ASTM D4449-90(1999)

(Test Method)Standard Test Method for Visual Evaluation of Gloss Differences Between Surfaces of Similar Appearance

Standard Test Method for Visual Evaluation of Gloss Differences Between Surfaces of Similar Appearance

SCOPE

1.1 This method covers the visual evaluation of gloss differences of coating surfaces, using special types of lamps for illumination. It identifies six aspects or types of gloss that one may look for when using the lamp to assess gloss differences between surfaces. It describes the conditions for using the lamps to best identify small differences in each of the six types of gloss. Four levels of visual gloss differences are distinguished.

1.2 While this technique is useful for both weathered and unweathered specimens, it has not been applied to metallics.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4449 – 90 (Reapproved 1999)

Standard Test Method for

Visual Evaluation of Gloss Differences Between Surfaces of

Similar Appearance

This standard is issued under the fixed designation D 4449; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.3 gloss, of a surface—perceived directionally selective

reflecting properties responsible for the degree to which

1.1 This test method covers the visual evaluation of gloss

reflected highlights or images of objects may be seen as

differences of coating surfaces, using special types of lamps for

superimposed on the surface.

illumination. It identifies six aspects or types of gloss that one

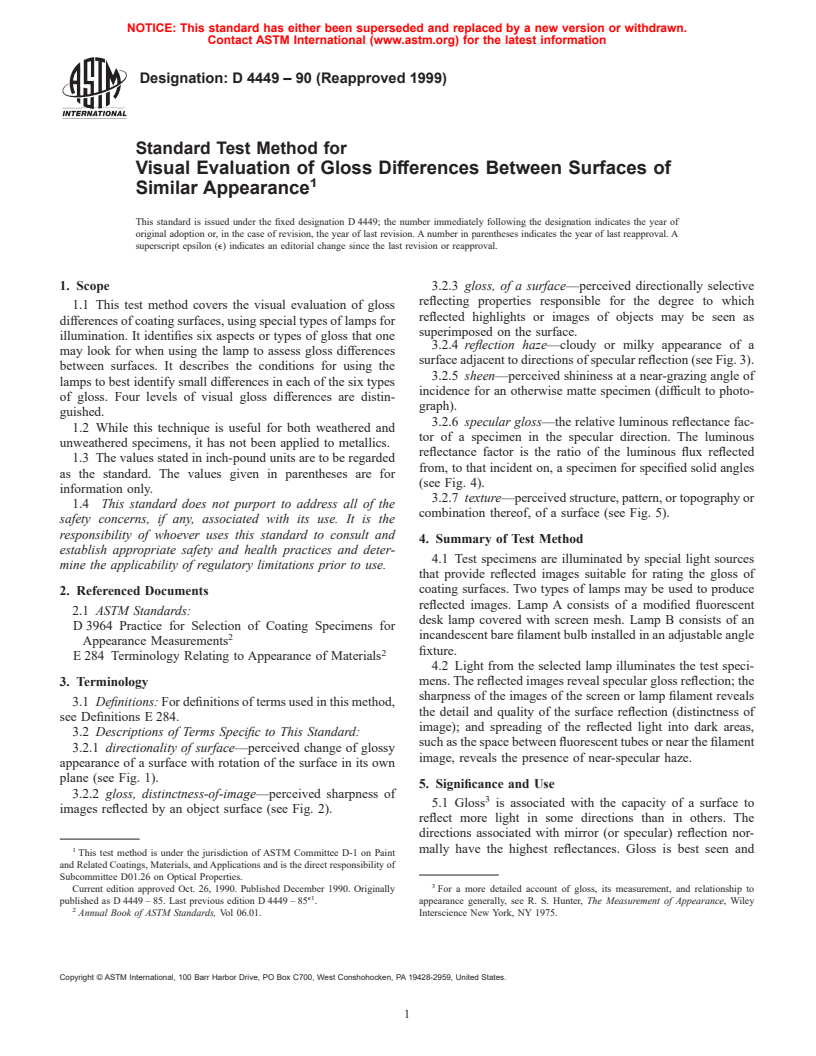

3.2.4 reflection haze—cloudy or milky appearance of a

may look for when using the lamp to assess gloss differences

surface adjacent to directions of specular reflection (see Fig. 3).

between surfaces. It describes the conditions for using the

3.2.5 sheen—perceived shininess at a near-grazing angle of

lamps to best identify small differences in each of the six types

incidence for an otherwise matte specimen (difficult to photo-

of gloss. Four levels of visual gloss differences are distin-

graph).

guished.

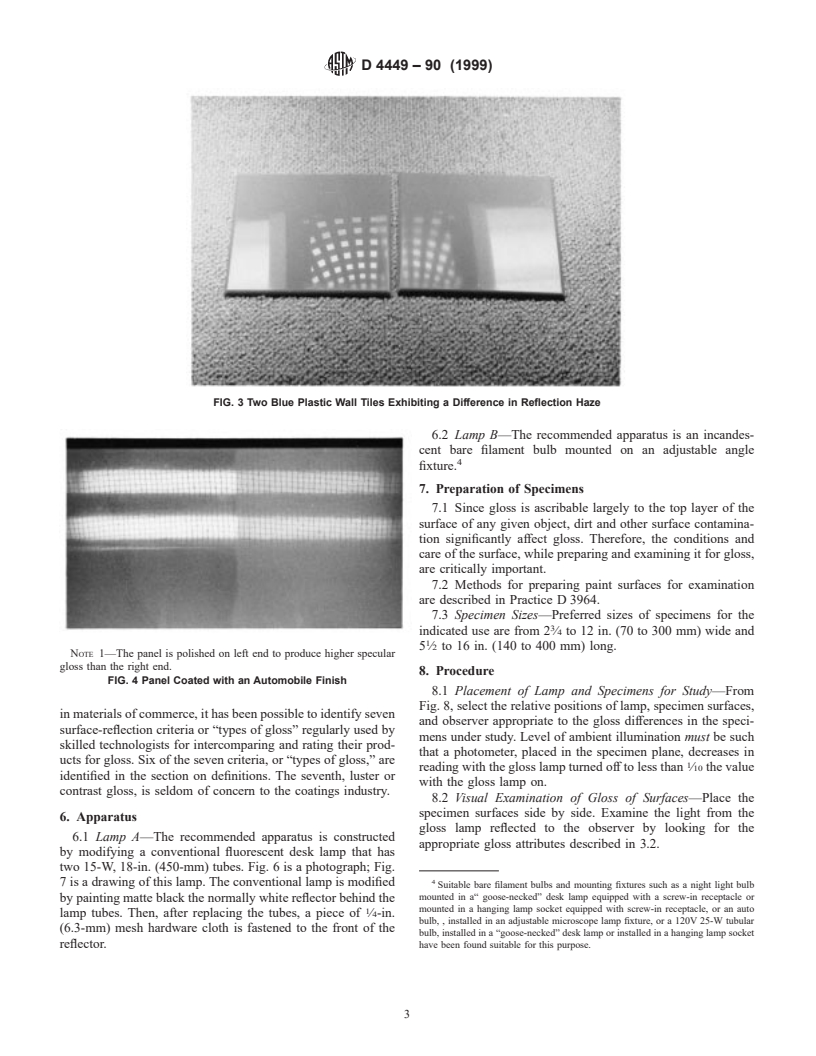

3.2.6 specular gloss—the relative luminous reflectance fac-

1.2 While this technique is useful for both weathered and

tor of a specimen in the specular direction. The luminous

unweathered specimens, it has not been applied to metallics.

reflectance factor is the ratio of the luminous flux reflected

1.3 The values stated in inch-pound units are to be regarded

from, to that incident on, a specimen for specified solid angles

as the standard. The values given in parentheses are for

(see Fig. 4).

information only.

3.2.7 texture—perceived structure, pattern, or topography or

1.4 This standard does not purport to address all of the

combination thereof, of a surface (see Fig. 5).

safety concerns, if any, associated with its use. It is the

responsibility of whoever uses this standard to consult and

4. Summary of Test Method

establish appropriate safety and health practices and deter-

4.1 Test specimens are illuminated by special light sources

mine the applicability of regulatory limitations prior to use.

that provide reflected images suitable for rating the gloss of

coating surfaces. Two types of lamps may be used to produce

2. Referenced Documents

reflected images. Lamp A consists of a modified fluorescent

2.1 ASTM Standards:

desk lamp covered with screen mesh. Lamp B consists of an

D 3964 Practice for Selection of Coating Specimens for

incandescent bare filament bulb installed in an adjustable angle

Appearance Measurements

fixture.

E 284 Terminology Relating to Appearance of Materials

4.2 Light from the selected lamp illuminates the test speci-

mens. The reflected images reveal specular gloss reflection; the

3. Terminology

sharpness of the images of the screen or lamp filament reveals

3.1 Definitions: For definitions of terms used in this method,

the detail and quality of the surface reflection (distinctness of

see Definitions E 284.

image); and spreading of the reflected light into dark areas,

3.2 Descriptions of Terms Specific to This Standard:

such as the space between fluorescent tubes or near the filament

3.2.1 directionality of surface—perceived change of glossy

image, reveals the presence of near-specular haze.

appearance of a surface with rotation of the surface in its own

plane (see Fig. 1).

5. Significance and Use

3.2.2 gloss, distinctness-of-image—perceived sharpness of

5.1 Gloss is associated with the capacity of a surface to

images reflected by an object surface (see Fig. 2).

reflect more light in some directions than in others. The

directions associated with mirror (or specular) reflection nor-

1 mally have the highest reflectances. Gloss is best seen and

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.26 on Optical Properties.

Current edition approved Oct. 26, 1990. Published December 1990. Originally For a more detailed account of gloss, its measurement, and relationship to

e1

published as D 4449 – 85. Last previous edition D 4449 – 85 . appearance generally, see R. S. Hunter, The Measurement of Appearance, Wiley

Annual Book of ASTM Standards, Vol 06.01. Interscience New York, NY 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4449 – 90 (1999)

NOTE 1—The left panel is free of directionality. The right panel is highly directional because of buffing marks.

FIG. 1 Reflection of Bright Incandescent Lamp in Two Panels

NOTE 1—The panels exhibit a difference in distinctness-of-reflected image.

FIG. 2 Two White Porcelain Enamel Panels

analyzed when the surfaces studied are illuminated by a light tions and intensities of this surface-reflected light are (for real

source that provides strong contrasting patterns of light and materials) highly variable and affected by a variety of factors:

dark. Such a light source is described in this test method. surface smoothness and contour, refractive index, absorptance,

5.2 The simplest concept of gloss is that it corresponds to angle of incidence, and (to a generally small extent) wave-

the mirror-like reflectances of surfaces. However, the distribu- length. From the great variety of surface-reflection patterns met

D 4449 – 90 (1999)

FIG. 3 Two Blue Plastic Wall Tiles Exhibiting a Difference in Reflection Haze

6.2 Lamp B—The recommended apparatus is an incandes-

cent bare filament bulb mounted on an adjustable angle

fixture.

7. Preparation of Specimens

7.1 Since gloss is ascribable largely to the top layer of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.