ASTM D2486-06(2016)

(Test Method)Standard Test Methods for Scrub Resistance of Wall Paints

Standard Test Methods for Scrub Resistance of Wall Paints

SIGNIFICANCE AND USE

4.1 Paints often become soiled, especially near doorways, windows, and in work and play areas. These test methods cover the determination of the relative resistance of different paints to erosion when repeatedly scrubbed during the life of the paint.

4.2 Test Method D4213 is a similar scrub resistance test using a weight-loss technique and reporting volumetric film erosion rates.

4.3 Test Method A measures scrub resistance by the traditional cycles-to-failure concept. Poor correlation in scrub testing can be attributable to among other things variations in the stiffness of the brush bristles, condition of washability tester, application and drying conditions. In an attempt to improve reproducibility, Test Method B has been developed.

SCOPE

1.1 These test methods cover a procedure for determining the resistance of wall paints to erosion caused by scrubbing, referred to herein after as “scrub resistance.”

1.2 Two test methods are covered as follows:

1.2.1 Test Method A—Cycles-to-failure obtained on test paint.

1.2.2 Test Method B—Ratio expressed as a percentage of cycles-to-failure obtained on the test paint to that obtained on a concurrent run with a known reference paint.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2486 − 06 (Reapproved 2016)

Standard Test Methods for

Scrub Resistance of Wall Paints

This standard is issued under the fixed designation D2486; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 12.7 wide by 0.25-mm thick ( ⁄2-in. by 10-mil) shim and held

in place on a drawdown plate in a washability machine by

1.1 These test methods cover a procedure for determining

means of a gasketed frame. The coated panel is then scrubbed

the resistance of wall paints to erosion caused by scrubbing,

with a bristle brush and an abrasive scrub medium until the

referred to herein after as “scrub resistance.”

paint film is removed in one continuous thin line across the

1.2 Two test methods are covered as follows:

shim.

1.2.1 Test Method A—Cycles-to-failure obtained on test

3.2 InTestMethodB,thetestpaintandareferencepaintare

paint.

applied simultaneously perpendicular to the length of the black

1.2.2 Test Method B—Ratio expressed as a percentage of

plastic panel.After curing, the coated panel is placed over two

cycles-to-failure obtained on the test paint to that obtained on

12.7 by 0.25-mm ( ⁄2-in. by 10-ml) shims that are positioned

a concurrent run with a known reference paint.

under each coating. The coatings are then scrubbed with a

1.3 The values stated in SI units are to be regarded as the

bristle brush and an abrasive scrub medium until each paint

standard. The values given in parentheses are for information

film is removed in one continuous thin line across its own

only.

shim.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Paints often become soiled, especially near doorways,

priate safety and health practices and determine the applica-

windows,andinworkandplayareas.Thesetestmethodscover

bility of regulatory limitations prior to use.

thedeterminationoftherelativeresistanceofdifferentpaintsto

erosion when repeatedly scrubbed during the life of the paint.

2. Referenced Documents

4.2 Test Method D4213 is a similar scrub resistance test

2.1 ASTM Standards:

using a weight-loss technique and reporting volumetric film

D3924 Specification for Environment for Conditioning and

erosion rates.

Testing Paint, Varnish, Lacquer, and Related Materials

4.3 Test Method A measures scrub resistance by the tradi-

(Withdrawn 2016)

tional cycles-to-failure concept. Poor correlation in scrub

D4213 Test Method for Scrub Resistance of Paints by

testing can be attributable to among other things variations in

Abrasion Weight Loss

the stiffness of the brush bristles, condition of washability

3. Summary of Test Method tester, application and drying conditions. In an attempt to

improve reproducibility, Test Method B has been developed.

3.1 In Test Method A, the test paint is applied to a black

plastic panel. After curing, the coated panel is placed over a

5. Apparatus

5.1 Straight Line Washability Machine.

These test methods are under the jurisdiction of ASTM Committee D01 on

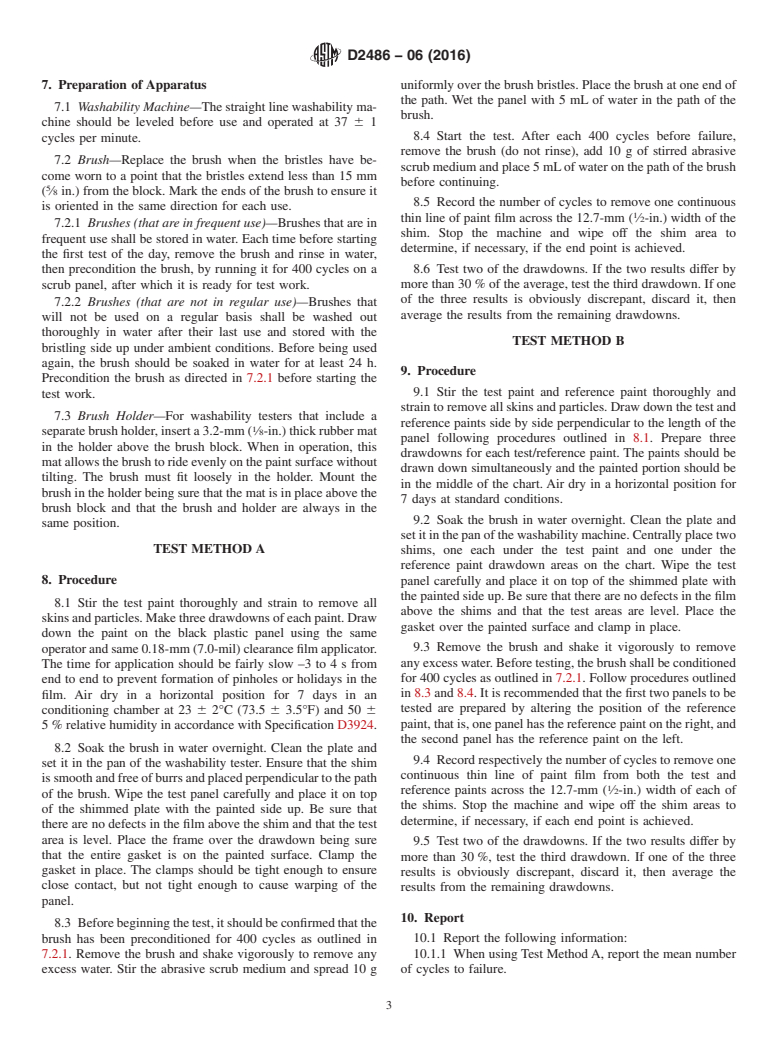

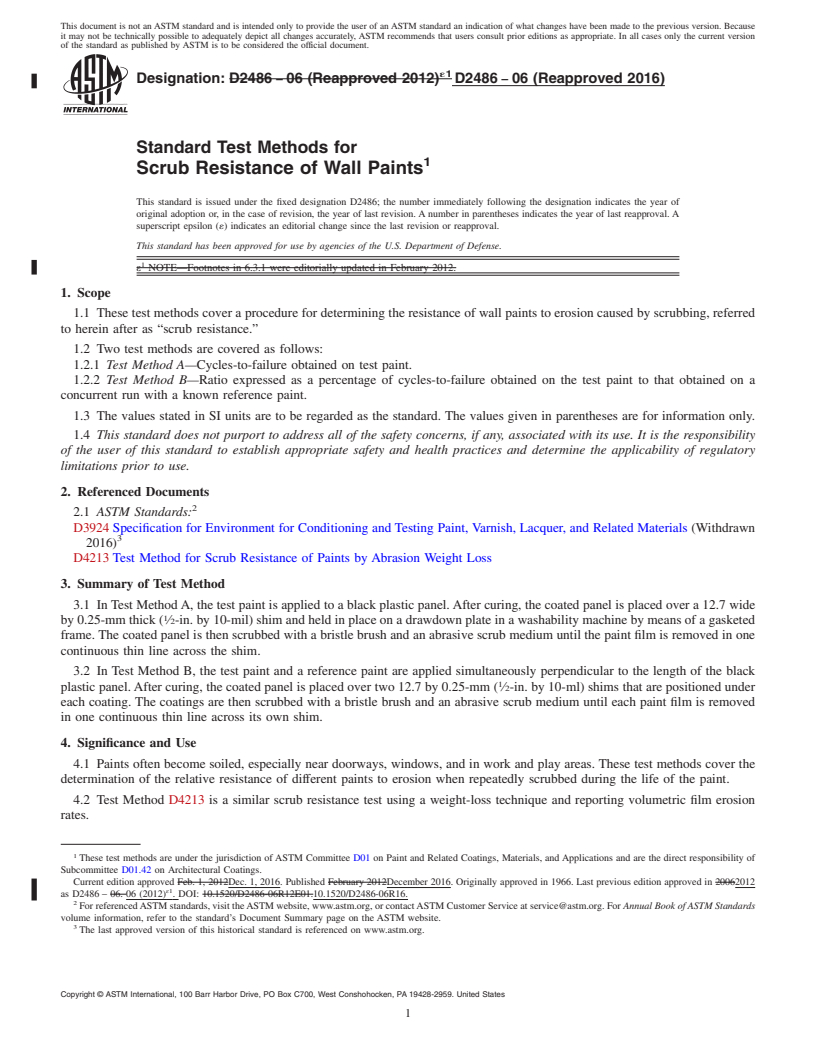

5.1.1 Accessory Apparatus: (see Figs. 1 and 2).

Paint and Related Coatings, Materials, and Applications and are the direct

5.1.1.1 Nylon Bristle Brush and Accessories, (total weight

responsibility of Subcommittee D01.42 on Architectural Coatings.

454 6 10 g).

Current edition approved Dec. 1, 2016. Published December 2016. Originally

ɛ1

approved in 1966. Last previous edition approved in 2012 as D2486 – 06 (2012) .

5.1.1.2 Drawdown Plate, 454 by 165 by 6.3 mm (17 ⁄8 by

DOI: 10.1520/D2486-06R16.

1 1

6 ⁄2 by ⁄4 in.).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.1.3 Brass Shims, 12.7- by 0.25-mm ( ⁄2-in. by 10-mils).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Its length can be fitted to the width of the drawdown plate.

the ASTM website.

5.2 Film Applicator, having 0.18-mm (7-mil) clearance and

The last approved version of this historical standard is referenced on

1 1

www.astm.org. 6.25-mm ( ⁄4-in.) edge and width of 135 mm (5 ⁄4-in.).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2486 − 06 (2016)

FIG. 2 Accessory Apparatus for Scrub Test

FIG. 1 Accessory Apparatus for Scrub Test

grams

A

Water, distilled or deionized 49.4

5,7

Hydroxyethyl cellulose 0.8

Ammonium hydroxide, 28 % 0.1

5,8

6. Reagents and Materials Detergent 2.0

Trisodium phosphate, anhydrous 2.0

5,9

6.1 Purity of Reagents—Reagent grade chemicals shall be Silica 45.0

B

Acetic acid (glacial) 0.7

used in all tests.

5,10

Preservative 0.03g

4,5

6.2 Black Plastic Panels.

A

Adjust to achieve viscosity of 110 to 120 Krebs units before use.

5,6

B

6.3 Abrasive Scrub Medium. Vary to achieve a pH of 9.5 to 10.

6.3.1 Laboratory standardized abrasive scrub medium con-

6.4 Reference paint when using Test Method B.

sisting of the following:

Cellosize QP-4400H, The Dow Chemical Company, Midland, Michigan, was

Dull black plastic panels, P-121-10N, 165 by 432 by 0.25 mm (6 ⁄2 by 17 in. used in developing the Precision and Bias statement. Other equivalent molecular

by 10 mils) manufactured by The Leneta Co., 15 Whitney Rd., Mahwah, NJ 07430 weight cellulosic thickeners can be used such as Natrosol 250 MR, Ashland

were used in the original development of this standard in order to get the results in Aqualon, Wilmington, Delaware.

these test methods. The sole source of supply of the Triton X-100 detergent known to the

If you are aware of alternative suppliers, please provide this information to committee at this time is The Dow Chemical Company, Midland, Michigan.

ASTM International Headquarters. Your comments will receive careful consider- The sole source of supply of the Imsil 45 known to the committee at this time

ation at a meeting of the responsible technical committee, which you may attend. is Unimin Specialty Minerals Inc., 258 Elm St., New Canaan, CT 06840.

6 10

The sole source of supply of the abrasive scrub medium known to the The preservative package recommended is BIT, 1,2–Benzisothiazol-3(2H)-

committee at this time is The Leneta Company. one. There are several suppliers who offer BIT-based agents.

D2486 − 06 (2016)

7. Preparation of Apparatus uniformly over the brush bristles. Place the brush at one end of

the path. Wet the panel with 5 mL of water in the path of the

7.1 WashabilityMachine—The straight line washability ma-

brush.

chine should be leveled before use and operated at 37 6 1

8.4 Start the test. After each 400 cycles before failure,

cycles per minute.

remove the brush (do not rinse), add 10 g of stirred abrasive

7.2 Brush—Replace the brush when the bristles have be-

scrub medium and place 5 mLof water on the path of the brush

come worn to a point that the bristles extend less than 15 mm

before continuing.

( ⁄8 in.) from the block. Mark the ends of the brush to ensure it

8.5 Record the number of cycles to remove one continuous

is oriented in the same direction for each use.

thin line of paint film across the 12.7-mm ( ⁄2-in.) width of the

7.2.1 Brushes(thatareinfrequentuse)—Brushes that are in

shim. Stop the machine and wipe off the shim area to

frequent use shall be stored in water. Each time before starting

determine, if necessary, if the end point is achieved.

the first test of the day, remove the brush and rinse in wate

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D2486 − 06 (Reapproved 2012) D2486 − 06 (Reapproved 2016)

Standard Test Methods for

Scrub Resistance of Wall Paints

This standard is issued under the fixed designation D2486; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Footnotes in 6.3.1 were editorially updated in February 2012.

1. Scope

1.1 These test methods cover a procedure for determining the resistance of wall paints to erosion caused by scrubbing, referred

to herein after as “scrub resistance.”

1.2 Two test methods are covered as follows:

1.2.1 Test Method A—Cycles-to-failure obtained on test paint.

1.2.2 Test Method B—Ratio expressed as a percentage of cycles-to-failure obtained on the test paint to that obtained on a

concurrent run with a known reference paint.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3924 Specification for Environment for Conditioning and Testing Paint, Varnish, Lacquer, and Related Materials (Withdrawn

2016)

D4213 Test Method for Scrub Resistance of Paints by Abrasion Weight Loss

3. Summary of Test Method

3.1 In Test Method A, the test paint is applied to a black plastic panel. After curing, the coated panel is placed over a 12.7 wide

by 0.25-mm thick ( ⁄2-in. by 10-mil) shim and held in place on a drawdown plate in a washability machine by means of a gasketed

frame. The coated panel is then scrubbed with a bristle brush and an abrasive scrub medium until the paint film is removed in one

continuous thin line across the shim.

3.2 In Test Method B, the test paint and a reference paint are applied simultaneously perpendicular to the length of the black

plastic panel. After curing, the coated panel is placed over two 12.7 by 0.25-mm ( ⁄2-in. by 10-ml) shims that are positioned under

each coating. The coatings are then scrubbed with a bristle brush and an abrasive scrub medium until each paint film is removed

in one continuous thin line across its own shim.

4. Significance and Use

4.1 Paints often become soiled, especially near doorways, windows, and in work and play areas. These test methods cover the

determination of the relative resistance of different paints to erosion when repeatedly scrubbed during the life of the paint.

4.2 Test Method D4213 is a similar scrub resistance test using a weight-loss technique and reporting volumetric film erosion

rates.

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

Current edition approved Feb. 1, 2012Dec. 1, 2016. Published February 2012December 2016. Originally approved in 1966. Last previous edition approved in 20062012

ɛ1

as D2486 – 06. 06 (2012) . DOI: 10.1520/D2486-06R12E01.10.1520/D2486-06R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2486 − 06 (2016)

4.3 Test Method A measures scrub resistance by the traditional cycles-to-failure concept. Poor correlation in scrub testing can

be attributable to among other things variations in the stiffness of the brush bristles, condition of washability tester, application and

drying conditions. In an attempt to improve reproducibility, Test Method B has been developed.

5. Apparatus

5.1 Straight Line Washability Machine.Straight Line Washability Machine.

5.1.1 Accessory Apparatus: (see Figs. 1 and 2).

5.1.1.1 Nylon Bristle Brush and Accessories, Nylon Bristle Brush and Accessories,(total weight 454 6 10 g).

7 1 1

5.1.1.2 Drawdown Plate, Drawdown Plate,454 by 165 by 6.3 mm (17 ⁄8 by 6 ⁄2 by ⁄4 in.).

5.1.1.3 Brass Shims, Brass Shims,12.7- by 0.25-mm ( ⁄2-in. by 10-mils). Its length can be fitted to the width of the drawdown

plate.

5.2 Film Applicator, Film Applicator,having 0.18-mm (7-mil) clearance and 6.25-mm ( ⁄4-in.) edge and width of 135 mm

(5 ⁄4-in.).

6. Reagents and Materials

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests.

4,5

6.2 Black Plastic Panels.

5,6

6.3 Abrasive Scrub Medium.

Dull black plastic panels, P-121-10N, 165 by 432 by 0.25 mm (6 ⁄2 by 17 in. by 10 mils) manufactured by The Leneta Co., 15 Whitney Rd., Mahwah, NJ 07430 were

used in the original development of this standard in order to get the results in these test methods.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee, which you may attend.

The sole source of supply of the abrasive scrub medium known to the committee at this time is The Leneta Company.

FIG. 1 Accessory Apparatus for Scrub Test

D2486 − 06 (2016)

FIG. 2 Accessory Apparatus for Scrub Test

6.3.1 Laboratory standardized abrasive scrub medium consisting of the following:

grams

A

Water, distilled or deionized 49.4

5 ,7

Hydroxyethyl cellulose 0.8

Ammonium hydroxide, 28 % 0.1

5,8

Detergent 2.0

Trisodium phosphate, anhydrous 2.0

5,9

Silica 45.0

B

Acetic acid (glacial) 0.7

5,10

Preservative 0.03g

A

Adjust to achieve viscosity of 110 to 120 Krebs units before use.

B

Vary to achieve a pH of 9.5 to 10.

6.4 Reference paint when using Test Method B.

7. Preparation of Apparatus

7.1 Washability Machine—The straight line washability machine should be leveled before use and operated at 37 6 1 cycles

per minute.

7.2 Brush—Replace the brush when the bristles have become worn to a point that the bristles extend less than 15 mm ( ⁄8 in.)

from the block. Mark the ends of the brush to ensure it is oriented in the same direction for each use.

7.2.1 Brushes (that are in frequent use)—Brushes that are in frequent use shall be stored in water. Each time before starting the

first test of the day, remove the brush and rinse in water, then precondition the brush, by running it for 400 cycles on a scrub panel,

after which it is ready for test work.

Cellosize QP-4400H, The Dow Chemical Company, Midland, Michigan, was used in developing the Precision and Bias statement. Other equivalent molecular weight

cellulosic thickeners can be used such as Natrosol 250 MR, Ashland Aqualon, Wilmington, Delaware.

The sole source of supply of the Triton X-100 detergent known to the committee at this time is The Dow Chemical Company, Midland, Michigan.

The sole source of supply of the Imsil 45 known to the committee at this time is Unimin Specialty Minerals Inc., 258 Elm St., New Canaan, CT 06840.

The preservative package recommended is BIT, 1,2–Benzisothiazol-3(2H)-one. There are several suppliers who offer BIT-based agents.

D2486 − 06 (2016)

7.2.2 Brushes (that are not in regular use)—Brushes that will not be used on a regular basis shall be washed out thoroughly in

water after their last use and stored with the brist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.