ASTM D2597-94(1999)

(Test Method)Standard Test Method for Analysis of Demethanized Hydrocarbon Liquid Mixtures Containing Nitrogen and Carbon Dioxide by Gas Chromatography

Standard Test Method for Analysis of Demethanized Hydrocarbon Liquid Mixtures Containing Nitrogen and Carbon Dioxide by Gas Chromatography

SCOPE

1.1 This test method covers the analysis of demethanized liquid hydrocarbon streams containing nitrogen/air and carbon dioxide, and purity products such as an ethane/ propane mix that fall within the compositional ranges listed in Table 1. This test method is limited to mixtures containing less than 5 mol % of heptanes and heavier fractions.

1.2 The heptanes and heavier fraction, when present in the sample, is analyzed by either ( ) reverse flow of carrier gas after -hexane and peak grouping or ( ) precut column to elute heptanes and heavier first as a single peak. For purity mixes without heptanes and heavier no reverse of carrier flow is required. Note 1-In the case of unknown samples with a relatively large C plus or C plus fraction and where precise results are important, it is desirable to determine the molecular weight (or other pertinent physical properties) of these fractions. Since this test method makes no provision for determining physical properties, the physical properties needed can be determined by an extended analysis or agreed to by the contracting parties.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Annex A3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 2597 – 94 (Reapproved 1999)

Standard Test Method for

Analysis of Demethanized Hydrocarbon Liquid Mixtures

Containing Nitrogen and Carbon Dioxide by Gas

Chromatography

This standard is issued under the fixed designation D 2597; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

TABLE 1 Components and Compositional Ranges Allowed

1. Scope

Concentration Range,

1.1 This test method covers the analysis of demethanized

Components

Mol %

liquid hydrocarbon streams containing nitrogen/air and carbon

Nitrogen 0.01–5.0

dioxide, and purity products such as an ethane/propane mix

Carbon Dioxide 0.01–5.0

that fall within the compositional ranges listed in Table 1. This

Methane 0.01–5.0

Ethane 0.01–95.0

test method is limited to mixtures containing less than 5 mol %

Propane 0.01–100.0

of heptanes and heavier fractions.

Isobutane 0.01–100.0

1.2 The heptanes and heavier fraction, when present in the

n-Butane and 2,2-Dimethylpropane 0.01–100.0

Isopentane 0.01–15.0

sample, is analyzed by either (1) reverse flow of carrier gas

n-Pentane 0.01–15.0

after n-hexane and peak grouping or (2) precut column to elute

2,2-Dimethylbutane 0.01–0.5

heptanes and heavier first as a single peak. For purity mixes

2,3-Dimethylbutane and 2-Methylpentane

3-Methylpentane and Cyclopentane 0.01–15.0

without heptanes and heavier no reverse of carrier flow is

n-Hexane

required.

Heptanes and Heavier 0.01–5.0

NOTE 1—Caution: In the case of unknown samples with a relatively

large C plus or C plus fraction and where precise results are important,

6 7

it is desirable to determine the molecular weight (or other pertinent

GPA Standard 2177 Analysis of Demethanized Hydrocar-

physical properties) of these fractions. Since this test method makes no

bon Liquid Mixtures Containing Nitrogen and Carbon

provision for determining physical properties, the physical properties

Dioxide by Gas Chromatography

needed can be determined by an extended analysis or agreed to by the

contracting parties.

3. Summary of Test Method

1.3 The values stated in SI units are to be regarded as the

3.1 Components to be determined in a demethanized hydro-

standard. The values given in parentheses are for information

carbon liquid mixture are physically separated by gas chroma-

only.

tography and compared to calibration data obtained under

1.4 This standard does not purport to address all of the

identical operating conditions.Afixed volume of sample in the

safety concerns, if any, associated with its use. It is the

liquid phase is isolated in a suitable sample inlet system and

responsibility of the user of this standard to establish appro-

entered onto the chromatographic column.

priate safety and health practices and determine the applica-

3.1.1 Components nitrogen/air through n-hexane are indi-

bility of regulatory limitations prior to use. For specific hazard

vidually separated with the carrier flow in the forward direc-

statements see Annex A3.

tion.The numerous heavy end components are grouped into an

irregular shape peak by reversing direction of carrier gas

2. Referenced Documents

throughthecolumnbymeansofaswitchingvalveimmediately

2.1 ASTM Standards:

following the elution of normal hexane. (See Fig. 1.) Samples

D 3700 PracticeforContainingHydrocarbonFluidSamples

that contain no heptanes plus fraction are analyzed until the

Using a Floating Piston Cylinder

final component has eluted with no reverse of carrier flow.

2.2 Other Standard:

3.1.2 An alternative to the single column backflush method

istheuseofaprecutcolumnwhichisbackflushedtoobtainthe

heptanes plus as a single peak at the beginning of the

This test method is under the jurisdiction of Committee D-2 on Petroleum

chromatogram. Two advantages of the alternate method are as

Products and Lubricants and is the direct responsibility of Subcommittee D02.H on

follows:(1)betterprecisioninmeasuringtheC plusportionof

Liquefied Petroleum Gas.

Current edition approved July 15, 1994. Published September 1994. Originally

published as D 2597 – 67T. Last previous edition D 2597 – 88.

2 3

Annual Book of ASTM Standards, Vol 05.02. Available from Gas Processors Assn., 6526 E. 60th St., Tulsa, OK 74145.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 2597 – 94 (1999)

the analyzing column. The fixed sample volume should not

exceed 1.0 µLand should be reproducible such that successive

runs agree within 62 % on each component peak area. The

liquid sampling valve is mounted exterior of any type heated

compartment and thus can operate at laboratory ambient

conditions.

5.1.3 Sample Inlet System, Gas (Instrument Linearity)—

Provision is to be made to introduce a gas phase sample into

the carrier gas stream ahead of the chromatographic column so

that linearity of the instrument can be estimated from response

curves. The fixed volume loop in the gas sample valve shall be

sized to deliver a total molar volume approximately equal to

that delivered by the liquid sample valve in accordance with

FIG. 1 Chromatogram of Demethanized Hydrocarbon Liquid

5.1.2. (See Section 6 for further explanation of instrument

Mixture (Frontal Carrier Gas Flow ThroughN-Hexane, Reverse

Grouping Heptanes Plus) linearity check procedures.)

5.1.4 Chromatographic Columns:

5.1.4.1 Column No. 1—A partition column shall be pro-

the sample and (2) reduction in analysis time over the single

vided capable of separating nitrogen/air, carbon dioxide, and

column approach by approximately 40 %.

the hydrocarbons methane through normal hexane. (See Fig. 1

3.2 Thechromatogramisinterpretedbycomparingtheareas

and Fig. 2.) Separation of carbon dioxide shall be sufficient so

of component peaks obtained from the unknown sample with

that a 1-µL sample containing 0.01 mol % carbon dioxide will

correspondingareasobtainedfromarunofaselectedreference

produceameasurablepeakonthechromatogram.(Thesilicone

standard. Any component in the unknown suspected to be

200/500 column, containing a 27 to 30 weight % liquid phase

outside the linearity range of the detector, with reference to the

load, has proven satisfactory for this type of analysis.)

known amount of that component in the reference standard,

5.1.4.2 Column No. 2—A partition column similar to Col-

must be determined by a response curve. Peak height method

umn No. 1. It shall be of the same diameter as Column No. 1.

of integration can be used only if the chromatograph is

Thecolumnshallbeofanappropriatelengthtoclearlyseparate

operating in the linear range for all components analyzed.

the heptanes plus fraction from the hexanes and lighter

Linearity must be proved by peak height for all components

components.

when using peak height method. (See Section 6 for further

5.1.5 Attenuator—A multistep device shall be included in

explanation of instrument linearity check procedures.)

the detector output circuitry to attenuate the signal from the

detector to the recorder when using manual calculation meth-

4. Significance and Use

ods. The attenuation between steps shall be accurate to

4.1 The component distribution of hydrocarbon liquid mix-

60.5 %.

tures is often required as a specification analysis for these

5.1.6 Temperature Control—The chromatographic col-

materials.Wide use of these hydrocarbon mixtures as chemical

umn(s) and the detector shall be maintained at their respective

feedstocks or as fuel require precise compositional data to

ensure uniform quality of the reaction product. In addition,

custody transfer of these products is often made on the basis of

component analyses of liquid mixtures.

4.2 The component distribution data of hydrocarbon mix-

tures can be used to calculate physical properties such as

specific gravity, vapor pressure, molecular weight, and other

important properties. Precision and accuracy of compositional

data are extremely important when these data are used to

calculate physical properties of these products.

5. Apparatus

5.1 Any gas chromatograph can be used that meets the

following specifications.

5.1.1 Detector—The detector shall be a thermal-

conductivity type. It must be sufficiently sensitive to produce a

deflection of at least 0.5 mv for 1 mol % of n-butane in a

1.0-µL sample.

5.1.2 SampleInletSystem,Liquid—Aliquid sampling valve

shall be provided, capable of entrapping a fixed volume of

sample at a pressure at least 200 psi (1379 kPa) above the

FIG. 2 Chromatogram of Demethanized Hydrocarbon Liquid

vapor pressure of the sample at valve temperature, and intro-

Mixture (Precut Column Grouping Heptanes Plus, Frontal Carrier

ducing this fixed volume into the carrier gas stream ahead of Gas Flow Remaining Components)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 2597 – 94 (1999)

temperatures, constant to 60.3°C during the course of the

sample and corresponding reference standard runs.

5.2 Carrier Gas—Pressure-reducing and control devices to

give repeatable flow rates.

5.3 Recorder—Astrip chart recorder with a full-scale range

of 1 mv shall be required when using manual calculation

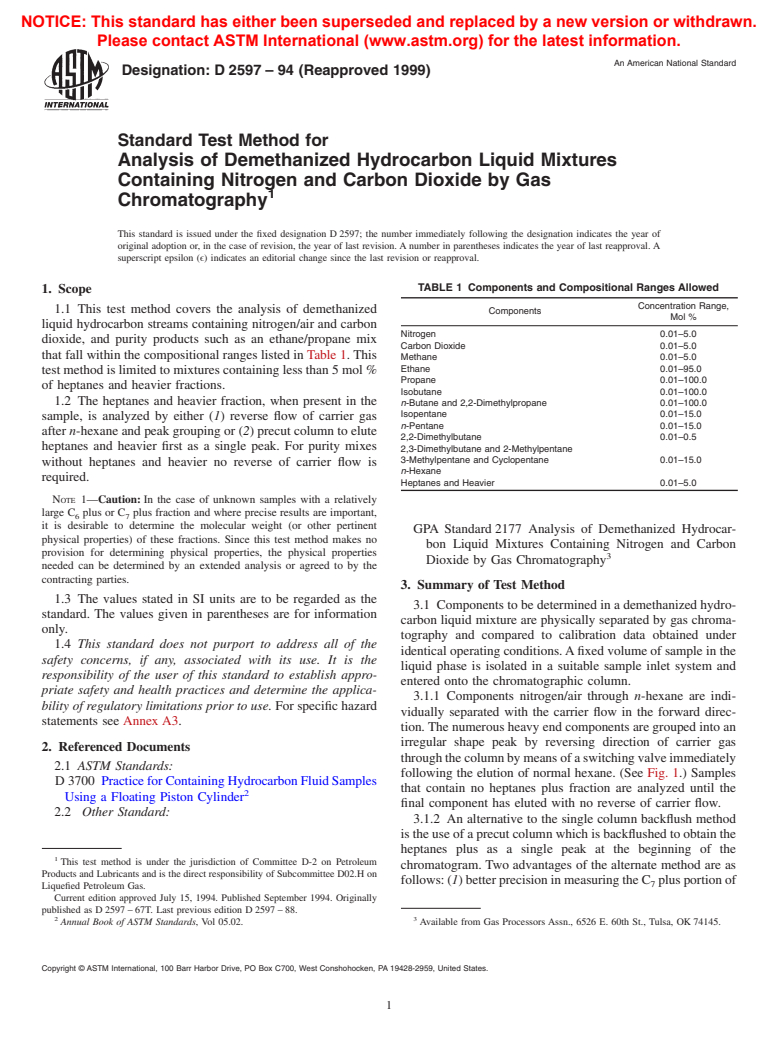

FIG. 3 Repressuring System and Chromatographic Valving with

methods.Amaximum pen response time of 1 s and a minimum

Floating Piston Cylinder

chart speed of 1 cm/min (0.5 in./min accepted) shall be

required. Faster speeds up to 10 cm/min (3 in./min accepted)

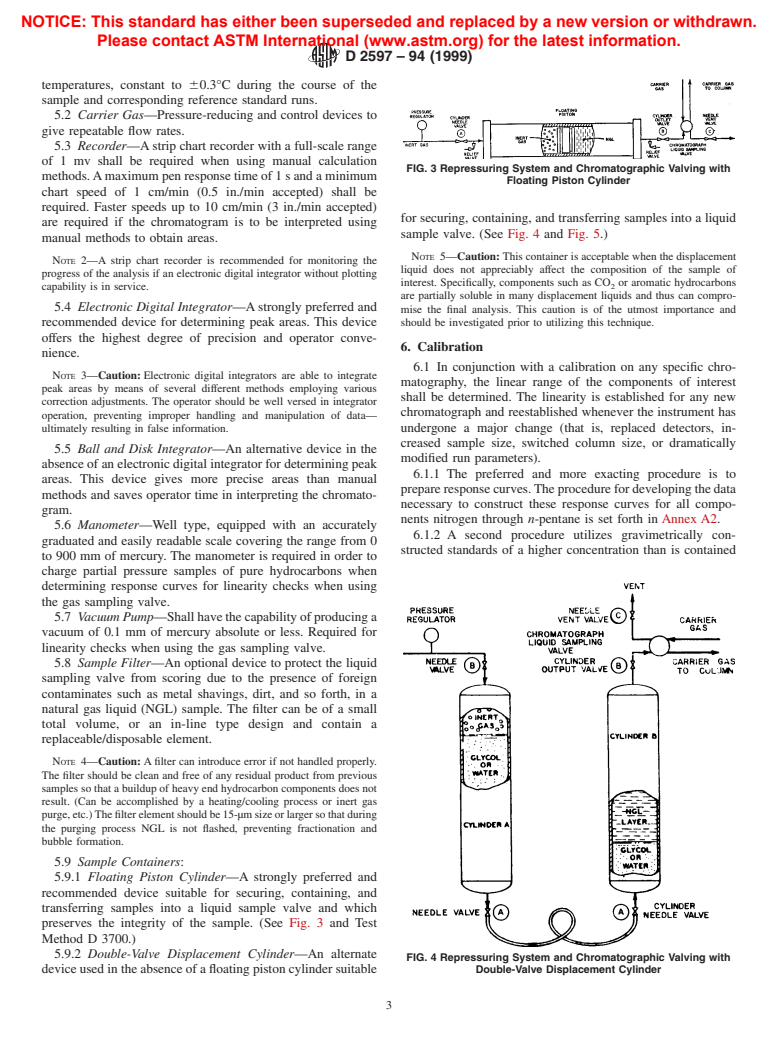

for securing, containing, and transferring samples into a liquid

are required if the chromatogram is to be interpreted using

sample valve. (See Fig. 4 and Fig. 5.)

manual methods to obtain areas.

NOTE 5—Caution: This container is acceptable when the displacement

NOTE 2—A strip chart recorder is recommended for monitoring the

liquid does not appreciably affect the composition of the sample of

progress of the analysis if an electronic digital integrator without plotting

interest. Specifically, components such as CO or aromatic hydrocarbons

capability is in service.

are partially soluble in many displacement liquids and thus can compro-

5.4 Electronic Digital Integrator—Astrongly preferred and

mise the final analysis. This caution is of the utmost importance and

should be investigated prior to utilizing this technique.

recommended device for determining peak areas. This device

offers the highest degree of precision and operator conve-

6. Calibration

nience.

6.1 In conjunction with a calibration on any specific chro-

NOTE 3—Caution: Electronic digital integrators are able to integrate

matography, the linear range of the components of interest

peak areas by means of several different methods employing various

shall be determined. The linearity is established for any new

correction adjustments. The operator should be well versed in integrator

chromatograph and reestablished whenever the instrument has

operation, preventing improper handling and manipulation of data—

ultimately resulting in false information. undergone a major change (that is, replaced detectors, in-

creased sample size, switched column size, or dramatically

5.5 Ball and Disk Integrator—An alternative device in the

modified run parameters).

absence of an electronic digital integrator for determining peak

6.1.1 The preferred and more exacting procedure is to

areas. This device gives more precise areas than manual

prepareresponsecurves.Theprocedurefordevelopingthedata

methods and saves operator time in interpreting the chromato-

necessary to construct these response curves for all compo-

gram.

nents nitrogen through n-pentane is set forth in Annex A2.

5.6 Manometer—Well type, equipped with an accurately

6.1.2 A second procedure utilizes gravimetrically con-

graduated and easily readable scale covering the range from 0

structed standards of a higher concentration than is contained

to 900 mm of mercury. The manometer is required in order to

charge partial pressure samples of pure hydrocarbons when

determining response curves for linearity checks when using

the gas sampling valve.

5.7 VacuumPump—Shallhavethecapabilityofproducinga

vacuum of 0.1 mm of mercury absolute or less. Required for

linearity checks when using the gas sampling valve.

5.8 Sample Filter—An optional device to protect the liquid

sampling valve from scoring due to the presence of foreign

contaminates such as metal shavings, dirt, and so forth, in a

natural gas liquid (NGL) sample. The filter can be of a small

total volume, or an in-line type design and contain a

replaceable/disposable element.

NOTE 4—Caution: A filter can introduce error if not handled properly.

The filter should be clean and free of any residual product from previous

samples so that a buildup of heavy end hydrocarbon components does not

result. (Can be accomplished by a heating/cooling process or inert gas

purge,etc.)Thefilterelementshouldbe15-µmsizeorlargersothatduring

the purging process NGL is not flashed, preventing fractionation and

bubble formation.

5.9 Sample Containers:

5.9.1 Floating Piston Cylinder—A strongly preferred and

recommended device suitable for securing, containing, and

transferring samples into a liquid sample valve and which

preserves the integrity of the sample. (See Fig. 3 and Test

Method D 3700.)

5.9.2 Double-Valve Displacement Cylinder—An alternate

FIG. 4 Repressuring System and Chromatographic Valving with

device used in the absence of a floating piston cylinder suitable Double-Valve Displacement Cylinder

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

D 2597 – 94 (1999)

second (or third) gravimetrically determined standard (either

purity or blend) can then be run, using the originally obtained

response factors, which contain a concentration of individual

components exceeding the expected amounts in the unknowns.

When both (or all three) runs match their respective standards

within the precision guidelines allowed in Section 10, then the

instrument can be considered linear within that range.

NOTE 6—This test method omits the need of a gas sample valve on the

chromatographic instrument. However, several accurate primary NGL

standards are required and the exact point at which nonlinearity occurs is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.