ASTM D710-97

(Specification)Standard Specification for Vulcanized Fibre Sheets, Rods, and Tubes Used for Electrical Insulation

Standard Specification for Vulcanized Fibre Sheets, Rods, and Tubes Used for Electrical Insulation

SCOPE

1.1 This specification covers vulcanized fibre (Note 1) sheets, round rods, and round tubes of such grades suitable for use as electrical insulation.

Note 1—The variant spelling "fibre" has been approved by Committee D09 for use in this standard.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 710 – 97 An American National Standard

Standard Specification for

Vulcanized Fibre Sheets, Rods, and Tubes Used for

Electrical Insulation

This standard is issued under the fixed designation D 710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope ated cellulose in which the fibrous structure is retained in

varying degrees depending on the grade of paper used and on

1.1 This specification covers vulcanized fibre (Note 1)

the processing conditions. Material up to about 25 mm in

sheets, round rods, and round tubes of such grades suitable for

thickness is produced by bonding multiple layers of paper (or

use as electrical insulation.

board) after chemical treatment. Vulcanized fibre does not

NOTE 1—The variant spelling “fibre” has been approved by Committee

contain vulcanized rubber or sulfur as the name might imply.

D-9 for use in this standard.

Thin vulcanized fibre has sometimes been termed “fish paper.”

1.2 The values stated in inch-pound units are to be regarded

4. Grades

as the standard.

4.1 Three grades of vulcanized fibre are covered, as follows:

2. Referenced Documents

4.1.1 Bone Grade—This grade is characterized by the

2.1 ASTM Standards:

greater hardness and stiffness associated with higher density. It

D 495 Test Method for High-Voltage, Low-Current, Dry

machines more smoothly and with less tendency to separate the

Arc Resistance of Solid Electrical Insulation

plies in difficult machining operations than the other grades. It

1 1

D 619 Test Methods for Vulcanized Fibre Used for Electri-

is made in thickness of ⁄32 to ⁄4in. (0.79 to 6.35 mm).

cal Insulation

4.1.2 Commercial Grade—This grade is considered as the

D 696 Test Method for Coefficient of Linear Thermal Ex-

general-purpose grade and is sometimes referred to as me-

pansion of Plastics Between − 30°C and 30°C

chanical and electrical grade. It possesses good physical and

D 952 Test Method for Bond or Cohesive Strength of Sheet

electrical properties and can be fabricated satisfactorily by

Plastics and Electrical Insulating Materials

punching, turning, and forming operations. It is made in

D 3636 Practice for Sampling and Judging Quality of Solid

thicknesses from 0.010 to ⁄4 in. (0.25 to 6.35 mm).

Electrical Insulating Materials

4.1.3 Electrical Insulation Grade—This grade is intended

2.2 Other Documents:

primarily for electrical applications and others involving diffi-

IEEE Publication No. 1, “General Principles for Tempera-

cult bending or forming operations. It is made in thicknesses

ture Limits in the Rating of Electrical Equipment.”

from 0.004 to ⁄8 in. (0.10 to 3.2 mm). Thin material of this

grade is sometimes referred to as “fish paper.”

3. Terminology

4.2 The three grades of fibre are available in laminated sheet

3.1 Definitions:

form in greater thicknesses than those listed in 4.1.1 to 4.1.3.

3.1.1 vulcanized fibre, n—a material made from chemically

Laminated (or built-up) fibre is composed of a number of plies

gelatinized cellulosic paper or board using zinc chloride as the

bonded together with a suitable adhesive. It retains all the basic

gelatinizing agent.

properties of solid fibre, including high arc resistance on edges

3.1.1.1 Discussion—The zinc chloride is subsequently re-

and faces, and in addition has better dimensional stability and

moved by leaching. The resulting product, after being dried

less warpage. Laminated fibre is usually furnished when the

and finished by calendering, is a material of partially regener- 1

thickness is over ⁄4 in. (6.35 mm), and may be furnished in

thicknesses down to ⁄8 in. (3.2 mm). Thicknesses up to 4 in.

(102 mm) are commercially available.

This specification is under the jurisdiction of ASTM Committee D-9 on

4.3 Thin sheet material, up to ⁄16 in. thick is available in a

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

lower density uncalendered condition which may not meet the

Current edition approved Sept. 10, 1997. Published November 1997. Originally

requirements of this specification.

published as D 710 – 43 T. Last previous edition D 710 – 96.

Annual Book of ASTM Standards, Vol 10.01.

3 5. Forms and Colors

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 10.02.

5.1 Vulcanized fibre is available in the forms and colors

Available from The Institute of Electrical and Electronics Engineers, Inc., 345

listed in Table 1.

E. 47th St., New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 710

TABLE 1 Forms and Colors Available TABLE 3 Flexural Strength Requirement for Sheets, min, psi

(MPa)

A B

Grades Forms Colors

Bone Grade Commercial Grade

Bone sheets and rods, gray

Nominal Thickness in.

Length- Cross- Length- Cross-

tubes gray, black, red

(mm)

wise wise wise wise

Commercial sheets and rods gray, black, red

A A

1 1

⁄16 (1.59) up to ⁄8 16 000 14 000 15 000 13 000

Electrical Insulation sheets gray

(3.18), incl (110) (97) (103) (90)

A

1 1

Sheets and rods are available in both single-layer and laminated form. Thin

Over ⁄8 (3.18) to ⁄2 15 000 13 000 14 000 12 000

sheets are available in both rolls and flat sheets in thicknesses up to ⁄16 in. (1.6

(12.7), incl (103) (90) (97) (83)

mm).

Over ⁄2 (12.7) to 1 . . 13 000 11 000

B

In any of these standard colors, considerable variation of shade may be

(25.4), incl (90) (76)

expected.

A

These two values also apply to Electrical Insulation Grade.

6. Chemical Composition

TABLE 4 Water Absorption and Dielectric Strength Requirements

6.1 The material shall conform to the requirements for

for Sheets

chemical composition prescribed in Table 2.

A

Dielectric

Water Absorption,

B

Nominal Thickness, Strength,

max, %

Grade

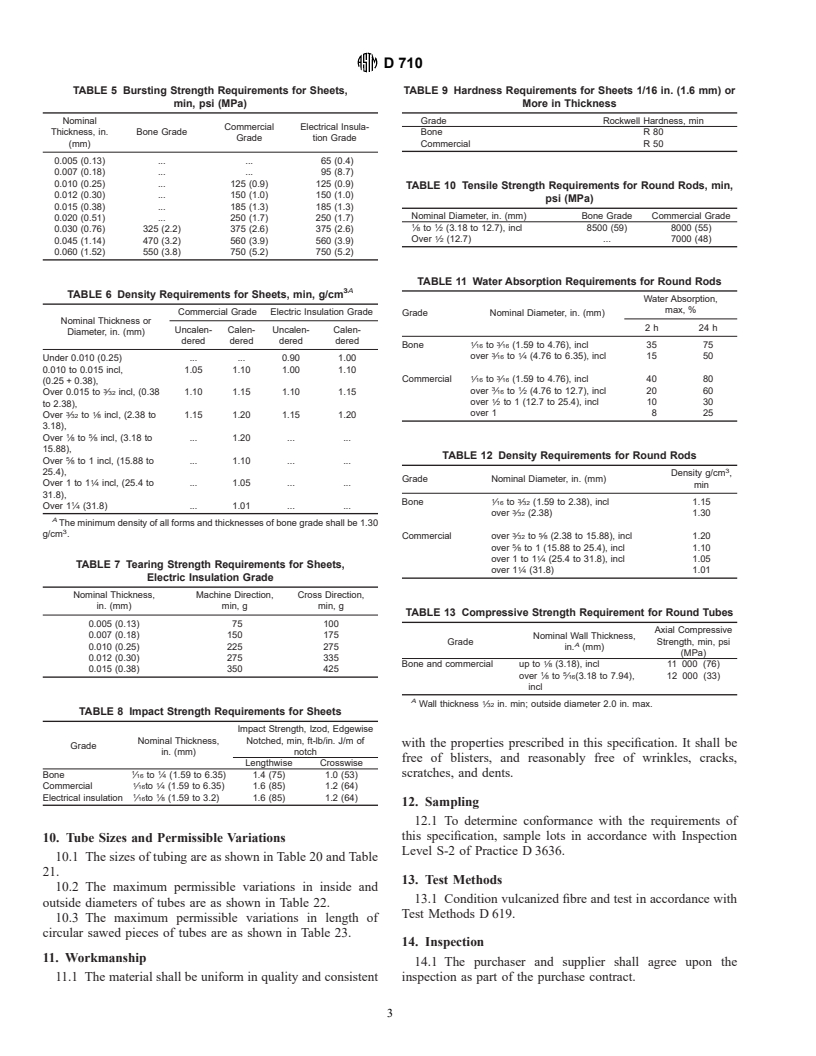

7. Detail Requirements

in. (mm) min,

2 h 24 h

V/mil (kV/mm)

7.1 Sheets—Sheet material, calendered only, unless other-

Bone ⁄32 (0.79) 55 63 175 (6.9)

wise specified, shall conform to the requirements as to physical

⁄16 (1.59) 30 55 175 (6.9)

and electrical properties prescribed in Tables 3-9.

⁄8 (3.18) 20 48 150 (5.9)

7.1.1 Bond Strength (Laminated Sheets Only)—Tested in ⁄16 (4.76) 17 42 100 (3.9)

⁄4 (6.35) 14 37 100 (3.9)

accordance with Test Method D 952 shall conform to the

following requirements:

Commercial ⁄32 (0.79) 60 68 175 (6.9)

⁄16 (1.59) 52 66 175 (6.9)

Thicknesses Psi, (MPa) min

⁄8 (3.18) 35 61 150 (5.9)

All 800 (5.5)

⁄16 (4.76) 24 56 100 (3.9)

7.2 Round Rods—Round rods shall conform to the require- ⁄4 (6.35) 20 52 100 (3.9)

ments as to physical properties prescribed in Tables 10 and 11,

Electrical 0.004 to 0.007 . . 200 (7.9)

and Table 12.

insulation (0.10 to 0.18),

7.3 Round Tubes—Round tubes shall conform to the re- incl

over 0.007 to 0.040 . . 250 (9.8)

quirements as to physical and electrical properties prescribed in

(0.18 to 1.02),

Tables 13 and 14. Density of tubing shall conform to the

incl

requirements prescribed in Table 6 for the respective grade and over 0.040 to ⁄8 . . 175 (6.9)

(1.02 to 3.18),

thickness.

incl

⁄32 (0.80) 60 68 .

8. Sheet Sizes and Permissible Variations

⁄16 (1.59) 52 66 .

⁄8 (3.17) 35 61 .

8.1 Sheets shall be furnished in the manufacturer’s standard

⁄4 (6.35) 20 52 100 (3.9)

sheet sizes.

⁄16 (7.94) 17 47 100 (3.9)

⁄8 (9.52) 15 43 100 (3.9)

NOTE 2—The range of manufacturer’s standard sizes for the various

⁄16 (11.11) 14 39 50 (2.0)

grades and thicknesses are shown in Table 15.

⁄2 (12.7) 13 36 50 (2.0)

A

⁄8 (15.88) 11 31

8.2 When sheets and rolls are trimmed to a specified width,

3 A

⁄4 (19.05) 10 27

the maximum permissible variation in width is 6 ⁄2 in. (612.7 A

⁄8 (22.22) 8 23

A

1 (25.4) 8 21

mm).

A

1 ⁄4 (31.8) 8 18

8.3 When sheets are trimmed to a specified length, the

A

1 ⁄2 (38.1) 8 17

A

maximum permissible variation in length is 6 ⁄2 in.

2 (50.8) and over 8 17

8.4 The maximum permissible variations in widths of strips

A

For intermediate thicknesses, the value for the next smaller thickness shall

cut from sheets by the indicated operations are as prescribed in apply.

B

For intermediate thicknesses, the value for the next larger thickness shall

Table 16.

apply.

8.5 The maximum permissible variation in thickness of full

sheets is as prescribed in Table 17.

8.6 The maximum permissible variations in thickness of

9. Rod Sizes and Permissible Variations

sheets cut in halves, thirds, or quarters are as shown in Table

9.1 Furnish rods in the same nominal sizes as sheets. Cut

17.

rods from sheet, the length being limited by the length of the

TABLE 2 Chemical Requirements sheet.

9.2 The maximum permissible variations in diameters of

Zinc Chloride, Silica Content,

Grade Color Ash max, %

max, % max, %

rods are as shown in Table 18.

All gray, black 0.1 1.5 0.3

9.3 The maximum permissible variations in lengths of

red 0.1 7 0.3

circular sawed pieces of rods are as shown in Table 19.

D 710

TABLE 5 Bursting Strength Requirements for Sheets, TABLE 9 Hardness Requirements for Sheets 1/16 in. (1.6 mm) or

min, psi (MPa) More in Thickness

Nominal Grade Rockwell Hardness, min

Commercial Electrical Insula-

Thickness, in. Bone Grade Bone R 80

Grade tion Grade

(mm)

Commercial R 50

0.005 (0.13) . . 65 (0.4)

0.007 (0.18) . . 95 (8.7)

0.010 (0.25) . 125 (0.9) 125 (0.9)

TABLE 10 Tensile Strength Requirements for Round Rods, min,

0.012 (0.30) . 150 (1.0) 150 (1.0)

psi (MPa)

0.015 (0.38) . 185 (1.3) 185 (1.3)

Nominal Diameter, in. (mm) Bone Grade Commercial Grade

0.020 (0.51) . 250 (1.7) 250 (1.7)

1 1

⁄8 to ⁄2 (3.18 to 12.7), incl 8500 (59) 8000 (55)

0.030 (0.76) 325 (2.2) 375 (2.6) 375 (2.6)

Over ⁄2 (12.7) . 7000 (48)

0.045 (1.14) 470 (3.2) 560 (3.9) 560 (3.9)

0.060 (1.52) 550 (3.8) 750 (5.2) 750 (5.2)

TABLE 11 Water Absorption Requirements for Round Rods

3A

TABLE 6 Density Requirements for Sheets, min, g/cm

Water Absorption,

max, %

Commercial Grade Electric Insulation Grade

Grade Nominal Diameter, in. (mm)

Nominal Thickness or

2 h 24 h

Uncalen- Calen- Uncalen- Calen-

Diameter, in. (mm)

dered dered dered dered

1 3

Bone ⁄16 to ⁄16 (1.59 to 4.76), incl 35 75

3 1

over ⁄16 to ⁄4 (4.76 to 6.35), incl 15 50

Under 0.010 (0.25) . . 0.90 1.00

0.010 to 0.015 incl, 1.05 1.10 1.00 1.10

1 3

Commercial ⁄16 to ⁄16 (1.59 to 4.76), incl 40 80

(0.25 + 0.38),

3 1

over ⁄16 to ⁄2 (4.76 to 12.7), incl 20 60

Over 0.015 to ⁄32 incl, (0.38 1.10 1.15 1.10 1.15

over ⁄2 to 1 (12.7 to 25.4), incl 10 30

to 2.38),

3 1

over 1 8 25

Over ⁄32 to ⁄8 incl, (2.38 to 1.15 1.20 1.15 1.20

3.18),

1 5

Over ⁄8 to ⁄8 incl, (3.18 to . 1.20 . .

15.88),

TABLE 12 Density Requirements for Round Rods

Over ⁄8 to 1 incl, (15.88 to . 1.10 . .

25.4),

Density g/cm ,

Grade Nominal Diameter, in. (mm)

Over1to1 ⁄4 incl, (25.4 to . 1.05 . .

min

31.8),

1 3

Bone ⁄16 to ⁄32 (1.59 to 2.38), incl 1.15

Over 1 ⁄4 (31.8) . 1.01 . .

over ⁄32 (2.38) 1.30

A

The minimum density of all forms and thicknesses of bone grade shall be 1.30

g/cm . 3 5

Commercial over ⁄32 to ⁄8 (2.38 to 15.88), incl 1.20

over ⁄8 to 1 (15.88 to 25.4), incl 1.10

over1to1 ⁄4 (25.4 to 31.8), incl 1.05

TABLE 7 Tearing Strength Requirements for Sheets,

over 1 ⁄4 (31.8) 1.01

Electric Insulation Grade

Nominal Thickness, Machine Direction, Cross Direction,

in. (mm) min, g min, g

TABLE 13 Compressive Strength Requirement for Round Tubes

0.005 (0.13) 75 100

Axial Compressive

0.007 (0.18) 150 175

Nominal Wall Thickness,

Grade Strength, min, psi

A

0.010 (0.25) 225 275 in. (mm)

(MPa)

0.012 (0.30) 275 335

Bone and commercial up to ⁄8 (3.18), incl 11 000 (76)

0.015 (0.38) 350 425

1 5

over ⁄8 to ⁄16(3.18 to 7.94), 12 000 (33)

incl

A

Wall thickness ⁄32 in. min; outside diameter 2.0 in. max.

TABLE 8 Impact Strength Requirements for Sheets

Impact Strength, Izod, Edgewise

Nominal Thickness, Notched, min, ft-lb/in. J/m of

with the properties prescribed in this specification. It shall be

Grade

in. (mm) notch

free of blisters, and reasonably free of wrinkles, cracks,

Lengthwise Crosswise

1 1

Bone ⁄16 to ⁄4 (1.59 to 6.35) 1.4 (75) 1.0 (53) scratches, and dents.

1 1

Commercial ⁄16to ⁄4 (1.59 to 6.35) 1.6 (85) 1.2 (64)

1 1

Electrical insulation ⁄16to ⁄8 (1.59 to 3.2) 1.6 (85) 1.2 (64)

12. Sampling

12.1 To determine conformance with the requirements of

this specification, sample lots in accordance with Inspection

10. Tube Sizes and Permissible Variations

Level S-2 of Practice D 3636.

10.1 The sizes of tubing are as shown in Table 20 and Table

21.

13. Test Methods

10.2 The maximum permissible variations in inside and

13.1 Condition vulcanized fibre and test in accordance with

outside diameters of tubes are as shown in Table 22.

Test Methods D 619.

10.3 The maximum permissible variations in length of

circular sawed pieces of tubes are as shown in Table 23.

14. Inspection

11. Workmanship

14.1 The purchaser and supplier shall agree upon the

11.1 The material shall be uniform in quality and consistent inspection as part of the purchase contract.

D 710

TABLE 14 Water Absorption and Dielectric Strength Requirements for Round Tubes

Water Absorption, max, %

Dielectric Strength, min,

Grade Nominal Wall Thickness, in. (mm)

V/mil (kV/mm)

2 h 24 h

Bone and commercial up to ⁄16 (1.59) . . 175 (6.9)

1 1

over ⁄16 to ⁄8 (1.59 to 3.18), incl . . 150 (5.9)

1 1

⁄32 to ⁄8 (0.79 to 3.18), incl 50 75 .

1 1

over ⁄8 to ⁄4 (3.18 to 6.35), incl 20 50 100 (3.9)

1 5

over ⁄4 to ⁄16 (6.35 to 7.94), incl 10 25 100 (3.9)

TABLE 15 Range of Manufacturers’ Sheet Sizes TABLE 17 Permissible Variations in Thickness of Full Sheets

A

and Sheets Cut in Halves, Thirds, and Quarters of all Grades

NOTE 1—Due to variations in the size of manufacturing equipment,

1 1 1

⁄2, ⁄3, ⁄4 Sheets,

there is some variation in the length and width of manufacturers’ standard

Full Sheets, plus or

Nominal Thickness, in. (mm) plus or minus,

minus, in. (mm)

sheet sizes. Consult manufacturers’ catalogs for sizes available. The

in. (mm)

ranges of manufacturers’ standard sheet sizes are as follows:

0.004 to 0.040 (0.10 to 1.02) 10 % 8 %

Grade Width, in. (mm) Length, in. (mm)

0.041 to 0.049 (1.04 to 1.24) 0.004 (0.10) 8 %

0.050 to 0.062 (1.27 to 1.57) 0.005 (0.13) 0.004 (0.10)

Bone 40 to 54 66 to 86

0.063 to 0.094 (1.60 to 2.39) 0.007 (0.18) 0.005 (0.13)

(1016 to 1322) (1676 to 2184)

0.095 to 0.125 (2.41

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.