ASTM B807/B807M-13

(Practice)Standard Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

Standard Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

ABSTRACT

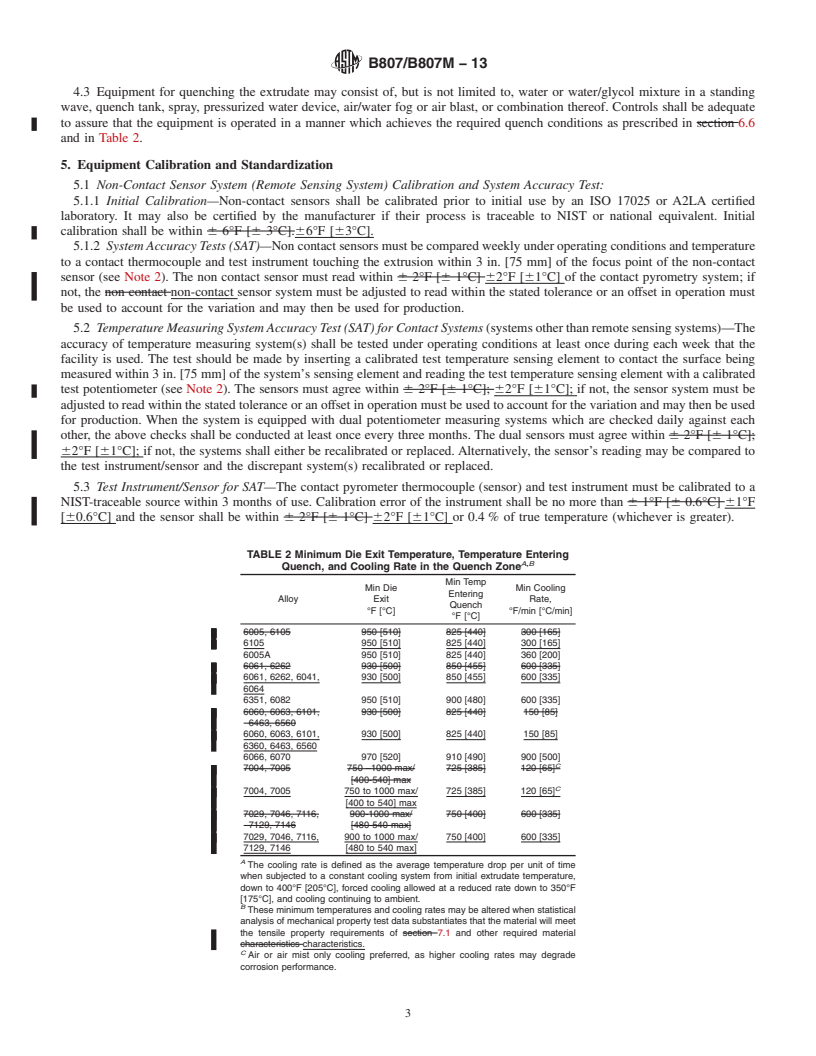

This practice covers the controls required and standards for extrusion press solution heat treatment for 6xxx and 7xxx series aluminum alloys. For alloys such as 6005, 6005A and 6105 alloys, this practice is an alternative to solution heat treatment in a furnace. This practice only applies to extrusion press solution heat treatment for aluminum alloys and does not cover precipitation hardening (aging) processing. The alloy billets shall be preheated prior to being extruded. Heating methods shall include, but not limited to, induction, flame impingement, or forced air. Pertinent control points shall include billet or log temperature in the heating equipment, billet temperature upon being charged into the press container, container temperature, ram speed, profile configuration, extrudate temperature upon exiting the press platen, extrudate temperature at quench entry, quench media temperature, and quench rate.

SCOPE

1.1 This practice establishes the controls required for extrusion press solution heat treatment of the 6xxx and 7xxx series aluminum alloys in Table 1 when ASTM material specifications allow use of this process in lieu of furnace solution heat treatment. For the alloys listed in Table 1, this practice is an alternate process to solution heat treatment in a furnace, such as specified in Practice B918/B918M for the attainment of T3, T4, T6, T7, T8 and T9-type tempers (see ANSI H35.1/H35.1M).

1.2 This practice applies only to extrusion press solution heat treatment for aluminum alloys. Precipitation hardening (aging) processing and equipment calibration shall meet the practice and requirements of Practice B918/B918M.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The SI units are shown in brackets or in separate tables. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B807/B807M − 13

Standard Practice for

Extrusion Press Solution Heat Treatment for Aluminum

1

Alloys

This standard is issued under the fixed designation B807/B807M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope* 2.2 ASTM Standards:

B557 Test Methods for Tension Testing Wrought and Cast

1.1 This practice establishes the controls required for extru-

Aluminum- and Magnesium-Alloy Products

sion press solution heat treatment of the 6xxx and 7xxx series

B557M Test Methods for Tension Testing Wrought and Cast

aluminum alloys in Table 1 when ASTM material specifica-

Aluminum- and Magnesium-Alloy Products (Metric)

tions allow use of this process in lieu of furnace solution heat

B647 Test Method for Indentation Hardness of Aluminum

treatment. For the alloys listed in Table 1, this practice is an

Alloys by Means of a Webster Hardness Gage

alternate process to solution heat treatment in a furnace, such

B648 Test Method for Indentation Hardness of Aluminum

as specified in Practice B918/B918M for the attainment of T3,

Alloys by Means of a Barcol Impressor

T4, T6, T7, T8 and T9-type tempers (see ANSI H35.1/

B881 Terminology Relating toAluminum- and Magnesium-

H35.1M).

Alloy Products

1.2 This practice applies only to extrusion press solution

B918/B918M Practice for Heat Treatment of Wrought Alu-

heat treatment for aluminum alloys. Precipitation hardening

minum Alloys

(aging) processing and equipment calibration shall meet the

E10 Test Method for Brinell Hardness of Metallic Materials

practice and requirements of Practice B918/B918M.

E18 Test Methods for Rockwell Hardness of Metallic Ma-

terials

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The SI units are E2281 Practice for Process and Measurement Capability

Indices

shown in brackets or in separate tables. The values stated in

2

each system may not be exact equivalents; therefore, each

2.3 ASTM Manual:

system shall be used independently of the other. Combining

ASTM MNL 7 Manual on Presentation of Data and Control

values from the two systems may result in non-conformance

Chart Analysis

with the standard.

3

2.4 ANSI Standard:

1.4 This standard does not purport to address all of the

H35.1/H35.1M Alloy and Temper Designation Systems for

safety concerns, if any, associated with its use. It is the

Aluminum

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions—Refer to Terminology B881 for definitions

of product terms used in this specification.

2. Referenced Documents

3.1.1 extrudate, n—material exiting an extrusion die subject

2.1 The following documents of the issue in effect on the

to further processing (quenching, stretching, cutting), to be-

dateofmaterialpurchaseformapartofthisspecificationtothe come an extruded profile.

extent referenced herein:

3.1.2 extrusion billet, n—solid or hollow form, commonly

cylindrical, used as the final length of material charged into the

extrusion press cylinder, and is usually a cast product, but may

be a wrought product or sintered from powder compact.

1 2

This practice is under the jurisdiction of ASTM Committee B07 on Light For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Aluminum Alloy Wrought Products. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJune1,2013.PublishedJuly2013.Originallyapproved the ASTM website.

3

in 1990. Last previous edition approved in 2006 as B807/B807M – 06. DOI: Available from Aluminum Association, Inc., 1525 Wilson Blvd., Suite 600,

10.1520/B0807_B0807M-13. Arlington, VA 22209, http://www.aluminum.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B807/B807M − 13

A

TABLE 1 Extrusion Billet or Log Temperature High Limit heating equipment used, and the starting microstructure of the billet/log.

Some heating equipment achieves very rapid temperature rise and may

Billet or Log Temperature

Alloy

require the metal to be soaked for a period to ensure that sufficient

Upper °F [Upper °C]

applicable alloying elements are taken into solid solution. This soaking

6005A, 6105 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B807/B807M − 06 B807/B807M − 13

Standard Practice for

Extrusion Press Solution Heat Treatment for Aluminum

1

Alloys

This standard is issued under the fixed designation B807/B807M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice establishes the controls required for extrusion press solution heat treatment of the 6xxx and 7xxx series

aluminum alloys in Table 1 when ASTM material specifications allow use of this process in lieu of furnace solution heat treatment.

For the alloys listed in Table 1, this practice is an alternate process to solution heat treatment in a furnace, such as specified in

Practice B918B918/B918M for the attainment of T3, T4, T6, T7, T8 and T9-type tempers (see ANSI H35.1).H35.1/H35.1M).

1.2 This practice applies only to extrusion press solution heat treatment for aluminum alloys. Precipitation hardening (aging)

processing and equipment calibration shall meet the practice and requirements of Practice B918B918/B918M.

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standards.standard. The

SI units are shown in brackets or in separate tables. The values stated in each system aremay not be exact equivalents; therefore,

each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with

the practice.standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B557M Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric)

B647 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage

B648 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

B918B918/B918M Practice for Heat Treatment of Wrought Aluminum Alloys

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E2281 Practice for Process and Measurement Capability Indices

2

2.3 ASTM Manual:

ASTM MNL 7 Manual on Presentation of Data and Control Chart Analysis

3

2.4 ANSI Standards:Standard:

H35.1H35.1/H35.1M Alloy and Temper Designation Systems for Aluminum

H35.1M Alloy and Temper Designation Systems for Aluminum [Metric]

1

This practice is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum Alloy

Wrought Products.

Current edition approved March 15, 2006June 1, 2013. Published March 2006July 2013. Originally approved in 1990. Last previous edition approved in 20022006 as

B807 – 02.B807/B807M – 06. DOI: 10.1520/B0807_B0807M-06.10.1520/B0807_B0807M-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.Aluminum Association, Inc., 1525 Wilson Blvd., Suite

600, Arlington, VA 22209, http://www.aluminum.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B807/B807M − 13

A

TABLE 1 Extrusion Billet or Log Temperature High Limit

Billet or Log Temperature

Alloy

Upper °F [Upper °C]

6005, 6005A, 6105 1050 565

6005A, 6105 1050 565

6061, 6262 1050 565

6061, 6262, 6041, 6064 1050 565

6060, 6063, 6101, 1060 570

6463, 6360, 6560

6351, 6082, 1050 565

6066, 6070 1020 550

7004, 7005 1000 540

7029, 704

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.