ASTM D6617-08

(Practice)Standard Practice for Laboratory Bias Detection Using Single Test Result from Standard Material

Standard Practice for Laboratory Bias Detection Using Single Test Result from Standard Material

SIGNIFICANCE AND USE

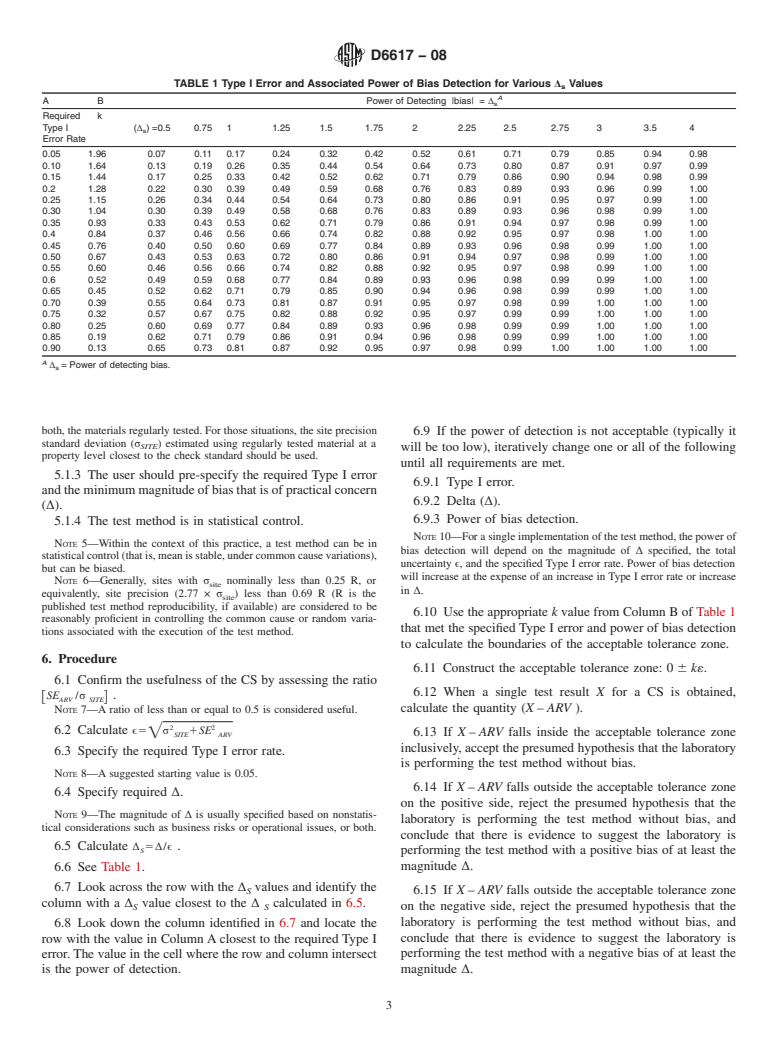

Laboratories performing petroleum test methods can use this practice to set an acceptable tolerance zone for infrequent testing of CS or CCS material, based on ε, and a desired Type I error, for the purpose of ascertaining if the test method is being performed without bias.

This practice can be used to estimate the power of correctly detecting bias of different magnitudes, using the acceptable tolerance zone set in 4.1, and hence, gain insight into the limitation of the true bias detection capability associated with this acceptable tolerance zone. With this insight, trade-offs can be made between desired Type I error versus desired bias detection capability to suit specific business needs.

The CS testing activities described in this practice are intended to augment and not replace the regular statistical monitoring of test method performance as described in Practice D 6299.

SCOPE

1.1 This practice covers a methodology for establishing an acceptable tolerance zone for the difference between the result obtained from a single implementation of a test method on a CS and its ARV, based on user-specified Type I error, the user-established test method precision, the standard error of the ARV, and a presumed hypothesis that the laboratory is performing the test method without bias.

Note 1—Throughout this practice, the term user refers to the user of this practice; and the term laboratory (see 1.1) refers to the organization or entity that is performing the test method.

1.2 For the tolerance zone established in 1.1, a methodology is presented to estimate the probability that the single test result will fall outside the zone, in the event that there is a bias (positive or negative) of a user-specified magnitude that is deemed to be of practical concern (that is, the presumed hypothesis is not true).

1.3 This practice is intended for ASTM Committee D02 test methods that produce results on a continuous numerical scale.

1.4 This practice assumes that the normal (Gaussian) model is adequate for the description and prediction of measurement system behavior when it is in a state of statistical control.

Note 2—While this practice does not cover scenarios in which multiple results are obtained on the same CS under site precision or repeatability conditions, the statistical concepts presented are applicable. Users wishing to apply these concepts for the scenarios described are advised to consult a statistician and to reference the CS methodology described in Practice D 6299.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6617 − 08 AnAmerican National Standard

Standard Practice for

Laboratory Bias Detection Using Single Test Result from

1

Standard Material

This standard is issued under the fixed designation D6617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Due to the inherent imprecision in all test methods, a laboratory cannot expect to obtain the

numerically exact accepted reference value (ARV) of a check standard (CS) material every time one

is tested. Results that are reasonably close to theARV should provide assurance that the laboratory is

performing the test method either without bias, or with a bias that is of no practical concern, hence

requiring no intervention. Results differing from the ARV by more than a certain amount, however,

should lead the laboratory to take corrective action.

a statistician and to reference the CS methodology described in Practice

1. Scope*

D6299.

1.1 This practice covers a methodology for establishing an

acceptable tolerance zone for the difference between the result

2. Referenced Documents

obtained from a single implementation of a test method on a

2

2.1 ASTM Standards:

CS and its ARV, based on user-specified Type I error, the

D2699Test Method for Research Octane Number of Spark-

user-establishedtestmethodprecision,thestandarderrorofthe

Ignition Engine Fuel

ARV, and a presumed hypothesis that the laboratory is per-

D6299Practice for Applying Statistical Quality Assurance

forming the test method without bias.

and Control Charting Techniques to Evaluate Analytical

NOTE 1—Throughout this practice, the term user refers to the user of

Measurement System Performance

thispractice;andthetermlaboratory(see1.1)referstotheorganizationor

E178Practice for Dealing With Outlying Observations

entity that is performing the test method.

1.2 Forthetolerancezoneestablishedin1.1,amethodology

3. Terminology

ispresentedtoestimatetheprobabilitythatthesingletestresult

will fall outside the zone, in the event that there is a bias

3.1 Definitions for accepted reference value (ARV),

(positive or negative) of a user-specified magnitude that is

accuracy, bias, check standard (CS), in statistical control, site

deemed to be of practical concern (that is, the presumed

precision, site precision standard deviation (σ ), site preci-

SITE

hypothesis is not true).

sion conditions, repeatability conditions, and reproducibility

conditions can be found in Practice D6299.

1.3 ThispracticeisintendedforASTMCommitteeD02test

methods that produce results on a continuous numerical scale.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptable tolerance zone, n—a numerical zone

1.4 This practice assumes that the normal (Gaussian) model

is adequate for the description and prediction of measurement bounded inclusively by zero 6 k ϵ (k is a value based on a

system behavior when it is in a state of statistical control. user-specifiedTypeIerror;ϵisdefinedin3.2.7)suchthatifthe

differencebetweentheresultobtainedfromasingleimplemen-

NOTE2—Whilethispracticedoesnotcoverscenariosinwhichmultiple

tation of a test method for a CS and its ARV falls inside this

results are obtained on the same CS under site precision or repeatability

zone, the presumed hypothesis that the laboratory or testing

conditions,thestatisticalconceptspresentedareapplicable.Userswishing

to apply these concepts for the scenarios described are advised to consult

organization is performing the test method without bias is

accepted, and the difference is attributed to normal random

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

Products and Lubricantsand is the direct responsibility of Subcommittee D02.94 on

2

Coordinating Subcommittee on Quality Assurance and Statistics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2008. Published January 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2000. Last previous edition approved in 2005 as D6617–05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6617-08. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6617 − 08

variation of the test method. Conversely, if the difference falls 3.2.8.1 Discussion—Type I error, commonly known as al-

outside this zone, the presumed hypothesis is rejected. pha (α) error

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D6617–05 Designation:D6617–08

Standard Practice for

Laboratory Bias Detection Using Single Test Result from

1

Standard Material

This standard is issued under the fixed designation D 6617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Due to the inherent imprecision in all test methods, a laboratory cannot expect to obtain the

numerically exact accepted reference value (ARV) of a check standard (CS) material every time one

is tested. Results that are reasonably close to theARV should provide assurance that the laboratory is

performing the test method either without bias, or with a bias that is of no practical concern, hence

requiring no intervention. Results differing from the ARV by more than a certain amount, however,

should lead the laboratory to take corrective action.

1. Scope*

1.1 This practice covers a methodology for establishing an acceptable tolerance zone for the difference between the result

obtained from a single implementation of a test method on a CS and its ARV, based on user-specified Type I error, the

user-established test method precision, the standard error of theARV, and a presumed hypothesis that the laboratory is performing

the test method without bias.

NOTE 1—Throughout this practice, the term user refers to the user of this practice; and the term laboratory (see 1.1) refers to the organization or entity

that is performing the test method.

1.2 For the tolerance zone established in 1.1, a methodology is presented to estimate the probability that the single test result

will fall outside the zone, in the event that there is a bias (positive or negative) of a user-specified magnitude that is deemed to

be of practical concern (that is, the presumed hypothesis is not true).

1.3 This practice is intended for ASTM Committee D02 test methods that produce results on a continuous numerical scale.

1.4 This practice assumes that the normal (Gaussian) model is adequate for the description and prediction of measurement

system behavior when it is in a state of statistical control.

NOTE 2—While this practice does not cover scenarios in which multiple results are obtained on the same CS under site precision or repeatability

conditions, the statistical concepts presented are applicable. Users wishing to apply these concepts for the scenarios described are advised to consult a

statistician and to reference the CS methodology described in Practice D 6299.

1.5Software program SiteBias, Version 1.0.1 (ADJD6617) performs the necessary calculations prescribed by this practice.

2. Referenced Documents

2

2.1 ASTM Standards:

D 2699 Test Method for Research Octane Number of Spark-Ignition Engine Fuel

D 6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

E 178 Practice for Dealing With Outlying Observations

2.2ASTM Adjuncts:

ADJD6617

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.94 on

Coordinating Subcommittee on Quality Assurance and Statistics.

Current edition approved Nov.Dec. 1, 2005.2008. Published February 2006.January 2009. Originally approved in 2000. Last previous edition approved in 20002005 as

D 6617–005.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6617–08

3. Terminology

3.1 Definitionsforacceptedreferencevalue(ARV),accuracy,bias,checkstandard(CS),instatisticalcontrol,siteprecision,site

precisionstandarddeviation(s ),siteprecisionconditions,repeatabilityconditions,andreproducibilityconditionscanbefound

SITE

in Practice D 6299.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptable tolerance zone, n—a numerical zone bounded inclusively by zero 6 k ´ (k is a value based on a user-specified

Type I error; ´ is defined in 3.2.7) suc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D6617–05 Designation:D6617–08

Standard Practice for

Laboratory Bias Detection Using Single Test Result from

1

Standard Material

This standard is issued under the fixed designation D 6617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Due to the inherent imprecision in all test methods, a laboratory cannot expect to obtain the

numerically exact accepted reference value (ARV) of a check standard (CS) material every time one

is tested. Results that are reasonably close to theARV should provide assurance that the laboratory is

performing the test method either without bias, or with a bias that is of no practical concern, hence

requiring no intervention. Results differing from the ARV by more than a certain amount, however,

should lead the laboratory to take corrective action.

1. Scope*

1.1 This practice covers a methodology for establishing an acceptable tolerance zone for the difference between the result

obtained from a single implementation of a test method on a CS and its ARV, based on user-specified Type I error, the

user-established test method precision, the standard error of theARV, and a presumed hypothesis that the laboratory is performing

the test method without bias.

NOTE 1—Throughout this practice, the term user refers to the user of this practice; and the term laboratory (see 1.1) refers to the organization or entity

that is performing the test method.

1.2 For the tolerance zone established in 1.1, a methodology is presented to estimate the probability that the single test result

will fall outside the zone, in the event that there is a bias (positive or negative) of a user-specified magnitude that is deemed to

be of practical concern (that is, the presumed hypothesis is not true).

1.3 This practice is intended for ASTM Committee D02 test methods that produce results on a continuous numerical scale.

1.4 This practice assumes that the normal (Gaussian) model is adequate for the description and prediction of measurement

system behavior when it is in a state of statistical control.

NOTE 2—While this practice does not cover scenarios in which multiple results are obtained on the same CS under site precision or repeatability

conditions, the statistical concepts presented are applicable. Users wishing to apply these concepts for the scenarios described are advised to consult a

statistician and to reference the CS methodology described in Practice D 6299.

1.5Software program SiteBias, Version 1.0.1 (ADJD6617) performs the necessary calculations prescribed by this practice.

2. Referenced Documents

2

2.1 ASTM Standards:

D 2699 Test Method for Research Octane Number of Spark-Ignition Engine Fuel

D 6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

E 178 Practice for Dealing With Outlying Observations

2.2ASTM Adjuncts:

ADJD6617

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.94 on

Coordinating Subcommittee on Quality Assurance and Statistics.

Current edition approved Nov.Dec. 1, 2005.2008. Published February 2006.January 2009. Originally approved in 2000. Last previous edition approved in 20002005 as

D 6617–005.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6617–08

3. Terminology

3.1 Definitionsforacceptedreferencevalue(ARV),accuracy,bias,checkstandard(CS),instatisticalcontrol,siteprecision,site

precisionstandarddeviation(s ),siteprecisionconditions,repeatabilityconditions,andreproducibilityconditionscanbefound

SITE

in Practice D 6299.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 acceptable tolerance zone, n—a numerical zone bounded inclusively by zero 6 k ´ (k is a value based on a user-specified

Type I error; ´ is defined in 3.2.7) suc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.