ASTM D922-00a

(Specification)Standard Specification for Nonrigid Vinyl Chloride Polymer Tubing

Standard Specification for Nonrigid Vinyl Chloride Polymer Tubing

SCOPE

1.1 This specification covers nonrigid tubing of vinyl chloride polymer or its copolymers with other materials for use in electrical insulation in three grades, as follows:

1.1.1 Grade A--General-purpose.

1.1.2 Grade B--Low-temperature.

1.1.3 Grade C--High-temperature.

Note 1--This standard is similar but not identical to IEC 60684-3-100 to -105.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 922 – 00a

Standard Specification for

Nonrigid Vinyl Chloride Polymer Tubing

This standard is issued under the fixed designation D922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4.1.2 Size and color,

4.1.3 Total length in feet (or metres),

1.1 This specification covers nonrigid tubing of vinyl chlo-

4.1.4 Length of cut pieces in inches (or centimetres), if any,

ride polymer or its copolymers with other materials for use in

and

electrical insulation in three grades, as follows:

4.1.5 Amount of tubing on each spool or in each coil, if not

1.1.1 Grade A—General-purpose.

standard packaging with the supplier.

1.1.2 Grade B—Low-temperature.

1.1.3 Grade C—High-temperature.

5. Color

NOTE 1—This standard is similar but not identical to IEC 60684-3-100

5.1 Clear transparent, black, white, yellow, green, blue, and

to -105.

red shall be considered standard colors. Other colors shall be

considered special. The color desired shall be specified in the

2. Referenced Documents

purchase order.

2.1 ASTM Standards:

D876 Test Methods for Nonrigid Vinyl Chloride Polymer

6. Dimensional Requirements

Tubing Used for Electrical Insulation

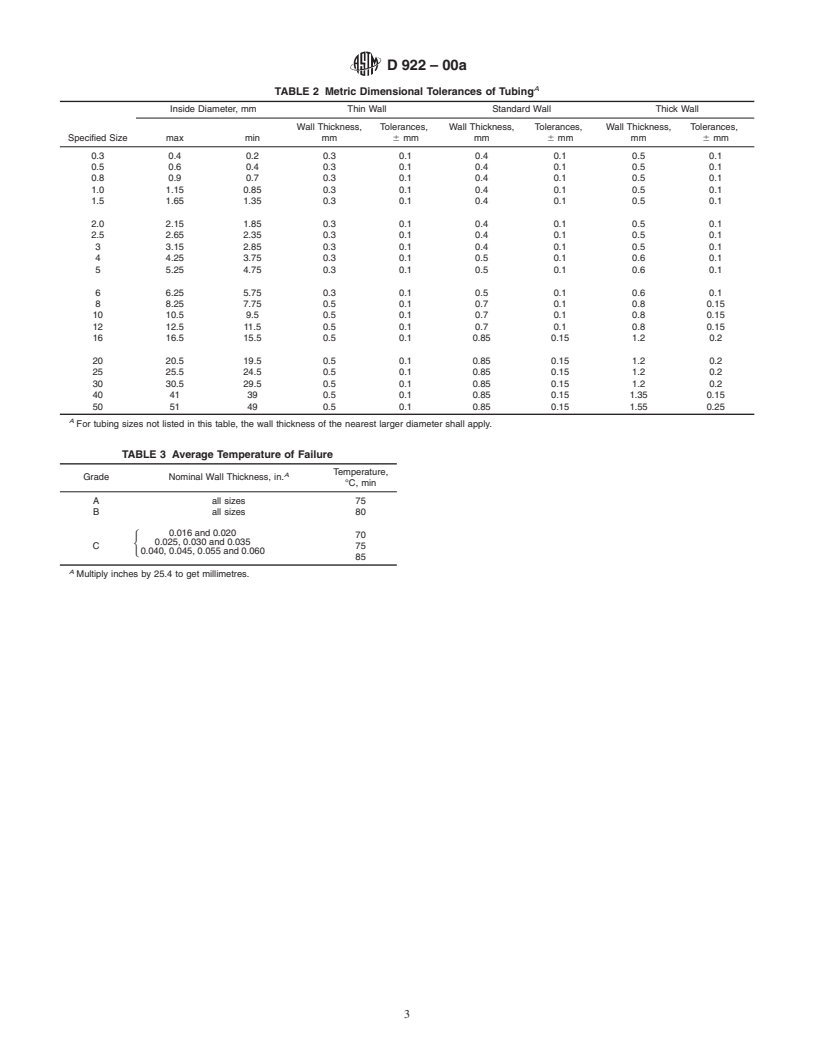

6.1 Inside Diameter—The inside diameter of the tubing

D1711 Terminology Relating to Electrical Insulation

shall conform to the requirements prescribed in Table 1 or

D3636 Practice for Sampling and Judging Quality of Solid

Table 2.

Electrical Insulating Materials

6.2 Wall Thickness—The wall thickness of the tubing shall

E176 Terminology of Fire Standards

conform to the requirements prescribed in Table 1 or Table 2.

2.2 IEC Standards:

6.3 Commercial Lengths—The tubing shall be supplied in

IEC-60684-3-100 to -105 Flexible insulating sleeving, Part

continuous lengths.

3, Sheets 100 to 105: Extruded PVC sleeving

7. Workmanship, Finish, and Appearance

3. Terminology

7.1 The surface shall be smooth, free of blisters, cracks, or

3.1 Definitions:

anyotherdefectsthatmaydetrimentallyaffectitssuitabilityfor

3.1.1 Fordefinitionspertainingtoelectricalinsulation,refer

the service intended. It shall not be subject to peeling, scaling,

to Terminology D1711.

or flaking.

3.1.2 For definitions pertaining to fire standards, refer to

Terminology E176.

8. Physical and Electrical Requirements

8.1 Tubing shall conform to the following requirements for

4. Ordering Information

physical and electrical properties:

4.1 Orders for material covered by this specification shall

8.1.1 Flammability—The average duration of burning shall

include the following:

notexceed15sandthepaperindicatorshallshownoevidence

4.1.1 Grade of tubing,

of being affected.

8.1.2 Tensile Strength—The average tensile strength shall

1 benotlessthan2000psi(15MPa)forGradesAandC,andnot

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of lessthan1800psi(13MPa)forGradeB.Theaverageultimate

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

elongationshallbenotlessthan200%forGradesAandCand

Current edition approved Sept. 10, 2000. Published November 2000. Originally

not less than 250% for Grade B.

published as D922–47T. Last previous edition D922–00.

8.1.3 Effect of Elevated Temperatures— When MethodAis

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 10.02.

used, the average loss of ultimate elongation after exposure to

Annual Book of ASTM Standards, Vol 04.07.

elevatedtemperaturesshallbenotgreaterthan35%forGrades

AvailablefromtheAmericanNationalStandardsInstitute,11W.42ndSt.,13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 922 – 00a

A,B

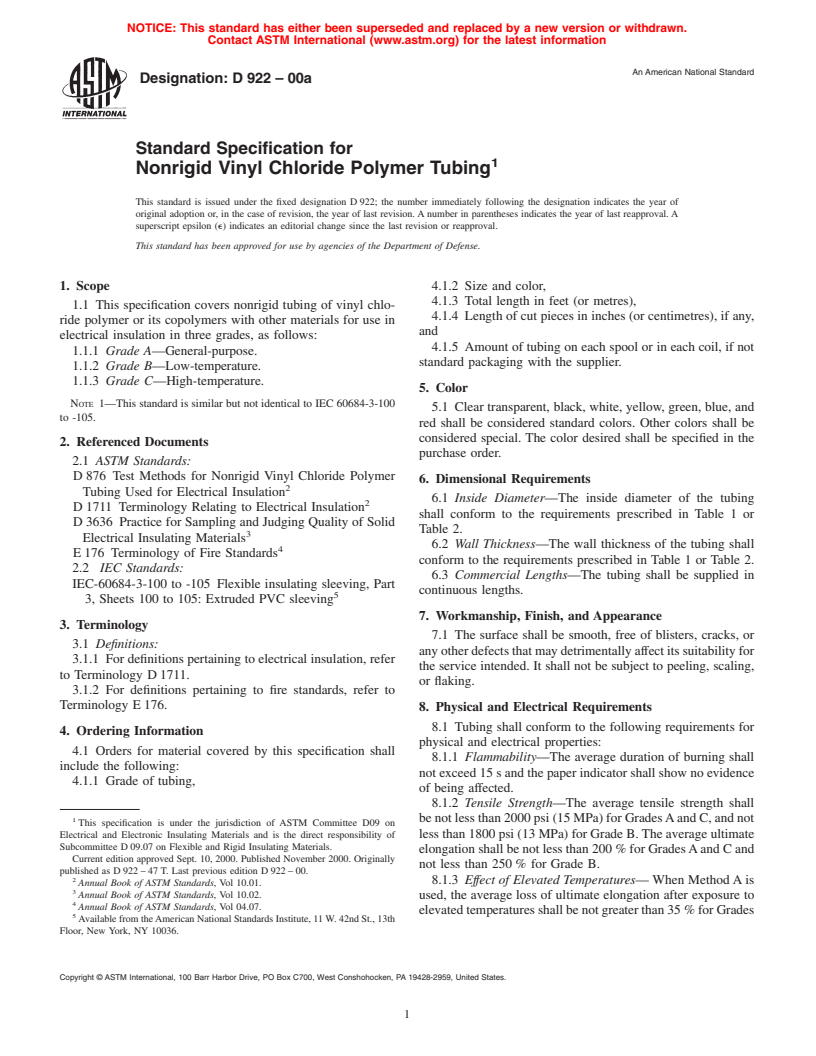

TABLE 1 Dimensional Tolerances of Tubing

8.1.9 Dielectric Breakdown at High Humidity—The aver-

Inside Diameter, in. Wall Thickness age dielectric breakdown strength at 96% relative humidity

shallbenotlessthan90%forGradeA,75%forGradeB,and

Tolerances,

Specified Size

Wall Thick-

max min plus or

85% for Grade C of the dry value obtained on test.

ness, in.

minus, in.

8.1.10 Strain Relief—Thechangeinlength(shrinkage)shall

No. 24 (0.022 in.) 0.027 0.020 0.012 0.002

not exceed 18% for sizes AWG No. 24 to No. 20, inclusive;

No. 22 (0.027 in.) 0.032 0.025 0.012 0.002

14% for sizesAWG No. 18 to 10, inclusive; and 9% for sizes

No. 20 (0.034 in.) 0.039 0.032 0.016 0.003

No. 18 (0.042 in.) 0.049 0.040 0.016 0.003

AWG No. 9 to 2 in. (50 mm), inclusive.

No. 16 (0.053 in.) 0.061 0.051 0.016 0.003

8.1.11 Corrosive Effect—The resistance of the copper wire

No. 14 (0.066 in.) 0.074 0.064 0.016 0.003

shall increase by not more than 2%.

No. 12 (0.085 in.) 0.091 0.081 0.016 0.003

No. 11 (0.095 in.) 0.101 0.091 0.016 0.003

9. Sampling

No. 10 (0.106 in.) 0.112 0.102 0.016 0.003

No. 9 (0.118 in.) 0.124 0.114 0.020 0.003

9.1 Fordimensionalandvisualtests,lotsshallbesampledin

No. 8 (0.133 in.) 0.141 0.129 0.020 0.003

accordance with Inspection Level II of Practice D3636.

No. 7 (0.148 in.) 0.158 0.144 0.020 0.003

9.2 To determine conformity with the requirements for

No. 6 (0.166 in.) 0.178 0.162 0.020 0.003

No. 5 (0.186 in.) 0.198 0.182 0.020 0.003 physical and electrical properties, lots shall be sampled in

No. 4 (0.208 in.) 0.224 0.204 0.020 0.003

accordance with Inspection Level II. A quantity large enough

tocompletealloftherequiredtestsshallbeselectedatrandom

No. 3 (0.234 in.) 0.249 0.229 0.020 0.003

No. 2 (0.263 in.) 0.278 0.258 0.020 0.003 from one fifth of the units sampled.

No. 1 (0.294 in.) 0.311 0.289 0.020 0.003

No. 0 (0.330 in.) 0.347 0.325 0.020 0.003

5 10. Test Methods

⁄16 in. 0.334 0.312 0.025 0.003

3 10.1 Determine the properties enumerat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.