ASTM A476-90(1997)

(Specification)Standard Specification for Ductile Iron Castings for Paper Mill Dryer Rolls (Withdrawn 2000)

Standard Specification for Ductile Iron Castings for Paper Mill Dryer Rolls (Withdrawn 2000)

SCOPE

1.1 This specification covers ductile iron castings for use in pressure containing paper mill dryer rolls at temperatures up to 450°F.

1.2 No precise quantitative relationship can be stated between the properties of the iron in various locations of the same casting or between the properties of a casting and those of a test specimen cast from the same iron (see Appendix X1).

1.3 A complete metric companion to Specification A476 has been developed-A476M; therefore, no metric equivalents are presented in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 476 – 90 (Reapproved 1997)

Standard Specification for

1,2

Ductile Iron Castings for Paper Mill Dryer Rolls

This standard is issued under the fixed designation A 476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.1.6 Certification, if required (see 12.1),

4.1.7 Marking location (see 13.1), and

1.1 This specification covers ductile iron castings for use in

4.1.8 Additional requirements.

pressure containing paper mill dryer rolls at temperatures up to

450°F.

5. Heat Treatment

1.2 No precise quantitative relationship can be stated be-

5.1 The castings may be stress relieved at a temperature not

tweenthepropertiesoftheironinvariouslocationsofthesame

to exceed 1200°F.

castingorbetweenthepropertiesofacastingandthoseofatest

specimen cast from the same iron (see Appendix X1).

6. Mechanical Properties

1.3 A complete metric companion to Specification A 476

6.1 The iron represented by test coupons shall conform to

has been developed—A 476M; therefore, no metric equiva-

tensile requirements prescribed in Table 1.

lents are presented in this specification.

6.2 The yield strength prescribed in Table 1 may be deter-

2. Referenced Documents mined by any of the approved procedures described in 7.3 of

Test Methods E 8.

2.1 ASTM Standards:

6.3 The Brinell hardness of the material shall be a minimum

A 644 Terminology Relating to Iron Castings

4 of 201 HB. Hardness tests shall be conducted in accordance

E 8 TestMethodsforTensionTestingofMetallicMaterials

withTest Method E 10, using a 3000-kgf load.The test may be

E 10 Test Method for Brinell Hardness of Metallic Materi-

4 made on either the casting or on a test coupon representing the

als

casting.

E 94 Guide for Radiographic Testing

E 446 Reference Radiographs for Steel Castings Up to 2 in.

7. Workmanship, Finish, and Appearance

(51 mm) in Thickness

7.1 The castings shall conform to the dimensions on the

3. Terminology drawings furnished by the purchaser, or if no drawing has been

provided, to the dimensions predicated by the pattern supplied

3.1 Definitions for many terms common to iron castings are

by the purchaser. Surfaces of the castings shall be free of

found in Terminology A 644.

adheringsand.Runners,risers,fins,andotherextraneousmetal

4. Ordering Information shall be removed.

4.1 Ordersformaterialpurchasedtotherequirementsofthis

8. Sampling

specification should include the following information:

8.1 Test coupons shall be poured from the same iron as the

4.1.1 Quantity,

castings represented.

4.1.2 Specification number and date of issue,

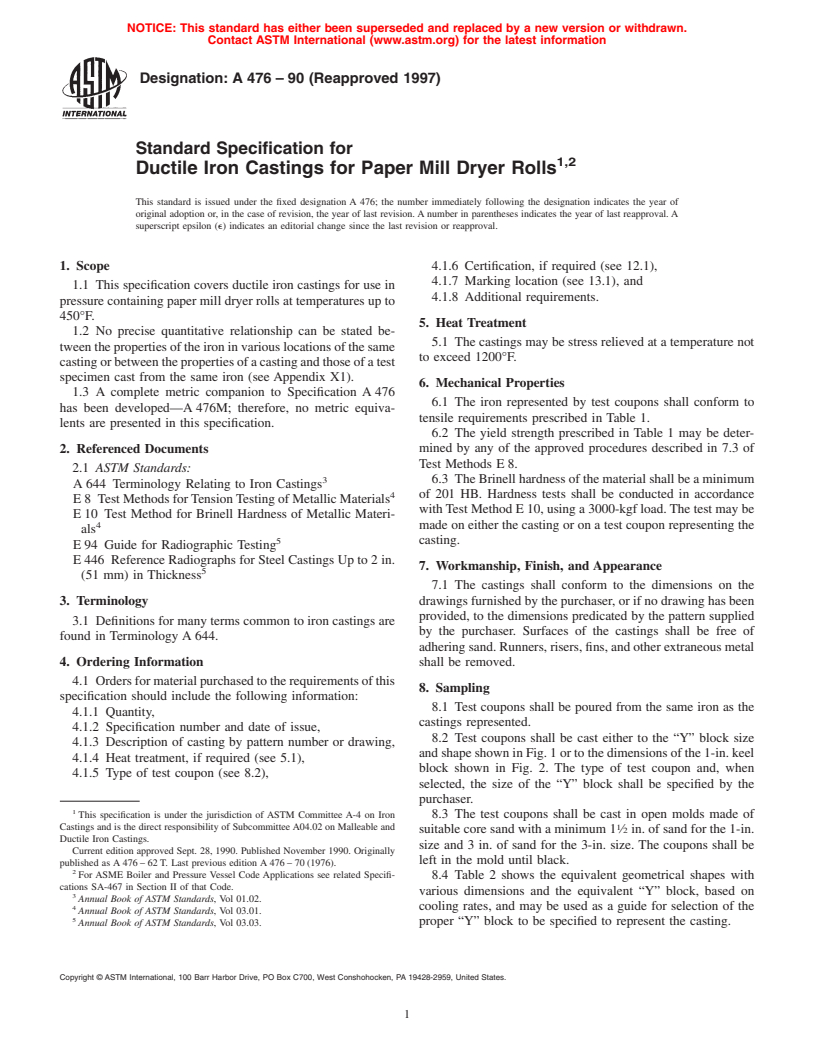

8.2 Test coupons shall be cast either to the “Y” block size

4.1.3 Description of casting by pattern number or drawing,

andshapeshowninFig.1ortothedimensionsofthe1-in.keel

4.1.4 Heat treatment, if required (see 5.1),

block shown in Fig. 2. The type of test coupon and, when

4.1.5 Type of test coupon (see 8.2),

selected, the size of the “Y” block shall be specified by the

purchaser.

This specification is under the jurisdiction of ASTM Committee A-4 on Iron 8.3 The test coupons shall be cast in open molds made of

Castings and is the direct responsibility of SubcommitteeA04.02 on Malleable and 1

suitable core sand with a minimum 1 ⁄2 in. of sand for the 1-in.

Ductile Iron Castings.

size and 3 in. of sand for the 3-in. size. The coupons shall be

Current edition approved Sept. 28, 1990. Published November 1990. Originally

left in the mold until black.

published as A 476 – 62 T. Last previous edition A 476 – 70 (1976).

For ASME Boiler and Pressure Vessel Code Applications see related Specifi-

8.4 Table 2 shows the equivalent geometrical shapes with

cations SA-467 in Section II of that Code.

various dimensions and the equivalent “Y” block, based on

Annual Book of ASTM Standards, Vol 01.02.

4 cooling rates, and may be used as a guide for selection of the

Annual Book of ASTM Standards, Vol 03.01.

proper “Y” block to be specified to represent the casting.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

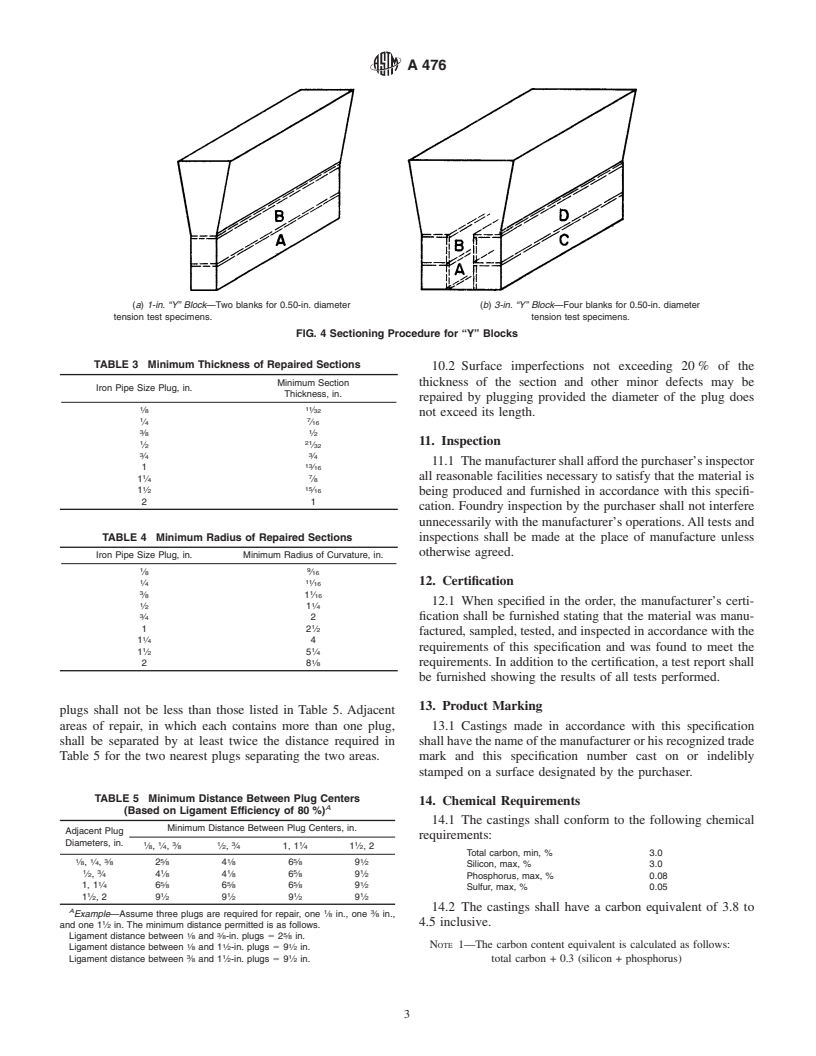

A 476

TABLE 1 Tensile Requirements TABLE 2 Equivalent Geometric Shapes Corresponding to “Y”

Blocks

Test Coupon Section Thickness 1 in. 3 in.

“Y” Block Infinite Plate Round Di- Cube Edge,

Tensile strength, min, ksi 80 80

Size, in. Thickness, in. ameter, in. in.

Yield strength, min, ksi 60 60

Elongation in 2 in., min, % 3.0 1.0

1 0.9 1.75 2.75

3 1.6 3.1 4.8

NOTE—The gage length and fillets shall be as shown, but the ends may

be of any shape to fit the holders of the testing machine in such a way that

“Y” Block Size

theloadshallbeaxial.Thereducedsectionshallhaveagradualtaperfrom

the ends toward the center, with the ends 0.003 to 0.005 in. larger in

For Castings of Thick- For Castings of Thick-

Dimensions

1 1 1

diameter than the center.

ness ⁄2in. to 1 ⁄2 in. ness of 1 ⁄2 in. and Over

FIG. 3 Standard Round Tension Test Specimen with 2-in. Gage

in. in.

Length

A1 3

B1 ⁄8 5

C3 4

9.4 If an apparently sound test specimen fails to conform to

D6 8

the tensile requirements, two retests may be made. If either

E7 7

approx approx

retest fails to conform to the requirements specified, the

FIG. 1 “Y” Blocks for Test Coupons castings shall be rejected.

10. Repairs

10.1 Castings made to this specification that leak on subse-

quent hydrostatic testing may be repaired by using threaded

plugs provided the following requirements are met.

10.1.1 No welding or brazing shall be permitted.

10.1.2 The diameter of the plug shall not exceed the

diameter of a standard 2-in. iron pipe size pipe plug.

10.1.3 The plugs, where practical, shall conform in all

dimensions to the standard iron pipe size pipe plugs. In

addition, they shall have full thread engagement corresponding

to the thickness of the repaired section. Where a tapered plug

is impractical because of the excess wall thickness in terms of

plug diameter and coincident thread engagement, other types

ofplugsmaybeusedprovidedbothfullthreadengagementand

effective sealing against pressure are obtained. Where possible

theendsoftheplugsshouldbegroundsmoothafterinstallation

to conform to the inside and outside contours of the cylinder.

NOTE—The length of keel block shall be 6 in.

10.1.4 The material from which the plug is manufactured

FIG. 2 Keel Block for Test Coupons

shall conform in all respects to this specification.

10.1.5 The area adjacent to the drilled hole should be

8.5 Whenthecastingsareheattreated,thetestcouponsshall

examinedradiographicallyinaccordancewith

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.