ASTM F708-92(2014)

(Practice)Standard Practice for Design and Installation of Rigid Pipe Hangers

Standard Practice for Design and Installation of Rigid Pipe Hangers

ABSTRACT

This practice covers acceptable methods of fabricating and installing rigid pipe hangers used to support shipboard piping systems, it provides guidance for the design of hanger caps, straps and standoffs, selection of hanger and hanger liner materials, hanger bolting, and hanger spacing. The pipe hanger style includes: split cap hanger, 3strap hanger, welded hanger, U-bolt hanger, J band type hanger, Nelson hanger, clamp hanger assembled with mounting channel, poly-block twin clamp hanger, crimp-on weld stud-type hangers, banded weld stud-type hanger, and poly-block single-clamp hanger. Guidance in determining pipe hanger spacing are provided. Special consideration should be given to areas of concentrated loads, such as risers, valves, or groups of fittings, and to piping configurations that could create rotational forces. Hangers need not be lined unless the hanger and pipe are of dissimilar material. All hanger bolts within tanks or other inaccessible areas shall be secured with lock nuts, lock washers, or by some other means. Pipe hangers and standoffs located in areas subject to corrosion, such as in bilges, ballast tanks, and areas exposed to the weather, should be zinc-plated or blasted and coated with inorganic zinc or coated with the same material as that of the surrounding area. Standoffs fabricated from pipe should not be used within tanks. Consideration should be given to thermal growth of the piping when selecting or locating hangers so as not to overstress the piping or hangers.

SCOPE

1.1 This practice covers acceptable methods of fabricating and installing rigid pipe hangers used to support shipboard piping systems with temperatures of 650°F (343°C) or less.

1.2 This practice provides guidance for the design of hanger caps, straps and standoffs, selection of hanger and hanger liner materials, hanger bolting, and hanger spacing.

1.3 Other hanger designs may be used provided they result in an adequately supported vibration-free piping system and are compatible with the intended system service and temperature limitations.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F708 − 92 (Reapproved 2014) An American National Standard

Standard Practice for

1

Design and Installation of Rigid Pipe Hangers

ThisstandardisissuedunderthefixeddesignationF708;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice covers acceptable methods of fabricating

and installing rigid pipe hangers used to support shipboard

2. Referenced Documents

piping systems with temperatures of 650°F (343°C) or less.

2

2.1 ASTM Standards:

1.2 This practice provides guidance for the design of hanger

A307 Specification for Carbon Steel Bolts, Studs, and

caps, straps and standoffs, selection of hanger and hanger liner

Threaded Rod 60 000 PSI Tensile Strength

materials, hanger bolting, and hanger spacing.

3. Terminology

1.3 Other hanger designs may be used provided they result

3.1 Definitions:

in an adequately supported vibration-free piping system and

3.1.1 liner—the material used to isolate a pipe from its

are compatible with the intended system service and tempera-

hanger.

ture limitations.

3.1.2 rider bar—a protective strip of material installed

1.4 The values stated in inch-pound units are to be regarded

between the pipe and the hanger where frequent linear move-

as the standard. The values given in parentheses are for

ment of the pipe is expected.

information only.

3.1.3 rigid pipe hanger—a device that transfers the load

1.5 This standard does not purport to address all of the

imposed by the piping, insulation, and system medium to the

safety concerns, if any, associated with its use. It is the

supporting structure.

responsibility of the user of this standard to establish appro-

3.1.4 standoff—the rigid member that connects the hanger

strap, saddle, or band to the supporting structure. A standoff is

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

2

Machinery and Piping Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2014. Published September 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2008 as F708 – 92 (2008). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F0708-92R14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F708 − 92 (2014)

usually made up of one or more pieces of flat bar, pipe, angle 5. Hanger Designs

bar, or flanged plate to suit a specific location.

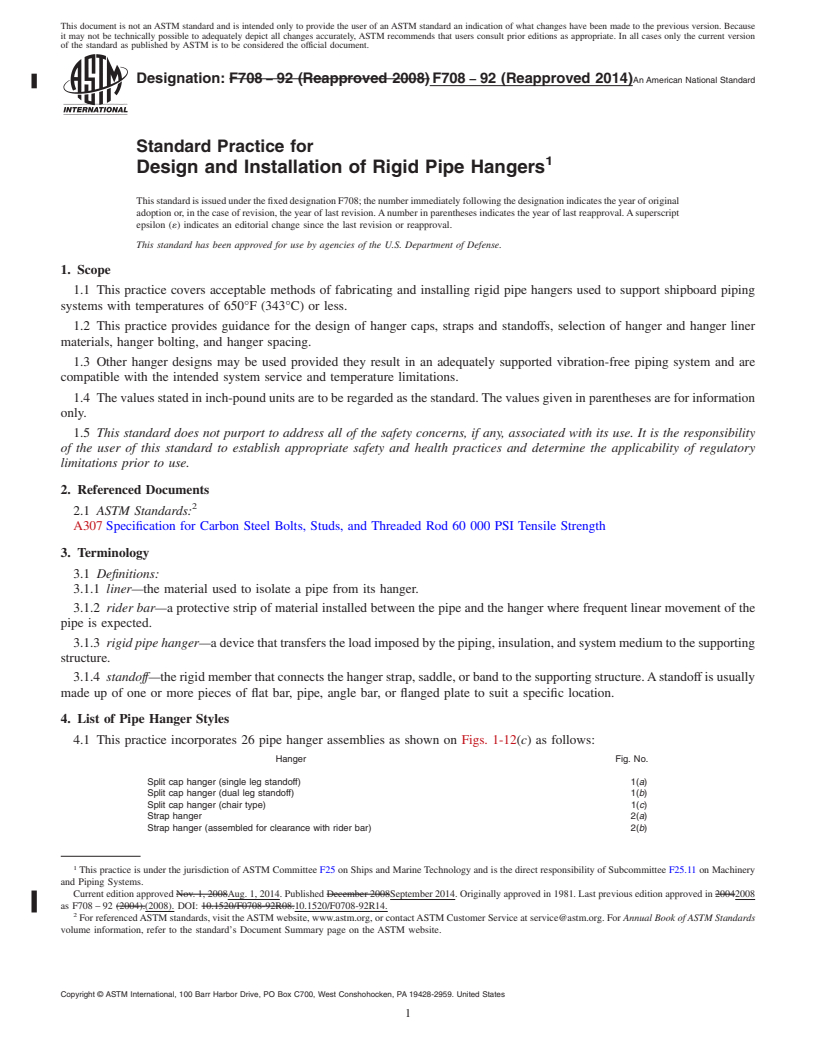

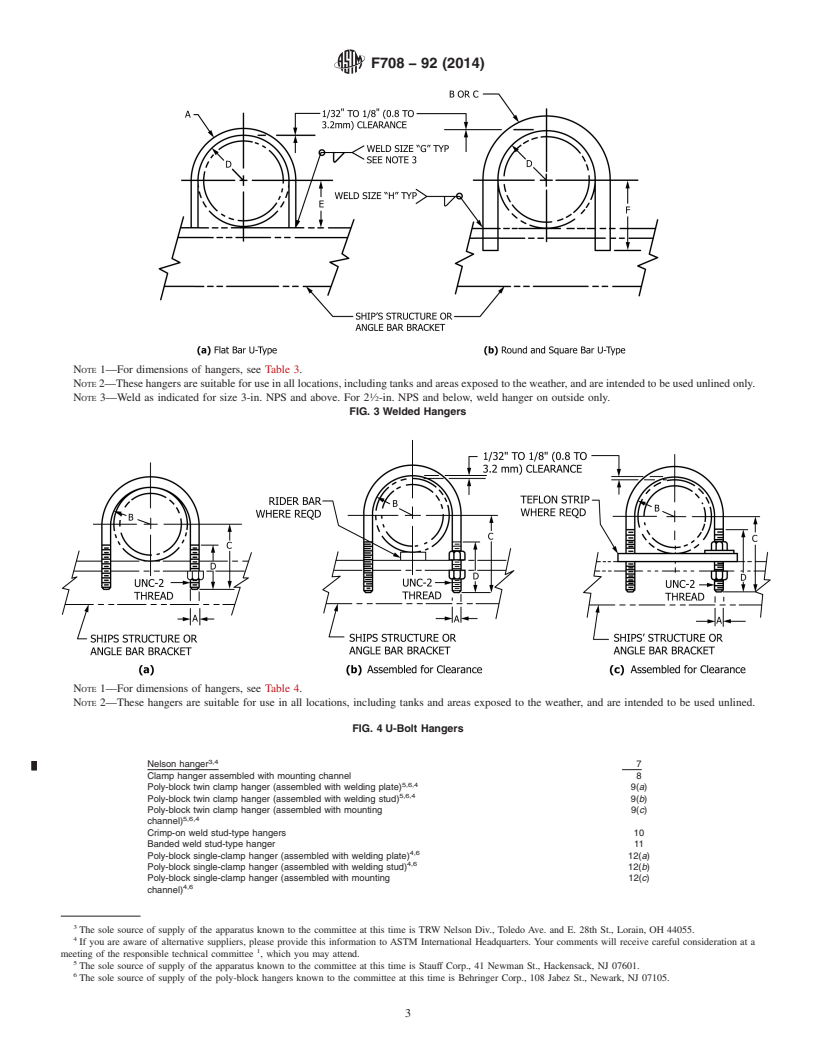

5.1 Figs. 1-5 and Fig. 6(a) hangers are designs generally

4. List of Pipe Hanger Styles manufactured by shipyards or their subcontractors. See also

Tables 1-6.

4.1 This practice incorporates 26 pipe hanger assemblies as

shown on Figs. 1-12(c) as follows:

5.2 Fig. 6, Fig. 8, Fig. 10, and Fig. 11 hangers are commer-

cially available from various vendors. Fig. 8, Fig. 10, and Fig.

Hanger Fig. No.

11 hangers are primarily designed for use in supporting

Split cap hanger (single leg standoff) 1(a)

electrical cables, but are suitable for hanging small size pipe

Split cap hanger (dual leg standoff) 1(b)

and tubing.

Split cap hanger (chair type) 1(c)

3,4

Strap hanger 2(a)

5.2.1 The Fig. 7 hanger is a specific design that has been

Strap hanger (assembled for clearance with rider bar) 2(b)

patented by Nelson Division of TRW.

Strap hanger (assembled for clearance with TFE-fluorocarbon 2(c)

5,6,4

strip)

5.2.2 The Fig. 9 and Fig. 12 hangers are primarily

Welded hanger (flat bar U-type) 3(a)

designed for use when supporting multiple runs of pipe or

Welded hanger (round bar U-type) 3(b)

Welded hanger (square bar U-type) 3(b) tubing.

U-bolt hanger 4(a)

U-bolt hanger (assembled for clearance with rider bar) 4(b)

6. Materials and Manufacture

U-bolt hanger (assembled for clearance with TFE-fluorocarbon 4(c)

strip)

6.1 Hanger materials for straps, saddles, and U-bolts for

Welded hanger (single leg standoff welded direct to pipe) 5(a)

Welded hanger (dual leg standoff welded direct to pipe) 5(b) Figs. 1-5 hangers and standoffs should be fabricated from

“J” band type hanger (insulated pipe) 6(a)

commercial quality carbon steel. The steel should be a weld-

“J” band type hanger (bare pipe) 6(b)

3,4 able grade wit

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F708 − 92 (Reapproved 2008) F708 − 92 (Reapproved 2014)An American National Standard

Standard Practice for

1

Design and Installation of Rigid Pipe Hangers

This standard is issued under the fixed designation F708; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice covers acceptable methods of fabricating and installing rigid pipe hangers used to support shipboard piping

systems with temperatures of 650°F (343°C) or less.

1.2 This practice provides guidance for the design of hanger caps, straps and standoffs, selection of hanger and hanger liner

materials, hanger bolting, and hanger spacing.

1.3 Other hanger designs may be used provided they result in an adequately supported vibration-free piping system and are

compatible with the intended system service and temperature limitations.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A307 Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength

3. Terminology

3.1 Definitions:

3.1.1 liner—the material used to isolate a pipe from its hanger.

3.1.2 rider bar—a protective strip of material installed between the pipe and the hanger where frequent linear movement of the

pipe is expected.

3.1.3 rigid pipe hanger—a device that transfers the load imposed by the piping, insulation, and system medium to the supporting

structure.

3.1.4 standoff—the rigid member that connects the hanger strap, saddle, or band to the supporting structure. A standoff is usually

made up of one or more pieces of flat bar, pipe, angle bar, or flanged plate to suit a specific location.

4. List of Pipe Hanger Styles

4.1 This practice incorporates 26 pipe hanger assemblies as shown on Figs. 1-12(c) as follows:

Hanger Fig. No.

Split cap hanger (single leg standoff) 1(a)

Split cap hanger (dual leg standoff) 1(b)

Split cap hanger (chair type) 1(c)

Strap hanger 2(a)

Strap hanger (assembled for clearance with rider bar) 2(b)

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved Nov. 1, 2008Aug. 1, 2014. Published December 2008September 2014. Originally approved in 1981. Last previous edition approved in 20042008

as F708 – 92 (2004).(2008). DOI: 10.1520/F0708-92R08.10.1520/F0708-92R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F708 − 92 (2014)

NOTE 1—For dimensions of hangers, see Table 1.

NOTE 2—These hangers are suitable for use in all locations, including tanks and areas exposed to the weather, and can be used lined or unlined.

NOTE 3—For Fig. 1(b), length of standoff legs may be unequal and angle of attachment may vary as required to suit conditions.

NOTE 4—Maximum length of standoff “L” shall be as follows: flat bar = 18 in.; pipe = 30 in.; and angle bar = 42 in.

FIG. 1 Split Cap Hangers

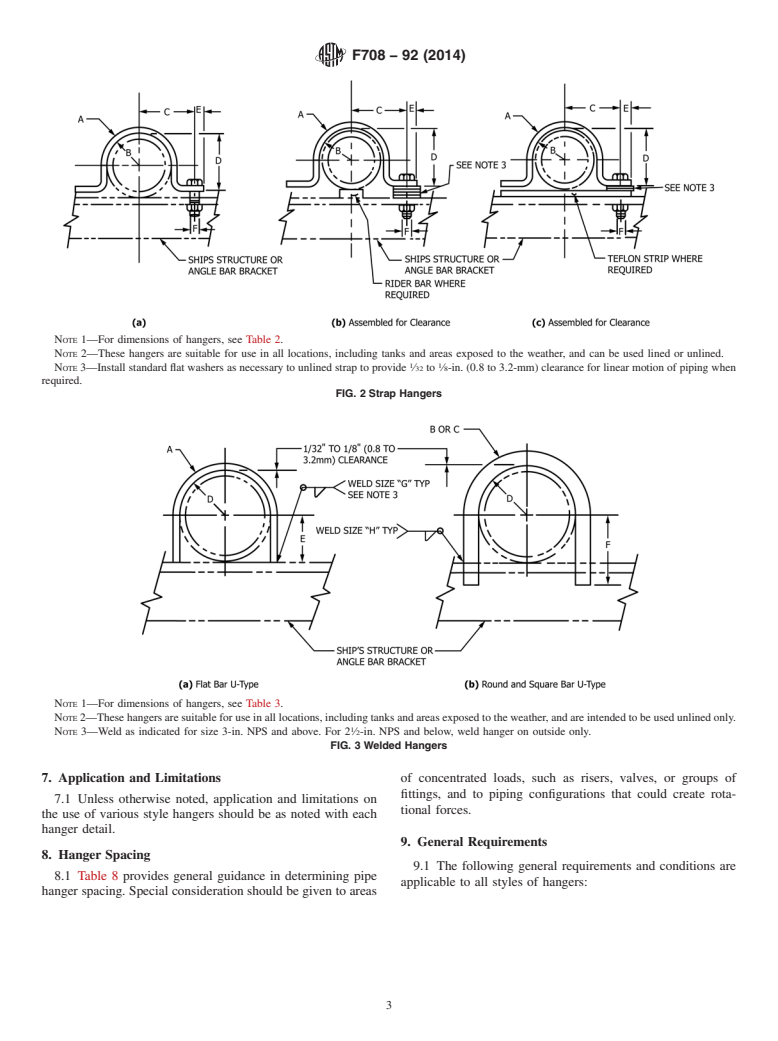

NOTE 1—For dimensions of hangers, see Table 2.

NOTE 2—These hangers are suitable for use in all locations, including tanks and areas exposed to the weather, and can be used lined or unlined.

1 1

NOTE 3—Install standard flat washers as necessary to unlined strap to provide ⁄32 to ⁄8-in. (0.8 to 3.2-mm) clearance for linear motion of piping when

required.

FIG. 2 Strap Hangers

Strap hanger (assembled for clearance with TFE-fluorocarbon 2(c)

strip)

Welded hanger (flat bar U-type) 3(a)

Welded hanger (round bar U-type) 3(b)

Welded hanger (square bar U-type) 3(

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.