ASTM C227-03

(Test Method)Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method)

SCOPE

1.1 This test method covers the determination of the susceptibility of cement-aggregate combinations to expansive reactions involving hydroxyl ions associated with the alkalies (sodium and potassium) by measurement of the increase (or decrease) in length of mortar bars containing the combination during storage under prescribed conditions of test.

1.2 Alkalies participating in the expansive reactions usually are derived from the cement; under some circumstances they may be derived from other constituents of the concrete or from external sources. Two types of alkali reactivity of aggregates are recognized: (1) an alkali-silica reaction involving certain siliceous rocks, minerals, and natural or artificial glasses and (2) an alkali-carbonate reaction involving dolomite in certain calcitic dolomites and dolomitic limestones (see Standard C 294). The method is not recommended as a means to detect the latter reaction because expansions produced in the mortar-bar test by the alkali-carbonate reaction (see Test Method C 586) are generally much less than those produced by the alkali-silica reaction for combinations having equally harmful effects in service.

1.3 The values stated in SI units are to be regarded as standard. The non-SI values, shown in parentheses, are for informational purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C227–03

Standard Test Method for

Potential Alkali Reactivity of Cement-Aggregate

1

Combinations (Mortar-Bar Method)

This standard is issued under the fixed designation C227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 This test method covers the determination of the sus- 2.1 ASTM Standards:

ceptibility of cement-aggregate combinations to expansive C33 Specification for Concrete Aggregates

reactions involving hydroxyl ions associated with the alkalies C109/C109M Test Method for Compressive Strength of

(sodium and potassium) by measurement of the increase (or Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

decrease) in length of mortar bars containing the combination Specimens)

during storage under prescribed conditions of test. C289 Test Method for Potential Alkali-Silica Reactivity of

1.2 Alkalies participating in the expansive reactions usually Aggregates (Chemical Method)

are derived from the cement; under some circumstances they C294 Descriptive Nomenclature for Constituents of Con-

may be derived from other constituents of the concrete or from crete Aggregates

external sources. Two types of alkali reactivity of aggregates C295 Guide for Petrographic Examination of Aggregates

are recognized: (1) an alkali-silica reaction involving certain for Concrete

siliceous rocks, minerals, and natural or artificial glasses and C305 Practice for Mechanical Mixing of Hydraulic Cement

(2) an alkali-carbonate reaction involving dolomite in certain Pastes and Mortars of Plastic Consistency

calcitic dolomites and dolomitic limestones (see Standard C490 Practice for Use of Apparatus for the Determination

C294). The method is not recommended as a means to detect of Length Change of Hardened Cement Paste, Mortar, and

the latter reaction because expansions produced in the mortar- Concrete

bar test by the alkali-carbonate reaction (see Test Method C511 Specification for Mixing Rooms, Moist Cabinets,

C586) are generally much less than those produced by the Moist Rooms, and Water Storage Tanks Used in the

alkali-silica reaction for combinations having equally harmful Testing of Hydraulic Cements and Concretes

effects in service. C586 Test Method for Potential Alkali Reactivity of Car-

1.3 The values stated in SI units are to be regarded as bonate Rocks as Concrete Aggregates (Rock-Cylinder

standard. The non-SI values, shown in parentheses, are for Method)

informational purposes only. C856 Practice for Petrographic Examination of Hardened

1.4 This standard does not purport to address all of the Concrete

safety concerns, if any, associated with its use. It is the C1437 Test Method for Flow of Hydraulic Cement Mortar

responsibility of the user of this standard to establish appro- E11 SpecificationforWovenWireTestSieveClothandTest

priate safety and health practices and determine the applica- Sieves

bility of regulatory limitations prior to use.

1

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

2

C09.26 on Chemical Reactions of Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 10, 2003. Published September 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1950. Last previous edition approved in 1997 as C227 – 97a. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0227-03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

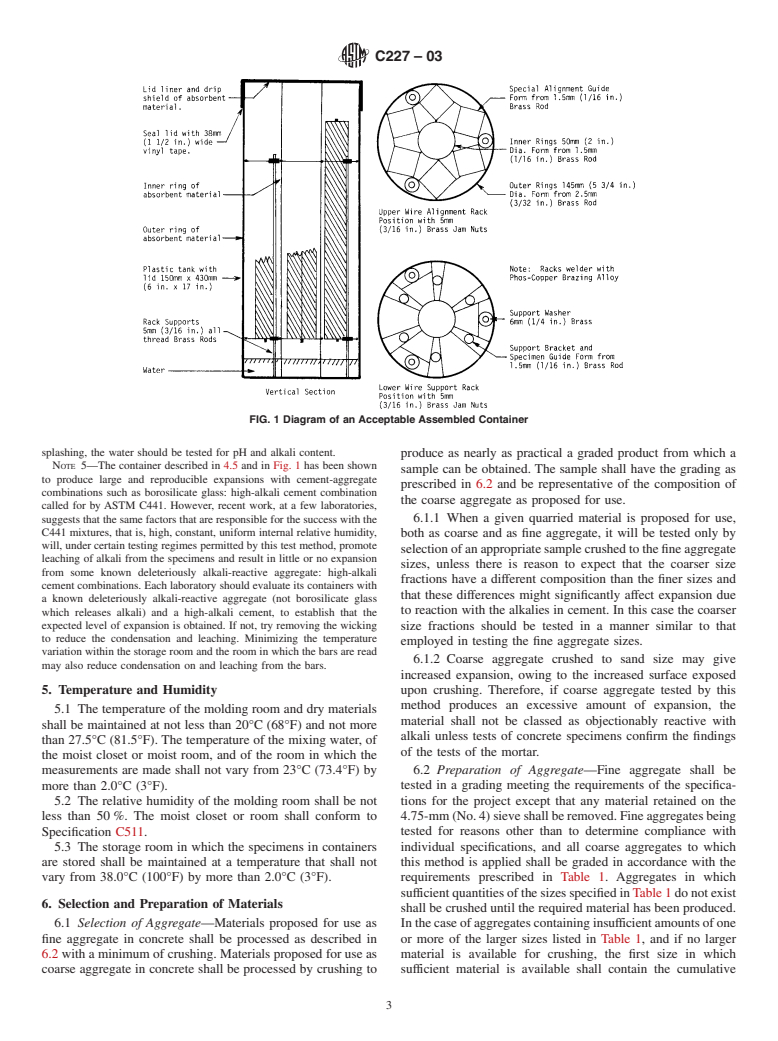

C227–03

3. Significance and Use 4. Apparatus

4.1 The apparatus shall conform to Specification C490,

3.1 Data correlating the results of tests performed using this

except as follows:

test method with performance of cement-aggregate combina-

4.2 Sieves—Square hole, woven-wire cloth sieves, shall

tionsinconcreteinservice,resultsofpetrographicexamination

conform to Specification E11.

of aggregates (Guide C295), and results of tests for potential

4.3 Mixer, Paddle, and Mixing Bowl— Mixer, paddle, and

reactivity of aggregates by chemical methods have been

mixing bowl shall conform to the requirements of Method

published in Test Method C289 and should be consulted in

C305, except that the clearance between the lower end of the

connection with the use of results of tests performed us

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.