ASTM G181-11

(Practice)Standard Test Method for Conducting Friction Tests of Piston Ring and Cylinder Liner Materials Under Lubricated Conditions

Standard Test Method for Conducting Friction Tests of Piston Ring and Cylinder Liner Materials Under Lubricated Conditions

SIGNIFICANCE AND USE

The efficiency and fuel economy of spark ignition and diesel engines is affected in part to the friction between moving parts. Although no reliable, in situ friction measurements exist for fired internal combustion engines, it has been estimated that at least half of the friction losses in such engines are due to those at the ring and liner interface. This test method involves the use of a reciprocating sliding arrangement to simulate the type of oscillating contact that occurs between a piston ring and its mating cylinder bore surface near the top-dead-center position in the cylinder where most severe surface contact conditions occur. There are many types of engines and engine operating environments; therefore, to allow the user the flexibility to tailor this test to conditions representative of various engines, this standard test method allows flexibility in selecting test loads, speeds, lubricants, and durations of testing. Variables that can be adjusted in this procedure include: normal force, speed of oscillation, stroke length, duration of testing, temperature of testing, method of specimen surface preparation, and the materials and lubricants to be evaluated. Guidance is provided here on the set-up of the test, the manner of specimen fixturing and alignment, the selection of a lubricant to simulate conditioned oil characteristics (for a diesel engine), and the means to run-in the ring specimens to minimize variability in test results.

Engine oil spends the majority of its operating lifetime in a state that is representative of use-conditioned oil. That is, fresh oil is changed by exposure to the heat, chemical environment, and confinement in lubricated contact. It ages, changing viscosity, atomic weight, solids content, acidity, and chemistry. Conducting piston ring and cylinder liner material evaluations in fresh, non-conditioned oil is therefore unrealistic for material screening. But additive-depleted, used oil can result in high wear and corrosive attac...

SCOPE

1.1 This test method covers procedures for conducting laboratory bench-scale friction tests of materials, coatings, and surface treatments intended for use in piston rings and cylinder liners in diesel or spark-ignition engines. The goal of this procedure is to provide a means for preliminary, cost-effective screening or evaluation of candidate ring and liner materials. A reciprocating sliding arrangement is used to simulate the contact that occurs between a piston ring and its mating liner near the top-dead-center position in the cylinder where liquid lubrication is least effective, and most wear is known to occur. Special attention is paid to specimen alignment, running-in, and lubricant condition.

1.2 This test method does not purport to simulate all aspects of a fired engine’s operating environment, but is intended to serve as a means for preliminary screening for assessing the frictional characteristics of candidate piston ring and liner material combinations in the presence of fluids that behave as use-conditioned engine oils. Therefore, it is beyond the scope of this test method to describe how one might establish correlations between the described test results and the frictional characteristics of rings and cylinder bore materials for specific engine designs or operating conditions.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G181 −11

Standard Test Method for

Conducting Friction Tests of Piston Ring and Cylinder Liner

1

Materials Under Lubricated Conditions

This standard is issued under the fixed designation G181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers procedures for conducting 2.1 ASTM Standards:

laboratory bench-scale friction tests of materials, coatings, and D6838 Test Method for Cummins M11 High Soot Test

surface treatments intended for use in piston rings and cylinder E177 Practice for Use of the Terms Precision and Bias in

liners in diesel or spark-ignition engines. The goal of this ASTM Test Methods

procedure is to provide a means for preliminary, cost-effective E691 Practice for Conducting an Interlaboratory Study to

screening or evaluation of candidate ring and liner materials.A Determine the Precision of a Test Method

reciprocating sliding arrangement is used to simulate the G40 Terminology Relating to Wear and Erosion

contact that occurs between a piston ring and its mating liner

3. Terminology

near the top-dead-center position in the cylinder where liquid

lubrication is least effective, and most wear is known to occur. 3.1 For definitions, see Terminology G40.

Special attention is paid to specimen alignment, running-in,

3.2 Definitions of Terms Specific to This Standard:

and lubricant condition.

3.2.1 conditioned oil—a lubricating oil whose viscosity,

1.2 This test method does not purport to simulate all aspects composition, and other function-related characteristics have

of a fired engine’s operating environment, but is intended to been altered by use in an operating engine, such that the oil’s

serve as a means for preliminary screening for assessing the effects on friction and wear reflect those characteristic of the

frictional characteristics of candidate piston ring and liner long-term, steady-state engine operation.

material combinations in the presence of fluids that behave as

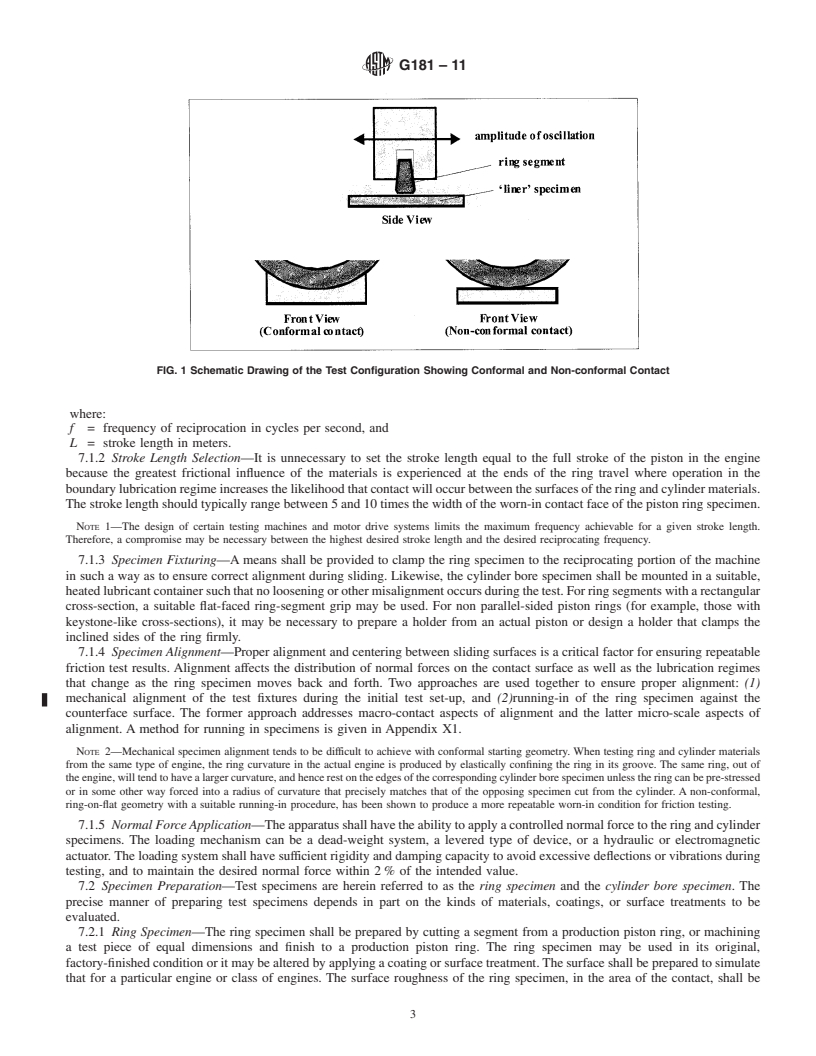

3.2.2 conformal contact—in friction and wear testing, any

use-conditioned engine oils. Therefore, it is beyond the scope

macro-geometric specimen configuration in which the curva-

of this test method to describe how one might establish

ture of one contact surface matches that of the countersurface.

correlationsbetweenthedescribedtestresultsandthefrictional

3.2.2.1 Discussion—Examples of conformal contact include

characteristics of rings and cylinder bore materials for specific

a flat surface sliding on a flat surface and a ball rotating in a

engine designs or operating conditions.

socket that conforms to the shape of the ball.Apair of surfaces

may begin a wear or friction test in a non-conforming contact

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this configuration, but develop a conformal contact as a result of

wear.

standard.

3.2.3 lubrication regime—in liquid-lubricated sliding

1.4 This standard does not purport to address all of the

contact, a certain range of friction coefficients that results from

safety concerns, if any, associated with its use. It is the

a combination of contact geometry, lubricant viscosity

responsibility of the user of this standard to establish appro-

characteristics, surface roughness, normal pressure, and the

priate safety and health practices and determine the applica-

relative speed of the bearing surfaces.

bility of regulatory limitations prior to use.

3.2.3.1 Discussion—Common designations for lubrication

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

2

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2011. Published May 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2009 as G181–04(2009). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0181-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G181−11

FIG. 1Schematic Drawing of the Test Configuration Showing Conformal and Non-conformal Contact

regimes are boundary lubrication, mixed film lubrication, engine), and the means to run-in the ring specimens to

elasto-hydrodynamic lubrication and hydrodynamic lubrica- minimize variability in test results.

tion.

5.2 Engine

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:G181–04 (Reapproved 2009)

Standard Practice for Designation: G181 – 11

Standard Test Method for

Conducting Friction Tests of Piston Ring and Cylinder Liner

1

Materials Under Lubricated Conditions

This standard is issued under the fixed designation G181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice test method covers procedures for conducting laboratory bench-scale friction tests of materials, coatings, and

surfacetreatmentsintendedforuseinpistonringsandcylinderlinersindieselorspark-ignitionengines.Thegoalofthisprocedure

is to provide a means for preliminary, cost-effective screening or evaluation of candidate ring and liner materials.Areciprocating

sliding arrangement is used to simulate the contact that occurs between a piston ring and its mating liner near the top-dead-center

position in the cylinder where liquid lubrication is least effective, and most wear is known to occur. Special attention is paid to

specimen alignment, running-in, and lubricant condition.

1.2 This practice test method does not purport to simulate all aspects of a fired engine’s operating environment, but is intended

to serve as a means for preliminary screening for assessing the frictional characteristics of candidate piston ring and liner material

combinations in the presence of fluids that behave as use-conditioned engine oils. Therefore, it is beyond the scope of this

practicetest method to describe how one might establish correlations between the described test results and the frictional

characteristics of rings and cylinder bore materials for specific engine designs or operating conditions.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D6838 Test Method for Cummins M11 High Soot Test

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G40 Terminology Relating to Wear and Erosion

3. Terminology

3.1 For definitions, see Terminology G40.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 conditioned oil—a lubricating oil whose viscosity, composition, and other function-related characteristics have been

altered by use in an operating engine, such that the oil’s effects on friction and wear reflect those characteristic of the long-term,

steady-state engine operation.

3.2.2 conformal contact—in friction and wear testing, any macro-geometric specimen configuration in which the curvature of

one contact surface matches that of the countersurface.

3.2.2.1 Discussion—Examples of conformal contact include a flat surface sliding on a flat surface and a ball rotating in a socket

that conforms to the shape of the ball. A pair of surfaces may begin a wear or friction test in a non-conforming contact

configuration, but develop a conformal contact as a result of wear.

1

This practice test method is under the jurisdiction ofASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved Oct.May 1, 2009.2011. Published February 2010.May 2011. Originally approved in 2004. Last previous edition approved in 20042009 as

G181–04(2009). DOI: 10.1520/G0181-04R09.10.1520/G0181-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G181 – 11

3.2.3 lubrication regime—in liquid-lubricated sliding contact, a certain range of friction coefficients that results from a

combination of contact geometry, lubricant viscosity characteristics, surface roughness, normal pressure, and the relative s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.