ASTM D5200-03(2008)e1

(Test Method)Standard Test Method for Determination of Weight Percent Volatile Content of Solvent-Borne Paints in Aerosol Cans

Standard Test Method for Determination of Weight Percent Volatile Content of Solvent-Borne Paints in Aerosol Cans

SIGNIFICANCE AND USE

This test method is the procedure of choice for determining the volatile content in aerosol coatings under specified test conditions modeled after Method 35. The inverse value, nonvolatile, is used to determine the weight percent solids content. This information is useful to the paint producer, user, and to environmental interests for determining the grams of volatile organic compounds per gram of solids emitted from aerosol cans.

SCOPE

1.1 This test method is for the determination of the weight percent volatile organic compounds of solvent-borne paints in aerosol cans. It offers a unique way to obtain paint specimens from aerosol cans.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. A specific hazard statement is given in 6.7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5200 − 03 (Reapproved2008)

Standard Test Method for

Determination of Weight Percent Volatile Content of Solvent-

Borne Paints in Aerosol Cans

This standard is issued under the fixed designation D5200; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in subsection 1.2 was corrected editorially in November 2008.

1. Scope 3. Summary of Test Method

3.1 Adesignatedquantityfromanaerosolcoatingissprayed

1.1 This test method is for the determination of the weight

into an adapter glass tube assembly and heated in an oven at

percent volatile organic compounds of solvent-borne paints in

110 6 5°C for 60 min. The percent volatile is calculated from

aerosol cans. It offers a unique way to obtain paint specimens

the loss in weight.

from aerosol cans.

1.2 The values stated in SI units are to be regarded as

4. Significance and Use

standard. No other units of measurement are included in this

4.1 This test method is the procedure of choice for deter-

standard.

mining the volatile content in aerosol coatings under specified

1.3 This standard does not purport to address all of the

test conditions modeled after Method 35. The inverse value,

safety concerns, if any, associated with its use. It is the

nonvolatile, is used to determine the weight percent solids

responsibility of the user of this standard to establish appro-

content. This information is useful to the paint producer, user,

priate safety and health practices and determine the applica-

and to environmental interests for determining the grams of

bility of regulatory limitations prior to use. A specific hazard

volatile organic compounds per gram of solids emitted from

statement is given in 6.7.

aerosol cans.

2. Referenced Documents

5. Apparatus

5.1 Adapter Glass Tube Assembly, (Fig. 1).

2.1 ASTM Standards:

5.1.1 Sample Adapter Tube, straight connecting with 35/25

E145 Specification for Gravity-Convection and Forced-

spherical joints. Loosely fill with glass wool and precondition

Ventilation Ovens

for 30 min in an oven at 110 6 5°C and store in a dessicator

E180 Practice for Determining the Precision of ASTM

5,6

prior to use.

Methods for Analysis and Testing of Industrial and Spe-

5.1.2 Charcoal Adapter Tube, straight connecting with

cialty Chemicals (Withdrawn 2009)

35/25 spherical joints. Fill with activated charcoal and plug

2.2 Other Standard:

both ends with glass wool. This tube is used to prevent the

Method 35 Determination of PercentVolatile Organic Com-

6,7

solvent vapors from contaminating the vacuum pump.

pounds (VOC) in Solvent Based Aerosol Paints

6,8

5.1.3 Adapters, connecting hose with 35/25 socket joints.

6,9

5.1.4 Adapter, connecting hose with 35/25 ball joint.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. The sole source of supply of the adapter tube, No. 5035-35 known to the

Current edition approved Nov. 1, 2008. Published November 2008. Originally committee at this time is Ace Glass Inc., P.O. Box 688, 1430 Northwest Blvd.,

approved in 1991. Last previous edition approved in 2003 as D5200 – 03. DOI: Vineland, NJ 08360.

10.1520/D5200-03R08E01. If you are aware of alternative suppliers, please provide this information to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ASTM International Headquarters. Your comments will receive careful consider-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ation at a meeting of the responsible technical committee, which you may attend.

Standards volume information, refer to the standard’s Document Summary page on The sole source of supply of the charcoal adapter tube, No. 5035-3 known to

the ASTM website. the committee at this time is Ace Glass Inc.

3 8

The last approved version of this historical standard is referenced on The sole source of supply of the adapters (socket joints) No. 5217-35 known to

www.astm.org. the committee at this time is Ace Glass Inc.

4 9

Bay Area Air Quality Management District, (BAAQMD) Manual of The sole source of supply of the adapter (ball joint) No. 5216-35 known to the

Procedures, Vol III, 939 Ellis St., San Francisco, CA 94109. committee at this time is Ace Glass Inc.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D5200 − 03 (2008)

6. Procedure

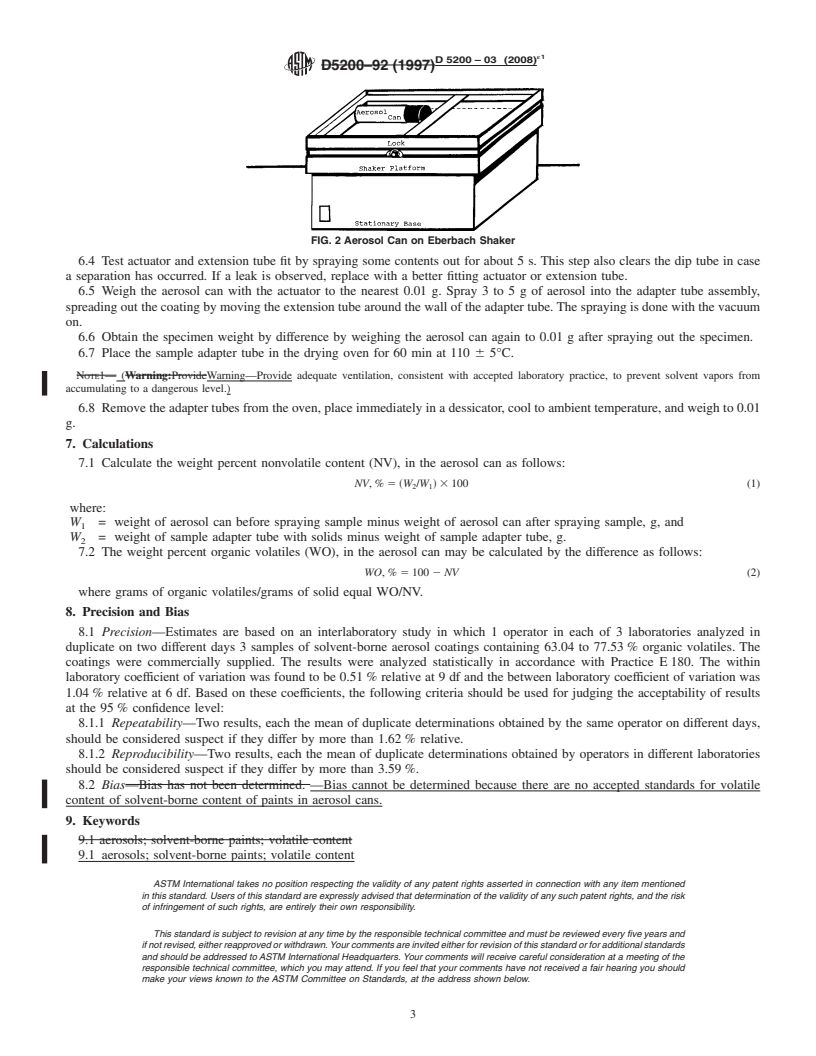

6.1 Mix the aerosol can thoroughly using a shaker, similar

to the Eberbach shaker in Fig. 2, for 15 min at the low-speed

setting. It is essential that the samples be well mixed to obtain

valid results.

6.2 Weigh accurate

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D5200–03(Reapproved2008)

Designation:D5200–92(Reapproved 1997)

Standard Test Method for

Determination of Weight Percent Volatile Content of Solvent-

Borne Paints in Aerosol Cans

This standard is issued under the fixed designation D 5200; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made in the footnotes in September 1997.

—The units statement in subsection 1.2 was corrected editorially in November 2008.

1. Scope

1.1 Thistestmethodisforthedeterminationoftheweightpercentvolatileorganiccompoundsofsolvent-bornepaintsinaerosol

cans. It offers a unique way to obtain paint specimens from aerosol cans.

1.2

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. A specific hazard statement is given in Note 16.7.

2. Referenced Documents

2.1 ASTM Standards:

E 145 Specification for Gravity-Convection and Forced-Ventilation Ovens

E 180 Practice for Determining the Precision ofASTM Methods forAnalysis andTesting of Industrial and Specialty Chemicals

2.2 Other Standard:

Method 35 Determination of Percent Volatile Organic Compounds (VOC) in Solvent Based Aerosol Paints

3. Summary of Test Method

3.1 Adesignated quantity from an aerosol coating is sprayed into an adapter glass tube assembly and heated in an oven at 110

6 5°C for 60 min. The percent volatile is calculated from the loss in weight.

4. Significance and Use

4.1This4.1 This test method is the procedure of choice for determining the volatile content in aerosol coatings under specified

test conditions modeled after Method 35. The inverse value, nonvolatile, is used to determine the weight percent solids content.

This information is useful to the paint producer, user, and to environmental interests for determining the grams of volatile organic

compounds per gram of solids emitted from aerosol cans.

5. Apparatus

5.1 Adapter Glass Tube Assembly, (Fig. 1).

5.1.1 Sample Adapter Tube, straight connecting with 35/25 spherical joints. Loosely fill with glass wool and precondition for

4,5

30 min in an oven at 110 6 5°C and store in a dessicator prior to use.

This test method is under the jurisdiction of ASTM Committee D-1D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved May 15, 1992.Nov. 1, 2008. Published July 1992.November 2008. Originally published as D5200–91.approved in 1991. Last previous edition

D5200–91.approved in 2003 as D 5200 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 15.05.

Bay Area Air Quality Management District, (BAAQMD) Manual of Procedures, Vol III, 939 Ellis St., San Francisco, CA 94109.

Bay Area Air Quality Management District, (BAAQMD) Manual of Procedures, Vol III, 939 Ellis St., San Francisco, CA 94109.

The sole source of supply of the adapter tube, No. 5035-35 known to the committee at this time is Ace Glass Inc., P.O. Box 688, 1430 Northwest Blvd., Vineland, NJ

08360.

The sole source of supply of the adapter tube, No. 5035-35 known to the committee at this time is Ace Glass Inc., P.O. Box 688, 1430 Northwest Blvd., Vineland, NJ

08360.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D5200–03 (2008)

D5200–92 (1997)

FIG. 1 Adapter Glass Tube Assembly

5.1.2 Charcoal Adapter Tube, straight connecting with 35/25 spherical joints. Fill with activated charcoal and plug both ends

5,6

with glass wool. This tube is used to prevent the solvent vapors from contaminating the vacuum pump.

,

5 7

5.1.3 Adapters, connecting hose with 35/25 socket joints.

5,8

5.1.4 Adapter, connecting hose with 35/25 ball joint.

,

5 9

5.1.5 Clamps, pinch type, with screw-locking device.

5.1.6 Glass Wool, medium-fine silk.

5.1.7 Activated Charcoal, coconut, 8 to 12 mesh.

5.1.8 Tygon Tubing.

5.1.9 Iron Stands.

5.1.10 Utility Clamps.

5.2 Vacuum Pump.

5.3 Forced Draft Oven, Type II A or Type II B as specified in Specification E 145.

5.4 Actuators (Valves), with extension tubes.

5.5 Top-Loading Balance, capable of weighing to 0.01 g.

5.6 Shaker, similar to the Eberbach shaker in Fig. 2.

6. Procedure

6.1 Mix the aerosol can thoroughly using a shaker, similar to the Eberbach shaker in Fig. 2, for 15 min at the low-speed setting.

It is essential that the samples be well mixed to obtain valid results.

6.2 Weighac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.