ASTM G101-04(2010)

(Guide)Standard Guide for Estimating the Atmospheric Corrosion Resistance of Low-Alloy Steels

Standard Guide for Estimating the Atmospheric Corrosion Resistance of Low-Alloy Steels

SIGNIFICANCE AND USE

In the past, ASTM specifications for low-alloy weathering steels, such as Specifications A242/A242M, A588/A588M, A606 Type 4, A709/A709M Grade 50W, HPS 70W, and 100W, A852/A852M, and A871/A871M stated that the atmospheric corrosion resistance of these steels is “approximately two times that of carbon structural steel with copper.” A footnote in the specifications stated that “two times carbon structural steel with copper is equivalent to four times carbon structural steel without copper (Cu 0.02 maximum).” Because such statements relating the corrosion resistance of weathering steels to that of other steels are imprecise and, more importantly, lack significance to the user (1 and 2) , the present guide was prepared to describe more meaningful methods of estimating the atmospheric corrosion resistance of weathering steels.

The first method of this guide is intended for use in estimating the expected long-term atmospheric corrosion losses of specific grades of low-alloy steels in various environments, utilizing existing short-term atmospheric corrosion data for these grades of steel.

The second method of this guide is intended for use in estimating the relative atmospheric corrosion resistance of a specific heat of low-alloy steel, based on its chemical composition.

It is important to recognize that the methods presented here are based on calculations made from test data for flat, boldly exposed steel specimens. Atmospheric corrosion rates can be much higher when the weathering steel remains wet for prolonged periods of time, or is heavily contaminated with salt or other corrosive chemicals. Therefore, caution must be exercised in the application of these methods for prediction of long-term performance of actual structures.

SCOPE

1.1 This guide presents two methods for estimating the atmospheric corrosion resistance of low-alloy weathering steels, such as those described in Specifications A242/A242M, A588/A588M, A606 Type 4, A709/A709M grades 50W, HPS 70W, and 100W, A852/A852M, and A871/A871M. One method gives an estimate of the long-term thickness loss of a steel at a specific site based on results of short-term tests. The other gives an estimate of relative corrosion resistance based on chemical composition.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G101 − 04(Reapproved 2010)

Standard Guide for

Estimating the Atmospheric Corrosion Resistance of Low-

Alloy Steels

This standard is issued under the fixed designation G101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Structural Steel Plate With Atmospheric Corrosion Resis-

tance

1.1 This guide presents two methods for estimating the

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

atmospheric corrosion resistance of low-alloy weathering

sion Test Specimens

steels, such as those described in Specifications A242/A242M,

G16 Guide for Applying Statistics to Analysis of Corrosion

A588/A588M, A606 Type 4, A709/A709M grades 50W, HPS

Data

70W, and 100W, A852/A852M, and A871/A871M. One

G50 Practice for Conducting Atmospheric Corrosion Tests

method gives an estimate of the long-term thickness loss of a

on Metals

steel at a specific site based on results of short-term tests. The

other gives an estimate of relative corrosion resistance based

3. Terminology

on chemical composition.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as

3.1.1 low-alloy steels—Iron-carbon alloys containing

standard. No other units of measurement are included in this

greater than 1.0 % but less than 5.0 %, by mass, total alloying

standard.

elements.

3.1.1.1 Discussion—Most “low-alloy weathering steels”

2. Referenced Documents

contain additions of both chromium and copper, and may also

2.1 ASTM Standards:

contain additions of silicon, nickel, phosphorus, or other

A242/A242M Specification for High-Strength Low-Alloy

alloying elements which enhance atmospheric corrosion resis-

Structural Steel

tance.

A588/A588M Specification for High-Strength Low-Alloy

Structural Steel, up to 50 ksi [345 MPa] Minimum Yield

4. Summary of Guide

Point, with Atmospheric Corrosion Resistance

4.1 In this guide, two general methods are presented for

A606 Specification for Steel, Sheet and Strip, High-

estimating the atmospheric corrosion resistance of low-alloy

Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

weathering steels. These are not alternative methods; each

Improved Atmospheric Corrosion Resistance

methodisintendedforaspecificpurpose,asoutlinedin5.2and

A709/A709M Specification for Structural Steel for Bridges

5.3.

A852/A852M Specification for Quenched and Tempered

4.1.1 The first method utilizes linear regression analysis of

Low-Alloy Structural Steel Plate with 70 ksi [485 MPa]

short-term atmospheric corrosion data to enable prediction of

Minimum Yield Strength to 4 in. [100 mm] Thick (With-

long-term performance by an extrapolation method.

drawn 2010)

4.1.2 Thesecondmethodutilizespredictiveequationsbased

A871/A871M Specification for High-Strength Low-Alloy

on the steel composition to calculate indices of atmospheric

corrosion resistance.

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

5. Significance and Use

Metals and is the direct responsibility of Subcommittee G01.04 on Atmospheric

Corrosion.

5.1 In the past, ASTM specifications for low-alloy weath-

Current edition approved May 1, 2010. Published May 2010. Originally

ering steels, such as Specifications A242/A242M, A588/

approved in 1989. Last previous edition approved in 2004 as G101–04. DOI:

A588M, A606 Type 4, A709/A709M Grade 50W, HPS 70W,

10.1520/G0101-04R10.

and 100W, A852/A852M, and A871/A871M stated that the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

atmospheric corrosion resistance of these steels is “approxi-

Standards volume information, refer to the standard’s Document Summary page on

matelytwotimesthatofcarbonstructuralsteelwithcopper.”A

the ASTM website.

footnote in the specifications stated that “two times carbon

The last approved version of this historical standard is referenced on

www.astm.org. structural steel with copper is equivalent to four times carbon

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G101 − 04 (2010)

Differentiation of Eq 2 with respect to time gives the corrosion rate (R)

structural steel without copper (Cu 0.02 maximum).” Because

at any given time:

such statements relating the corrosion resistance of weathering

~B21!

steels to that of other steels are imprecise and, more

R 5 ABt (3)

Also, the time to a given corrosion loss can be calculated as follows:

importantly,lacksignificancetotheuser (1 and 2) ,thepresent

1/B

guide was prepared to describe more meaningful methods of

t 5 C/A (4)

~ !

estimating the atmospheric corrosion resistance of weathering

6.2.3 Examples of projected atmospheric corrosion losses

steels.

over a period of fifty years for low-alloy weathering steels in

5.2 The first method of this guide is intended for use in

various environments are presented in Appendix X1.

estimating the expected long-term atmospheric corrosion

losses of specific grades of low-alloy steels in various NOTE2—Ithasbeenreported (6 and 7)thatforsomeenvironments,use

of log-log linear regression extrapolations may result in predictions which

environments, utilizing existing short-term atmospheric corro-

aresomewhatlowerorsomewhathigherthanactuallosses.Specifically,in

sion data for these grades of steel.

environments of very low corrosivity, the log-log predictions may be

5.3 The second method of this guide is intended for use in

higher than actual losses (6), whereas in environments of very high

estimating the relative atmospheric corrosion resistance of a corrosivity the opposite may be true (7). For these cases, use of numerical

optimizationorcompositemodelingmethods (7 and 8)mayprovidemore

specific heat of low-alloy steel, based on its chemical compo-

accurate predictions. Nevertheless, the simpler log-log linear regression

sition.

method described above provides adequate estimates for most purposes.

5.4 It is important to recognize that the methods presented

6.3 Predictive Methods Based on Steel Composition—Two

here are based on calculations made from test data for flat,

approaches are provided for prediction of relative corrosion

boldly exposed steel specimens. Atmospheric corrosion rates

resistance from composition. The first is based on the data of

can be much higher when the weathering steel remains wet for

Larrabee and Coburn (6.3.1). Its advantage is that it is

prolonged periods of time, or is heavily contaminated with salt

comparatively simple to apply. This approach is suitable when

or other corrosive chemicals. Therefore, caution must be

the alloying elements are limited to Cu, Ni, Cr, Si, and P, and

exercised in the application of these methods for prediction of

in amounts within the range of the original data. Corrosion

long-term performance of actual structures.

indices by either of the two approaches can be easily deter-

6. Procedure

mined by use of the tool provided on the ASTM website at

http://www.astm.org/COMMIT/G01_G101Calculator.xls.

6.1 Atmospheric corrosion data for the methods presented

here should be collected in accordance with Practice G50. 6.3.1 Predictive Method Based on the Data of Larabee and

Coburn—Equations for predicting corrosion loss of low-alloy

Specimen preparation, cleaning, and evaluation should con-

form to Practice G1. steels after 15.5 years of exposure to various atmospheres,

basedonthechemicalcompositionofthesteel,werepublished

6.2 Linear Regression Extrapolation Method:

by Legault and Leckie (9). The equations are based on

6.2.1 This method essentially involves the extrapolation of

extensive data published by Larrabee and Coburn (10).

logarithmic plots of corrosion losses versus time. Such plots of

6.3.1.1 For use in this guide, the Legault-Leckie equation

atmospheric corrosion data generally fit well to straight lines,

for an industrial atmosphere (Kearny, NJ) was modified to

and can be represented by equations in slope-intercept form,

(3-5): allow calculation of an atmospheric corrosion resistance index

based on chemical composition. The modification consisted of

logC 5 logA1Blogt (1)

deletion of the constant and changing the signs of all the terms

where:

in the equation. The modified equation for calculation of the

C = corrosion loss,

atmospheric corrosion resistance index (I) is given below. The

t = time, and

higher the index, the more corrosion resistant is the steel.

Aand B = constants.Ais the corrosion loss at t = 1, and B is

I 5 26.01 ~%Cu!13.88 ~%Ni!11.20 ~%Cr!

the slope of a log C versus log + plot.

11.49 ~%Si!117.28 ~%P! 2 7.29 ~%Cu!~%Ni!

C may be expressed as mass loss per unit area, or as a

29.10 ~%Ni!~%P! 2 33.39 ~%Cu!

calculated thickness loss or penetration based on mass loss.

NOTE 3—Similar indices can be calculated for the Legault-Leckie

6.2.2 The method is best implemented by linear regression

equations for marine and semi-rural atmospheres. However, it has been

found that the ranking of the indices of various steel compositions is the

analysis, using the method of least squares detailed in Guide

same for all these equations. Therefore, only one equation is required to

G16.At least three data points are required. Once the constants

rank the relative corrosion resistance of different steels.

of the equation are determined by the linear regression

analysis, the projected corrosion loss can be calculated for any

6.3.1.2 Thepredictiveequationshouldbeusedonlyforsteel

given time. A sample calculation is shown in Appendix X1.

compositions within the range of the original test materials in

the Larrabee-Coburn data set (7). These limits are as follows:

NOTE 1—Eq 1 can also be written as follows:

Cu 0.51 % max

B

C 5 At (2)

Ni 1.1 % max

Cr 1.3 % max

4 Si 0.64 % max

The boldface numbers in parentheses refer to a list of references at the end of

this standard. P 0.12 % max

G101 − 04 (2010)

6.3.1.3 Examples of averages and ranges of atmospheric (2) The times for pure iron to reach a 254-µm loss at the

corrosion resistance indices calculated by the Larrabee-Coburn three sites are then calculated by use of Eq 4.

methodfor72heatsofeachoftwoweatheringsteelsareshown

(3) For a given low alloy steel, A and B values at each site

in Table X2.1.

are calculated from the regression constants and coefficients in

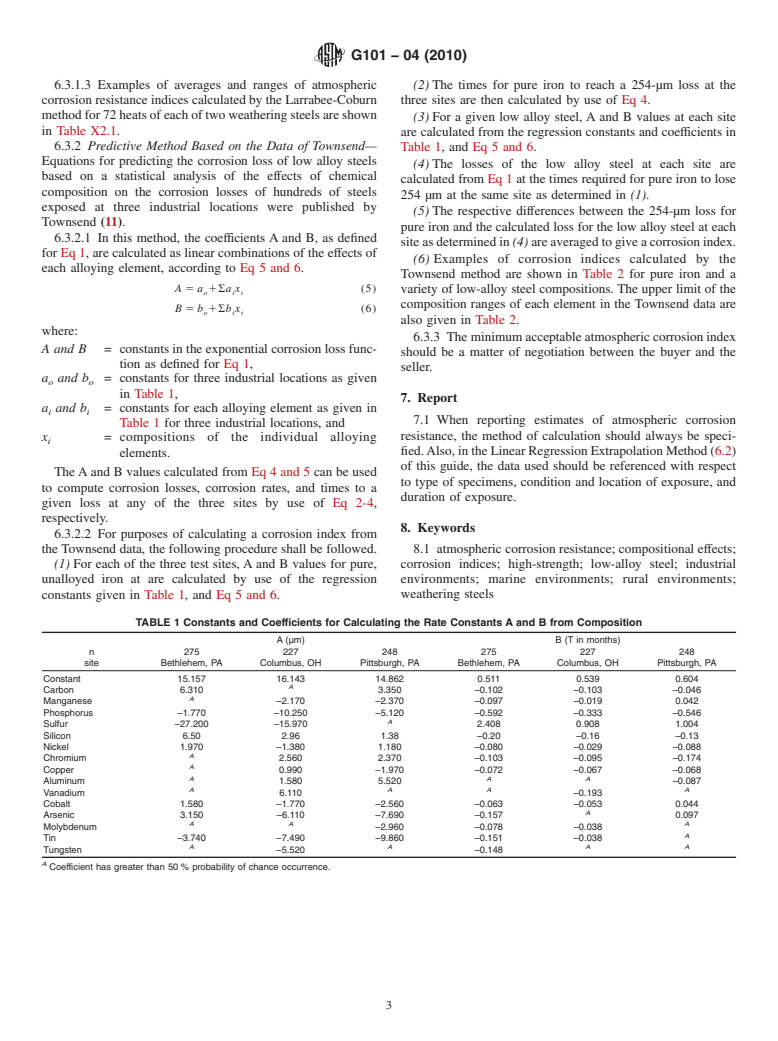

6.3.2 Predictive Method Based on the Data of Townsend—

Table 1, and Eq 5 and 6.

Equations for predicting the corrosion loss of low alloy steels

(4) The losses of the low alloy steel at each site are

based on a statistical analysis of the effects of chemical

calculated from Eq 1 at the times required for pure iron to lose

composition on the corrosion losses of hundreds of steels

254 µm at the same site as determined in (1).

exposed at three industrial locations were published by

(5) The respective differences between the 254-µm loss for

Townsend (11).

pure iron and the calculated loss for the low alloy steel at each

6.3.2.1 In this method, the coefficients A and B, as defined

siteasdeterminedin (4)areaveragedtogiveacorrosionindex.

for Eq 1, are calculated as linear combinations of the effects of

(6) Examples of corrosion indices calculated by the

each alloying element, according to Eq 5 and 6.

Townsend method are shown in Table 2 for pure iron and a

A 5 a 1Σa x (5)

variety of low-alloy steel compositions. The upper limit of the

o i i

composition ranges of each element in the Townsend data are

B 5 b 1Σb x (6)

o i i

also given in Table 2.

where:

6.3.3 Theminimumacceptableatmosphericcorrosionindex

A and B = constants in the exponential corrosion loss func-

should be a matter of negotiation between the buyer and the

tion as defined for Eq 1,

seller.

a and b = constants for three industrial locations as given

o o

in Table 1,

7. Report

a and b = constants for each alloying element as given in

i i

7.1 When reporting estimates of atmospheric corrosion

Table 1 for three industrial locations, and

resistance, the method of calculation should always be speci-

x = compositions of the individual alloying

i

fied.Also,intheLinearRegressionExtrapolationMethod(6.2)

elements.

of this guide, the data used should be referenced with respect

TheAand B values calculated from Eq 4 and 5 can be used

to type of specimens, condition and location of exposure, and

to compute corrosion losses, corrosion rates, and times to a

duration of exposure.

given loss at any of the three sites by use of Eq 2-4,

respectively.

8. Keywords

6.3.2.2 For purposes of calculating a corrosion index from

8.1 atmospheric corrosion resistance; compositional effects;

the Townsend data, the following procedure shall be followed.

(1) For each of the three test sites, A and B values for pure, corrosion indices; high-strength; low-alloy steel; industrial

environments; marine environments; rural environments;

unalloyed iron at are calculated by use of the regression

constants given in Table 1, and Eq 5 and 6. weathering steels

TABLE 1 Constants and Coefficients for Calculating the Rate Constants A and B from Composition

A (µm) B (T in months)

n 275 227 248 275 227 248

site Bethlehem, PA Columbus, OH Pittsburgh, PA Bethlehem, PA Columbus, OH Pittsburgh, PA

Constant 15.157 16.143 14.862 0.511 0.539 0.604

A

Carbon 6.310 3.350 –0.102 –0.103 –0.046

A

Manganese –2.170 –2.370 –0.097 –0.019 0.042

Phosphorus –1.770 –10.250 –5.120 –0.592 –0.333 –0.546

A

Sulfur –27.200 –15.970 2.408 0.908 1.004

Silicon 6.50 2.96 1.38 –0.20 –0.16 –0.13

Nickel 1.970 –1.380 1.180 –0.080 –0.029 –0.088

A

Chromium 2.560 2.370 –0.103 –0.095 –0.174

A

Copper 0.990 –1.970 –0.072 –0.067 –0.068

A AA

Aluminum 1.580 5.520 –0.087

A AA A

Vanadium 6.110 –0.193

Cobalt 1.580 –1.770 –2.560 –0.063 –0.053 0.044

A

Arsenic 3.150 –6.110 –7.690 –0.157 0.097

AA A

Molybdenum –2.960 –0.078 –0.038

A

Tin –3.740 –7.490 –9.860 –0.151 –0.038

A A AA

Tungsten –5.520 –0.148

A

Coefficient has greater than 50 % probability of chance occurrence.

G101 − 04 (2010)

A

TABLE 2 Corrosion Indices for Pure Iron and Various Low-Alloy Steels

Element Range Pure Fe Typical A36 + Min. Alloy 1 Typical Alloy 2 Max. Alloy 3 Alloy 4

w/o Maximum A36 0.2% Cu A588 A588 A588

C 1.50 0.000 0.160 0.160 0.060 0.075 0.100 0.060 0.190 0.091 0.060

Mn 1.50 0.000 1.010 1.010 0.800 0.690 1.180 1.090 1.250 0.580 1.000

P 0.30 0.000 0.012 0.012 0.005 0.030 0.012 0.007 0.040 0.004 0.010

S 0.30 0.000 0.013 0.013 0.001 0.004 0.011 0.002 0.050 0.001 0.002

Si 1.50 0.000 0.220 0.220 0.300 0.280 0.360 0.290 0.650 0.200 0.250

Ni 1.10 0.000 0.01

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.