ASTM B19-01

(Specification)Standard Specification for Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)

Standard Specification for Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)

SCOPE

1.1 This specification establishes the requirements for sheet, strip, plate, bar, and disks for the manufacture of ammunition of component parts thereof from alloy UNS C26000.

1.2 Values given in inch-pound units are the standard except for grain size which is stated in metric units. SI values given in parenthesis are for information only.

1.3 The following safety caveat pertains only to the test method described in Section 10 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 19 – 01

Standard Specification for

1

Cartridge Brass Sheet, Strip, Plate, Bar, and Disks

ThisstandardisissuedunderthefixeddesignationB 19;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * E 255 Practice for Sampling Copper and CopperAlloys for

5

Determination of Chemical Composition

1.1 This specification establishes the requirements for sheet,

E 478 Test Methods for Chemical Analysis of Copper

strip, plate, bar, and disks for the manufacture of ammunition

5

Alloys

of component parts thereof from alloy UNS C26000.

6

E 527 Practice for Numbering Metals and Alloys (UNS)

1.2 Valuesgivenininch-poundunitsarethestandardexcept

7

2.2 Federal Standards:

for grain size which is stated in metric units. SI values given in

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

parenthesis are for information only.

Fed. Std. No. 185 Identification Marking of Copper and

1.3 The following safety caveat pertains only to the test

Copper-Base Alloy Mill Products

method described in Section 10 of this specification. This

7

2.3 Military Standards:

standard does not purport to address all of the safety concerns,

MIL-STD-105 Sampling Procedures and Tables for Inspec-

if any, associated with its use. It is the responsibility of the user

tion by Attributes

of this standard to establish appropriate safety and health

MIL-STD-129 Marking for Shipment and Storage

practices and determine the applicability of regulatory limita-

MIL-C-3993 Packaging of Copper and Copper-Base Alloy

tions prior to use.

Mill Products

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—For standard terms related to copper and

B 154 Test Method for Mercurous Nitrate Test for Copper

2

copper alloys, refer to Terminology B 846.

and Copper Alloys

B 248 Specification for General Requirements for Wrought

4. Ordering Information

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

2 4.1 Orders for products should include the following infor-

Bar

mation:

B 601 Practice for Temper Designations for Copper and

2 4.1.1 ASTM designation and year of issue (for example,

Copper Alloys—Wrought and Cast

2 B19-XX),

B 846 Terminology for Copper and Copper Alloys

4.1.2 Product form: sheet, strip, plate, bar, or disks (blanks),

B 858 Test Method for Determination of Susceptibility to

4.1.3 Temper (Section 7),

Stress Corrosion Cracking in Copper Alloys Using an

2 4.1.4 Dimension: thickness, width, length,

Ammonia Vapor Test

3 4.1.5 How furnished: flat lengths, coils, or blanks,

E 3 Practice for Preparation of Metallographic Specimens

3 4.1.6 Quantity:totalweighteachtemper,form,andsize,and

E 8 Test Methods forTensionTesting of Metallic Materials

4.1.7 When severe drawing or deep cupping is required.

E 29 Practice for Using Significant Digits in Test Data to

4

4.2 The following options are available and should be

Determine Conformance with Specifications

3 specified in the contrast or purchase order when required:

E 112 Test Methods for Determining Average Grain Size

4.2.1 Heat identification or traceability details,

4.2.2 Caliber or diameter of Type IV cups or disks (Section

1 11),

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.2.3 Mercurous Nitrate Test (Section 10),

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

Sheet, and Strip.

Current edition approved April 10, 2001. Published June 2001. Originally

5

published as B 19 – 19 T. Last previous edition B 19 – 95. Annual Book of ASTM Standards, Vol 03.05.

2 6

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 01.01.

3 7

Annual Book of ASTM Standards, Vol 03.01. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

4

Annual Book of ASTM Standards, Vol 14.02. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B19

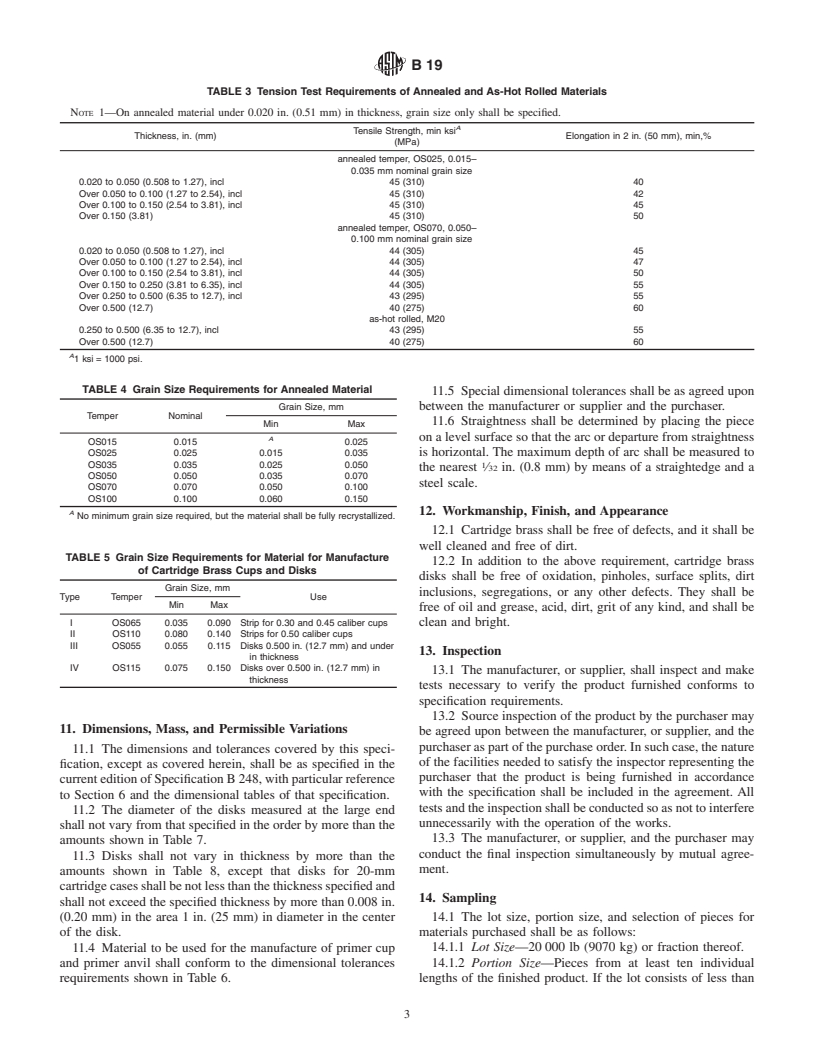

4.2.4 Product Marking (Section 22), 8.1.1 Rolled-to-temper material shall conform to the re-

4.2.5 On-site inspection (Section 13), quirements specified in Table 2.

4.2.6 Certification (Section 20), and 8.1.2 Annealed material shall conform to the requirements

4.2.7 Test Report (Mill) (Section 21). specified in Table 3.

8.1.3 Material furnished as-hot rolled shall conform to the

5. Material and Manufacture

requirements specified in Table 3.

5.1 Material:

5.1.1 The material of manufacture sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.