ASTM E1135-97(2008)e1

(Test Method)Standard Test Method for Comparing the Brightness of Fluorescent Penetrants

Standard Test Method for Comparing the Brightness of Fluorescent Penetrants

SCOPE

1.1 This test method describes the techniques for comparing the brightness of the penetrants used in the fluorescent dye penetrant process. This comparison is performed under controlled conditions which eliminate most of the variables present in actual penetrant examination. Thus, the brightness factor is isolated and is measured independently of the other factors which affect the performance of a penetrant system.

1.2 The brightness of a penetrant indication is dependent on the developer with which it is used. This test method however, measures the brightness of a penetrant on a convenient filter paper substrate which serves as a substitute for the developer.

1.3 The brightness measurement obtained is color-corrected to approximate the color response of the average human eye. Since most examination is done by human eyes, this number has more practical value than a measurement in units of energy emitted. Also, the comparisons are expressed as a percentage of some chosen standard penetrant because no absolute system of measurement exists at this time.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1135 – 97 (Reapproved 2008)

Standard Test Method for

Comparing the Brightness of Fluorescent Penetrants

This standard is issued under the fixed designation E1135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Added Note 1 and Note 3 in July 2008.

1. Scope 3.1.1 Definitionsoftermsapplicabletothistestmethodmay

be found in Terminology E1316.

1.1 Thistestmethoddescribesthetechniquesforcomparing

the brightness of the penetrants used in the fluorescent dye

4. Summary of Test Method

penetrant process. This comparison is performed under con-

4.1 Simulated indications are prepared by impregnating

trolledconditionswhicheliminatemostofthevariablespresent

filterpaperwithaspecifiedquantityofthepenetrantundertest.

in actual penetrant examination. Thus, the brightness factor is

The samples and similarly prepared standards are then mea-

isolated and is measured independently of the other factors

sured in a fluorometer equipped to excite the penetrant with

which affect the performance of a penetrant system.

near ultraviolet (black) light and respond to color approxi-

1.2 The brightness of a penetrant indication is dependent on

mately as does the human eye under the conditions encoun-

the developer with which it is used. This test method however,

tered during a normal examination. The fluorometer must be

measures the brightness of a penetrant on a convenient filter

equipped with a special sample holder to accept the samples

paper substrate which serves as a substitute for the developer.

employed.

1.3 The brightness measurement obtained is color-corrected

4.2 The sample preparation is not indicative of the total

to approximate the color response of the average human eye.

system performance but is convenient as a lot acceptance test.

Since most examination is done by human eyes, this number

A known amount of penetrant is diluted with a specified

has more practical value than a measurement in units of energy

amountofavolatilesolvent,piecesoffilterpaperaresoakedin

emitted.Also,thecomparisonsareexpressedasapercentageof

the mixture, the paper is dried under specified conditions at

some chosen standard penetrant because no absolute system of

room temperature, placed in the sample holder, and measured

measurement exists at this time.

with the fluorometer.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The penetrant is one of the major components of the

priate safety and health practices and determine the applica-

fluorescentpenetrantprocess,andveryinfluentialinthedegree

bility of regulatory limitations prior to use.

of performance attained by a given system or group of

materials. The penetrant must enter the discontinuity, be

2. Referenced Documents

removed from the part surface but not from the discontinuity,

2.1 ASTM Standards:

bebroughtoutofthediscontinuitybythedeveloper,andfinally

E691 Practice for Conducting an Interlaboratory Study to

viewed and detected by the inspector. If all processing param-

Determine the Precision of a Test Method

eters are optimized for the parts being examined and the

E1316 Terminology for Nondestructive Examinations

examination materials in use, the intrinsic brightness of the

3. Terminology penetrant becomes the factor which governs the sensitivity of

the system.

3.1 Definitions:

5.2 Because the eye responds logarithmically rather than

linearly to changes of brightness, differences in brightness

This test method is under the jurisdiction of ASTM Committee E07 on

must be fairly large to be significant. Differences of 25 % are

Nondestructive Testing and is the direct responsibility of Subcommittee E07.03 on

obvious, 12 % noticeable, and 6 % detectable by the eye.

Liquid Penetrant and Magnetic Particle Methods.

Experts may sometimes detect 3 % differences, but these are

Current edition approved July 1, 2008. Published September 2008. Originally

approved in 1986. Last previous edition approved in 2003 as E1135 – 97 (2003).

not usually significant to the average observer.

DOI: 10.1520/E1135-97R08E01.

5.3 The significance of the results also depends on the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

deviation between readings on the same material sample.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Different samples, even when prepared out of the same initial

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E1135 – 97 (2008)

quantity of penetrant will not exactly reproduce readings. 6.4 Paper Drying Holders—“Crocodile” type battery clips

These differences occur because of paper differences and 2 in. long with ⁄2 in. opening have been found satisfactory. Set

penetrant migration on the paper samples. up holders to allow drying inside desiccator.

5.4 To determine the confidence limits for the test results, it 6.5 Methylene Chloride or Acetone, technical grade.

is necessary to perform certain statistical calculations. The 6.6 Desiccator, 250-mm diameter or larger.

confidence limits are determined by the equation: 6.7 Silica Gel, for use as desiccant.

¯

CL 5 X 6 ts/ n (1)

=

7. Sample Preparation

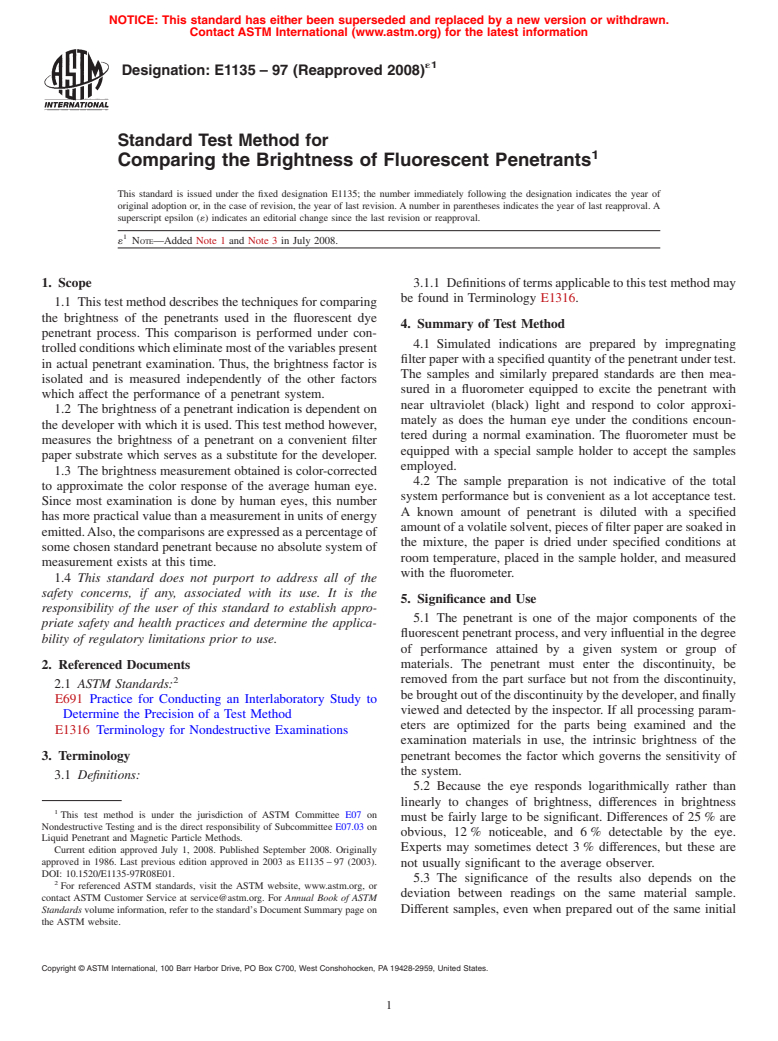

FIG. 1 Turner Fluorometer, with Door Open Showing Sample Holder and Filters in Place

7.1 Sample Preparation—Normally a set of samples of a

where:

standard material must be prepared along with any test

CL = the limits within which we can be confident the value

samples.

lies,

¯

X = the average of all readings, 7.1.1 Pipet 1.0 mL of chosen penetrant into a 25-mL

t = “student’s t” (values of which are given by statistical stoppered volumetric flask.

manuals), 7.1.2 Fill flask to line with methylene chloride, stopper and

n = the number of readings used,

mix. (If penetrant is not soluble in methylene chloride, use

s = the standard deviation determined by the equation:

acetone.)

¯

7.1.3 Pour 10 to 20 mL of mixture into a 50-mL beaker.

( X 2 X!

~

S 5 (2)

Œ

7.1.4 Using forceps, dip 4 papers (cut to size for sample

n 2 1

holder in use), one at a time, into beaker, withdraw by drawing

across the lip of the beaker to remove excess liquid, and clip

where:

into paper drying holder. Holder shall cover as small an area of

X = the individual readings.

paper as possible.

7.1.5 Hang papers in a vertical position inside desiccator

In this use, the 95 % confidence level (the value will lie within

until dry. This will require approximately 5 min at room

the limits 95 % of the time) is sufficient. At this level, t for 4

temperature.

samples is 3.182.

5.4.1 If the confidence limits of two material samples

8. Procedure for Turner Fluorometer

overlap, the materials must be considered equal even though

NOTE 1—This instrument is no longer in production and can not be

the measured average values are different.

purchased from Turner.

NOTE 2—All available apparatus may not be suitable for these appli-

6. Apparatus

cations.

6.1 Filter Paper,Whatman#4,afast,openstructuredpaper.

8.1 Sample Holder, designed for the fluorometer in use.

6.2 Pipets, 1-mL capacity.

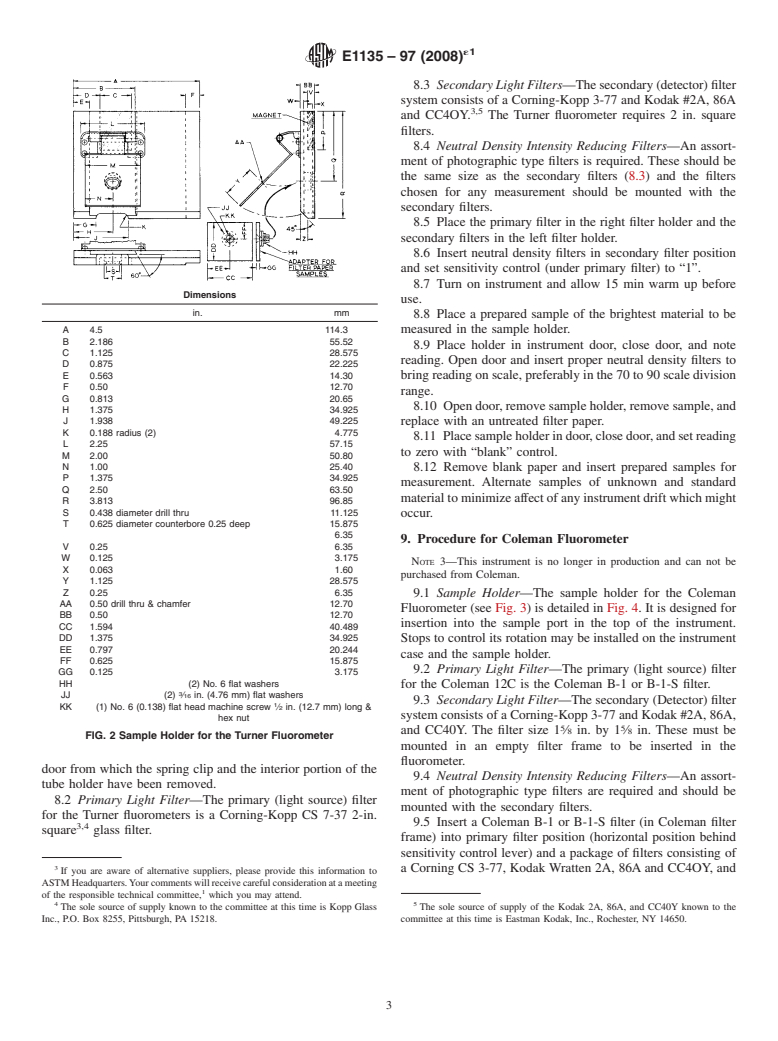

8.1.1 The sample holder for the Turner Fluorometers (see

6.3 Volumetric Flasks, with stopper, 25-mL. Fig.1)isdetailedinFig.2.Itisdesignedforuseinthestandard

´1

E1135 – 97 (2008)

8.3 Secondary Light Filters—Thesecondary(detector)filter

system consists of a Corning-Kopp 3-77 and Kodak #2A, 86A

,

3 5

and CC4OY. The Turner fluorometer requires 2 in. square

filters.

8.4 Neutral Density Intensity Reducing Filters—An assort-

ment of photographic type filters is required. These should be

the same size as the secondary filters (8.3) and the filters

chosen for any measurement should be mounted with the

secondary filters.

8.5 Place the primary filter in the right filter holder and the

secondary filters in the left filter holder.

8.6 Insert neutral density filters in secondary filter position

and set sensitivity control (under primary filter) to “1”.

8.7 Turn on instrument and allow 15 min warm up before

Dimensions

use.

in. mm

8.8 Place a prepared sample of the brightest material to be

A 4.5 114.3 measured in the sample holder.

B 2.186 55.52

8.9 Place holder in instrument door, close door, and note

C 1.125 28.575

reading. Open door and insert proper neutral density filters to

D 0.875 22.225

E 0.563 14.30 bring reading on scale, preferably in the 70 to 90 scale division

F 0.50 12.70

range.

G 0.813 20.65

8.10 Opendoor,removesampleholder,removesample,and

H 1.375 34.925

J 1.938 49.225

replace with an untreated filter paper.

K 0.188 radius (2) 4.775

8.11 Placesampleholderindoor,closedoor,andsetreading

L 2.25 57.15

to zero

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.