ASTM C1446-07

(Test Method)Standard Test Method for Measuring Consistency of Self-Flowing Castable Refractories

Standard Test Method for Measuring Consistency of Self-Flowing Castable Refractories

SIGNIFICANCE AND USE

This test method is used to measure the consistency (degree of self-flow) that a castable refractory demonstrates at a given level of tempering liquid at specified time intervals after the liquid is added. A self-flow of 25 % has been selected as the minimum at which a mix can be poured into typical molds or forms in normal practice.

Castable refractories which are self-flowing at one level of tempering liquid will require vibration for placement at some lower level of tempering liquid. At the tempering liquid levels which require vibration or tamping for placement, the castable refractory should be characterized using test methods which are appropriate for castable refractories designed for vibration placement, such as Test Method C 1445.

This test method is not appropriate for determining the pumpability of castable refractories.

SCOPE

1.1 This test method covers the determination of the consistency (degree of self-flow) and working time of self-flowing castable refractories. This test may optionally be used to determine working time of self-flowing castables.

1.2 The values stated in inch-lb. units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1446–07

Standard Test Method for

Measuring Consistency of Self-Flowing Castable

1

Refractories

This standard is issued under the fixed designation C1446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 working time of self-flowing castable refractories—

the elapsed time from the first addition of liquid during mixing

1.1 This test method covers the determination of the con-

until the mix will only achieve 25 % self-flow using the

sistency (degree of self-flow) and working time of self-flowing

procedure described in this test method.

castable refractories. This test may optionally be used to

determine working time of self-flowing castables.

4. Summary of Test Method

1.2 The values stated in inch-lb. units are to be regarded as

4.1 The castable refractory is mixed with a tempering liquid

the standard. The values given in parentheses are for informa-

and the percentage of self-flow is measured. Self-flow is the

tion only.

percent increase in the diameter of the sample after removing

1.3 This standard does not purport to address all of the

the Specification C230/C230M cone mold and allowing the

safety concerns, if any, associated with its use. It is the

specimen to flow (spread) under it own weight for 120 s. The

responsibility of the user of this standard to establish appro-

consistency is measured 10 min after water addition. Working

priate safety and health practices and determine the applica-

time may optionally be determined by repeating the self flow

bility of regulatory limitations prior to use.

test at regular time intervals.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards:

5.1 This test method is used to measure the consistency

C71 Terminology Relating to Refractories

(degree of self-flow) that a castable refractory demonstrates at

C230/C230M Specification for Flow Table for Use in Tests

a given level of tempering liquid at specified time intervals

of Hydraulic Cement

after the liquid is added.Aself-flow of 25 % has been selected

C860 Practice for Determining the Consistency of Refrac-

as the minimum at which a mix can be poured into typical

tory Castable Using the Ball-In-Hand Test

molds or forms in normal practice.

C862 Practice for Preparing Refractory Concrete Speci-

5.2 Castable refractories which are self-flowing at one level

mens by Casting

of tempering liquid will require vibration for placement at

C1445 Test Method for Measuring Consistency of Castable

some lower level of tempering liquid. At the tempering liquid

Refractory Using a Flow Table

levels which require vibration or tamping for placement, the

3. Terminology castable refractory should be characterized using test methods

which are appropriate for castable refractories designed for

3.1 Definitions of Terms Specific to This Standard:

vibration placement, such as Test Method C1445.

3.1.1 consistency of self-flowing castable refractories—the

5.3 This test method is not appropriate for determining the

degree of mobility (self-flow) of the refractory castable under

pumpability of castable refractories.

its own weight as described in this test method at the specified

times after adding liquid to the mixer.

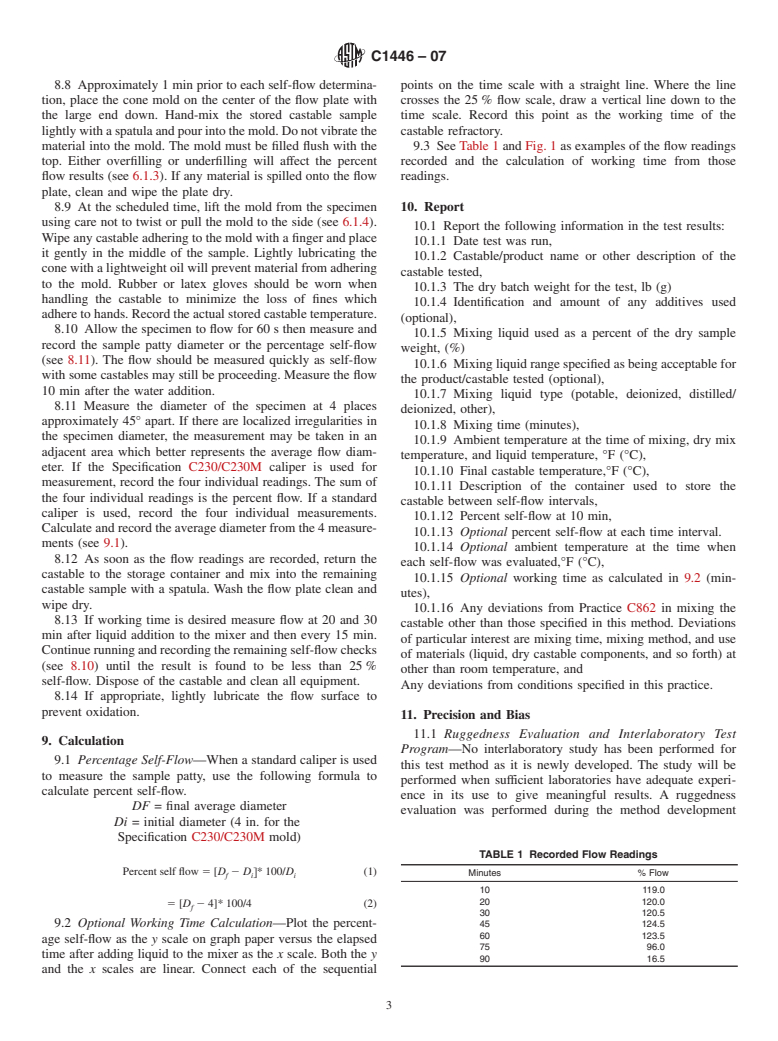

6. Interferences (Factors Known to Affect Results)

6.1 During method development, a ruggedness evaluation

1

This test method is under the jurisdiction of ASTM Committee C08 on

was performed using a castable comprised of 5 % cement,

Refractories and is the direct responsibility of Subcommittee C08.09 on Monolith-

17 % reactive alumina, and 78 % tabular alumina. Several

ics.

factors were found to cause statistically significant effects on

Current edition approved March 1, 2007. Published April 2007. Originally

the measured results. See ASTM Research Report No.

approved in 1999. Previous edition approved in 1999 as C1446 – 99. DOI:

10.1520/C1446-07.

C08–1016.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1 Amount of Mixing Liquid—The amount of mixing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

liquid affects the measured results for typical self-flowing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. castable refractories unless added by weight to within 6 0.002

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1446–07

lb (6 1 g) of the target weight for a 16.52–lb (7500-g) sample from oxidation. A galvanized or stainless steel or other non-

weight.The target liquid level is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.