ASTM C42/C42M-99

(Test Method)Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

SCOPE

1.1 This test method covers obtaining, preparing, and testing (1) cores drilled from concrete for length or compressive or splitting tensile strength determinations and (2) beams sawed from concrete for flexural strength determinations.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 42/C 42M – 99 American Association State

Highway and Transportation Officials Standard

AASHTO No.: T24

Standard Test Method for

Obtaining and Testing Drilled Cores and Sawed Beams of

Concrete

This standard is issued under the fixed designation C 42/C 42M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Significance and Use

1.1 This test method covers obtaining, preparing, and test- 3.1 This test method provides standardized procedures for

ing (1) cores drilled from concrete for length or compressive or obtaining and testing specimens to determine the compressive,

splitting tensile strength determinations and ( 2) beams sawed tensile and flexural strength of in-place concrete. Sampling and

from concrete for flexural strength determinations. sample preparation requirements are given to ensure that

1.2 The values stated in either inch-pound units or SI units dimensional requirements are met and that the specimens are

shall be regarded separately as standard. SI units are shown in comprised of intact sound concrete as free of flaws as the

brackets. The values stated may not be exact equivalents, particular structure will allow.

therefore each system must be used independently of the other. 3.2 Generally, test specimens are obtained when doubt

Combining values of the two units may result in non- exists about the in-place concrete quality due either to low

conformance. strength test results during construction or signs of distress in

1.3 This standard does not purport to address the safety the structure. Additionally, this method may be used to provide

concerns, if any, associated with its use. It is the responsibility strength information on older structures.

of the user of this standard to establish appropriate safety and 3.3 There is no universal relationship between the compres-

health practices and determine the applicability of regulatory sive strength of a core and the corresponding compressive

limitations prior to use. strength of standard-cured molded cylinders. The relationship

is affected by many factors such as the strength level of the

2. Referenced Documents

concrete, the in-place temperature and moisture history, and the

2.1 ASTM Standards:

strength gain characteristics of the concrete. Historically, it has

C 39 Test Method for Compressive Strength of Cylindrical been assumed that core strengths are generally 85 % of the

Concrete Specimens

corresponding standard-cured cylinder strengths, but this is not

C 78 Test Method for Flexural Strength of Concrete (Using applicable to all situations. The acceptance criteria for core

Simple Beam with Third-Point Loading)

strength is to be established by the specifying authority. ACI

C 174 Test Method for Measuring Length of Drilled Con- 318 provides core strength acceptance criteria for new con-

crete Cores

struction.

C 496 Test Method for Splitting Tensile Strength of Cylin-

4. Apparatus

drical Concrete Specimens

C 617 Practice for Capping Cylindrical Concrete Speci- 4.1 Core Drill, for obtaining cylindrical core specimens

mens with diamond impregnated bits attached to a core barrel.

C 670 Practice for Preparing Precision and Bias Statements 4.2 Saw, for cutting beam specimens to size for flexural

for Test Methods for Construction Materials strength tests and to trim ends of cores. The saw shall have a

2.2 ACI Standards: diamond or silicon-carbide cutting edge and shall be capable of

318 Building Code Requirements for Reinforced Concrete cutting specimens which conform to the prescribed dimen-

sions, without excessive heating or shock.

5. Sampling

This test method is under the jurisdiction of ASTM Committee C-9 on Concrete

5.1 General:

and Concrete Aggregatesand is the direct responsibility of Subcommittee C09.61on

Testing Concrete for Strength. 5.1.1 Samples of hardened concrete for use in the prepara-

Current edition approved Feb. 10, 1999. Published May 1999. Originally

tion of strength test specimens shall not be taken until the

published as C 42 – 21 T. Last previous edition C 42 – 94.

concrete is strong enough to permit sample removal without

Annual Book of ASTM Standards, Vol 04.02.

Available from American Concrete Institute, P.O. Box 9094, Farmington Hills,

MI 48333.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 42/C 42M

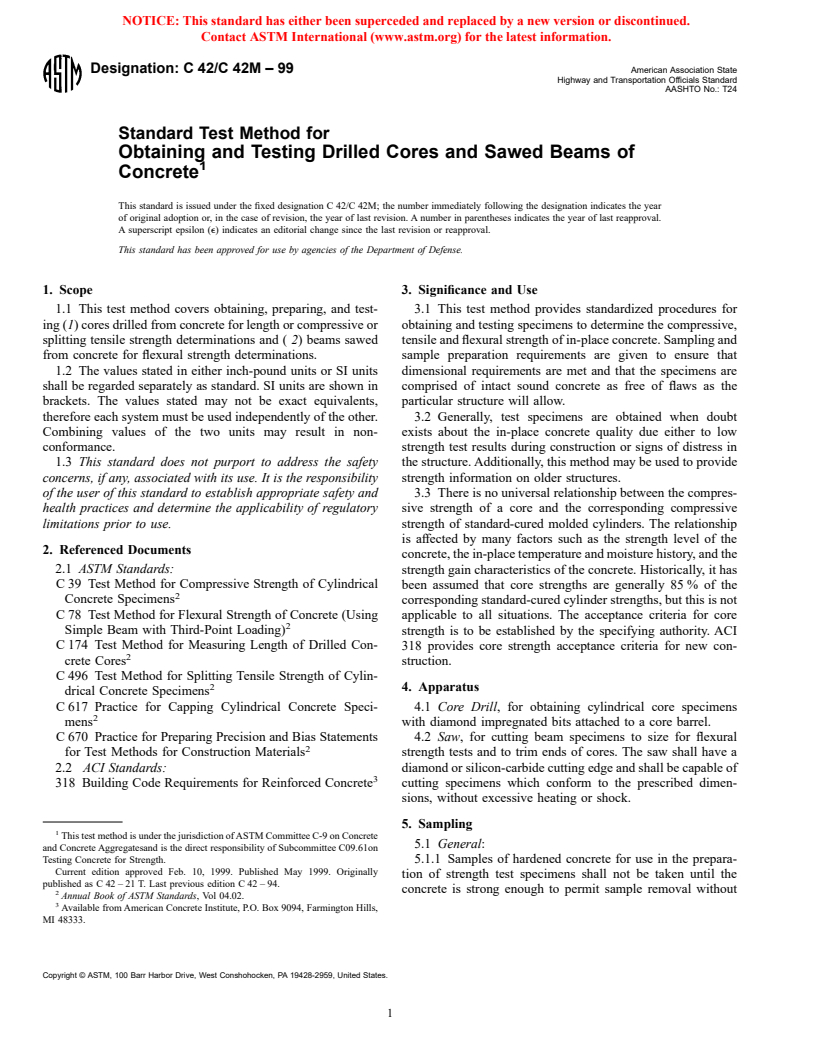

disturbing the bond between the mortar and the coarse aggre- 2.1 and 1.9. Core specimens with length-to-diameter ratios less

gate (see Note 1). When preparing strength test specimens from than 1.8 require corrections to the measured compressive

samples of hardened concrete, samples that show defects or strength (see 7.7.1). A core having a maximum length of less

samples that have been damaged in the process of removal than 95 % of its diameter before capping or a length less than

shall not be used. its diameter after capping shall not be tested.

5.1.2 Specimens containing embedded reinforcement shall 7.2 End Preparation—The ends of core specimens to be

not be used for determining splitting tensile strength and

tested in compression shall be essentially smooth, perpendicu-

specimens for determining flexural strength shall not be used if lar to the longitudinal axis, and of the same diameter as the

reinforcement is embedded in the tensile portion of the

body of the specimen. If necessary, saw the ends of the

specimen. specimens until the following requirements are met:

7.2.1 Projections, if any, shall not extend more than 0.2 in.

NOTE 1—It is not possible to specify a minimum age when concrete is

[5 mm] above the end surfaces,

strong enough to withstand damage during removal, because the strength

7.2.2 The end surfaces shall not depart from perpendicular-

at any age depends on the curing history and strength grade of the

concrete. If time permits, the concrete should not be removed before it is

ity to the longitudinal axis by more than 0.5°, and

14 days old. If this is not practical, removal of concrete can proceed if the

7.2.3 The diameters of the ends shall not depart more than

cut surfaces do not display erosion of the mortar and the exposed coarse

0.1 in. [2.5 mm] from the mean diameter of the specimen.

aggregate particles are embedded firmly in the mortar. In-place test

7.3 Moisture Conditioning—Test specimens shall be tested

methods may be used to estimate the level of strength development prior

in a moisture condition representative of the in-place concrete

to attempting removal of concrete samples.

or as directed by the specifying authority.

5.2 Core Drilling—A core specimen taken perpendicular to

7.3.1 Compressive strength test results are usually used for

a horizontal surface shall be located, when possible, so that its

the evaluation of the in-place concrete strength; therefore, the

axis is perpendicular to the bed of the concrete as originally

cores shall be conditioned in a moisture condition most

placed and not near formed joints or obvious edges of a unit of

representative of the in-place strength. If the concrete service

deposit. A specimen taken perpendicular to a vertical surface,

condition is dry, the cores can be tested in either an “as

or perpendicular to a surface with a batter, shall be taken from

received condition” after allowing the drilling moisture to

near the middle of a unit of deposit when possible and not near

evaporate in accordance with 7.3.2 or tested in a “dry condi-

formed joints or obvious edges of a unit of deposit.

tion” where the cores are air dried in a temperature range of 60

5.3 Slab Removal—Remove a slab sufficiently large to

to 80°F [16 to 27°C] at a relative humidity less than 60 % for

secure the desired test specimens without the inclusion of any

seven days, as directed by the specifying authority.

concrete which has been cracked, spalled, undercut, or other-

7.3.2 The following procedure is used to bring the cores to

wise damaged.

the “as received condition.” After drilling, transport the cores

to the testing laboratory within 24 h. Dry the cores for 12 to 24

DRILLED CORES

h in air at a temperature between 60 and 80° [16 to 27°C] and

at less than 50 % relative humidity. Cap or grind the cores, and

6. Length of Drilled Cores

test them within 48 h of receipt.

6.1 Core specimens drilled through a structure for the

7.3.3 When the specifying authority so directs, cores shall

purpose of measuring structural dimensions shall have a

be tested in a moisture condition other than achieved by

diameter of at least 3.75 in. [95 mm]. Measure the lengths of

conditioning according to 7.3.1 or 7.3.2.

such cores in accordance with Test Method C 174.

7.3.4 Further guidance for core strength evaluation consid-

6.2 For cores which are not intended for measuring struc-

erations is found in ACI 318, Chapter 5.

tural dimensions, measure the longest and shortest lengths on

7.4 Capping—The ends of the cores shall conform to the

the cut surface along lines parallel to the core axis. Record the

tolerance requirements of Test Method C 39. The ends shall be

average length to the nearest ⁄4 in. [5 mm].

sawed or ground to tolerance or capped in accordance with

capping procedures for hardened concrete specimens of Prac-

7. Cores for Compressive Strength

tice C 617.

7.1 Test Specimen—The nominal diameter of core speci-

mens for the determination of compressive strength shall be at NOTE 2—Prior to capping, the density of a core may be determined by

weighing it and dividing it by the volume calculated from the average

least 3.75 in. [95 mm]. Core diameters less than 3.75 in.

diameter and length, or by any other standard method for determining

[95mm] are permitted when it is impossible to obtain cores

density.

with length to diameter (L/D) ratio $ 1 for compressive

strength evaluations in cases other than load bearing situations. 7.5 Measurement—Prior to testing, measure the length of

the capped specimen to the nearest 0.1 in. [2.0 mm] and use

For concrete with nominal maximum aggregate size greater

than 1 ⁄2 in. [37.5 mm], the nominal diameter should preferably this length to compute the length-to-diameter ratio. Determine

the average diameter by averaging two measurements taken at

be at least three times the nominal maximum size of

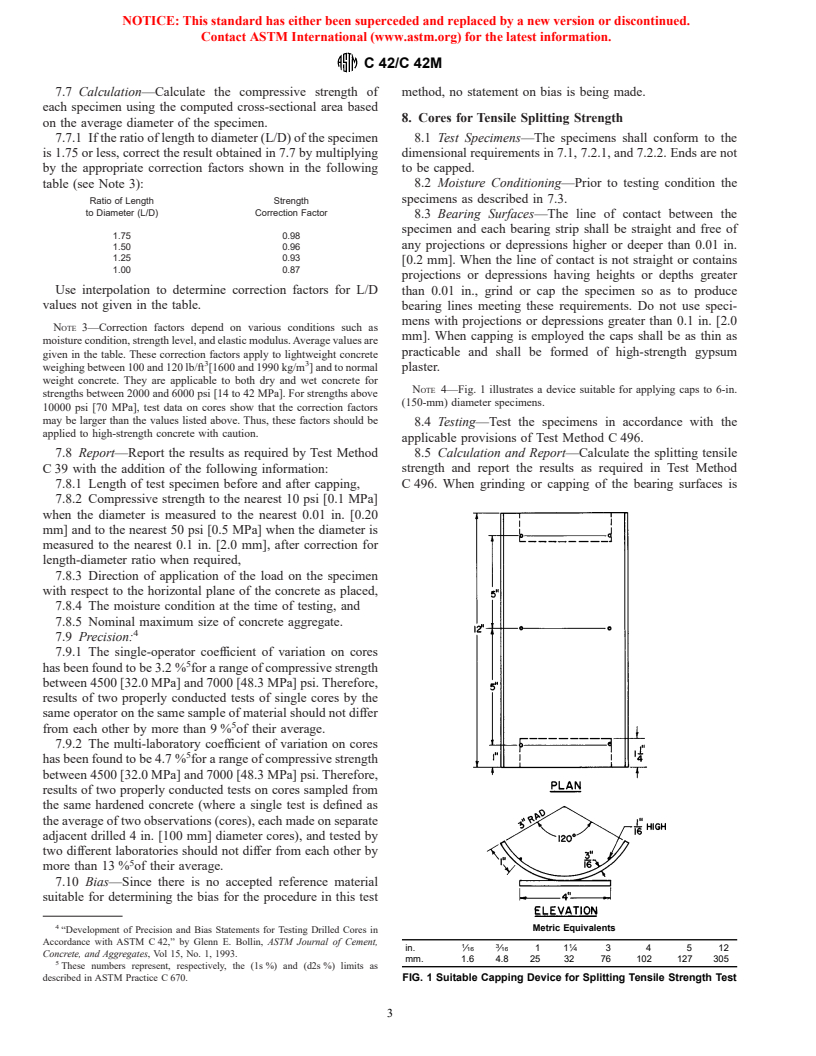

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.