ASTM F3148-17a

(Specification)Standard Specification for High Strength Structural Bolt Assemblies, Steel and Alloy Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch Dimensions

Standard Specification for High Strength Structural Bolt Assemblies, Steel and Alloy Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch Dimensions

ABSTRACT

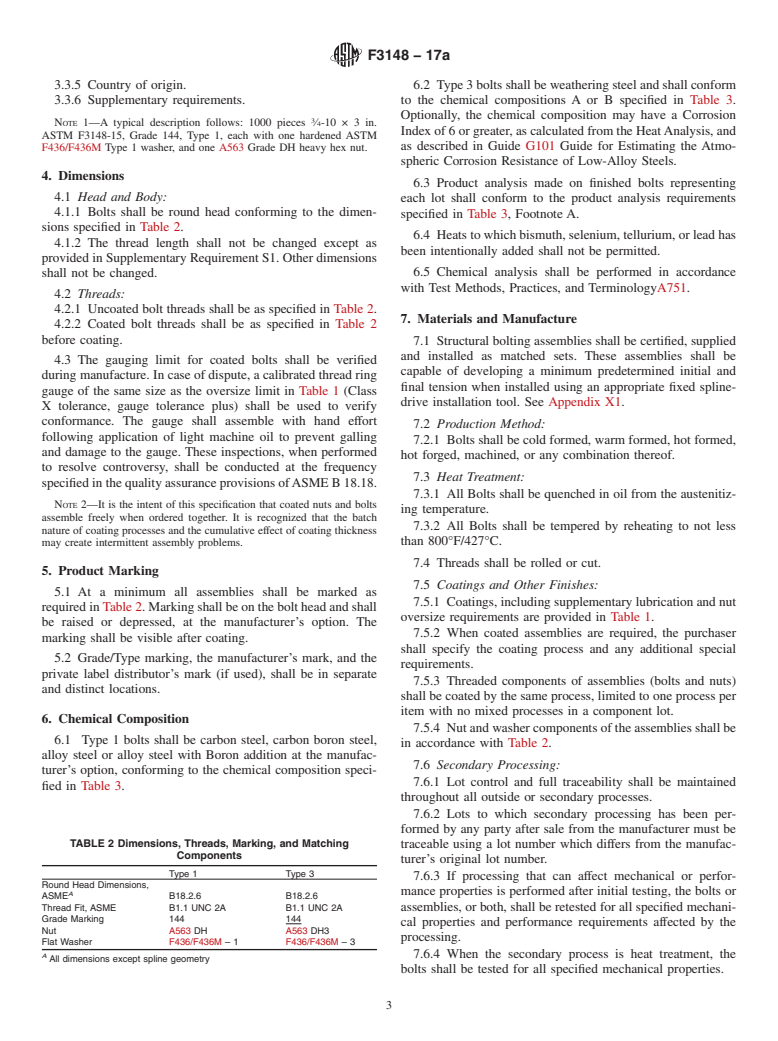

This specification defines chemical, dimensional, physical and mechanical requirements for quenched and tempered bolts manufactured from steel and alloy steel, in inch dimensions. Structural bolting assemblies are designated as Grade 144. Bolts are designated by type denoting raw material chemical composition: Type 1 (144ksi - carbon steel, carbon boron steel, alloy steel or alloy steel with boron addition) and Type 3 (144ksi - weathering steel). Bolts manufactured under this specification, and structural bolting assemblies supplied under this specification, are intended for use in structural connections covered in the Specification for Structural Joints Using High-Strength Bolts and installed using the torque-and-angle or part turn/combined installation method.

This specification covers materials and manufacturing practice requirements; permitted coatings; dimensions, threads, marking, and matching components; chemical and mechanical properties; testing and lot control; workmanship; quality assurance; and product marking. Products shall undergo tensile strength, proof load, surface discontinuities, hardness, micro-hardness, carburization/decarburization, coating thickness, magnetic particle, rotational capacity, and assembly tension testing.

SCOPE

1.1 This specification covers chemical, dimensional, physical and mechanical requirements for quenched and tempered bolts manufactured from steel and alloy steel, in inch dimensions. The bolts are available as structural bolting assemblies which include a fixed spline bolt, a suitable nut and at least one washer covered by reference herein.

1.2 Intended Use:

1.2.1 Bolts manufactured under this specification, and structural bolting assemblies supplied under this specification, are intended for use in structural connections covered in the Specification for Structural Joints Using High-Strength Bolts and installed using the torque-and-angle or part turn/combined installation method.

1.2.2 Structural bolting assemblies in this specification are furnished in nominal diameters from 1/2 to 1-1/4 in. inclusive.

1.3 Classification:

1.3.1 Structural bolting assemblies are designated as Grade 144.

1.3.2 Bolts are designated by type denoting raw material chemical composition.

Type 1 -

144ksi - carbon steel, carbon boron steel, alloy steel or alloy steel with boron addition

Type 3 -

144ksi - weathering steel

1.4 Terms used in the specification are defined in Terminology F1789.

1.4.1 Torque-and-Angle Fixed-Spline Structural Bolt—bolt that includes an integral fixed-spline end which extends beyond the threaded portion of the bolt and is used as a component of a torque-and-angle fixed-spline structural bolting assembly.

1.4.2 Torque-and-Angle Fixed-Spline Structural Bolting Assembly2— a fastener assembly comprised of a torque-and-angle fixed-spline bolt with a suitable nut and at least one washer, installed and tightened using a special electric wrench and socket system which has an inner socket that engages the fixed-spline end of the bolt and with an outer socket that engages and turns the nut, in two separate and distinct operations, the first is a controlled torque application and the second is a specified angle.

1.4.3 Combined Method—A tightening method comprised of two steps, the first tightening step using a torque regulating tool and the second tightening step in which a specified turn is applied to the turned part of the assembly. Also known as the ‘part turn method’.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned in this standard. Users of this ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3148 −17a

Standard Specification for

High Strength Structural Bolt Assemblies, Steel and Alloy

Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch

1

Dimensions

This standard is issued under the fixed designation F3148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.2 Torque-and-Angle Fixed-Spline Structural Bolting

2

Assembly — a fastener assembly comprised of a torque-and-

1.1 This specification covers chemical, dimensional, physi-

angle fixed-spline bolt with a suitable nut and at least one

cal and mechanical requirements for quenched and tempered

washer, installed and tightened using a special electric wrench

bolts manufactured from steel and alloy steel, in inch dimen-

and socket system which has an inner socket that engages the

sions. The bolts are available as structural bolting assemblies

fixed-spline end of the bolt and with an outer socket that

whichincludeafixedsplinebolt,asuitablenutandatleastone

engages and turns the nut, in two separate and distinct

washer covered by reference herein.

operations, the first is a controlled torque application and the

1.2 Intended Use:

second is a specified angle.

1.2.1 Boltsmanufacturedunderthisspecification,andstruc-

1.4.3 Combined Method—A tightening method comprised

tural bolting assemblies supplied under this specification, are

of two steps, the first tightening step using a torque regulating

intended for use in structural connections covered in the

tool and the second tightening step in which a specified turn is

Specification for Structural Joints Using High-Strength Bolts

applied to the turned part of the assembly. Also known as the

and installed using the torque-and-angle or part turn/combined

‘part turn method’.

installation method.

1.5 This standard does not purport to address all of the

1.2.2 Structural bolting assemblies in this specification are

safety concerns, if any, associated with its use. It is the

1 1

furnished in nominal diameters from ⁄2 to 1- ⁄4 in. inclusive.

responsibility of the user of this standard to establish appro-

1.3 Classification:

priate safety and health practices and determine the applica-

1.3.1 Structural bolting assemblies are designated as Grade

bility of regulatory limitations prior to use.

144.

1.6 ASTM International takes no position respecting the

1.3.2 Bolts are designated by type denoting raw material

validity of any patent rights asserted in connection with any

chemical composition.

item mentioned in this standard. Users of this standard are

Type 1 - 144ksi - carbon steel, carbon boron steel, alloy steel or alloy steel expresslyadvisedthatdeterminationofthevalidityofanysuch

with boron addition

patent rights, and the risk of infringement of such rights, are

Type 3 - 144ksi - weathering steel

entirely their own responsibility.

1.4 Terms used in the specification are defined inTerminol-

1.7 This international standard was developed in accor-

ogy F1789.

dance with internationally recognized principles on standard-

1.4.1 Torque-and-Angle Fixed-Spline Structural Bolt—bolt

ization established in the Decision on Principles for the

thatincludesanintegralfixed-splineendwhichextendsbeyond

Development of International Standards, Guides and Recom-

the threaded portion of the bolt and is used as a component of

mendations issued by the World Trade Organization Technical

a torque-and-angle fixed-spline structural bolting assembly.

Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee F16 on

2

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, The torque-and-angle fixed-spline structural bolting system has a patent

Nuts, Rivets and Washers. application pending. Interested parties are invited to submit information regarding

Current edition approved May 15, 2017. Published June 2017. Originally the identification of an alternative(s) to this patent-pending item to the ASTM

approved in 2015. Last previous edition approved in 2017 as F3148–17. DOI: International Headquarters. Your comments will receive careful consideration at a

10.1520/F3148-17A meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3148−17a

4

2. Referenced Documents 2.2 ASME Standards:

3 B 1.1Unified Screw Threads

2.1 ASTM Standards:

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3148 − 17 F3148 − 17a

Standard Specification for

High Strength Structural Bolt Assemblies, Steel and Alloy

Steel, Heat Treated, 144ksi Minimum Tensile Strength, Inch

1

Dimensions

This standard is issued under the fixed designation F3148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers chemical, dimensional, physical and mechanical requirements for quenched and tempered bolts

manufactured from steel and alloy steel, in inch dimensions. The bolts are available as structural bolting assemblies which include

a fixed spline bolt, a suitable nut and at least one washer covered by reference herein.

1.2 Intended Use:

1.2.1 Bolts manufactured under this specification, and structural bolting assemblies supplied under this specification, are

intended for use in structural connections covered in the Specification for Structural Joints Using High-Strength Bolts and installed

using the torque-and-angle or part turn/combined installation method.

1 1

1.2.2 Structural bolting assemblies in this specification are furnished in nominal diameters from ⁄2 to 1- ⁄4 in. inclusive.

1.3 Classification:

1.3.1 Structural bolting assemblies are designated as Grade 144.

1.3.2 Bolts are designated by type denoting raw material chemical composition.

Type 1 - 144ksi - carbon steel, carbon boron steel, alloy steel or alloy steel with boron addition

Type 3 - 144ksi - weathering steel

1.4 Terms used in the specification are defined in Terminology F1789.

1.4.1 Torque-and-Angle Fixed-Spline Structural Bolt—bolt that includes an integral fixed-spline end which extends beyond the

threaded portion of the bolt and is used as a component of a torque-and-angle fixed-spline structural bolting assembly.

2

1.4.2 Torque-and-Angle Fixed-Spline Structural Bolting Assembly — a fastener assembly comprised of a torque-and-angle

fixed-spline bolt with a suitable nut and at least one washer, installed and tightened using a special electric wrench and socket

system which has an inner socket that engages the fixed-spline end of the bolt and with an outer socket that engages and turns the

nut, in two separate and distinct operations, the first is a controlled torque application and the second is a specified angle.

1.4.3 Combined Method—A tightening method comprised of two steps, the first tightening step using a torque regulating tool

and the second tightening step in which a specified turn is applied to the turned part of the assembly. Also known as the ‘part turn

method’.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item

mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights,

and the risk of infringement of such rights, are entirely their own responsibility.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved March 1, 2017May 15, 2017. Published March 2017June 2017. Originally approved in 2015. Last previous edition approved in 20152017 as

F3148–15.–17. DOI: 10.1520/F3148-1710.1520/F3148-17A

2

The torque-and-angle fixed-spline structural bolting system has a patent application pending. Interested parties are invited to submit information regarding the

identification of an alternative(s) to this patent-pending item to the ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Consh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.