shall be obtained from one remelted ingot of each primary

over 0.02 to 0.19, incl 0.01

Tungsten to 0.50, incl 0.02

melt. The chemical analysis thus determined shall conform to

over 0.50 to 1.00, incl 0.03

the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A960/A960M − 14 A960/A960M − 14a

Standard Specification for

Common Requirements for Wrought Steel Piping Fittings

This standard is issued under the fixed designation A960/A960M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a group of common requirements that shall apply to wrought steel piping fittings covered in any

of the following individual product specifications or any other ASTM specification that invokes this specification or portions

thereof:

Title of Specification ASTM

Designation

Specification for Piping Fittings of Wrought A234/A234M

Carbon Steel and Alloy Steel for Moderate and

Elevated Temperatures

Specification for Wrought Austenitic Stainless A403/A403M

Steel Piping Fittings

Specification for Piping Fittings of Wrought Carbon A420/A420M

Steel and Alloy Steel for Low-Temperature Service

Specification for Butt-Welding, Wrought-Carbon A758/A758M

Steel, Piping Fittings with Improved Notch Toughness

Specification for As-Welded Wrought Austenitic A774/A774M

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate Temperatures

Specification for Wrought Ferritic, Ferritic/Austenitic, A815/A815M

and Martensitic Stainless Steel Piping Fittings

Specification for Heat-Treated Carbon Steel A858/A858M

Fittings for Low-Temperature and Corrosive Service

Specification for Wrought High-Strength A860/A860M

Low-Alloy Steel Butt-Welded Fittings

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general

requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.3 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (See 4.1.8). The

acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the

order as agreed upon by the purchaser and supplier.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text and the

tables, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore each system

shall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. The inch-pound units shall apply unless the “M” designation [SI] of the product specification is specified in the order.

2. Referenced Documents

2.1 ASTM Standards:

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A234/A234M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature

Service

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved May 1, 2014Nov. 1, 2014. Published May 2014November 2014. Originally approved in 1996. Last previous edition approved in 20132014 as

A960/A960M–13.–14. DOI: 10.1520/A0960_A0960M-14.10.1520/A0960_A0960M-14A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A960/A960M − 14a

A403/A403M Specification for Wrought Austenitic Stainless Steel Piping Fittings

A420/A420M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A758/A758M Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness

A763 Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

A774/A774M Specification for As-Welded Wrought Austenitic Stainless Steel Fittings for General Corrosive Service at Low and

Moderate Temperatures

A815/A815M Specification for Wrought Ferritic, Ferritic/Austenitic, and Martensitic Stainless Steel Piping Fittings

A858/A858M Specification for Heat-Treated Carbon Steel Fittings for Low-Temperature and Corrosive Service

A860/A860M Specification for Wrought High-Strength Ferritic Steel Butt-Welding Fittings

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A967 Specification for Chemical Passivation Treatments for Stainless Steel Parts

A1058 Test Methods for Mechanical Testing of Steel Products—Metric

E165 Practice for Liquid Penetrant Examination for General Industry

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E709 Guide for Magnetic Particle Testing

E1916 Guide for Identification of Mixed Lots of Metals

2.2 Manufacturer’s Standardization Society Standards:

MSS-SP-25 The Standard Marking System of Valves, Fittings, Flanges and Unions

MSS-SP-43 Standard Practice for Light Weight Stainless Steel Butt-Welding Fittings

MSS-SP-75 Specification for High Test Wrought Butt-Welding Fittings

MSS-SP-79 Socket Welding Reducer Inserts

MSS-SP-83 Class 3000 Steel Pipe Unions, Socket Welding and Threaded

MSS-SP-95 Swage(d) Nipples and Bull Plugs

MSS-SP-97 Integrally Reinforced Forged Branch Outlet Fittings—Socket Welding, Threaded and Buttwelding Ends

2.3 American Society of Nondestructive Testing:

SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel Qualification and Certification

2.4 ASME Standards:

B16.9 Steel Butt-Welding Fittings

B16.11 Forged Steel Fittings, Socket Welding and Threaded

Boiler and Pressure Vessel Code Section IX

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 bar—a solid section that is long in relationship to its cross sectional dimensions, with a relatively constant cross section

throughout its length. (See Specification A29/A29M for definitions relating to the production of hot wrought and cold finished

bars.)

3.1.2 certifying organization—the company or association responsible for the conformance of, the marking of, and the

certification of the product to the specification requirements.

3.1.3 fitting—a component for non-bolted joints used in piping systems and pressure vessels.

3.1.4 flange—a component for bolted joints used in piping systems and pressure vessels.

3.1.5 forging—the product of a substantially compressive hot or cold plastic working operation that consolidates the material

and produces the required shape.

3.1.6 Discussion—The plastic working must be performed by a forging machine, such as a hammer, press, or ring rolling

machine and must deform the material to produce an essentially wrought structure throughout the material cross section.

3.2 Definitions—For definitions of other terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 It is the purchaser’s responsibility to specify in the purchase order all ordering information necessary to purchase the needed

material. Examples of such information include but are not limited to the following:

4.1.1 Quantity,

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

A960/A960M − 14a

4.1.2 Description of fitting and nominal dimensions (standard or special),

4.1.3 Steel composition by grade and class designation,

4.1.4 Construction, seamless or welded (unless seamless or welded construction is specified by the purchaser, either may be

furnished at the option of the supplier),

4.1.5 Specification number (including the year/date of issue),

4.1.6 Choice of testing track from the options listed in Test Methods A1058 when material is ordered to an M suffix (SI units)

product standard. If the choice of test track is not specified in the order, then the default ASTM track shall be used as noted in Test

Methods A1058.

4.1.7 Supplementary requirements, and

4.1.8 Additional requirements.

5. Material

5.1 The material for fittings shall consist of forgings, bars, plates and seamless or welded tubular products.

5.2 The steel shall conform to the chemical requirements of the individual product specification and may be made from any

process.

5.3 Ferritic steels shall be fully killed.

5.4 If secondary melting is employed, the heat shall be defined as all ingots remelted from a primary heat.

6. Manufacture

6.1 Forging or shaping operations may be performed by any of the methods included in the individual product specification.

6.2 Hollow cylindrically shaped parts up to and including NPS 4 may be machined from bar or seamless tubular material

provided the axial length of the part is approximately parallel to the axial length of the fitting. Elbows, return bends, tees and header

tees shall not be machined directly from bar stock.

6.3 Fittings, after forming at an elevated temperature, shall be cooled to a temperature below the critical range under suitable

conditions to prevent injury by cooling too rapidly.

6.4 All classes of fittings shall have the welders, welding operators, and welding procedures qualified under the provision of

Section IX of the ASME Boiler and Pressure Vessel Code except that welds from the original pipe manufacturer made without the

addition of filler metal do not require such qualification.

7. Heat Treatment

7.1 Fittings requiring heat treatment shall be treated as specified in the individual product specification using the following

procedures:

7.1.1 Full Annealing—Fittings shall be uniformly reheated to a temperature above the transformation range and, after holding

for a sufficient time at this temperature, cooled slowly to a temperature below the transformation range.

7.1.2 Solution Annealing—Fittings shall be heated to a temperature that causes the carbides to go into solution and then

quenched in water or rapidly cooled by other means to prevent reprecipitation.

7.1.3 Isothermal Annealing—Isothermal annealing shall consist of austenitizing a ferrous alloy and then cooling to and holding

within the range of temperature at which the austenite transforms to a relatively soft ferrite-carbide aggregate.

7.1.4 Normalizing—Fittings shall be uniformly reheated to a temperature above the transformation range and subsequently

cooled in air at room temperature.

7.1.5 Tempering and Post-Weld Heat Treatment—Fittings shall be reheated to the prescribed temperature below the

transformation range, held at temperature for the greater of ⁄2 h or 1 h/in. [25.4 mm] of thickness at the thickest section and cooled

in still air.

7.1.6 Stress Relieving—Fittings shall be uniformly heated to the selected stress relieving temperature. The temperature shall not

vary from the selected temperature by more than 6 25 °F [6 14 °C].

7.1.7 Quench and Temper—Fittings shall be fully austenitized and immediately quenched in a suitable liquid medium. The

quenched fittings shall be reheated to a minimum temperature of 1100 °F [590 °C] and cooled in still air.

8. Chemical Requirements

8.1 Chemical Analysis—Samples for chemical analysis and methods of analysis shall be in accordance with Test Methods,

Practices and Terminology A751 for Chemical Analysis of Steel Products.

8.2 Heat Analysis—An analysis of each heat of steel shall be made by the manufacturer to determine the percentages of those

elements specified in the individual product specification. If secondary melting processes are employed, the heat analysis shall be

obtained from one remelted ingot of each primary melt. The chemical analysis thus determined shall conform to the requirements

of the individual product specification. Note that the product analysis (check analysis) tolerances are not to be applied to the heat

analysis requirements.

A960/A960M − 14a

8.2.1 For steels ordered under product specifications referencing this specification of general requirements, the steel shall not

contain an unspecified element, other than nitrogen for stainless steels, for the ordered grade to the extent that the steel conforms

to the requirements of another grade for which that element is a specified element having a required minimum content. For this

requirement, a grade is defined as an alloy described individually and identified by its own UNS or grade designation in a table

of chemical requirements within any specification listed within the scope as being covered by this specification.

8.3 Product Analysis—If a product analysis is performed it shall be in accordance with Test Methods, Practices, and

Terminology A751. The chemical composition thus determined shall conform to limits of the product specification, within the

permissible variations of Table 1 or Table 2 of this specification, as appropriate for the grade being supplied.

9. Mechanical Requirements

9.1 Method of Mechanical Test—All tests shall be conducted in accordance with Test Methods and Definitions A370 if the

inch-pound units are specified or Test Methods A1058 if the M suffix (SI Units) standard is specified.

9.2 The test specimen shall represent all material from the same heat and heat treatment load whose maximum thicknesses do

not exceed the thickness of the test specimen or blank by more than ⁄4 in. [6 mm].

TABLE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.