ASTM D7606-11

(Practice)Standard Practice for Sampling of High Pressure Hydrogen and Related Fuel Cell Feed Gases

Standard Practice for Sampling of High Pressure Hydrogen and Related Fuel Cell Feed Gases

SIGNIFICANCE AND USE

Hydrogen is delivered to fuel cell powered automotive vehicles and stationary appliances at pressures up to 87.5 MPa. The quality of hydrogen delivered is a significant factor in maximizing fuel cell efficiency and life span. Contamination can arise during the production of fuel cell feed gases, storage containers, station tubing and fuel lines up to the nozzle used for fuel delivery. Collection of a representative fuel sample without the introduction of contamination even as low as parts-per-billion (ppb) per contaminant during collection is crucial for assessing the quality of fuel in real world applications.

This practice is intended for application to high pressure, high purity hydrogen; however, the apparatus design and sampling techniques may be applicable to collection of other fuel cell supply gases. Many of the techniques used in this practice can be applied to lower pressure/lower purity gas streams.

SCOPE

1.1 This practice describes a hydrogen quality sampling apparatus (HQSA) and a procedure for the sampling of high pressure hydrogen at fueling nozzles of 35 or 70 Mega Pascal (MPa) fueling stations.

1.2 This practice does not include the analysis of the acquired sample. Applicable ASTM standards include but are not limited to test methods referenced in Section 2 of this practice.

1.3 This practice is not intended for sampling and measuring particulate matter in high pressure hydrogen. For procedures on sampling and measuring particulate matter see ASTM D7650 and D7651.

1.4 The values stated in SI units are standard. The values stated in inch-pounds are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7606 − 11

Standard Practice for

Sampling of High Pressure Hydrogen and Related Fuel Cell

Feed Gases

This standard is issued under the fixed designation D7606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope SAE J2799 70 MPa Compressed Hydrogen Surface Vehicle

Fuelling Connection Device and Optional Vehicle to

1.1 This practice describes a hydrogen quality sampling

Station Communications

apparatus (HQSA) and a procedure for the sampling of high

SAETIR J2719 Information Report of the Development of a

pressure hydrogen at fueling nozzles of 35 or 70 Mega Pascal

Hydrogen Quality Guideline for Fuel Cell Vehicles

(MPa) fueling stations.

2.3 California Code of Regulations:

1.2 This practice does not include the analysis of the

California Code of Regulations Title 4, Division 9, Chapter

acquired sample. Applicable ASTM standards include but are

6, Article 8, Sections 4180 – 4181

not limited to test methods referenced in Section 2 of this

3. Terminology

practice.

3.1 Definitions:

1.3 This practice is not intended for sampling and measur-

3.1.1 absolute pressure—Pressure measured with reference

ing particulate matter in high pressure hydrogen. For proce-

to absolute zero pressure, usually expressed in MPa, mm Hg,

dures on sampling and measuring particulate matter seeASTM

or pound per square inch (psi).

D7650 and D7651.

3.1.2 contaminant—impurity that adversely affects the com-

1.4 The values stated in SI units are standard. The values

ponents within fuel cell or hydrogen storage systems

stated in inch-pounds are for information only.

3.1.3 gauge pressure—Pressure measured above ambient

1.5 This standard does not purport to address all of the

atmospheric pressure. Zero gauge pressure is equal to ambient

safety concerns, if any, associated with its use. It is the

atmospheric (barometric) pressure.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.4 gaseous fuel—Material to be tested, as sampled, with-

bility of regulatory limitations prior to use. out change of composition by drying or otherwise.

3.1.5 hydrogen quality sampling apparatus (HQSA)—an

2. Referenced Documents

apparatus used to collect hydrogen from a 35 or 70 MPa

2.1 ASTM Standards:

hydrogen fueling nozzle (SAE J2600 and SAE J2799) into a

D7650 Test Method for Sampling of Particulate Matter in

sample container.

High Pressure Hydrogen used as a Gaseous Fuel with an

3.2 Definitions of Terms Specific to This Standard:

In-Stream Filter

3.2.1 high pressure hydrogen—For the purposes of this

D7651 Test Method for Gravimetric Measurement of Par-

practice, high pressure hydrogen is hydrogen defined as hydro-

ticulate Concentration of Hydrogen Fuel

gen pressurized to 35 or 70MPa.

2.2 SAE Standards

SAE J2600 Compressed Hydrogen Surface Vehicle Refuel-

4. Summary of Practice

ing Connection Devices

4.1 This practice describes an apparatus and procedure for

the sampling of high pressure hydrogen from fueling nozzles

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous

conforming to SAE J2600 or SAE J2799. This practice is

Fuels and is the direct responsibility of Subcommittee D03.14 on Hydrogen and

intended as a guideline for ensuring collection of a represen-

Fuel Cells.

tative sample without introducing trace levels of contaminants.

Current edition approved March 1, 2011. Published April 2011. DOI: 10.1520/

Samples collected using this practice should be suitable for

D7606–11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

trace analysis of contaminants, utilizing a variety of analytical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

techniques.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale, Available from Office of Administrative Law, 300 Capitol Mall Suite 1250,

PA 15096-0001, http://www.sae.org. Sacramento, CA 95814–4339.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7606 − 11

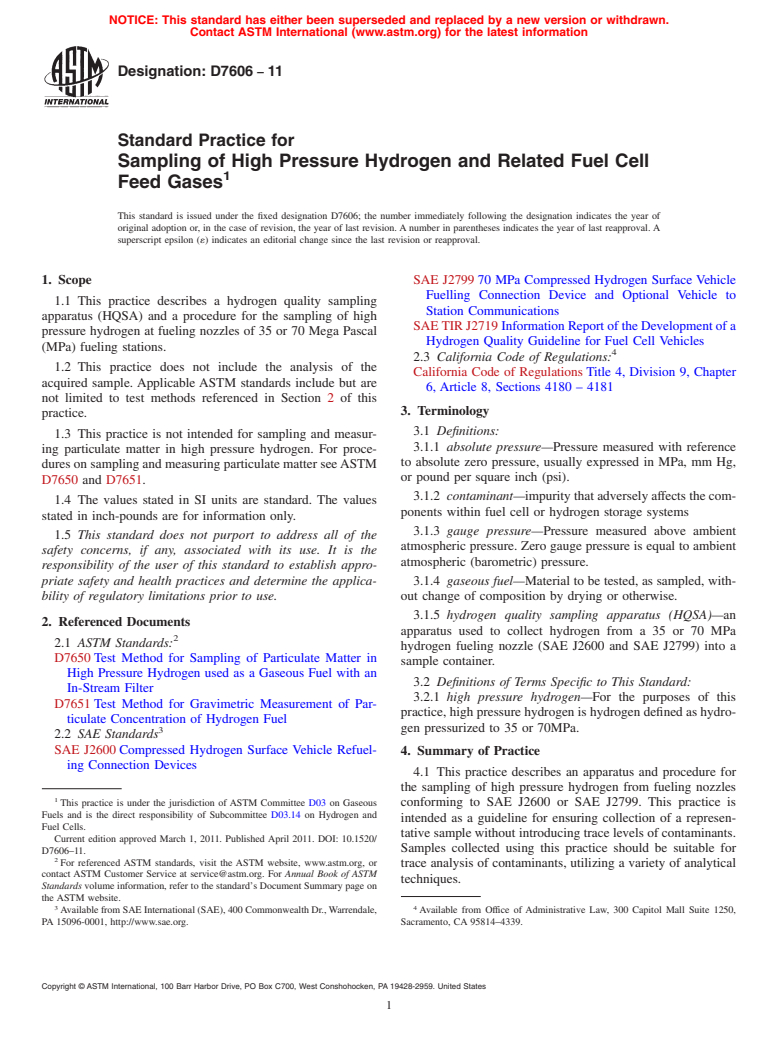

5. Significance and Use 6.2 HQSA Metal Support Plate ( 1, Fig. 1)—The HQSA

metal support plate is utilized to mitigate damage during

5.1 Hydrogen is delivered to fuel cell powered automotive

transportation and support the apparatus. The HQSA is firmly

vehicles and stationary appliances at pressures up to 87.5 MPa.

fixed to a metal support plate by tube supports (2, Fig. 1.).

The quality of hydrogen delivered is a significant factor in

6.3 Movable Adjustable Platform—Before sampling, the

maximizing fuel cell efficiency and life span. Contamination

metal plate holding the HQSAis firmly clamped onto a height

can arise during the production of fuel cell feed gases, storage

adjustable and movable platform, such as a heavy duty cart

containers, station tubing and fuel lines up to the nozzle used

with a hydraulic adjustable horizontal platform and brakes on

for fuel delivery. Collection of a representative fuel sample

its wheels. The cart is moved to a position close to the fueling

without the introduction of contamination even as low as

station and the height of platform is adjusted so that the fueling

parts-per-billion (ppb) per contaminant during collection is

nozzle attaches easily to the receptacle of HQSA.The platform

crucial for assessing the quality of fuel in real world applica-

height is adjusted to provide a safe and comfortable work

tions.

space. The cart is then locked into place using the cart wheel

5.2 This practice is intended for application to high

brakes.

pressure, high purity hydrogen; however, the apparatus design

6.4 SAE J2799 Receptacle (3, Fig. 1) – This receptacle can

and sampling techniques may be applicable to collection of

other fuel cell supply gases. Many of the techniques used in adapt to both 35 and 70MPa hydrogen fueling nozzles. For

safety reason, the receptacle must be positioned vertically so

this practice can be applied to lower pressure/lower purity gas

streams. that the fueling nozzle attaches to the receptacle from the top.

Tosupporttheweightofthefuelingnozzle,thereceptaclemust

6. Apparatus Design

have an additional support (3.1, Fig. 1), which is fixed to the

metal support plate (1, Fig. 1).

6.1 The general design of the HQSA is shown in Fig. 1,

which is a depiction of the apparatus with the nozzle hydrogen 6.5 Main Valve (4, Fig. 1)—The functions of the main valve

pressure regulated to approximate 6.9 MPa (1000 psi) before are explained as follows:

sampling. The pressure of 6.9 MPa (1000 psi) is selected as an 6.5.1 Station and HQSA leak test—The station leak test is

example since it is, generally, the lowest pressure tolerated by performed before hydrogen fuel sampling to ensure there are

hydrogen station safety shutoff systems while still providing a

noleaksinthehydrogenfueldeliverysystem.Forsamplingthe

sample that analytical laboratories can safely handle routinely. station personnel must attach the fueling nozzle to the SAE

All HQSA parts, including the ventilation tubes, are made of

J2799 receptacle (3, Fig. 1) first while the main valve is closed.

316 grade stainless steel (SS). The station leak test procedure is then initiated. A hand held

FIG. 1 Hydrogen Quality Sampling Apparatus

D7606 − 11

hydrogen leak detector is used to check for leaks around all the 6.11 Check Valve—The check valve (16, Fig. 1) with 69

connections from nozzle to the main valve as in 10.7. There is KiloPascal(KPa)(10psi)crackpressureisinstalledatthevent

oftheHQSA(Fig.1)topreventairfrombackdiffusionintothe

residual high pressure hydrogen left in the station hose when

HQSA.

the station is not fueling. The residual high pressure hydrogen

can be used for checking the leakage in the complete HQSA

6.12 Ventilation Assembly (17, Fig. 1)—The ventilation

system, including the sample container, as shown in 10.8.

assembly contains a 3 meter (m) (10 ft) long SS braided tubing

6.5.2 Prevention of High Pressure Hydrogen Passing interfaced to a dual 2.4 m (8 ft) long 1.27 cm ( ⁄2 in.) Outside

through the Regulator—If the main valve (4, Fig. 1)isnot Diameter (OD) SS tubing which is kept vertical to the ground.

During sampling, the hydrogen fuel flows through HQSA, then

installed and station fueling starts, the diaphragm of the

regulator (5, Fig. 1) may fail due to rapid hydrogen pressur- the check valve (16, Fig. 1), through thea3m long SS braided

tubing (17.1, Fig. 1) and dual 2.4 m long 1.27 cm ( ⁄2 in.) OD

ization. In this case, pressure relief valve (PRV) 15, (Fig. 1)

SS tubing (17.2, Fig. 1), before venting to atmosphere at

will open to release hydrogen pressure above 10.3 MPa (1500

approximately 2.4 m (8 ft) above ground.

psi). The main valve (4, Fig. 1) when closed is designed to

contain high pressure hydrogen when the station sampling

7. Additional Equipment Needed

starts.The main valve is slowly turned to the open position and

7.1 Hydrogen Leak Detector—Ahydrogen leak detector is a

the high pressure hydrogen is regulated to 6.9 MPa (1000 psi).

required as a safety device needed to detect hydrogen gas leaks

6.6 Regulator 5 (Fig. 1) and all connections from the SAE

when the HQSA is pressurized. Leak detection using soap

J2799 Receptacle to Regulator—The regulator and all the

bubbles must not be used due to possible moisture contamina-

connections, including tubing, tubing fittings, adapter fittings

tion.

and unions from the SAE J2799 receptacle to the main valve

and main valve to regulator must have a pressure rating of 103

8. Hazards

Mpa (15,000 psi) or higher. The regulator should have two

8.1 High hydrogen pressure—The hydrogen pressure can be

gauges, 5.1 and 5.2 in Fig. 1, to monitor both inlet and outlet

as high as 87.5MPa and constitutes both an explosion and fire

pressures.

hazard.

6.7 Inlet and Outlet Valves (6 and 12, Fig. 1, respectively)—

8.2 The total mass of hydrogen passing through the HQSA

The valves should be easily opened and closed, such as ball

during a sampling event is approximately 1 kilogram (kg).

valves. The HQSA and sample container are cleaned by

Smoking, camera flashes, or mobile phone usage is unsafe

pressurizing and, releasing hydrogen from the HQSA and

within 7.6 m (25 ft) of either the ventilation tubing (6.12)or

sample container (10.11) using these valves. This cleaning

hydrogen fueling station itself. Additional safety precautions

procedure can be repeated many times (10.11) but must be

mustbetakenasnecessarytopreventfireorexplosion,orboth.

performedatleast10timestoensureavalidsampleundermost

8.3 Static Charges—During gaseous sampling, the ex-

sampling conditions.

tremely high-speed hydrogen flow rate may generate a static

charge on HQSAcomponents. The static charge is removed by

6.8 Sample Containers—The pressure rating of the sample

groundingtheHQSAwithawirefromhydrogenfuelingstation

containers is 12.4 MPa (1800 psi). The sample containers and

or other available grounding wire(s).

both inlet and outlet valves (8 and 10, Fig. 1, respectively) are

internally coated with silicon (Si) since sulfur gas analysis to

9. HQSA Cleaning

low ppb is required under SAE TIR J2719 and other hydrogen

9.1 Do not clean the HQSAwith water, iso-propanol or any

fuel quality specifications. To avoid air contamination during

other solvent.

sampling, both inlet and outlet valves of sample containers are

equipped with quick connects – one end of the container has a

9.2 The HQSA must be cleaned by purging during sam-

quick-connect stem and the other end a quick-connect body.

pling. This is done by flowing one kilogram hydrogen fuel

These two quick-connections (7 and 11, Fig. 1) and the inlet

through the HQSAafter the nozzle pressure is regulated to 6.9

and outlet valves provide a double seal on both ends of the

MPa (1000 psi). The hydrogen flow rate at 1000 psi is

sample container.

approximately 33.3 grams per second for a total sampling time

of around 30 s. At this flow rate, SAE TIR J2719 targeted

6.9 HQSA Pressure Release Valve (14, Fig. 1)—The valve is

constituents will be removed from within the HQSA and

always closed before and during sampling.After collection, the

sampling lines. This procedure is the best way to conveniently

pressure release valve is opened before removal of the pres-

dehydrate and remove residual sulfur gases from the HQSA,

surized and sealed sample container to release the hydrogen

sampling line, and sample container. Dehydration of the

pressure in the HQSA through a check valve (16, Fig. 1).

apparatus cannot be safely achieved at the station through

Hydrogen at 6.9 MPa (1000 psi) contained inside the HQSA

evacuation or heating, or both.

must be released before next sample container can be safely

connected to the inlet quick-connection (7, Fig. 1).

10. Sampling Procedures

6.10 Proportional Release Valve (PRV, 15, Fig. 1)—The 10.1 Safety Precaution—During gaseous sampling, person-

PRVissetat10.3MPa(1500psi)toprotectthe12.4MPa(1800

nel must wear goggles, safety shoes and a flame resistant lab

psi) pressure proof sample container. coat or other industrial flame resistant clothing. Personnel not

D7606 − 11

directly involved in sampling should beat least 5 m away from sample container outlet valve and record the ending sampling

the HQSA during sampling. time once 1 kg of hydrogen has flowed through the HQSAand

sample container. The regulated hydrogen pressure should be

10.2 Attach a ground wire to the station ground.

back to 1000 psi. Close the sample container inlet valve. In

10.3 Fix the HQSA onto a platform of a hydraulic cart

general, the station fueling process will be shut down when

(6.3).

closing the sample container outlet valve. If not, shut down the

station fueling process.

10.4 Connect HQSA to the ventilation system (6.12).

10.5 Attach a 1-L 1800 psi stainless steel sample container 10.12 If additional sampling is to be performed, do not

to HQSA through quick connections (7 and 11, Fig. 1).

remove the fueling nozzle. Instead, close the main valve. Open

the HQSA pressure release valve (14, Fig. 1) to release the

10.6 Make sure all the valves of HQSA (Fig. 1) are closed

pressure inside the HQSA to atmospheric pressure, excepting

and attach the station 35 or 70 MPa nozzle to the SAE J2799

the pressure remaining between the receptacle and main valve

receptacle (3, Fig. 1).

(3 to 4, Fig. 1). The check valve (16, F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.