ASTM D2714-94(2003)

(Test Method)Standard Test Method for Calibration and Operation of the Falex Block-on-Ring Friction and Wear Testing Machine

Standard Test Method for Calibration and Operation of the Falex Block-on-Ring Friction and Wear Testing Machine

SIGNIFICANCE AND USE

This test method is used for the calibration of a block-on-ring testing machine by measuring the friction and wear properties of a calibration fluid under the prescribed test conditions.

The user of this test method should determine to his or her own satisfaction whether results of this test procedure correlate with field performance or other bench test machines. If the test conditions are changed, wear values can change and relative ratings of fluids can be different.

SCOPE

1.1 This test method covers the calibration and operation of a block-on-ring friction and wear testing machine.

1.2 The values stated in either SI (metric) units or inch-pound units to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. Combining values of the two systems may result in noncomformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2714–94 (Reapproved 2003)

Standard Test Method for

Calibration and Operation of the Falex Block-on-Ring

Friction and Wear Testing Machine

This standard is issued under the fixed designation D2714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.1.4 wear—damage to a solid surface, generally involving

progressive loss of material, due to relative motion between

1.1 This test method covers the calibration and operation of

that surface and a contacting substance or substances.

a block-on-ring friction and wear testing machine.

1.2 The values stated in either SI (metric) units or inch-

3. Summary of Test Method

pound units to be regarded separately as standard. Within the

3.1 The test machine is operated using a steel test ring

text the inch-pound units are shown in brackets. The values

rotating against a steel test block, the specimen assembly being

stated in each system are not exact equivalents; therefore each

partially immersed in the lubricant sample. The velocity of the

system must be used independently of the other. Combining

test ring is 7.9 6 0.16 m/min (26 6 0.52 ft/min) which is

values of the two systems may result in noncomformance with

equivalenttoaspindlespeedof72 61rpm.Thespecimensare

the standard.

subjected to 68 kg (150 lb) normal load applied by 6.8 kg (15

1.3 This standard does not purport to address all of the

lb) of dead weight on the 10:1 ratio lever system. Test duration

safety concerns, if any, associated with its use. It is the

is 5000 cycles.

responsibility of the user of this standard to establish appro-

3.2 Three determinations are made: (1) The friction force

priate safety and health practices and determine the applica-

after a certain number of revolutions, (2) the average width of

bility of regulatory limitations prior to use.

the wear scar on the stationary block at the end of the test, and

2. Terminology (3)theweightlossforthestationaryblockattheendofthetest.

2.1 Definitions:

4. Significance and Use

2.1.1 coeffıcient of friction, µ or f—in tribology, the dimen-

4.1 This test method is used for the calibration of a

sionlessratioofthefrictionforce(F)betweentwobodiestothe

block-on-ring testing machine by measuring the friction and

normal force (N) pressing these two bodies together.

wear properties of a calibration fluid under the prescribed test

µor f 5 ~F/N! (1)

conditions.

2.1.1.1 Discussion—A distinction is often made between

4.2 The user of this test method should determine to his or

static coeffıcient of friction and kinetic coeffıcient of friction.

her own satisfaction whether results of this test procedure

2.1.2 friction force—the resisting force tangential to the

correlate with field performance or other bench test machines.

interface between two bodies when, under the action of an

If the test conditions are changed, wear values can change and

external force, one body moves or tends to move relative to the

relative ratings of fluids can be different.

other.

5. Apparatus

2.1.3 kinetic coeffıcient of friction—the coefficient of fric-

tion under conditions of macroscopic relative motion between

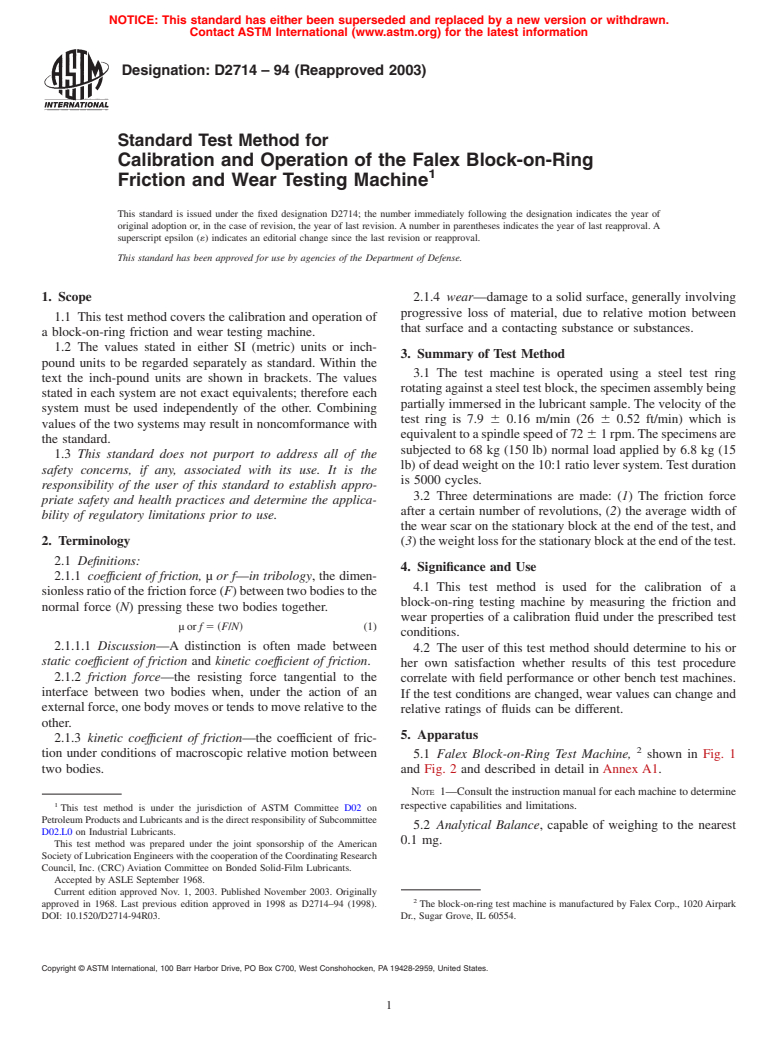

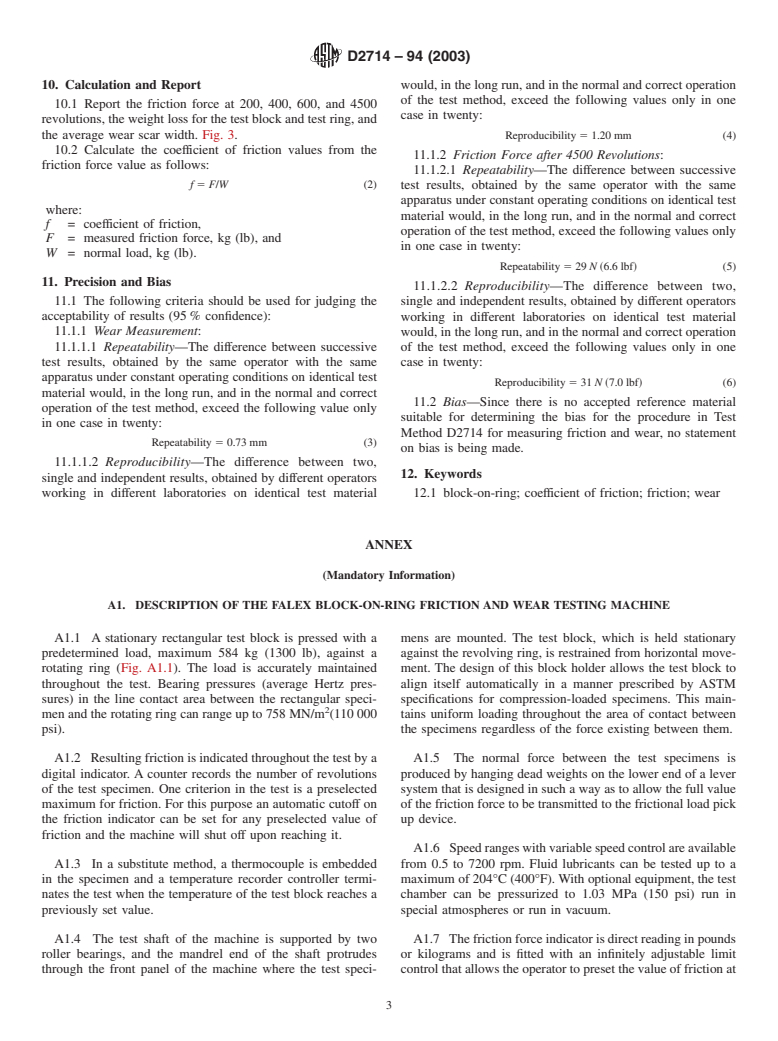

5.1 Falex Block-on-Ring Test Machine, shown in Fig. 1

two bodies. and Fig. 2 and described in detail in Annex A1.

NOTE 1—Consult the instruction manual for each machine to determine

respective capabilities and limitations.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.2 Analytical Balance, capable of weighing to the nearest

D02.L0 on Industrial Lubricants.

0.1 mg.

This test method was prepared under the joint sponsorship of the American

Society of Lubrication Engineers with the cooperation of the Coordinating Research

Council, Inc. (CRC) Aviation Committee on Bonded Solid-Film Lubricants.

Accepted by ASLE September 1968.

Current edition approved Nov. 1, 2003. Published November 2003. Originally

approved in 1968. Last previous edition approved in 1998 as D2714–94 (1998). The block-on-ring test machine is manufactured by Falex Corp., 1020 Airpark

DOI: 10.1520/D2714-94R03. Dr., Sugar Grove, IL 60554.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2714–94 (2003)

7.2 Weigh each test ring and test block to the nearest 0.1 mg

on the analytical balance. Then store the specimens in a

desiccator until ready for use.

7.3 Place the block holder on the block and carefully place

block and holder in upper specimen holder in test chamber.

Mount the test ring on the test shaft, taking care not to touch

the test area. Tighten the test ring on the shaft with 440 N (100

lbf) as measured on the friction force meter on the digital

instrument unit.

7.4 Place the heater door in position and fill the chamber

with test fluid to about halfway on the spindle (half of the test

ring is immersed). This volume must be measured (approxi-

FIG. 1 Falex Block-On-Ring Variable Drive Testing Machine

mately 100 mL) and the same amount used for each test. Set

the temperature control of the oil reservoir to 43.3°C (110°F).

It is preferable to control the temperature of the liquid being

tested, but if the machine is not equipped with a temperature

controller indicator, then record the liquid temperature.

8. Calibration

8.1 Amachine shall be judged to be in acceptable condition

whentheresultsobtainedonthecalibrationfluidfallwithinthe

following limits:

8.1.1 Wear measurement is between 1.70 and 2.90 mm.

8.1.2 Friction force after 4500 revolutions is between 66

and 97 N (15.0 and 22.0 lbf).

FIG. 2 Falex Block-On-Ring Test Machine with Microprocessor

Data Acquisition and Control System 9. Procedure

9.1 With the revolution counter set at zero, gently place a

5.3 Measuring Magnifier Glass, with SI or inch-pound

6.78-kg (15-lb) load on the bale rod, being very careful to

calibration so that the scar width can be measured with a

avoid shock-loading. When the fluid reaches temperature of

precision of 0.01 mm, or equivalent.

43.3°C (110°F) start the machine and bring the speed to 72

rpm. Record the friction force and the temperature of the liquid

6. Reagents and Materials

at 200, 400, 600, and 4500 revolutions and check the speed at

6.1 Test Rings, Falex Type S-10, SAE 4620 carburized

each of these times. Stop the machine at 5000 revolutions.

steel, having a hardness of 58 to 63 HRC. The test ring has a

Remove the test block and test ring and clean them thoroughly

width of 8.15 mm (0.321 in.), a diameter of 35 mm (1.3775 in.)

using solvents selected in 6.3. Remove any excess wear

and a maximum radial run out of 0.013 mm (0.0005 in.). The

particles that have accumulated on the side of the scar by

surface roughness shall be 0.15 to 0.30 µm (6 to 12 µin.) rms.

brushing with a camel’s hair brush; weigh the test ring and test

3 4

6.2 Test Blocks, Falex Type H-30, SAE 01 tool steel

block to the nearest 0.1 mg and measure the width of the wear

having two ground test surfaces of 0.10 to 0.20 µm (4 to 8 µin.)

scar of the test block

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.