ASTM G143-03(2018)

(Test Method)Standard Test Method for Measurement of Web/Roller Friction Characteristics

Standard Test Method for Measurement of Web/Roller Friction Characteristics

SIGNIFICANCE AND USE

5.1 This test method is intended to simulate the slip of a flexible web on a roller in a machine or tribosystem that conveys web materials. Flexible webs such as plastic sheeting, paper, elastomers, metal foils, and cloth are often transported in manufacturing processes by combinations of driving and idler rollers. The friction characteristics of the web/roller interface often affects the web transport process. If the web/roller friction is too low, the web can slip on the rollers and be damaged or damage the roller. High friction on the other hand, can lead to steering problems and overloading of driving motors.

5.2 This test method can be used to rank rollers for their ability to resist slip versus a particular web material (high friction). Conversely this test method can assess web materials or web surface coatings such as waxes and lubricants. In this latter case, the goal may be a low-friction product made from a web (film, magnetic media, paper, and so forth).

5.3 If a tribosystem involves transport of a flexible web on a roller, this is an appropriate test to use to measure the friction characteristics of the roller/web couple.

SCOPE

1.1 This test method covers the simulation of a roller/web transport tribosystem and the measurement of the static and kinetic coefficient of friction of the web/roller couple when sliding occurs between the two. The objective of this test method is to provide users with web/roller friction information that can be used for process control, design calculations, and for any other function where web/roller friction needs to be known.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G143 − 03 (Reapproved 2018)

Standard Test Method for

1

Measurement of Web/Roller Friction Characteristics

This standard is issued under the fixed designation G143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Specified Precision, the Average for a Characteristic of a

Lot or Process

1.1 This test method covers the simulation of a roller/web

E177 Practice for Use of the Terms Precision and Bias in

transport tribosystem and the measurement of the static and

ASTM Test Methods

kinetic coefficient of friction of the web/roller couple when

E691 Practice for Conducting an Interlaboratory Study to

sliding occurs between the two. The objective of this test

Determine the Precision of a Test Method

method is to provide users with web/roller friction information

G40 Terminology Relating to Wear and Erosion

that can be used for process control, design calculations, and

G115 Guide for Measuring and Reporting Friction Coeffi-

for any other function where web/roller friction needs to be

cients

known.

G117 Guide for Calculating and Reporting Measures of

1.2 The values stated in SI units are to be regarded as

Precision Using Data from Interlaboratory Wear or Ero-

3

standard. No other units of measurement are included in this

sion Tests (Withdrawn 2016)

standard.

G163 Guide for Digital Data Acquisition in Wear and

3

1.3 This standard does not purport to address all of the Friction Measurements (Withdrawn 2016)

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.1 Definitions of Terms Specific to This Standard:

mine the applicability of regulatory limitations prior to use.

3.1.1 blocking, n—unintentional adhesion between plastic

1.4 This international standard was developed in accor-

films or between a film and another surface. D883

dance with internationally recognized principles on standard-

3.1.2 coeffıcient of friction, µ, n—in tribology—the dimen-

ization established in the Decision on Principles for the

sionlessratioofthefrictionforce(F)betweentwobodiestothe

Development of International Standards, Guides and Recom-

normal force (N) pressing these bodies together. G40

mendations issued by the World Trade Organization Technical

3.1.3 friction force, n—the resisting force tangential to the

Barriers to Trade (TBT) Committee.

interface between two bodies when, under the action of

external force, one body moves or tends to move relative to the

2. Referenced Documents

other. G40

2

2.1 ASTM Standards:

3.1.4 kinetic coeffıcient of friction, n—the coefficient of

D883 Terminology Relating to Plastics

friction under conditions of macroscopic relative motion be-

D1894 Test Method for Static and Kinetic Coefficients of

tween two bodies. G40

Friction of Plastic Film and Sheeting

D3108/D3108M Test Method for Coefficient of Friction, 3.1.5 stick-slip, n—a cyclic fluctuation in the magnitudes of

friction force and relative velocity between two elements in

Yarn to Solid Material

E8/E8M Test Methods for Tension Testing of Metallic Ma- sliding contact, usually associated with a relaxation oscillation

dependent on elasticity in the tribosystem and on a decrease of

terials

the coefficient of friction with onset of sliding or with increase

E122 Practice for Calculating Sample Size to Estimate,With

of sliding velocity. G40

3.1.5.1 Discussion—Classical or true stick-slip, in which

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

each cycle consists of a stage of actual stick followed by a

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

stage of overshoot slip, requires that the kinetic coefficient is

CurrenteditionapprovedJune1,2018.PublishedJuly2018.Originallyapproved

lower than the static coefficient.Amodified form of relaxation

in 1996. Last previous edition approved in 2013 as G143 – 03 (2013). DOI:

oscillation, with near-harmonic fluctuation in motion, can

10.1520/G0143-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive,

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G143 − 03 (Reapproved 2018)

Standard Test Method for

1

Measurement of Web/Roller Friction Characteristics

This standard is issued under the fixed designation G143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Specified Precision, the Average for a Characteristic of a

Lot or Process

1.1 This test method covers the simulation of a roller/web

E177 Practice for Use of the Terms Precision and Bias in

transport tribosystem and the measurement of the static and

ASTM Test Methods

kinetic coefficient of friction of the web/roller couple when

E691 Practice for Conducting an Interlaboratory Study to

sliding occurs between the two. The objective of this test

Determine the Precision of a Test Method

method is to provide users with web/roller friction information

G40 Terminology Relating to Wear and Erosion

that can be used for process control, design calculations, and

G115 Guide for Measuring and Reporting Friction Coeffi-

for any other function where web/roller friction needs to be

cients

known.

G117 Guide for Calculating and Reporting Measures of

1.2 The values stated in SI units are to be regarded as

Precision Using Data from Interlaboratory Wear or Ero-

standard. No other units of measurement are included in this 3

sion Tests (Withdrawn 2016)

standard.

G163 Guide for Digital Data Acquisition in Wear and

3

1.3 This standard does not purport to address all of the

Friction Measurements (Withdrawn 2016)

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.1 Definitions of Terms Specific to This Standard:

mine the applicability of regulatory limitations prior to use.

3.1.1 blocking, n—unintentional adhesion between plastic

1.4 This international standard was developed in accor-

films or between a film and another surface. D883

dance with internationally recognized principles on standard-

3.1.2 coeffıcient of friction, µ, n—in tribology—the dimen-

ization established in the Decision on Principles for the

sionless ratio of the friction force (F) between two bodies to the

Development of International Standards, Guides and Recom-

normal force (N) pressing these bodies together. G40

mendations issued by the World Trade Organization Technical

3.1.3 friction force, n—the resisting force tangential to the

Barriers to Trade (TBT) Committee.

interface between two bodies when, under the action of

external force, one body moves or tends to move relative to the

2. Referenced Documents

other. G40

2

2.1 ASTM Standards:

3.1.4 kinetic coeffıcient of friction, n—the coefficient of

D883 Terminology Relating to Plastics

friction under conditions of macroscopic relative motion be-

D1894 Test Method for Static and Kinetic Coefficients of

tween two bodies. G40

Friction of Plastic Film and Sheeting

3.1.5 stick-slip, n—a cyclic fluctuation in the magnitudes of

D3108/D3108M Test Method for Coefficient of Friction,

Yarn to Solid Material friction force and relative velocity between two elements in

sliding contact, usually associated with a relaxation oscillation

E8/E8M Test Methods for Tension Testing of Metallic Ma-

dependent on elasticity in the tribosystem and on a decrease of

terials

the coefficient of friction with onset of sliding or with increase

E122 Practice for Calculating Sample Size to Estimate, With

of sliding velocity. G40

3.1.5.1 Discussion—Classical or true stick-slip, in which

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear each cycle consists of a stage of actual stick followed by a

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

stage of overshoot slip, requires that the kinetic coefficient is

Current edition approved June 1, 2018. Published July 2018. Originally approved

lower than the static coefficient. A modified form of relaxation

in 1996. Last previous edition approved in 2013 as G143 – 03 (2013). DOI:

oscillation, with near-harmonic fluctuation in motion, can

10.1520/G0143-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G1

...

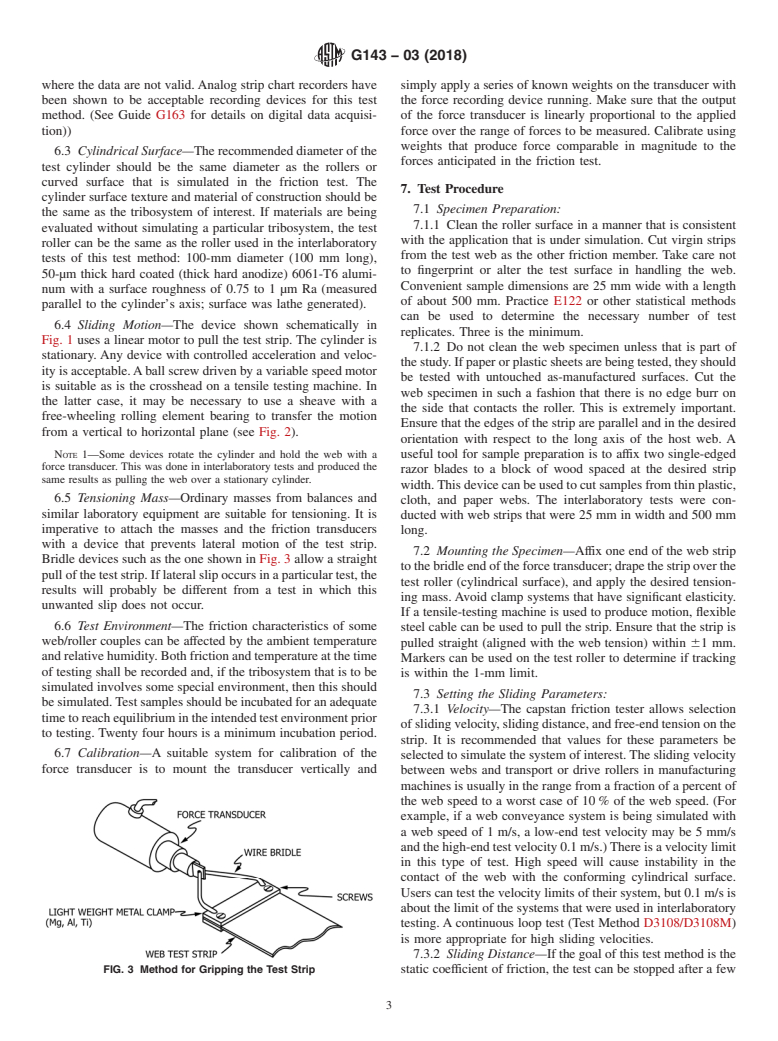

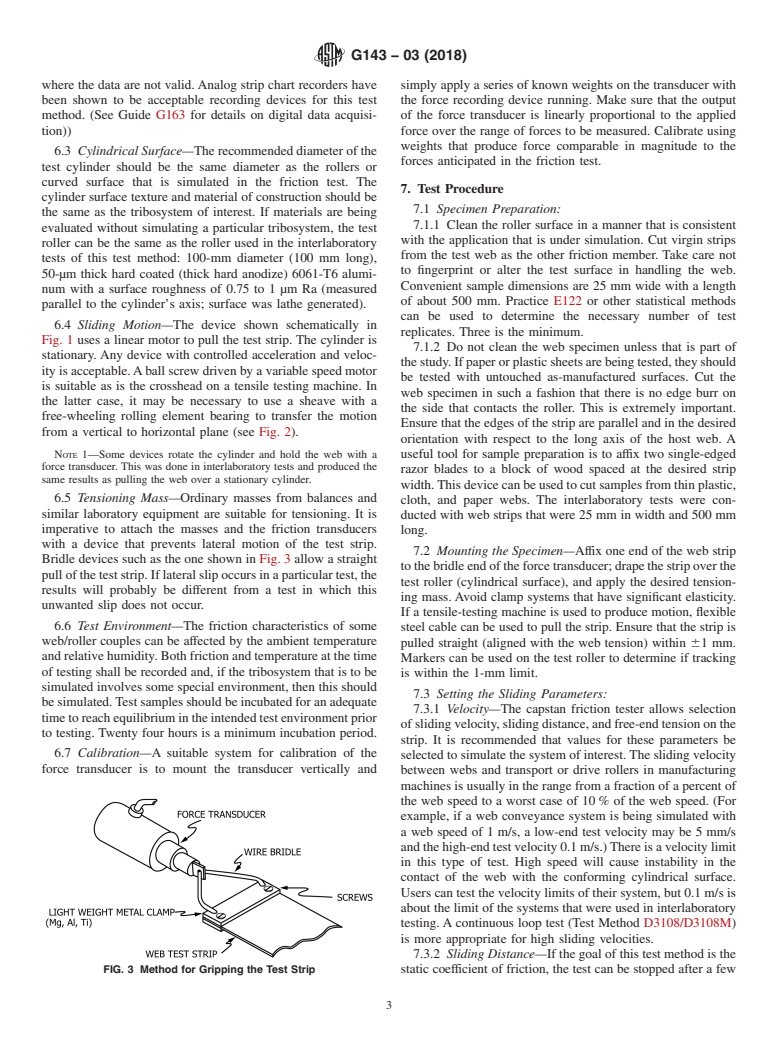

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G143 − 03 (Reapproved 2013) G143 − 03 (Reapproved 2018)

Standard Test Method for

1

Measurement of Web/Roller Friction Characteristics

This standard is issued under the fixed designation G143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the simulation of a roller/web transport tribosystem and the measurement of the static and kinetic

coefficient of friction of the web/roller couple when sliding occurs between the two. The objective of this test method is to provide

users with web/roller friction information that can be used for process control, design calculations, and for any other function

where web/roller friction needs to be known.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1894 Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

D3108D3108/D3108M Test Method for Coefficient of Friction, Yarn to Solid Material

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G40 Terminology Relating to Wear and Erosion

G115 Guide for Measuring and Reporting Friction Coefficients

G117 Guide for Calculating and Reporting Measures of Precision Using Data from Interlaboratory Wear or Erosion Tests

3

(Withdrawn 2016)

3

G163 Guide for Digital Data Acquisition in Wear and Friction Measurements (Withdrawn 2016)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 blocking, n—unintentional adhesion between plastic films or between a film and another surface. D883

3.1.2 coeffıcient of friction, μ, n—in tribology—the dimensionless ratio of the friction force (F) between two bodies to the

normal force (N) pressing these bodies together. G40

3.1.3 friction force, n—the resisting force tangential to the interface between two bodies when, under the action of external

force, one body moves or tends to move relative to the other. G40

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved Nov. 15, 2013June 1, 2018. Published November 2013July 2018. Originally approved in 1996. Last previous edition approved in 20092013 as

G143–03(2009).G143 – 03 (2013). DOI: 10.1520/G0143-03R13.10.1520/G0143-03R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G143 − 03 (2018)

3.1.4 kinetic coeffıcient of friction, n—the coefficient of friction under conditions of macroscopic relative motion between two

bodies. G40

3.1.5 stick-slip, n—a cyclic fluctuation in the magnitudes of friction force and relative velocity between two elements in sliding

contact, usually associated with a relaxation oscillation dependent on elasticity in the tribosystem and on a decrease of the

coefficient of fri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.