ASTM D6783-05(2011)

(Specification)Standard Specification for Polymer Concrete Pipe

Standard Specification for Polymer Concrete Pipe

ABSTRACT

This specification covers the testing and requirements fof polymer concrete pipes of specified lengths, intended for use in gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes. Although this specification is suited primarily for pipes to be installed by direct burial and pipe jacking, it may be used to the extent applicable for other installations such as slip-lining and rehabilitation of existing pipelines. Materials shall be appropriately sampled for purposes of testing their conformance to such requirements as: workmanship; dimension (diameter, length, thickness, straightness, roundness, and squareness of ends); three-edge bearing; hydrostatic pressure; compressive strength; chemical resistance; and joint tightness.

SCOPE

1.1 This specification covers polymer concrete pipe, 6 in. (150 mm) through 144 in. (3 660 mm), intended for use in gravity-flow systems for conveying sanitary sewage, storm water, and industrial wastes.

1.2 Although this specification is suited primarily for pipe to be installed by direct burial and pipe jacking, it may be used to the extent applicable for other installations such as sliplining and rehabilitation of existing pipelines.

Note 1—Unlike reinforced thermosetting resin pipes, polymer concrete pipe is designed and installed using rigid pipe design theory and practices.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification. This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

Note 2—There is no known ISO equivalent to this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6783 −05 (Reapproved 2011) An American National Standard

Standard Specification for

Polymer Concrete Pipe

This standard is issued under the fixed designation D6783; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C136 Test Method for Sieve Analysis of Fine and Coarse

Aggregates

1.1 This specification covers polymer concrete pipe, 6 in.

C579 Test Methods for Compressive Strength of Chemical-

(150 mm) through 144 in. (3 660 mm), intended for use in

Resistant Mortars, Grouts, Monolithic Surfacings, and

gravity-flow systems for conveying sanitary sewage, storm

Polymer Concretes

water, and industrial wastes.

D648 Test Method for Deflection Temperature of Plastics

1.2 Althoughthisspecificationissuitedprimarilyforpipeto

Under Flexural Load in the Edgewise Position

be installed by direct burial and pipe jacking, it may be used to

D883 Terminology Relating to Plastics

the extent applicable for other installations such as sliplining

D1600 Terminology forAbbreviatedTerms Relating to Plas-

and rehabilitation of existing pipelines.

tics

NOTE1—Unlikereinforcedthermosettingresinpipes,polymerconcrete

D2584 Test Method for Ignition Loss of Cured Reinforced

pipe is designed and installed using rigid pipe design theory and practices.

Resins

1.3 The values stated in inch-pound units are to be regarded

D3567 Practice for Determining Dimensions of “Fiberglass”

as the standard. The values given in parentheses are for

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

information only.

Fittings

1.4 The following safety hazards caveat pertains only to the D3681 Test Method for Chemical Resistance of “Fiberglass”

test methods portion, Section 8, of this specification. This

(Glass–Fiber–Reinforced Thermosetting-Resin) Pipe in a

standard may involve hazardous materials, operations, and Deflected Condition

equipment. This standard does not purport to address all of the

D3892 Practice for Packaging/Packing of Plastics

safety concerns, if any, associated with its use. It is the D4161 Specification for “Fiberglass” (Glass-Fiber-

responsibility of the user of this standard to establish appro- Reinforced Thermosetting-Resin) Pipe Joints Using Flex-

priate safety and health practices and determine the applica-

ible Elastomeric Seals

bility of regulatory requirements prior to use. F412 Terminology Relating to Plastic Piping Systems

F477 Specification for Elastomeric Seals (Gaskets) for Join-

NOTE 2—There is no known ISO equivalent to this standard.

ing Plastic Pipe

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—Unless otherwise indicated, definitions are

A276 Specification for Stainless Steel Bars and Shapes

in accordance with Terminologies C125, D883, and F412, and

C33 Specification for Concrete Aggregates

abbreviations are in accordance with Terminology D1600.

C117 Test Method for Materials Finer than 75-µm (No. 200)

3.2 Definitions of Terms Specific to This Standard:

Sieve in Mineral Aggregates by Washing

3.2.1 aggregate, n—a granular material, such as sand,

C125 Terminology Relating to Concrete and Concrete Ag-

gravel, or crushed stone, in accordance with to the require-

gregates

ments of Specification C33 except that the requirements for

gradation shall not apply.

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

3.2.2 pipe jacking, n—a system of directly installing pipes

Plastic Piping Systems and Chemical Equipment.

behind a shield machine by hydraulic jacking from a drive

Current edition approved Feb. 1, 2011. Published March 2011. Originally

shaft, such that the pipes form a continuous string in the

approved in 2002. Last previous edition approved in 2005 as D6783 - 05. DOI:

ground.

10.1520/D6783-05R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.3 polymer concrete, n—a composite material that con-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sists essentially of a thermosetting resin within which are

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. embedded particles or fragments of aggregate.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6783−05 (2011)

3.2.4 polymer concrete pipe, n—tubular product containing

aggregate, embedded in or surrounded by cured thermosetting

resin, which may also contain granular or platelet fillers,

thixotropic agents, pigments, or dyes.

3.2.5 qualification test, n—one or more tests used to prove

the design of a product and which are not routine quality

control tests.

4. Classification

4.1 Polymer concrete pipe furnished under this specification

is manufactured in strength classes I, II, III, IV, or V as given

in Table 1. (See also Note 5.)

NOTE 3—The D-Load is the three-edge bearing strength per unit length

divided by the inside diameter.

NOTE 4—Other strength categories shall be permitted by agreement

between the purchaser and the manufacturer.

FIG. 1Typical Coupling Joint Detail

5. Materials and Manufacture

5.1 Wall Composition—The wall composition shall consist

of a thermosetting resin and aggregate.

5.1.1 Thermosetting Resin—The resin shall have a mini-

mum deflection temperature of 158°F (70°C) when tested at

264 psi (1.820 mPa) following Test Method D648. The resin

content shall not be less than 7 % of the weight of the sample

as determined by Test Method D2584.

5.1.2 Aggregate—Aggregate, and mineral fillers tested in

accordance with all requirements of Test Methods C117 and

C136, except requirements for gradation shall not apply.

FIG. 2Typical Jacking Pipe Joint

5.2 Joints—The pipe shall have a gasket sealed joining

system that shall prevent leakage of fluid in the intended

The pipe shall be as uniform as commercially practicable in

service condition.

color, opacity, density, and other physical properties.

5.2.1 Couplings—Stainless Steel 316 , in accordance with,

6.1.1 The inside surface of each pipe shall be free of bulges,

Specification A276, or a glass-fiber- reinforced-thermosetting-

dents, ridges, and other defects that result in a variation of

resin coupling which uses an elastomeric seal. Alternate

insidediameterofmorethan ⁄8in.(3.2mm)fromthatobtained

materials may be permitted by agreement between the pur-

on adjacent unaffected portions of the surface.

chaser and the manufacturer. Figs. 1 and 2 show typical

6.1.2 Joint sealing surfaces shall be free of dents, gouges,

couplings.

and other surface irregularities that will affect the integrity of

5.2.2 Gaskets—Elastomeric gaskets used with this pipe

the joints.

shall conform to the requirements of Specification F477,

6.2 Dimensions:

except that composition of the elastomer shall be as agreed

6.2.1 Pipe Diameter—The pipe shall be supplied in the

upon between the purchaser and the supplier as being resistant

nominal diameters shown in Table 2 when measured in

to the intended chemical environments.

accordance with 8.1.1.

6.2.2 Lengths—Pipe shall be supplied in nominal lengths of

6. Requirements

3, 4, 5, 6, 8, and 10 ft. (0.92, 1.22, 1.52, 1.83, 2.44, and 3.05

6.1 Workmanship—Each pipe shall be free from all defects,

m) unless otherwise agreed to between purchaser and seller.

including indentations, cracks, foreign inclusions, and resin-

Tolerance on length shall be 62 in. (650 mm). The pipe shall

starved areas that, due to their nature, degree, or extent,

be measured in accordance with 8.1.2.

detrimentally affect the strength and serviceability of the pipe.

6.2.3 Wall Thickness—The average wall thickness of the

pipeshallnotbelessthanthenominalwallthicknesspublished

in the manufacturer’s literature current at the time of purchase,

TABLE 1 Strength Classes for Polymer Concrete Pipe

when measured in accordance with 8.1.3.

D-Load

6.2.4 Straightness of Pipe:

Strength

lb/ft/ft

Class

6.2.4.1 Direct Bury Pipe—Pipes shall not deviate from

(kN/m/m)

straight by more than 0.10 in/ft (8.3mm/m) for nominal

I 1200 (57.5)

II 1500 (71.9) diameters through 39 inch, 0.12 in/ft (10mm/m) for nominal

III 2000 (95.8)

diameters 42 in. through 78 in. and 0.14 in/ft (11.7mm/m) for

IV 3000 (143.8)

nominal diameters 84 in. through 144 in. when measured in

V 3750 (179.7)

accordance with 8.1.4.

D6783−05 (2011)

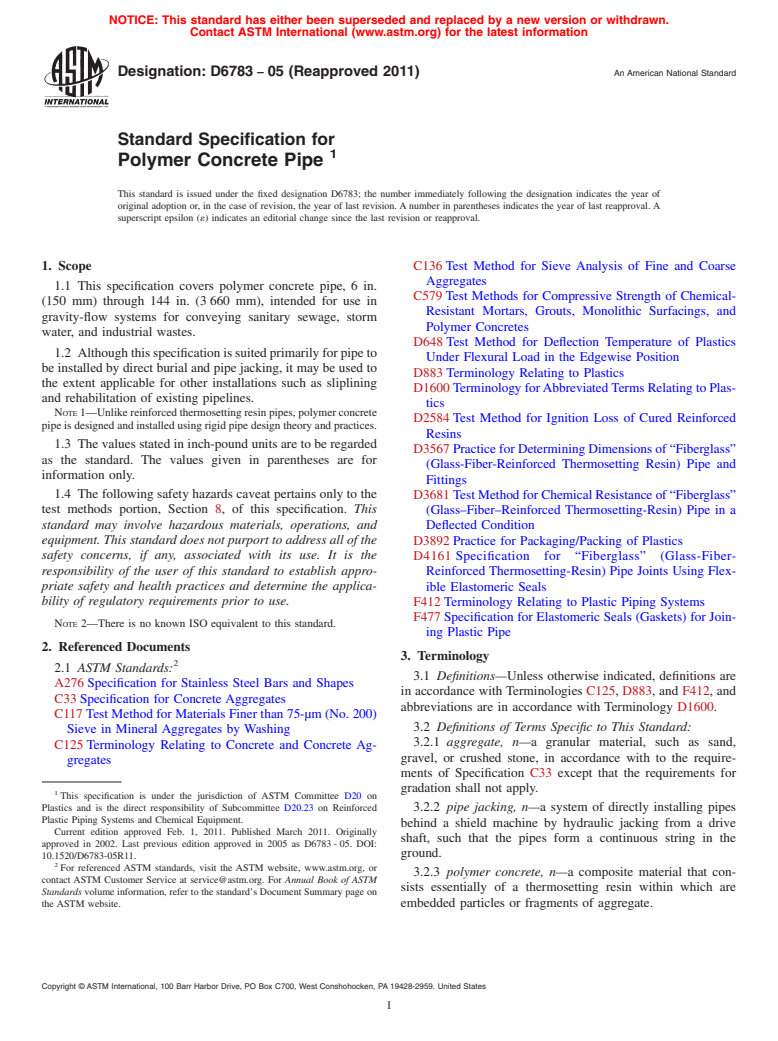

TABLE 2 Diameters for Polymer Concrete Pipe

6.5 Compressive Strength—The minimum axial compres-

Nominal Diameter, Inside Diameter Tolerance on ID sive strength shall be 10 000 psi (68.9 mPa) when tested in

in. in. (mm) in. (mm)

accordance with 8.4.

6 6.00 (152.4) ± 0.25 (6.4)

6.6 Chemical Resistance:

8 8.00 (203.2) ± 0.25 (6.4)

10 10.00 (254.0) ± 0.25 (6.4)

6.6.1 Long Term—When tested in accordance with 8.5, the

12 12.00 (304.8) ± 0.25 (6.4)

extrapolated 50 year strength value shall be at least 50 % of the

14 14.00 (355.6) ± 0.25 (6.4)

initial three-edge bearing strength of the test pipes.

15 15.00 (381.0) ± 0.25 (6.4)

16 16.00 (406.4) ± 0.25 (6.4)

6.6.2 Control Requirements—When tested in accordance

18 18.00 (457.2) ± 0.25 (6.4)

with 8.5, pipe specimens shall be capable of sustaining without

20 20.00 (508.0) ± 0.25 (6.4)

21 21.00 (533.4) ± 0.25 (6.4) failure for 1 000 h a load equal to 60 % of the initial three-edge

24 24.00 (609.6) ± 0.25 (6.4)

bearing strength of the test pipes.

27 27.00 (685.8) ± 0.27 (6.4)

30 30.00 (762.0) ± 0.30 (7.6)

6.7 Joint Tightness:

33 33.00 (838.2) ± 0.33 (8.4)

6.7.1 Direct Bury Pipe—The joint shall meet the laboratory

36 36.00 (914.4) ± 0.36 (9.1)

39 39.00 (990.6) ± 0.39 (9.9) performance requirements of Specification D4161, except that

42 42.00 (1066.8) ± 0.42 (10.7)

the internal pressure shall be 35 psi (0.25 mPa) and the

45 45.00 (1143.0) ± 0.45 (11.4)

minimum test time shall be 15 min.

48 48.00 (1219.2) ± 0.48 (12.2)

51 51.00 (1295.4) ± 0.51 (13.0)

6.7.2 Jacking Pipe—The joint shall meet the laboratory

54 54.00 (1371.6) ± 0.54 (13.7)

performance requirements of Specification D4161, except that

60 60.00 (1524.0) ± 0.60 (15.2)

the internal pressure shall be 35 psi (0.25 mPa), the minimum

66 66.00 (1676.4) ± 0.66 (16.8)

72 72.00 (1828.8) ± 0.72 (18.3)

test time shall be 15 min, and the joint angle as illustrated in

78 78.00 (1981.2) ± 0.78 (19.8)

Fig.2ofD4161shallnotapply.Thejointtestangleshallbethe

84 84.00 (2133.6) ± 0.84 (21.3)

maximum allowed deflection angle as designed and specified

90 90.00 (2286.0) ± 0.90 (22.9)

96 96.00 (2438.4) ± 0.96 (24.4)

by the manufacturer, but shall not be less than 0.50 degrees.

102 102.00 (2590.8) ±1 .00 (25.4)

108 108.00 (2743.2) ±1.00 (25.4)

7. Sampling

114 114.00 (2895.6) ±1.00 (25.4)

120 120.00 (3048.0) ±1 .00 (25.4)

7.1 Lot—Unless otherwise agreed upon between the pur-

132 132.00 (3352.8) ±1 .00 (25.4)

144 144.00 (3657.6) ±1.00 (25.4)

chaser and supplier, one lot shall consist of a manufacturing

run of no more than 100, but at least 20, lengths of pipe of each

NOTE 1—Other diameters shall be permitted by agreement between the

diameter and strength class produced.

purchaser and the manufacturer.

7.2 Production Tests—Select one pipe at random from each

lot to determine conformance of the material to the

6.2.4.2 Jacking Pipe—Pipes shall not deviate from straight

workmanship, dimensional, and physical requirements of 6.1,

by more than 0.04 in./ft (3.3 mm/m) for nominal diameters

6.2, 6.3 and 6.5, respectively.

through 39 inch, 0.06 in/ft (5.0mm/m) for nominal diameters

7.2.1 Pipe Acceptance—If the tested specimen of a desig-

42 in. through 78 in., and 0.08 in/ft (6.7mm/m) for nominal

natedlotpassesthetest,theentirelotshallbeacceptable.Ifthe

diameters 84 in. through 144 in. when measured in accordance

tested specimen of a designated lot fails to pass the test, then

with 8.1.4.

five additional specimens from that same lot shall be selected

6.2.5 Roundness of Pipe—The outside diameter shall not

fortesting.Ifthefiveadditionalspecimenspass,thelotshallbe

vary from a true circle by more than 1.0 % when measured in

acceptable. except the one previous failing specimen. If any of

accordance with 8.1.5.

the five additional specimens fail, the entire lot shall be

6.2.6 Squareness of Pipe Ends:

rejected.

6.2.6.1 Direct Bury Pipe—The ends of the pipe shall be

perpendicular to the longitudinal axis within 6 0.25 in (6 6.4

7.3 Qualification Tests—Sampling for qualification tests

mm) or 6 0.5 % of the nominal diameter, whichever is the

(see 3.2.5) is not required unless otherwise agreed upon

greater, when tested when tested in accordance with 8.1.6

betweenthepurchaserandthemanufacturer.Qualificationtests

6.2.6.2 Jacking Pipe —The ends of the pipe shall be

shall be conducted for changes in polymer aggregate and

perpendicular to the longitudinal axis within 0.06 in (1.5mm)

manufacturing process and for changes in pipe joint or gasket

for nominal diameters through 39 inch, 0.12 inch (3mm) for

geometry. Qualification tests for which a certification and test

nominal diameters 42 inch through 102 inch and 0.20 inch

report shall be furnished when requested by the purchaser

(5mm)fordiameters108inchthrough144inch,whentestedin

include the following:

accordance with 8.1.6.

7.3.1 Hydrostatic Pressure Test—(see 6.4).

7.3.2 Chemical Resistance Test—(see 6.6).

6.3 Three-Edge Bearing—The pipe shall withstand, without

failure, the three-edge bearing loads specified in Table 1 when 7.3.3 Joint-Tightness Test—(see 6.7).

tested in accordance with 8.2.

7.4 Control for Chemical Resistance Test—Perform sam-

6.4 Hydrostatic Pressure—The pipe shall withstand an in- pling and testing for the control requirements of the chemical

ternal pressure of 35 psi (0.25 mPa) when tested in accordance resistance test at least once annually, unless otherwise agreed

with 8.3. upon between the purchaser and the supplier.

D6783−05 (2011)

7.5 For individual orders, conduct only those additional The bottom contact surfaces shall be spaced apart 1 in./ft. (83

tests and number of tests specifically agreed upon between the mm/m)ofpipediameter,butinnocaselessthan1in.(25mm).

purchaser and the supplier.

8.2.2.5 The apparatus shall be capable of applying a load at

a uniform rate of 2 000 6 500 lbf/min/linear ft (29.4 6 7.4

8. Test Methods kN/min/linear m).

8.2.3 Test Procedure:

8.1 Dimensions:

8.2.3.1 The load shall be applied at a uniform rate of 2 000

8.1.1 Diameters:

6 500 lbf/min/linear ft (29.4 6 7.4 kN/min/linear m) of pipe

8.1.1.1 Inside Diameter—Take inside diameter measure-

length

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.