ASTM B858-06(2012)

(Test Method)Standard Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

Standard Test Method for Ammonia Vapor Test for Determining Susceptibility to Stress Corrosion Cracking in Copper Alloys

SIGNIFICANCE AND USE

This test method is an accelerated test to determine if a copper alloy product will be susceptible to stress-corrosion cracking when exposed to a particular atmospheric condition during service with the appropriate risk levelsee Annex A1.

This test method is generally intended to determine if a copper alloy product will crack because of internal stresses when subjected to the test, and is not intended for testing assemblies under applied stress. If used for this purpose, it shall be for information only and not a cause for rejection of the assembly, its component parts, or the original mill product.

SCOPE

1.1 This test method describes a procedure to determine the presence of residual stresses in wrought copper alloy products that may lead to stress corrosion cracking. An ammonia vapor atmosphere is used as an accelerated test.

1.2 This test method is only suitable for products fabricated from copper alloys that are known to be susceptible to stress corrosion cracking in ammonia vapor atmospheres. It is intended to create an environmental condition of reproducible severity.

Note 1—It is well known that the critical step in the cracking mechanism is the development of an environment in the condensate film that occurs on the surface of the test specimen, and is rich in copper complex ions.

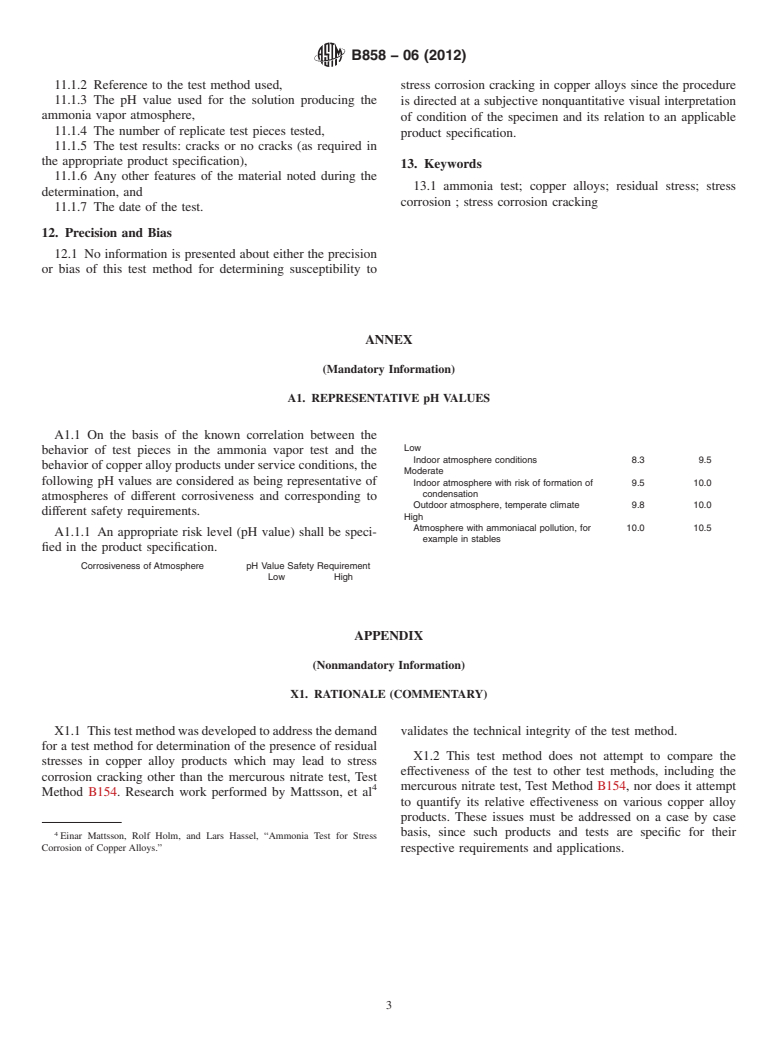

1.3 The severity of this test method depends upon the pH of the corrosive solution. In Annex A1 are given four different atmospheres to which the product may be exposed, and the appropriate pH of the solution to be used for the test, depending on the risk level associated with the intended application.

1.3.1 The appropriate pH value for the test shall be specified in the product specification, or as per established agreement between the supplier and purchaser, with respect to the alloy and its intended application.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B858 − 06 (Reapproved 2012)

Standard Test Method for

Ammonia Vapor Test for Determining Susceptibility to

Stress Corrosion Cracking in Copper Alloys

This standard is issued under the fixed designation B858; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method describes a procedure to determine the

B154Test Method for Mercurous Nitrate Test for Copper

presence of residual stresses in wrought copper alloy products

Alloys

that may lead to stress corrosion cracking.An ammonia vapor

B846Terminology for Copper and Copper Alloys

atmosphere is used as an accelerated test.

D1193Specification for Reagent Water

1.2 This test method is only suitable for products fabricated

3. Terminology

from copper alloys that are known to be susceptible to stress

corrosion cracking in ammonia vapor atmospheres. It is in-

3.1 For definitions of terms related to copper and copper

tended to create an environmental condition of reproducible

alloys, refer to Terminology B846.

severity.

3.2 Definitions:

3.2.1 applied stress, n—stress in a body as a result of

NOTE 1—It is well known that the critical step in the cracking

mechanism is the development of an environment in the condensate film application of an external load.

that occurs on the surface of the test specimen, and is rich in copper

complex ions.

4. Summary of Test Method

1.3 TheseverityofthistestmethoddependsuponthepHof 4.1 The prepared test specimen is placed in a closed

the corrosive solution. In Annex A1 are given four different container and exposed to ammonia vapor with a specific pH at

ambient temperature for 24 h. Upon removal from the test

atmospheres to which the product may be exposed, and the

atmosphere, the test specimen is examined for the presence of

appropriate pH of the solution to be used for the test,

cracks.

depending on the risk level associated with the intended

application.

5. Significance and Use

1.3.1 TheappropriatepHvalueforthetestshallbespecified

5.1 This test method is an accelerated test to determine if a

in the product specification, or as per established agreement

copper alloy product will be susceptible to stress-corrosion

between the supplier and purchaser, with respect to the alloy

cracking when exposed to a particular atmospheric condition

and its intended application.

during service with the appropriate risk level—see AnnexA1.

1.4 Units—The values stated in SI units are to be regarded

5.1.1 This test method is generally intended to determine if

asstandard.Nootherunitsofmeasurementareincludedinthis

a copper alloy product will crack because of internal stresses

standard.

when subjected to the test, and is not intended for testing

assembliesunderappliedstress.Ifusedforthispurpose,itshall

1.5 This standard does not purport to address all of the

be for information only and not a cause for rejection of the

safety concerns, if any, associated with its use. It is the

assembly, its component parts, or the original mill product.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

6. Apparatus

bility of regulatory limitations prior to use.

6.1 pH meter.

6.2 Closed vessel, such as a desiccator.

This test method is under the jurisdiction ofASTM Committee B05 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on

Methods of Test. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published August 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1995. Last previous edition approved in 2006 as B858 – 06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0858-06R12. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B858 − 06 (2012)

6.3 Equipment for examining test pieces at 10× to 15× 9. Test Specimen Preparation

magnification.

9.1 The test specimen size shall be prescribed in the

specification of the product or part being tested. In the event

7. Reagents and Materials

that a test specimen size is not prescribed in a given rod, wire,

7.1 Purity of Reagents—Reagent grade chemicals shall be

or tube specification, a full cross section having a minimum

used in all tests. Unless otherwise indicated, it is intended that

length of 152 mm shall be tested.

all reagents conform to the specifications of the Committee on

9.2 The presence of burrs on the test specimen may con-

Analytical Reagents of theAmerican Chemical Society where

tribute to acceleration of stress corrosion cracking if not

such specifications are available. Other grades may be used,

removed before the ammonia vapor test. The burrs shall be

provided it is first ascertained that the reagent is of sufficiently

removed by fine file or abrasive paper to facilitate this test.

high purity to permit its use without lessening the accuracy of

the determination. 9.3 Degrease the test specimen using the clean organic

solvent or alkaline solution.

7.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water as defined 9.4 After degreasing, clean the test piece in the pickling

by Type IV or better, of Specification D1193. solution and immediately thereafter thoroughly rinse it, first in

cold running water, then in hot water, and finally, completely

7.3 Ammonium Chloride Solution (4N)—Dissolve 107 g of

dry it in a stream of warm air.

ammonium chloride (NH Cl) in water and dilute to 500 mL.

Store the solution in a closed vessel.

10. Test Procedure

7.4 Hydrogen Peroxide (H O ),30to35%technicalgrade.

2 2

10.1 Allow the dry test piece to reach the exposure tem-

(Warning—Hydrogen peroxide in high concentrations can

perature specified below, and transfer it immediately to the

cause severe skin burns. Use of proper safety equipment is

closedvessel(see6.2)atthesametemperature,andcontaining

advised.)

thefreshlypreparedtestsolutionatthespecifiedpHvalue(see

7.5 Sodium Hydroxide Solution (300 to 500 g/L)—Dissolve

8.1).

300 to 500 g of sodium hydroxide (NaOH) into water and

10.1.1 Suspend (or place) the test piece such that the

dilute to 1 L. (Warning—Sodium hydroxide can cause chemi-

ammonia vapor has free access to all surfaces, not less than 50

cal burns to the skin and eyes. Use of proper safety equipment

mm above the test solution surface.

is advised.)

10.1.1.1 When placed on a porcelain support within the test

7.6 A clean o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.