ASTM D2481-81(1994)e1

(Test Method)Standard Test Method for Accelerated Evaluation of Wood Preservatives for Marine Services by Means of Small Size Specimens

Standard Test Method for Accelerated Evaluation of Wood Preservatives for Marine Services by Means of Small Size Specimens

SCOPE

1.1 This test method determines the relative effectiveness of wood preservatives in small wood specimens exposed to a natural marine environment. It is not within the scope of this procedure to determine the retention or duration of protection for commercial size piles and timbers.

1.2 The requirements for preparing the material for testing and the test procedures appear in the following order: Section Summary of Method 3 Test Specimens 5 Pretreatment Handling 6 Treatment Procedure 7 Post-Treatment Handling 8 Assembly of Test Specimens 9 Exposure 10 Inspection 11 Evaluation of Results 12 Reports 13

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 2481 – 81 (Reapproved 1994)

Standard Test Method for

Accelerated Evaluation of Wood Preservatives for Marine

Services by Means of Small Size Specimens

This standard is issued under the fixed designation D 2481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section 15 was added editorially in January 1995.

1. Scope tic Drain, Waste, and Vent Pipe and Fittings

1.1 This test method determines the relative effectiveness of

3. Summary of Test Method

wood preservatives in small wood specimens exposed to a

3.1 Small panels or blocks of wood are impregnated with an

natural marine environment. It is not within the scope of this

appropriate series of retentions of a preservative and are

procedure to determine the retention or duration of protection

prepared for exposure, according to specified procedures. They

for commercial size piles and timbers.

are then exposed by total immersion in a natural marine

1.2 The requirements for preparing the material for testing

environment. An index of physical condition determined dur-

and the test procedures appear in the following order:

ing periodic inspection is used to measure the effectiveness of

Section

preservative treatment.

Summary of Test Method 3

Test Specimens 5

Pretreatment Handling 6 4. Significance and Use

Treatment Procedure 7

4.1 This test method is useful in determining the relative

Post-Treatment Handling 8

Assembly of Test Specimens 9

efficacy between various treatments and naturally occurring

Exposure 10

wood-destroying agents. It is an initial means of estimating the

Inspection 11

tolerance limits of the biologically destructive agents or the

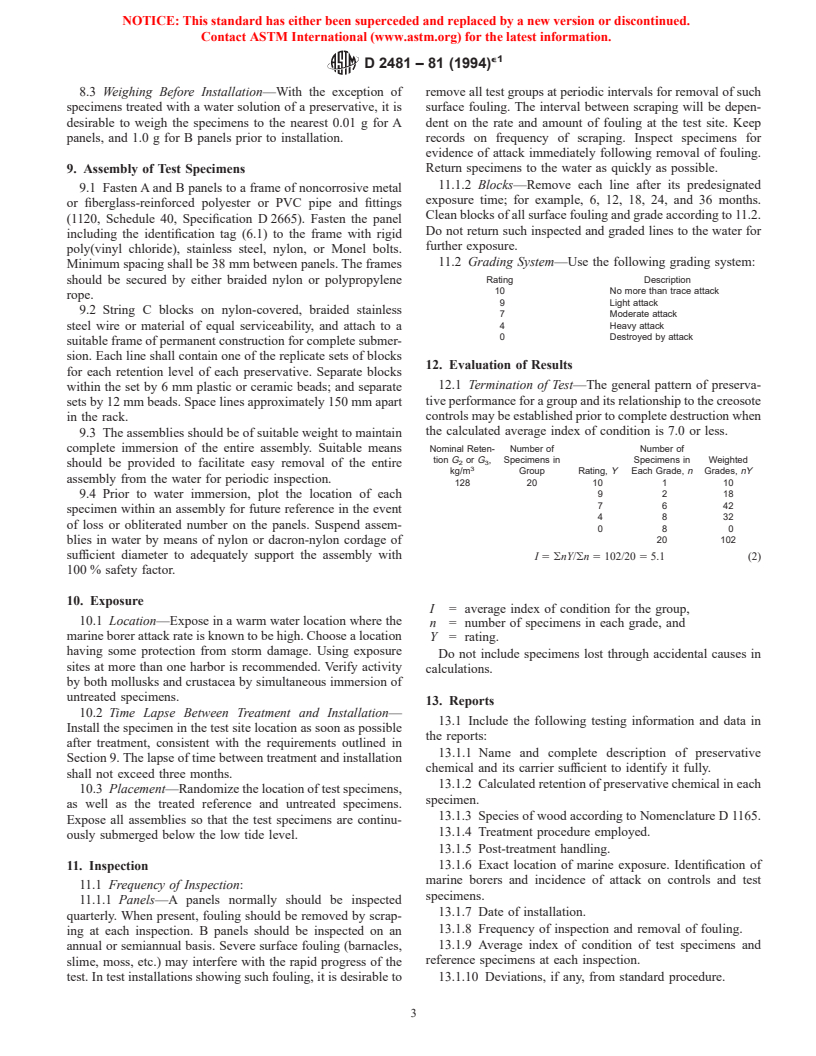

Evaluation of Results 12

Reports 13

threshold values of the chemical preservative, or both.

4.2 This test method is not intended to provide quantifiable

1.3 This standard does not purport to address all of the

reproducible values. It is a qualitative method designed to

safety concerns, if any, associated with its use. It is the

provide a reproducible means of establishing relative efficacy

responsibility of the user of this standard to establish appro-

between experimental contract levels.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Test Specimens

2. Referenced Documents 5.1 Selection of Wood—Use sapwood of southern or Pon-

derosa pine or Douglas-fir for standard comparative tests. Use

2.1 ASTM Standards:

boards free from knots or excessive resins, and showing no

D 390 Specification for Coal-Tar Creosote for the Preserva-

visible evidence of infection by mold, stain, or decay fungi.

tive Treatment of Piles, Poles, and Timbers for Marine,

2 Drill mounting holes before treatment.

Land, and Fresh Water Use

5.2 Selection of Size:

D 1165 Nomenclature of Domestic Hardwoods and Soft-

2 5.2.1 A Panels—6 by 38 by 152 mm, vertical grain with

woods

longitudinal grain direction in the 152 mm dimension.

D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

5.2.2 B Panels—19 by 76 by 460 mm.

5.2.3 C Blocks—19 by 19 by 19 mm, milled as accurately as

possible. If necessary (for example, for convenience in han-

This test method is under the jurisdiction of ASTM Committee D-7 on Wood dling) blocks may be drilled through the center of a tangential

and is the direct responsibility of Subcommittee D07.06 on Treatments for Wood

face with a 3-mm drill. The volume of the blocks without the

Products.

Current edition approved Oct. 30, 1981. Published December 1981. Originally

published as D 2481 – 66. Last previous edition D 2481 – 70 (1977).

2 3

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

D 2481 – 81 (1994)

hole should be approximately 6.9 mL and the blocks with the preferably in five graded retentions. The retention nearest the

hole approximately 6.8 mL. expected effective retention should be at or near the middle of

5.2.4 Sample size shall remain constant within a given the series. When little or nothing is known regarding the

series of tests. effectiveness of the preservative, wider ranges in retention

should be used.

6. Pretreatment Handling

7.6 Concentration of Treating Solutions—Make up the

6.1 Initial Conditioning and Initial Weights—Condition the aqueous treating solutions for tests in appropriate gradient

specimens for treatment by bringing them to moisture equilib- concentrations with a view to leaving in the panels or blocks

rium under 15 % ovendry basis in a constant-temperature after treatment a predetermined range of retentions running

room, in an appropriate dry storage room, or by kiln drying. from below to above an anticipated effective (protective)

6.2 Weighing—Specimens of uniform density as determined retention.

by their original weight facilitate uniform treatments within 7.7 Weight After Treatment—Determine the amount of pre-

groups. Before impregnation, number and weigh them to the servative absorbed by weighing the panels or blocks individu-

nearest 0.01 g for A panels, and 1.0 g for B panels. This weight ally immediately after treatment. The code designation for

is referred to as the initial or untreated weight of the specimen after-treatment weight shall be T (Note 1). In all treatments

(T ). Segregate specimens selected into treatment groups of with creosote or petroleum solutions, remove each specimen

approximate equal density as determined by weight. individually from the treating chamber, wipe lightly to remove

surface preservative or preservative solution, and weigh

NOTE 1—Coding the different weights as T , T , and T avoids

1 2 3

promptly to the nearest 0.01 g for A panels and 1.0 g for B

confusion and simplifies recording. The suggested system of T (tare)

panels to determine T . Follow the same procedure with

designation is as follows, with all weights recorded in grams: 2

waterborne preservatives.

T = initial weight of the test specimen before impregnation,

T = weight of the test specimen immediately after impregnation and 7.8 Calculation of Retention—Calculate the retention of

wiping (equals T plus grams of treating solution absorbed), and

1 preservative or preservative solution as follows:

T = weight of the test specimen just before installation at the location

kg/m 5 1000 GC/V (1)

site.

6.3 Identification—Identify each piece with die-stamped

where:

poly(vinyl chloride) or heavy polypropylene tags.

G = grams of treating solution absorbed by the speci-

mens. Use G or G , depending on how retention was

2 3

7. Treatment Procedure

deter- mined (T or T weights),

2 3

7.1 Treatment—Apply preservatives by a full-cell or empty-

G =(T − T ) = grams of preservative or preservative

2 2 1

cell process as retention warrants. Avoid solvent dilution of

solution absorbed by the specimen (initial weight of

oil-type preservatives.

specimen, subtracted from the initial weight plus the

7.2 Number of Specimens to be Treated:

amount absorbed),

7.2.1 Panels—Treat sufficient panels to permit selection

G =(T − T ) = grams of preservative remaining in the

3 3 1

after treatment of at least five panels having preservation specimen at the time of installation,

retentions closely approximating the desired retention level C = grams of preservative in 100 g of treating solution,

and

desired. If analysis of variance of attack gradings is desired, at

V = volume of specimen, mL.

least 20 replicates will be required. The retention in the

selected panels shall have a coefficient of variation not greater

8. Post-Treatment Handling

than 10 %.

7.2.2 Blocks—Treat sufficient blocks to permit the selection 8.1 Treatment with Water Solutions—Dry the specimens

of N replicate sets of blocks of approximate uniform retention treated with waterborne preservatives by air seasoning, kiln

for each preservative at each retention level. The N represents drying, or a combination of both; upon final weighing after

the number of planned removal periods. treatment, the specimens may be stacked so that air can

7.3 Treating Reference Specimens—Treat to obtain a mini- circulate freely between them until their moisture content is

mum of four panels or blocks at each retention of 128 and 256 less than 30 %; or the spe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.