ASTM D88-07

(Test Method)Standard Test Method for Saybolt Viscosity

Standard Test Method for Saybolt Viscosity

SCOPE

1.1 This test method covers the empirical procedures for determining the Saybolt Universal or Saybolt Furol viscosities of petroleum products at specified temperatures between 21 and 99°C (70 and 210°F). A special procedure for waxy products is indicated.

Note 1—Test Methods D 445 and D 2170 are preferred for the determination of kinematic viscosity. They require smaller samples and less time, and provide greater accuracy. Kinematic viscosities may be converted to Saybolt viscosities by use of the tables in Practice D 2161. It is recommended that viscosity indexes be calculated from kinematic rather than Saybolt viscosities.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D88 −07 AmericanAssociation State

Highway and Transportation Officials Standard

AASHTO No: T72

Method 304—Federal Test

Method Standard No. 791b

Replaces Method 4285 of Federal Test

Method Standard No. 141A

Standard Test Method for

1

Saybolt Viscosity

This standard is issued under the fixed designation D88; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.1 This test method covers the empirical procedures for

ity)

determining the Saybolt Universal or Saybolt Furol viscosities

D2161 Practice for Conversion of Kinematic Viscosity to

of petroleum products at specified temperatures between 21

Saybolt Universal Viscosity or to Saybolt Furol Viscosity

and 99°C (70 and 210°F). A special procedure for waxy

D2170 Test Method for Kinematic Viscosity of Asphalts

products is indicated.

(Bitumens)

NOTE 1—Test Methods D445 and D2170 are preferred for the deter-

D4057 Practice for Manual Sampling of Petroleum and

mination of kinematic viscosity. They require smaller samples and less

Petroleum Products

time, and provide greater accuracy. Kinematic viscosities may be con-

D4177 Practice for Automatic Sampling of Petroleum and

verted to Saybolt viscosities by use of the tables in Practice D2161.Itis

Petroleum Products

recommended that viscosity indexes be calculated from kinematic rather

than Saybolt viscosities.

E1 Specification for ASTM Liquid-in-Glass Thermometers

E11 Specification for Woven Wire Test Sieve Cloth and Test

1.2 The values stated in SI units are to be regarded as the

Sieves

standard. The values given in parentheses are for information

E102 TestMethodforSayboltFurolViscosityofBituminous

only.

Materials at High Temperatures

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1 Definitions:

bility of regulatory limitations prior to use.

3.1.1 Furol—an acronym of “Fuel and road oils.”

3.1.2 Saybolt Furol viscosity—the corrected efflux time in

2. Referenced Documents

seconds of 60 mLof sample flowing through a calibrated Furol

2

2.1 ASTM Standards:

orifice under specified conditions. The viscosity value is

D93 Test Methods for Flash Point by Pensky-Martens

reported in Saybolt Furol seconds, abbreviated SFS, at a

Closed Cup Tester

specified temperature.

D117 Guide for Sampling, Test Methods, and Specifications

3.1.3 Saybolt Universal viscosity—the corrected efflux time

for Electrical Insulating Oils of Petroleum Origin

in seconds of 60 mL of sample flowing through a calibrated

D140 Practice for Sampling Bituminous Materials

Universal orifice under specified conditions. The viscosity

D244 Test Methods and Practices for Emulsified Asphalts

value is reported in Saybolt Universal seconds, abbreviated

SUS, at a specified temperature.

1

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

and Waterproofing and is the direct responsibility of Subcommittee D08.05 on

Solvent-Bearing Bituminous Compounds for Roofing and Waterproofing. 4. Summary of Test Method

Current edition approved Nov. 1, 2007. Published November 2007. Originally

4.1 The efflux time in seconds of 60 mL of sample, flowing

approved in 1921. In 1923, combined with former Methods D47. Last previous

edition approved in 2005 as D88 – 94 (2005). DOI: 10.1520/D0088-07.

through a calibrated orifice, is measured under carefully

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

controlled conditions. This time is corrected by an orifice

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

factor and reported as the viscosity of the sample at that

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. temperature.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D88−07

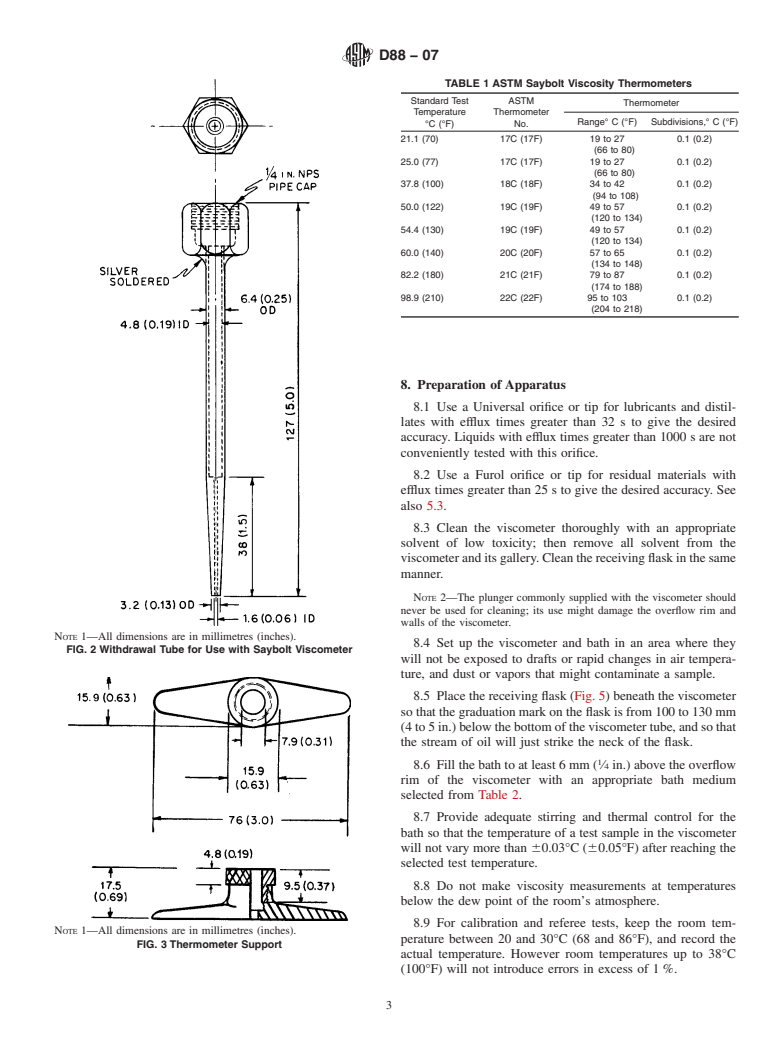

5. Significance and Use 6.4 Saybolt Viscosity Thermometers ,aslistedinTable1,for

reading the temperature of the sample. Each thermometer shall

5.1 This test method is useful in characterizing certain

conform to the requirements listed in Specification E1 for that

petroleum products, as one element in establishing uniformity

ASTM Thermometer Number.

of shipments and source

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

American Association State

Designation:D88–94 (Reapproved 2005) Designation: D 88 – 07Highway and Transportation Officials Standard

AASHTO No: T72

Method 304—Federal Test

Method Standard No. 791b

Replaces Method 4285 of Federal Test

Method Standard No. 141A

Standard Test Method for

1

Saybolt Viscosity

ThisstandardisissuedunderthefixeddesignationD 88;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the empirical procedures for determining the Saybolt Universal or Saybolt Furol viscosities of

petroleum products at specified temperatures between 21 and 99°C (70 and 210°F). A special procedure for waxy products is

indicated.

NOTE 1—Test Methods D 445 and D 2170 are preferred for the determination of kinematic viscosity. They require smaller samples and less time, and

provide greater accuracy. Kinematic viscosities may be converted to Saybolt viscosities by use of the tables in Practice D 2161. It is recommended that

viscosity indexes be calculated from kinematic rather than Saybolt viscosities.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D 117 Guide for Sampling, Test Methods, and Specifications for Electrical Insulating Oils of Petroleum Origin

D 140 Practice for Sampling Bituminous Materials

D 244 Test Methods and Practices for Emulsified Asphalts

D 445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and the Calculation of Dynamic Viscosity)

D 2161 Practice for Conversion of Kinematic Viscosity to Saybolt Universal Viscosity or to Saybolt Furol Viscosity

D 2170 Test Method for Kinematic Viscosity of Asphalts (Bitumens)

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D 4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

E 1 Specification for ASTM Liquid-in-Glass Thermometers

E 11 Specification for Wire Cloth and Sieves for Testing Purposes

E 102 Test Method for Saybolt Furol Viscosity of Bituminous Materials at High Temperatures

3. Terminology

3.1 Definitions:

3.1.1 Furol—an acronym of “Fuel and road oils.”

3.1.2 Saybolt Furol viscosity—thecorrectedeffluxtimeinsecondsof60mLofsampleflowingthroughacalibratedFurolorifice

under specified conditions. The viscosity value is reported in Saybolt Furol seconds, abbreviated SFS, at a specified temperature.

3.1.3 Saybolt Universal viscosity—the corrected efflux time in seconds of 60 mL of sample flowing through a calibrated

Universal orifice under specified conditions. The viscosity value is reported in Saybolt Universal seconds, abbreviated SUS, at a

specified temperature.

1

This test method is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.05 on

Solvent-Bearing Bituminous Compounds for Roofing and Waterproofing.

Current edition approved Nov. 1, 2005.2007. Published November 2005.2007. Originally approved in 1921. In 1923, combined with former Methods D 47. Last previous

edition approved in 19992005 as D88–94(1999). D 88 – 94 (2005).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D88–07

4. Summary of Test Method

4.1 The efflux time in seconds of 60 mLof sample, flowing through a calibrated orifice, is measured under carefully controlled

conditions. This time is corrected by an orifice factor and reported as the viscosity of the sample at that temperature.

5. Significance and Use

5.1 This test method is useful in character

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.