ASTM F288-96(2002)

(Specification)Standard Specification for Tungsten Wire for Electron Devices and Lamps

Standard Specification for Tungsten Wire for Electron Devices and Lamps

ABSTRACT

This specification covers three types of drawn pure and thoriated tungsten wire suitable for fabrication into parts for electron tubes, lamps, and other electron devices, and one type of rod for metal-to-glass sealing (grid wire is excepted): Type 1A, Type 1B, Type 2A, and Type 2B. Types 1A and 1B are designated as UNS R07005; Type 2A is designated as UNS R07911; and Type 2B is designated as UNS R07912. The wire and rod shall conform to the prescribed chemical requirements for thoria and tungsten and to the specified physical properties such as tensile strength, ductility, and surface defects. The weight/diameter conversion formulas are given. Wires shall be furnished in the following specified finishes: Finish 1, Finish 2, Finish 3, Finish 4, Finish 5, Finish 6, and Finish 7. The material shall be smooth, free of twists, bends, kinks, curls, and as free of dents, swaging marks, scratches, die marks, laps, seams, splits, slivers, inclusions, bumps, pits, grooves, cracks, and other physical defects Unless black finish is specified, all types of wire shall have a clean finish, free of graphite, grease, oil, and lubricants. Wire for hooks, supports, springs, anchors, and mesh shall have a bright smooth surface free of cracks holes, or craters. The requirements for straightness, and coiling and spooling are detailed as well. The following analysis and tests shall be performed: chemical analysis, tensile test, ductility test, visual inspection, dimensional measurements, and examination for surface flaws.

SCOPE

1.1 This specification covers three types of drawn wire suitable for fabrication into parts for electron tubes, lamps, and other devices; and one type of rod for metal-to-glass sealing (grid wire is excepted):

1.1.1 Type 1—ACommercially pure nonsag wire (Note 2 and Note 3).

1.1.2 Type 1—BCommercially pure rod suitable for metal-to-glass sealing.

1.1.3 Type 2—AThoriated filament wire containing 1 % thoria.

1.1.4 Type 2BThoriated filament wire containing 2 % thoria.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 Types 1A and 1B are designated as UNS R07005. Type 2A is designated as UNS R07911. Type 2B is designated as UNS R07912.

1.4 The following precautionary caveat pertains only to the Chemical Analysis, Section 12 of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—A dimensional measurement method for testing nonsag tungsten wire above 0.030 in. (0.76 mm) in diameter is provided in Test Method F 269.

Note 2—Acceptance of nonsag wire characteristics for particular applications of size shall be by agreement between producer and consumer based on either a flashed microstructure as shown by photomicrographs, or on dimensional measurement limits determined in accordance with Test Method F 269.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 288 – 96 (Reapproved 2002)

Standard Specification for

Tungsten Wire for Electron Devices and Lamps

This standard is issued under the fixed designation F 288; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope F 16 Test Methods for Measuring Diameter or Thickness of

Wire and Ribbon for Electronic Devices and Lamps

1.1 This specification covers three types of drawn wire

F 204 Test Method for Surface Flaws in Tungsten Seal Rod

suitable for fabrication into parts for electron tubes, lamps, and

and Wire

other devices; and one type of rod for metal-to-glass sealing

F 205 Test Method for Measuring Diameter of FineWire by

(grid wire is excepted):

Weighing

1.1.1 Type 1A—Commercially pure nonsag wire (Note 2

F219 TestMethodsofTestingFineRoundandFlatWirefor

and Note 3).

Electron Devices and Lamps

1.1.2 Type 1B—Commercially pure rod suitable for metal-

F 269 Test Method for Sag of Tungsten Wire

to-glass sealing.

2.2 Military Standards:

1.1.3 Type 2A—Thoriated filament wire containing 1 %

MIL-STD-105 Sampling Procedures and Tables for Inspec-

thoria.

tion by Attributes

1.1.4 Type 2B—Thoriated filament wire containing 2 %

MIL-STD-129 Marking for Shipment and Storage

thoria.

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard. The values given in parentheses are for

3.1 Definition of Terms Specific to This Standard:

information only.

3.1.1 wire—The term wire as used in this specification

1.3 Types 1A and 1B are designated as UNS R07005. Type

applies to all drawn material that is spooled or coiled, and to

2A is designated as UNS R07911. Type 2B is designated as

short cut lengths 0.020 in. (0.51 mm) or less in diameter.

UNS R07912.

3.1.2 nonsag or doped tungsten wire—This term designates

1.4 The following precautionary caveat pertains only to the

a wire which, when recrystallized, shows elongated interlock-

Chemical Analysis, Section 12 of this specification: This

ing grains.

standard does not purport to address all of the safety concerns,

3.1.3 rod—The term rod as used in this specification applies

if any, associated with its use. It is the responsibility of the user

to centerless ground material 0.020 in. (0.51 mm) or larger in

of this standard to establish appropriate safety and health

diameter, in short cut lengths or random cut lengths.

practices and determine the applicability of regulatory limita-

tions prior to use.

4. Ordering Information

NOTE 1—Adimensional measurement method for testing nonsag tung-

4.1 Orders for wire and rod furnished to this specification

sten wire above 0.030 in. (0.76 mm) in diameter is provided in Test

shall include the following information:

Method F 269.

4.1.1 Length in metres, or quantity of short cut lengths,

NOTE 2—Acceptance of nonsag wire characteristics for particular

4.1.2 Type and UNS No. (Section 1),

applicationsofsizeshallbebyagreementbetweenproducerandconsumer

4.1.3 Straightness (Section 10),

based on either a flashed microstructure as shown by photomicrographs,

orondimensionalmeasurementlimitsdeterminedinaccordancewithTest 4.1.4 Finish (Section 8),

Method F 269.

4.1.5 Weight or size (Section 7) and tolerance, and

4.1.6 Specification number.

2. Referenced Documents

NOTE 3—Atypical ordering description for straight chemically cleaned

2.1 ASTM Standards:

wire is as follows: xxxx metres, tungsten wire, Type 1A UNS R07005,

straightened, Finish 2; 280.8 mg/200 mm (63 %), to ASTM F288 – XX.

This specification is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

Materials.

Current edition approved June 10, 1996. Published August 1996. Originally Annual Book of ASTM Standards, Vol 10.04.

published as B 288 – 54 T; redesignated F 288 in 1955. Last previous edition AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

F 288 – 81 (1991). Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

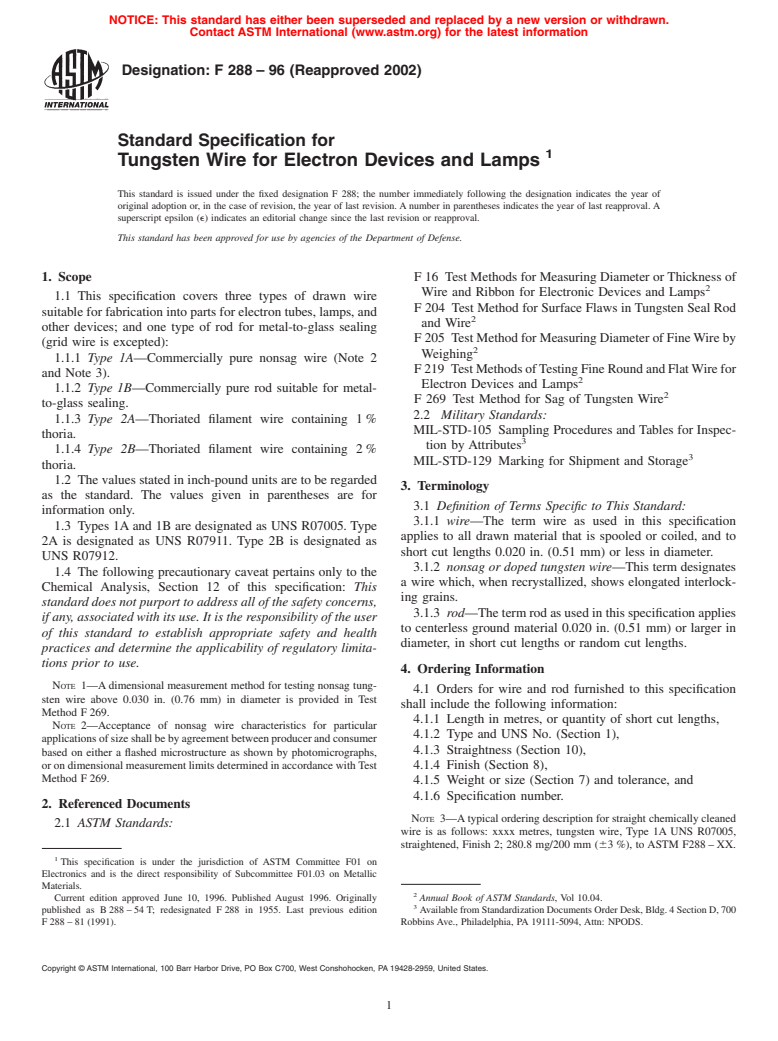

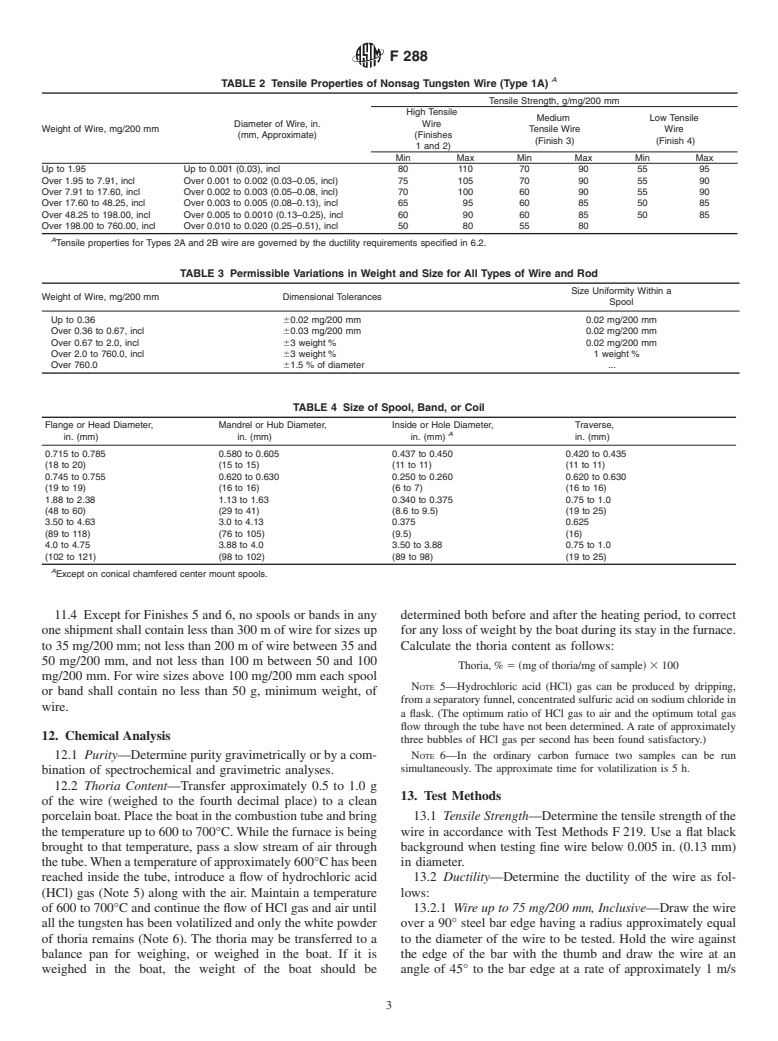

F 288

5. Chemical Composition

wt in mg/200 mm5~diameter in mils! 3 1.905, or

~diameter in mm! 3 2953

5.1 The wire and rod shall conform to the chemical require-

ments specified in Table 1. The sample for analysis shall be

representative of the lot submitted. Lot size, sample size, and 7.3.3 The weight of Type 2B wire (density 18.50), is as

sampling method shall be as agreed upon by the supplier and

follows:

purchaser.

wt in mg/200 mm5~diameter in mils! 3 1.875, or

~diameter in mm! 3 2906

6. Physical Properties

6.1 Tensile Strength—The tensile strength of a 10-in. (250-

mm) gage length of wire in grams per milligram per 200 mm

8. Workmanship, Finish, and Appearance

shall be within the limits specified in Table 2 when tested in

8.1 Furnish the wire in the following finishes:

accordance with 13.1.

8.1.1 Finish 1—Black, as-drawn,

6.2 General Ductility Requirements—The ductility ofTypes

8.1.2 Finish 2—Chemically cleaned,

1A, 2A, and 2B wire shall be sufficient to meet the following

8.1.3 Finish 3—Chemically cleaned and stress-relieved.

requirements:

8.1.4 Finish 4—Reducing atmosphere cleaned and an-

6.2.1 Wire up to 75 mg/200 mm, Inclusive—Six 1-m lengths

nealed,

shall be tested in accordance with 13.2. The wire shall not

8.1.5 Finish 5—Etched, and

break more than two times in the six tests. Where required, a

8.1.6 Finish 6—Electropolished.

lower limit may be negotiated between purchaser and seller.

8.2 The rod shall be furnished in the following finish:

6.2.2 Wire over 75 mg/200 mm—Thirty successive close-

8.2.1 Finish 7—Centerless ground.

wound turns completely around mandrels shall be free of

splitting or cracking when tested in accordance with 13.2.2 and

9. General Requirements

examined at a magnification of 303.

9.1 The material shall be smooth, free of twists, bends,

6.2.3 Special Ductility Requirements—Wire for certain ap-

kinks, curls, and as free of dents, swaging marks, scratches, die

plications may require a special ductility as agreed upon

marks, laps, seams, splits, slivers, inclusions, bumps, pits,

between the purchaser and the seller.

grooves, cracks, and other physical defects when examined at

6.3 Surface Defects—Type 1B rod shall not show faults

a magnification of 303 as best commercial practice will

when tested in accordance with 13.5.

permit.

9.2 Unless black finish is specified, all types of wire shall

7. Dimensions, Weights, and Permissible Variations

have a clean finish, free of graphite, grease, oil, and lubricants.

7.1 Dimensional tolerances for Type 1A (nonsag) wire for

All finishes shall be as free of dirt, oxide, stains, scale, and

use as incandescent filaments shall conform to the require-

other surface defects, as best commercial practice permits.

ments specified in Table 3.

Wire for hooks, supports, springs, anchors, and mesh shall

NOTE 4—Tolerances are industry standards; closer tolerances may be

have a bright smooth surface free of cracks, holes, or craters

obtained in certain instances, usually at a premium.

when examined at a magnification of 103.

9.3 Rod of Type 1B shall have a bright smooth surface and

7.2 Out-of-roundness of wire or rod over 0.020 in. (0.51

be capable of making acceptable metal-to-glass seals when

mm)indiametershallbewithin5 %ofthemaximumdiameter,

tested in accordance with Test Method F 204.

when measured by a method agreed upon by supplier and

purchaser. A referee method for this test is contained in

10. Straightness

Procedure B of Test Methods F 16.

10.1 When ordered as straightened, straightness of wire

7.3 Weight/Diameter Conversion Formulas:

3.00 mg/200 mm and larger shall be specified as the radius of

7.3.1 The weight of Type 1Awire and Type 1B rod (density

curvature or camber of a given length of wire as agreed upon

19.17), is as follows:

between the purchaser and supplier. For wire under 3.00

wt in mg/200 mm5~diameter in mils! 3 1.943, or

mg/200 mm, alternative methods for straightness requirements

~diameter in mm! 3 3011

may be used as agreed upon between the purchaser and the

supplier.

7.3.2 The weight of Type 2A wire (density 18.80), is as

follows:

11. Coiling and Spooling

11.1 Spools and bands shall be clean and free of open seams

A

TABLE 1 Chemical Requirements

or projections which might catch or tangle the wire during

winding or unwinding.

Type, Thoria, weight Tungsten, weight

UNS number % %

11.2 Wire shall be furnished in one continuous length and

1A and 1B (R07005) . 99.95 min

wound smoothly with no loose turns. There shall be no piling

2A (R07911) 0.8 min, 1.2 max balance

up of turns such as to prevent free unwinding or cause kinks or

2B (R07912) 1.7 min, 2.2 max balance

bends when the wire is removed from the spool. The outer end

A

For all Types:

shall be attached firmly to the spool or band by suitable means.

Other elements (each)—100 ppm max.

Total other elements—500 ppm max. 11.3 Spool and band dimensions are shown in Table 4.

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.