ASTM C1512-07

(Test Method)Standard Test Method for Characterizing the Effect of Exposure to Environmental Cycling on Thermal Performance of Insulation Products

Standard Test Method for Characterizing the Effect of Exposure to Environmental Cycling on Thermal Performance of Insulation Products

SIGNIFICANCE AND USE

Exposing a specimen to conditions of one-directional environmental cycling can increase its moisture content until a decrease in material properties occurs (at a specific number of cycles). Such a test could be inappropriate due to the number of cycles required to cause a decrease in material properties since product performance issues often arise only after many years of exposure. The use of a preconditioning procedure is not intended to duplicate expected field performance. Rather the purpose is to increase the moisture content of test materials prior to subjecting to them to environmental cycling.

The most important aspect of the preconditioning procedure is non-uniform moisture distribution in the specimen. The heat flow is one directional causing moisture flow towards the cold side resulting in zones of dry material on the warm side and high moisture content on the cold side. (Whether the high moisture content zone is located right at the cold surface of the specimen or at some distance from this surface depends upon temperature oscillation and ability of the cold surface to dry outwards). Because the preconditioning procedure involves thermal gradient, this preconditioning procedure results in a distribution of moisture content that may occur under field exposure conditions. However, the resulting moisture content may differ significantly from that which may be demonstrated in typical product applications.

The preconditioning results in accumulation of moisture in the thermal insulation resulting from the simultaneous exposure to a difference in temperature and water vapor pressure. This test method is not intended to duplicate field exposure. It is intended to provide comparative ratings. As excessive accumulation of moisture in a construction system may adversely affect its performance, the designer should consider the potential for moisture accumulation and the possible effects of this moisture on the system performance.

SCOPE

1.1 This test method is applicable to preformed or field manufactured thermal insulation products, such as board stock foams, rigid fibrous and composite materials manufactured with or without protective facings. See Note 0 This test method is not applicable to high temperature, reflective or loose fill insulation.Note 0

If the product is manufactured with a facer, test product with facer in place.

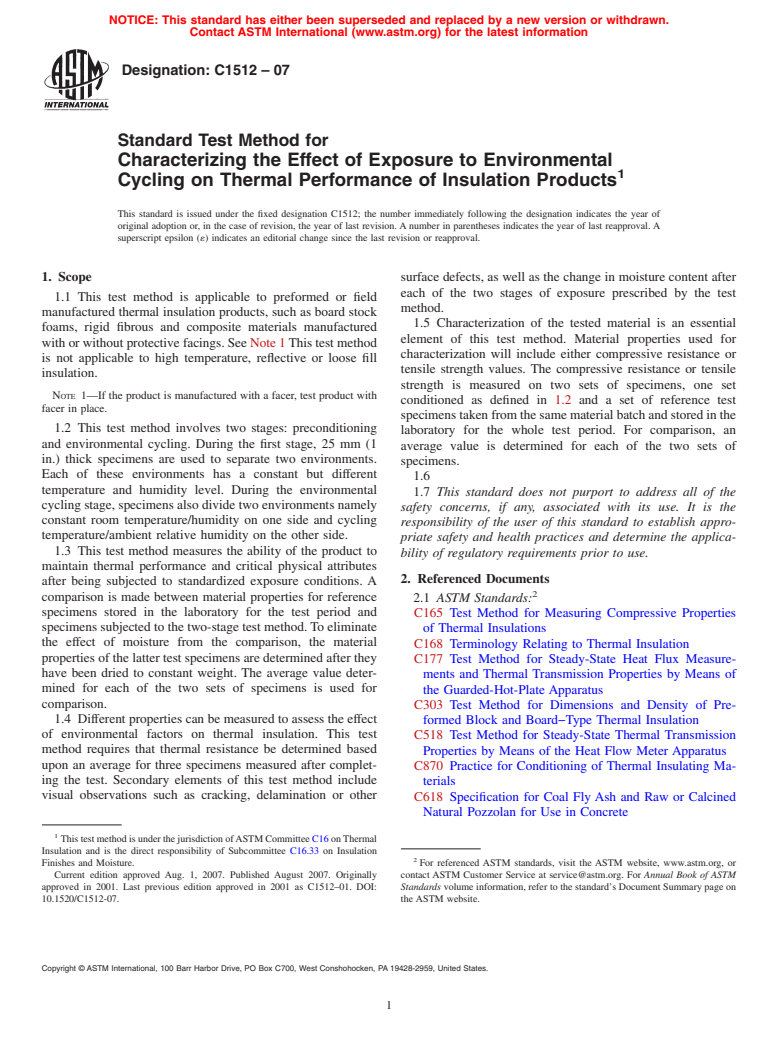

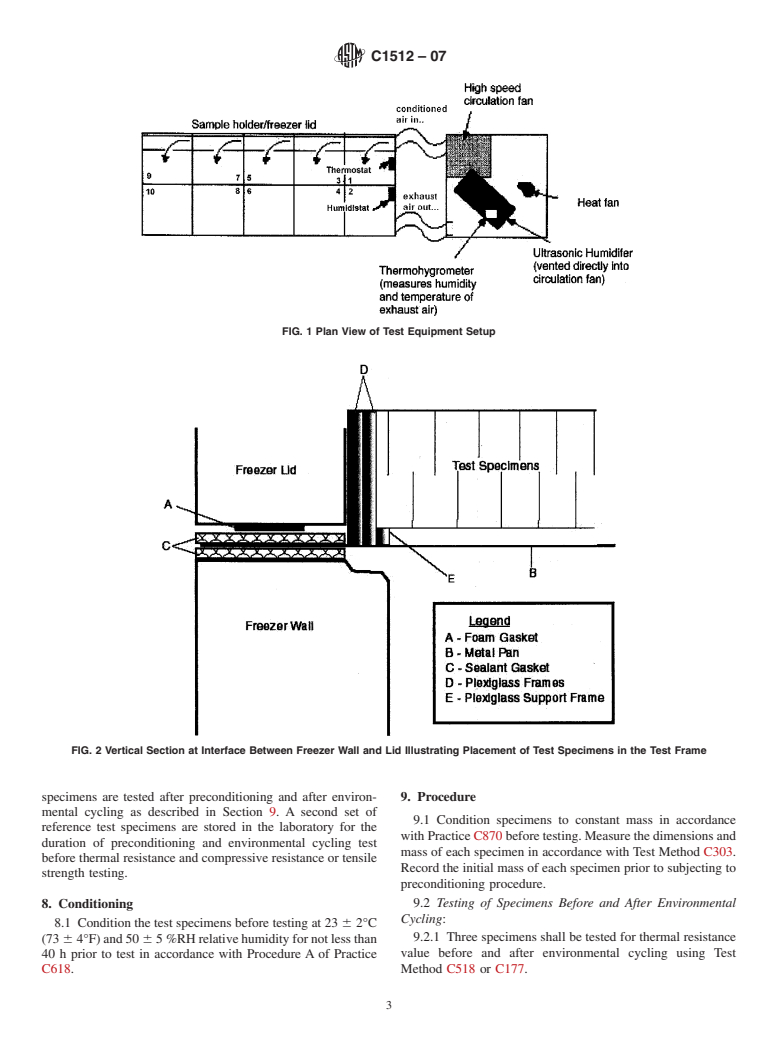

1.2 This test method involves two stages: preconditioning and environmental cycling. During the first stage, 25 mm (1 in.) thick specimens are used to separate two environments. Each of these environments has a constant but different temperature and humidity level. During the environmental cycling stage, specimens also divide two environments namely constant room temperature/humidity on one side and cycling temperature/ambient relative humidity on the other side.

1.3 This test method measures the ability of the product to maintain thermal performance and critical physical attributes after being subjected to standardized exposure conditions. A comparison is made between material properties for reference specimens stored in the laboratory for the test period and specimens subjected to the two-stage test method. To eliminate the effect of moisture from the comparison, the material properties of the latter test specimens are determined after they have been dried to constant weight. The average value determined for each of the two sets of specimens is used for comparison.

1.4 Different properties can be measured to assess the effect of environmental factors on thermal insulation. This test method requires that thermal resistance be determined based upon an average for three specimens measured after completing the test. Secondary elements of this test method include visual observations such as cracking, delamination or other surface defects, as well as the change in moisture content after each of the two stages of exposure prescribed by the test method.

1.5 Chara...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1512–07

Standard Test Method for

Characterizing the Effect of Exposure to Environmental

1

Cycling on Thermal Performance of Insulation Products

This standard is issued under the fixed designation C1512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope surface defects, as well as the change in moisture content after

each of the two stages of exposure prescribed by the test

1.1 This test method is applicable to preformed or field

method.

manufactured thermal insulation products, such as board stock

1.5 Characterization of the tested material is an essential

foams, rigid fibrous and composite materials manufactured

element of this test method. Material properties used for

withorwithoutprotectivefacings.SeeNote1Thistestmethod

characterization will include either compressive resistance or

is not applicable to high temperature, reflective or loose fill

tensile strength values. The compressive resistance or tensile

insulation.

strength is measured on two sets of specimens, one set

NOTE 1—If the product is manufactured with a facer, test product with

conditioned as defined in 1.2 and a set of reference test

facer in place.

specimenstakenfromthesamematerialbatchandstoredinthe

1.2 This test method involves two stages: preconditioning

laboratory for the whole test period. For comparison, an

and environmental cycling. During the first stage, 25 mm (1

average value is determined for each of the two sets of

in.) thick specimens are used to separate two environments.

specimens.

Each of these environments has a constant but different

1.6

temperature and humidity level. During the environmental

1.7 This standard does not purport to address all of the

cyclingstage,specimensalsodividetwoenvironmentsnamely

safety concerns, if any, associated with its use. It is the

constant room temperature/humidity on one side and cycling

responsibility of the user of this standard to establish appro-

temperature/ambient relative humidity on the other side.

priate safety and health practices and determine the applica-

1.3 This test method measures the ability of the product to

bility of regulatory requirements prior to use.

maintain thermal performance and critical physical attributes

2. Referenced Documents

after being subjected to standardized exposure conditions. A

2

comparison is made between material properties for reference

2.1 ASTM Standards:

specimens stored in the laboratory for the test period and

C165 Test Method for Measuring Compressive Properties

specimenssubjectedtothetwo-stagetestmethod.Toeliminate

of Thermal Insulations

the effect of moisture from the comparison, the material

C168 Terminology Relating to Thermal Insulation

propertiesofthelattertestspecimensaredeterminedafterthey

C177 Test Method for Steady-State Heat Flux Measure-

have been dried to constant weight. The average value deter-

ments and Thermal Transmission Properties by Means of

mined for each of the two sets of specimens is used for

the Guarded-Hot-Plate Apparatus

comparison.

C303 Test Method for Dimensions and Density of Pre-

1.4 Different properties can be measured to assess the effect

formed Block and Board−Type Thermal Insulation

of environmental factors on thermal insulation. This test

C518 Test Method for Steady-State Thermal Transmission

method requires that thermal resistance be determined based

Properties by Means of the Heat Flow Meter Apparatus

upon an average for three specimens measured after complet-

C870 Practice for Conditioning of Thermal Insulating Ma-

ing the test. Secondary elements of this test method include

terials

visual observations such as cracking, delamination or other

C618 Specification for Coal Fly Ash and Raw or Calcined

Natural Pozzolan for Use in Concrete

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

Insulation and is the direct responsibility of Subcommittee C16.33 on Insulation

2

Finishes and Moisture. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2007. Published August 2007. Originally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2001. Last previous edition approved in 2001 as C1512–01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1512-07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1512–07

D1621 Test Method for Compressive Properties Of Rigid exposure to a difference in temperature and wat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.