ASTM E2016-99e1

(Specification)Standard Specification for Industrial Woven Wire Cloth

Standard Specification for Industrial Woven Wire Cloth

SCOPE

1.1 This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. Wire cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. This specification does not apply to the following special types of wire cloth: filter cloth or dutch weave (see Appendix X1), fourdrinier and cylinder cloth, galvanized hardware cloth, insect wire screening, spiral weave wire cloth, testing sieve cloth, or welded wire cloth.

1.2 The values stated in inch-pound units shall be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 2016 – 99

Standard Specification for

1

Industrial Woven Wire Cloth

This standard is issued under the fixed designation E 2016; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Table 6 was corrected editorially in December 2003.

INTRODUCTION

Industrial wire cloth can be produced in many thousands of combinations of size and shape of

opening, wire diameter, type of weave, and metal. This specification covers woven wire cloth for

industrial use, including the separation of particles. Its purpose is to introduce standard terms and

definitions, to note the normal range of specifications woven, and to establish tolerances and

requirements. This specification excludes sieve cloth from its scope, since this is covered under

Specification E 11. If a user has a specific application for industrial wire cloth that is not within the

scope of this specification, it is recommended that the wire cloth supplier be consulted.

1. Scope 3.1.1 aperture, n—the dimensions defining an opening in a

screening surface (see also width opening).

1.1 This specification covers industrial woven wire fabric,

3.1.2 bolting cloth, n—a specific group of commonly used

referred to as wire cloth, for general use including the

mesh and wire diameter combinations. They are covered

separation of particles. Wire cloth can be made of any primary

within this specification.

metal or metal alloy wire that is suitable for weaving. This

3.1.3 coatings, n—the wire used for weaving wire cloth can

specification does not apply to the following special types of

be coated, plated, or in some other way finished prior to

wire cloth: filter cloth or dutch weave (see Appendix X1),

weaving, or wire cloth can be specified coated after weaving.

fourdrinier and cylinder cloth, galvanized hardware cloth,

Consult with a supplier as to the applicability of this specifi-

insect wire screening, spiral weave wire cloth, testing sieve

cation. Examples of possible coatings include, but are not

cloth, or welded wire cloth.

limited to, metallic plated, such as, copper, nickel, tin, etc.,

1.2 The values stated in inch-pound units shall be regarded

painted, or epoxy-coated or galvanized-steel wire cloth that has

as the standard. The values given in parentheses are for

been coated with zinc either before or after weaving.

information only.

3.1.4 Types of Crimps:

2. Referenced Documents

3.1.4.1 crimp, n—the corrugation in the warp or shute wire,

or both. The crimp in the wires is formed either during the

2.1 ASTM Standards:

weaving process, or with a crimping machine prior to weaving.

A 510 Specification for General Requirements for Wire

2

If formed during the weaving process, the tension existing

Rods and Coarse Round Wire, Carbon Steel

between the warp and shute wires fundamentally determines

A 555/A 555M Specification for General Requirements for

2

the respective amount or depth of crimp, which locks the wires

Stainless Steel Wire and Wire Rods

in place and in part establishes the firmness of the wire cloth.

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

3

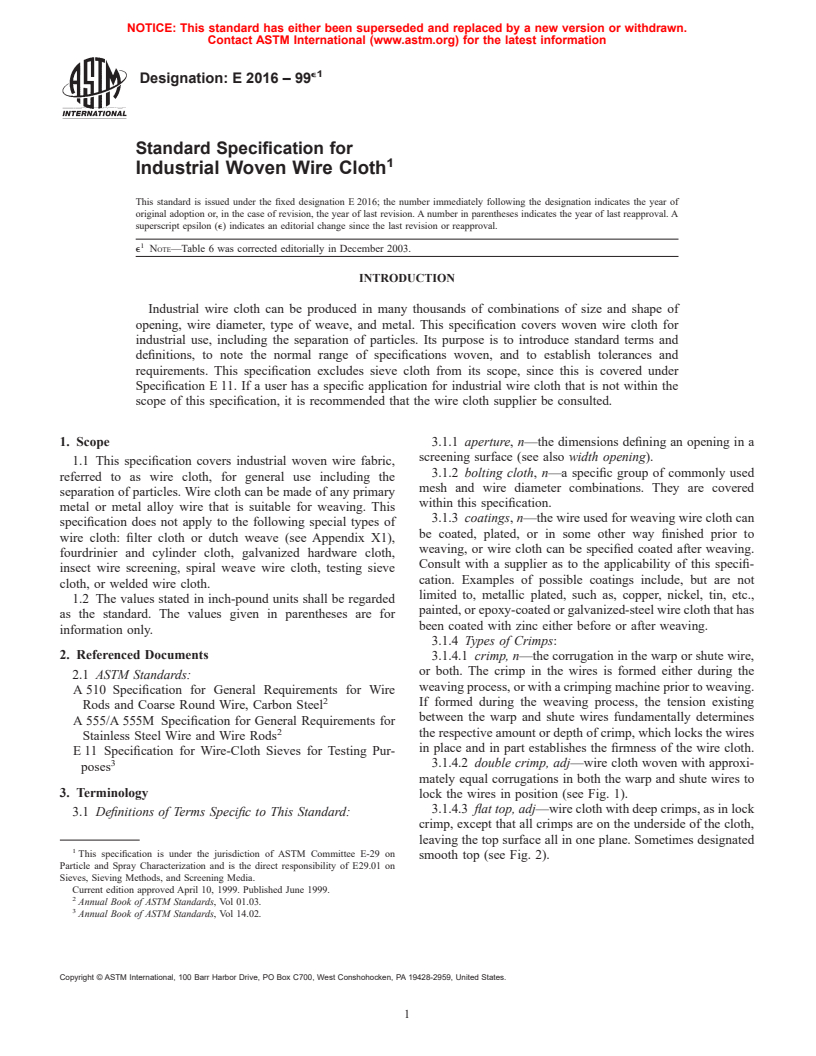

3.1.4.2 double crimp, adj—wire cloth woven with approxi-

poses

mately equal corrugations in both the warp and shute wires to

3. Terminology

lock the wires in position (see Fig. 1).

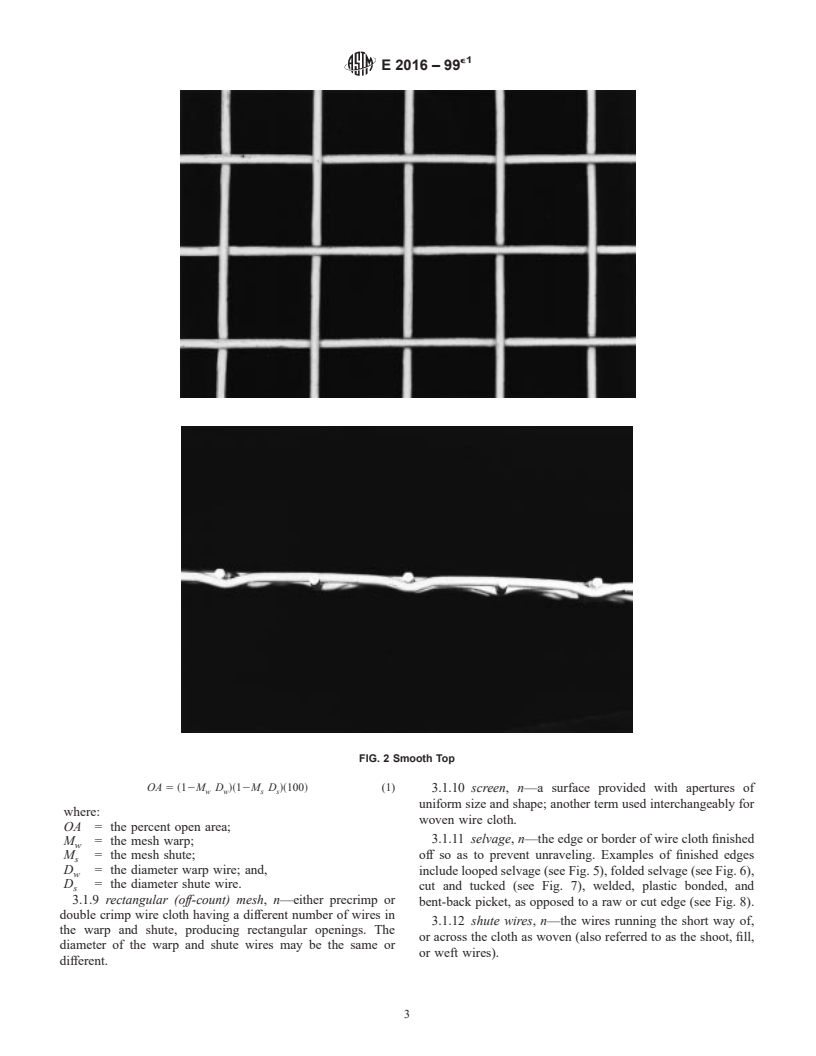

3.1.4.3 flat top, adj—wire cloth with deep crimps, as in lock

3.1 Definitions of Terms Specific to This Standard:

crimp, except that all crimps are on the underside of the cloth,

leaving the top surface all in one plane. Sometimes designated

1

This specification is under the jurisdiction of ASTM Committee E-29 on

smooth top (see Fig. 2).

Particle and Spray Characterization and is the direct responsibility of E29.01 on

Sieves, Sieving Methods, and Screening Media.

Current edition approved April 10, 1999. Published June 1999.

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

E2016–99

FIG. 1 Double Crimp

3.1.4.4 intermediate crimp, adj—precrimped wire cloth 3.1.5 market grade, n—a specific group of commonly used

with extra crimps or corrugations between the points or mesh and wire diameter combinations. They are covered

intersection; sometimes designated intercrimp or multiple within this specification.

crimp. The warp, or shute wires, or both, may be intermediate 3.1.6 mesh, n—the number of wires or openings per linear

crimped (see Fig. 3). inch (25.4 mm), counted from the center of any wire to a point

3.1.4.5 lock crim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.