ASTM D7255-06

(Test Method)Standard Test Method for Abrasion Resistance of Leather (Rotary Platform, Double-Head Method)

Standard Test Method for Abrasion Resistance of Leather (Rotary Platform, Double-Head Method)

SCOPE

1.1 This test method covers the determination of the abrasion resistance of leather using the rotary platform, double-head tester (RPDH).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7255–06

Standard Test Method for

Abrasion Resistance of Leather (Rotary Platform, Double-

Head Method)

This standard is issued under the fixed designation D 7255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For definitions of other leather terms used in this test

method, refer to Terminology D 1517.

1.1 This test method covers the determination of the abra-

sion resistance of leather using the rotary platform, double-

4. Summary of Test Method

head tester (RPDH).

4.1 Aspecimenisabradedusingrotaryrubbingactionunder

1.2 This standard does not purport to address all of the

controlled conditions of pressure and abrasive action. The test

safety concerns, if any, associated with its use. It is the

specimen, mounted on a turntable platform, turns on a vertical

responsibility of the user of this standard to establish appro-

axis, against the sliding rotation of two abrading wheels. One

priate safety and health practices and to determine the

abrading wheel rubs the specimen outward toward the periph-

applicability of regulatory limitations prior to use.

ery and the other, inward toward the center. The resulting

2. Referenced Documents abrasion marks form a pattern of crossed arcs over an area of

approximately 30 cm . Resistance to abrasion is evaluated by

2.1 ASTM Standards:

visual inspection of the specimen or change in weight, as

D 1517 Terminology Relating to Leather

described in Section 14.

D 1610 Practice for Conditioning Leather and Leather

Products for Testing

5. Significance and Use

D 2240 Test Method for Rubber Property—Durometer

5.1 The resistance of leather to abrasion, as measured on a

Hardness

testing machine in the laboratory, is generally only one of

D 2813 Practice for Sampling Leather for Physical and

several factors contributing to wear performance or durability

Chemical Tests

as experienced in the actual use of the material. While

3. Terminology “abrasion resistance” (often stated in terms of the number of

abrasion cycles) and “durability” (defined as the ability to

3.1 Definitions:

withstand deterioration or wear out in use, including the effects

3.1.1 abraser—a wear testing instrument, also referred to as

of abrasion) are frequently related, the relationship varies with

a rotary platform, double head (RPDH) tester or abrader.

differentendusesanddifferentfactorsmaybenecessaryinany

3.1.2 abrasion—the wearing away of any part of a material

calculation of predicted durability from specific abrasion data.

by rubbing against another surface.

This test method provides a comparative ranking of material

3.1.3 abrasion cycle—in abrasion testing, one or more

performance, which can be used as an indication of relative

movements of the abradant across a material surface, or the

end-use performance.

material surface across the abradant, that permits a return to its

5.2 The resistance of leather to abrasion may be affected by

starting position. In the case of the rotary platform test method,

factors including test conditions, type of abradant, pressure

it consists of one complete rotation of the specimen.

betweenthespecimenandabradant,mountingortensionofthe

3.1.4 resurface—the preparation of an abrasive wheel on a

specimen, and type, kind, or amount of finishing materials.

resurfacing disk or diamond tool wheel refacer, prior to use in

5.3 Abrasion tests utilizing the rotary platform, double-head

testing.

tester may be subject to variation due to changes in the

abradant during specific tests. Depending on abradant type and

This test method is under the jurisdiction ofASTM Committee D31 on Leather test specimen, the wheel surface may change (that is, become

and is the direct responsibility of Subcommittee D31.07 on Physical Properties.

clogged) due to the pick up of finishing or other materials from

Current edition approved April 1, 2006. Published April 2006.

test specimens and must be cleaned at regularly defined

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM intervals.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7255–06

5.4 The measurement of the relative amount of abrasion 6.1.5 Acounter to record the number of cycles (revolutions)

may also be affected by the method of evaluation and may be made by the turntable platform.

influenced by the judgment of the operator.

6.2 Abrasive Wheels, which are attached to the free end of

the pivoted arms, and are able to rotate freely about horizontal

6. Apparatus

spindles.

6.1 Rotary Platform, Double-Head (RPDH) Tester, con-

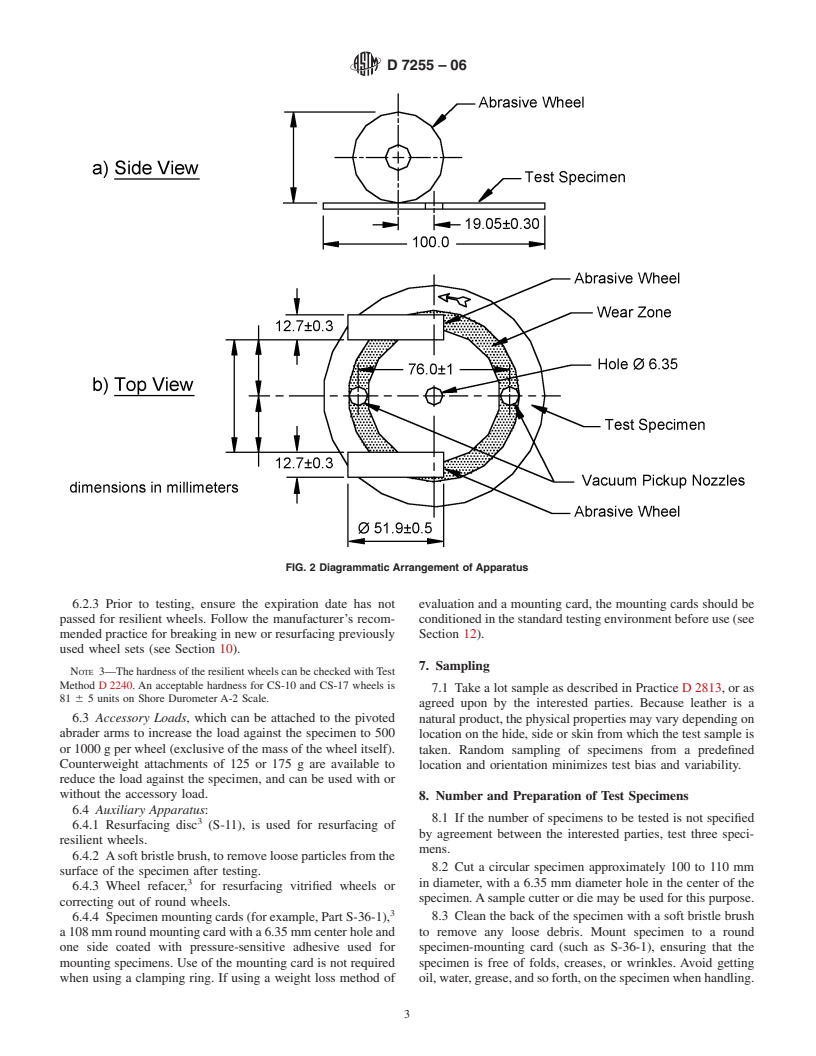

6.2.1 Their internal faces shall be 52.4 6 1.0 mm apart and

sisting of the elements described in 6.1.1-6.1.5 (see Fig. 1).

the hypothetical line through the two spindles shall be 19.05 6

6.1.1 A turntable platform, which is removable, parts pro-

0.3 mm away from the central axis of the turntable (see Fig. 2).

vided with the turntable include the S19 rubber pad, clamp

When resting on the specimen, the wheels will have a

plate and nut, and clamping ring to secure the specimen to the

peripheral engagement with the surface of the specimen, the

turntable. The turntable is motor driven and mounted so as to

direction of travel of the periphery of the wheels and of the

produce a circular surface travel of an essentially flat specimen

specimen at the contacting portions being at acute angles, and

in the plane of its surface,

the angles of travel of one wheel periphery being opposite to

6.1.2 Amotor capable of rotating the turntable platform at a

that of the other. Motion of the abrasive wheels, in opposite

speed of either 72 6 2 r/min for 110 V/60 Hz or 60 6 2 r/min

directions, is provided by rotation of the specimen and the

for 230 V/50 Hz,

associated friction there from.

6.1.3 A pair of pivoted arms to which the abrasive wheels

6.2.2 The wheels shall be 12.7 6 0.3 mm thick and have an

and accessory weights or counterweights are attached,

external diameter of 51.9 6 0.5 mm when new, and in no case

NOTE 1—Without auxiliary weights or counter weights applied, each

less than 44.4 mm. The abrasive wheels are either resilient or

arm will apply a load against the specimen of 250 6 1 g (exclusive of the

vitrified based, with both types of wheels consisting of hard

mass of the wheel itself).

particles embedded in a binder material and manufactured in

6.1.4 A vacuum suction system and vacuum pickup nozzle

different grades of abrasive quality.

to remove debris and abrasive particles from the specimen

NOTE 2—The H-19 wheels typically produce a harsher abrasion than

surface during testing.The height of the vacuum pickup nozzle

the CS-17 wheels, which produce a harsher abrasion than the CS-10

shall be adjustable, and will have two openings – with one

wheels.

opening positioned between the two wheels and over the wear

path and the other placed diametrically opposite. The distance

between the axes of the two openings shall be 76.0 6 1.0 mm,

and

The sole source of supply of the apparatus known to the committee at this time

is Taber Industries, 455 Bryant Street, North Tonawanda, NY 14120. If you are

aware of alternative suppliers, please provide this information to ASTM Interna-

Available from Tabert Industries, 455 Bryant Street, North Tonawanda, NY

tional Headquarters.Your comments will receive careful consideration at a meeting

14120.

of the responsible technical committee, which you may attend.

FIG. 1 Rotary Platform, Double-Head Tester

D7255–06

FIG. 2 Diagrammatic Arrangement of Apparatus

6.2.3 Prior to testing, ensure the expiration date has not evaluation and a mounting card, the mounting cards should be

passed for resilient wheels. Follow the manufacturer’s recom- conditionedinthestandardtestingenvironmentbeforeuse(see

mended practice for breaking in new or resurfacing previously Section 12).

used wheel sets (see Section 10).

7. Sampling

NOTE 3—The hardness of the resilient wheels can be checked withTest

Method D 2240. An acceptable hardness for CS-10 and CS-17 wheels is

7.1 Take a lot sample as described in Practice D 2813,oras

81 6 5 units on Shore Durometer A-2 Scale.

agreed upon by the interested parties. Because leather is a

6.3 Accessory Loads, which can be attached to the pivoted

natural product, the physical properties may vary depending on

abrader arms to increase the load against the specimen to 500

location on the hide, side or skin from which the test sample is

or 1000 g per wheel (exclusive of the mass of the wheel itself).

taken. Random sampling of specimens from a predefined

Counterweight attachments of 125 or 175 g are available to

location and orientation minimizes test bias and variability.

reduce the load against the specimen, and can be used with or

without the accessory load.

8. Number and Preparation of Test Specimens

6.4 Auxiliary Apparatus:

8.1 If the number of specimens to be tested is not specified

6.4.1 Resurfacing disc (S-11), is used for resurfacing of

by agreement between the interested parties, test three speci-

resilient wheels.

mens.

6.4.2 Asoft bristle brush, to remove loose particles from the

8.2 Cut a circular specimen approximately 100 to 110 mm

surface of the specimen after testing.

in diameter, with a 6.35 mm diameter hole in the center of the

6.4.3 Wheel refacer, for resurfacing vitrified wheels or

specimen.Asample cutter or die may be used for this purpose.

correcting out of round wheels.

6.4.4 Specimen mounting cards (for example, Part S-36-1), 8.3 Clean the back of the specimen with a soft bristle brush

to remove any loose debris. Mount specimen to a round

a108mmroundmountingcardwitha6.35mmcenterholeand

one side coated with pressure-sensitive adhesive used for specimen-mounting card (such as S-36-1), ensuring that the

specimen is free of folds, creases, or wrinkles. Avoid getting

mounting specimens. Use of the mounting card is not required

when using a clamping ring. If using a weight loss method of oil,water,grease,andsoforth,onthespecimenwhenhandling.

D7255–06

placing in service a new set of resilient wheels they must be subjected to

8.3.1 Alternatively, a sample of 130 6 5 mm diameter may

two (2) resurfacings of 50 cycles to ensure perfect contact of the abrading

be used, with or without a mounting card, and secured to the

faces with the specimen surface. The resurfacing disc is used only once

turntable with a clamp ring.

(maximum of 50 cycles), therefore this initial resurfacing of new wheels

8.4 If the leather has a pattern such as embossment, ensure

will require two (2) resurfacing discs.

that the specimen is a representative sampling of the pattern.

NOTE 6—Starting a Test with Previously Used Wheels—Before testing

a specimen with previously used wheels, resurface 25 to 50 cycles on a

9. Preparation of Apparatus

new resurfacing disc. When the previous test was short in duration

9.1 Load—A load of 1000 g per wheel should be used,

(<1,000 cycles), resurfacing of 25 cycles is sufficient. When the previous

unless otherwise agreed upon by the interested parties.

test was 1,000 cycles or more, a resurfacing of 50 cycles is recommended.

9.2 Vacuum Pickup Nozzle—The height of the vacuum Wheels that have not been used for an extended period of time may

require a break-in resurfacing like a new set of wheels.

pickup nozzle should be set 7 6 1 mm above the specimen

surface, unless otherwise agreed upon by the interested parties. NOTE 7—Resurfacing During Testing—To maintain consistency and

avoidcloggingofwheelfaces,thewheelsshouldberesurfacedafterevery

9.3 Vacuum Suction—The vacuum suction force should be

1000 cycles of use. During the course of a test which requires more than

adjusted to lift the abraded particles, but not lift the specimen.

1000cycles,removethespecimenafterevery1000cycles(orasagreedby

When the suction nozzles are in position, the air pressure in the

interested parties) and resurface the wheels for 25 to 50 cycles with a new

suction device shall be within the range stated in 11.1.5.A

resurfacingdisc.Thesampleshouldbecarefullyreplacedafterresurfacing

setting of 75 - 100 has been found to be sufficient and should

of the wheels.

beused,unlessotherwiseagreeduponbytheinterestedparties.

10.2 Preparation of Vitrified Abrading Wheels—Vitrified

NOTE 4—Vacuum suction force may be influenced by the condition of

wheels do not require refacing unless the abrading surface

the collection bag, which must be emptied or replaced on a regular basis.

becomes clogged, chipped or out of round. A wheel refacer

Any connection or seal leaks will also influence suction force.

should be used to correct any of these conditions.

9.4 Selection of Wheel Type—The CS-10 wheel should be

used, unless otherwise agreed upon by the interested parties.

11. Calibration

10. Standardization of Abrading Wheels

11.1 Verify calibration of the rotary platform, double head

10.1 Preparation of resilient abrading wheels—To ensure tester as directed by the equipment manufacturer (see Appen-

that the abrading function of the wheels is maintained at a dix X1).

constant level, prepare the resilient wheels following 10.1.1-

11.1.1 Wheel Position—The wheels should be spaced

10.1.4

equally on both sides from the wheel-mounting flange to the

10.1.1 Mount the selected resilient wheels on their respec-

centerofthespecimenholder(see6.2.1).Thedistancefromthe

tive flange holders, taking care not to handle them by their

inside of the wheel-mounting flange to the center of the

abrasive surfaces. Adjust the load on each wheel to 1000 g or

specimen holder is 38.8 6 0.5 mm.

the load agreed upon between the interested parties.

11.1.2 Wheel Bearings—The RPDH tester wheel bearings

10.1.2 Mount the resurfacing disc (S-11) on the turntable

installed in the free end of the pivoting arms to support the

and affix using the clamp plate and nut, and clamp ring. Lower

wheels should not stick when caused to spin rapidly by a quick

the abrading heads carefully until the wheels rest on the

driving motion of the forefinger.

resurfacing disc. Place the vacuum pick-up nozzle in position

11.1.3 Turntable Platform Position—The vertical distance

andadjustittoadistanceof7 61mmabovethesurfaceofthe

from the center of the pivot point of the RPDH tester arms to

disc.

the top of the specimen holder should be approximately

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.