ASTM D7724-18(2023)e1

(Test Method)Standard Test Method for Carbon Black—Non-Dispersible Matter by Mechanical Flushing (NDM)

Standard Test Method for Carbon Black—Non-Dispersible Matter by Mechanical Flushing (NDM)

SIGNIFICANCE AND USE

4.1 The quantity of non-dispersible matter of carbon black is important in some molded or extruded products as it may relate to the surface appearance of those products. The maximum amount of non dispersible matter and the minimum size of the particles to be analyzed in each application is normally determined and agreed to between the user and the producer.

SCOPE

1.1 This test method covers the determination of non-dispersible matter after mechanical water flushing of regular untreated carbon blacks. It may not be applicable to oil-treated carbon blacks because the oil would prevent proper wetting of the black by water.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D7724 − 18 (Reapproved 2023)

Standard Test Method for

Carbon Black—Non-Dispersible Matter by Mechanical

Flushing (NDM)

This standard is issued under the fixed designation D7724; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected Footnote 3 editorially in January 2023.

1. Scope E11 Specification for Woven Wire Test Sieve Cloth and Test

Sieves

1.1 This test method covers the determination of non-

dispersible matter after mechanical water flushing of regular

3. Summary of Test Method

untreated carbon blacks. It may not be applicable to oil-treated

3.1 A sample of carbon black is mechanically flushed with

carbon blacks because the oil would prevent proper wetting of

water through a wire-mesh screen of a specified size until all

the black by water.

that remains is a non-dispersible matter of carbon black. The

1.2 The values stated in SI units are to be regarded as

non-dispersible matter is dried, weighed, and the amount of

standard. No other units of measurement are included in this

residue is expressed as mg/kg (ppm) of the original sample.

standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 The quantity of non-dispersible matter of carbon black

safety concerns, if any, associated with its use. It is the

is important in some molded or extruded products as it may

responsibility of the user of this standard to establish appro-

relate to the surface appearance of those products. The maxi-

priate safety, health, and environmental practices and deter-

mum amount of non dispersible matter and the minimum size

mine the applicability of regulatory limitations prior to use.

of the particles to be analyzed in each application is normally

1.4 This international standard was developed in accor-

determined and agreed to between the user and the producer.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Apparatus

Development of International Standards, Guides and Recom-

5.1 Sieve Apparatus, as shown in Fig. 1.

mendations issued by the World Trade Organization Technical

5.2 Balance, with a sensitivity of 0.01 g.

Barriers to Trade (TBT) Committee.

5.3 Analytical Balance, with a sensitivity of 0.1 mg.

2. Referenced Documents

5.4 Oven, gravity-convection type, capable of temperature

2.1 ASTM Standards:

regulation within 61°C at 125°C and temperature uniformity

D1799 Practice for Carbon Black—Sampling Packaged

within 65°C.

Shipments

5.5 Sieves, diameter 100 mm, of either phosphor bronze or

D1900 Practice for Carbon Black—Sampling Bulk Ship-

stainless steel. The sieve shall be in accordance with Specifi-

ments

cation E11. The sieve size to be used shall be agreed upon

D4483 Practice for Evaluating Precision for Test Method

between the purchaser and the carbon black manufacture.

Standards in the Rubber and Carbon Black Manufacturing

Industries

5.6 Weighing Dishes.

6. Precautions

6.1 Install the apparatus as described in the manufacturer’s

This test method is under the jurisdiction of ASTM Committee D24 on Carbon

Black and is the direct responsibility of Subcommittee D24.31 on Non-Carbon

instructions and keep it clean at all times to prevent contami-

Black Components of Carbon Black.

nation.

Current edition approved Jan. 1, 2023. Published February 2023. Originally

ε1

approved in 2011. Last previous edition approved in 2018 as D7724 – 18 . DOI:

10.1520/D7724-18R23E01. The sole source of supply of the apparatus known to the committee at this time

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is HITEC Luxembourg S.A. 49, rue du Baerendall L-8212 Mamer – Luxembourg.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM If you are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters. Your comments will receive careful consideration at a

the ASTM website. meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D7724 − 18 (2023)

FIG. 1 Schematic Diagram of NDA Test Equipment

6.2 Examine the sieves each time they are used to make sure 8.6 Based on a predefined program the sample will be

that no cracks or holes have developed. flushed through the sieve by the water spray nozzles. For

details refer to Fig. 1.

7. Sampling

8.7 A vacuum is applied periodically to keep the non

7.1 Samples shall be taken in accordance with Practice dispersible particles immobilized on the sieve in order to wash

D1799 or Practice D1900.

dispersible product from the non dispersible matter. The

vacuum application is also part of the automated process.

8. Procedure

8.8 The end of the test is indicated by a vacuum application

8.1 Prior to each test series adjust the water pressure to 400

without any water flowing. After that the measurement stops.

6 20 kPa in accordance with the manufacturer’s instructions.

8.9 Disassemble the sieve and dry in an oven at a tempera-

Make sure that only the spraying nozzle is operating when

ture of 125°C for 1 h.

pressure is adjusted.

8.10 Quantitatively transfer the non dispersible matter to a

NOTE 1—The pressure will drop when the cleaning nozzles are

tared weighing dish and weigh to the nearest 0.1 mg using the

operating in addition to the spraying nozzle.

analytical balance.

8.2 Attach the sieve to the apparatus in accordance with the

9. Calculation

manufacturer’s instructions and push the “flush” button for at

least 5 s. The water is flushed through the nozzles as long as the

9.1 Calculate the non-dispersible matter to the nearest

“flush” button is pushed.

mg/kg (ppm) as follows:

8.3 After releasing the “flush” button disassemble the sieve

R 5 W/S × 10 (1)

~ !

and examine the sieve for particles. If no particles are observed

where:

reattach the sieve.

R = Non-dispersible matter (NDM), mg/kg (ppm),

8.4 Weigh 500 6 5 g of the sample into a container and

W = mass of sieve residue, g, and

transfer the sample quantitatively into the cylinder of the test

S = mass of sample, g.

apparatus. Note the correct weight for the calculation of the

non dispersible matter. 10. Report

8.5 Press the “start” button and close the lid slowly while 10.1 Report the following information:

the spraying nozzle is rotating without any water flushing. The 10.1.1 Proper identification of the sample,

flushing process will start automatically. 10.1.2 Identification of the sieve size, and

´1

D7724 − 18 (2023)

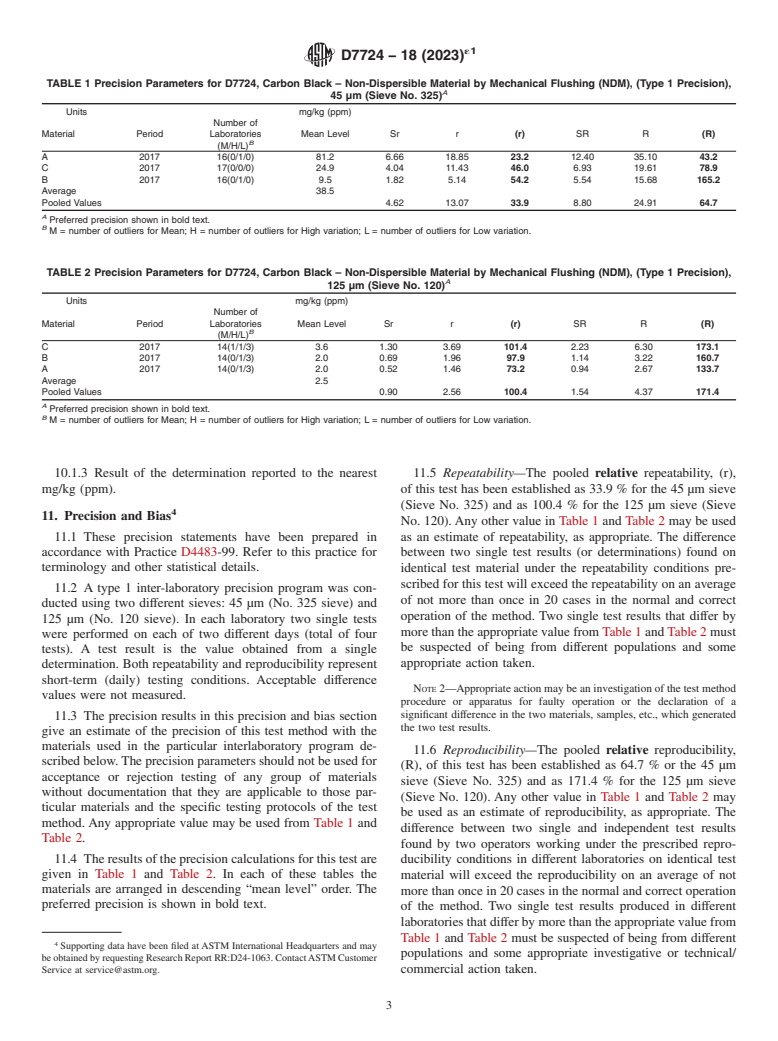

TABLE 1 Precision Parameters for D7724, Carbon Black – Non-Dispersible Material by Mechanical Flushing (NDM), (Type 1 Precision),

A

45 μm (Sieve No. 325)

Units mg/kg (ppm)

Number of

Material Period Laboratories Mean Level Sr r (r) SR R (R)

B

(M/H/L)

A 2017 16(0/1/0) 81.2 6.66 18.85 23.2 12.40 35.10 43.2

C 2017 17(0/0/0) 24.9 4.04 11.43 46.0 6.93 19.61 78.9

B 2017 16(0/1/0) 9.5 1.82 5.14 54.2 5.54 15.68 165.2

Average 38.5

Pooled Values 4.62 13.07 33.9 8.80 24.91 64.7

A

Preferred precision shown in bold text.

B

M = number of outliers for Mean; H = number of outliers for High variation; L = number of outliers for Low variation.

TABLE 2 Precision Parameters for D7724, Carbon Black – Non-Dispersible Material by Mechanical Flushing (NDM), (Type 1 Precision),

A

125 μm (Sieve No. 120)

Units mg/kg (ppm)

Number of

Material Period Laboratories Mean Level Sr r (r) SR R (R)

B

(M/H/L)

C 2017 14(1/1/3) 3.6 1.30 3.69 101.4 2.23 6.30 173.1

B 2017 14(0/1/3) 2.0 0.69 1.96 97.9 1.14 3.22 160.7

A 2017 14(0/1/3) 2.0 0.52 1.46 73.2 0.9

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.