ASTM D6900-10(2020)

(Test Method)Standard Test Method for Wet Adhesion of Latex Paints to a Gloss Alkyd Enamel Substrate

Standard Test Method for Wet Adhesion of Latex Paints to a Gloss Alkyd Enamel Substrate

SIGNIFICANCE AND USE

5.1 After application to either interior or exterior surfaces, latex paints may be subjected to conditions of high humidity, condensation, or precipitation. This may sometimes lead to a loss of adhesion to the substrate over which they have been applied. This method is a quantitative measure of the adhesion of latex paints to glossy substrates under such conditions.

SCOPE

1.1 This test method covers a procedure for measuring by scrubbing the adhesion of latex paints to glossy alkyd enamel substrates after exposure to wet conditions.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6900 − 10 (Reapproved 2020)

Standard Test Method for

Wet Adhesion of Latex Paints to a Gloss Alkyd Enamel

Substrate

This standard is issued under the fixed designation D6900; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for measuring by 3.1 Definitions of Terms Specific to This Standard:

scrubbing the adhesion of latex paints to glossy alkyd enamel

3.1.1 wet adhesion, n—the ability of a coating to resist

substrates after exposure to wet conditions.

removal by scrubbing from the surface beneath it after expo-

sure to wet conditions and abrasion.

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Summary of Test Method

only.

4.1 Test paints, with optional control paint, are drawn down

1.3 This standard does not purport to address all of the

using a 7-mil clearance Dow applicator (~11 m /L) across a

safety concerns, if any, associated with its use. It is the

cured alkyd gloss enamel previously drawn down on a black or

responsibility of the user of this standard to establish appro-

white plastic panel.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.2 The drawdown films are allowed to dry under standard-

1.4 This international standard was developed in accor-

izedconditions.Then,eighteencutsaremadetoforma6by10

dance with internationally recognized principles on standard-

cut block, creating sixty 6.4 mm (0.25 in) squares, in the center

ization established in the Decision on Principles for the

of each film with a razor blade.

Development of International Standards, Guides and Recom-

4.3 The panels are then soaked for 30 min in ambient tap

mendations issued by the World Trade Organization Technical

water. The panel is mounted in a washability tester and 20 mL

Barriers to Trade (TBT) Committee.

of water are applied. The panel is then scrubbed for up to 500

cycles or until all of the squares within each block are

2. Referenced Documents

2 completely removed.

2.1 ASTM Standards:

D523 Test Method for Specular Gloss

5. Significance and Use

D714 Test Method for Evaluating Degree of Blistering of

Paints

5.1 After application to either interior or exterior surfaces,

D2486 Test Methods for Scrub Resistance of Wall Paints

latex paints may be subjected to conditions of high humidity,

D3924 Specification for Standard Environment for Condi- condensation, or precipitation. This may sometimes lead to a

tioning and Testing Paint, Varnish, Lacquer, and Related

loss of adhesion to the substrate over which they have been

Materials applied. This method is a quantitative measure of the adhesion

E691 Practice for Conducting an Interlaboratory Study to

of latex paints to glossy substrates under such conditions.

Determine the Precision of a Test Method

E177 Practice for Use of the Terms Precision and Bias in

6. Apparatus

ASTM Test Methods

6.1 Constanttemperature/humidityroominaccordancewith

Specification D3924 [23 6 2°C (73.5 6 3.5°F) and 50 65%

1 relative humidity].

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

6.2 Drawdown Plate.

Subcommittee D01.42 on Architectural Coatings.

Current edition approved Dec. 1, 2020. Published December 2020. Originally

6.3 Straight Line Washability Tester and Accessories, per

approved in 2003. Last previous edition approved in 2015 as D6900 – 10 (2015).

Test Methods D2486.

DOI:10.1520/D6900-10R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.4 Nylon Bristle Brush and Accessories (nominal weight

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

455 g), having nylon brush bristles in 5/4 pattern extending 19

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mm ( ⁄4 in.) from block (as per Test Methods D2486).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

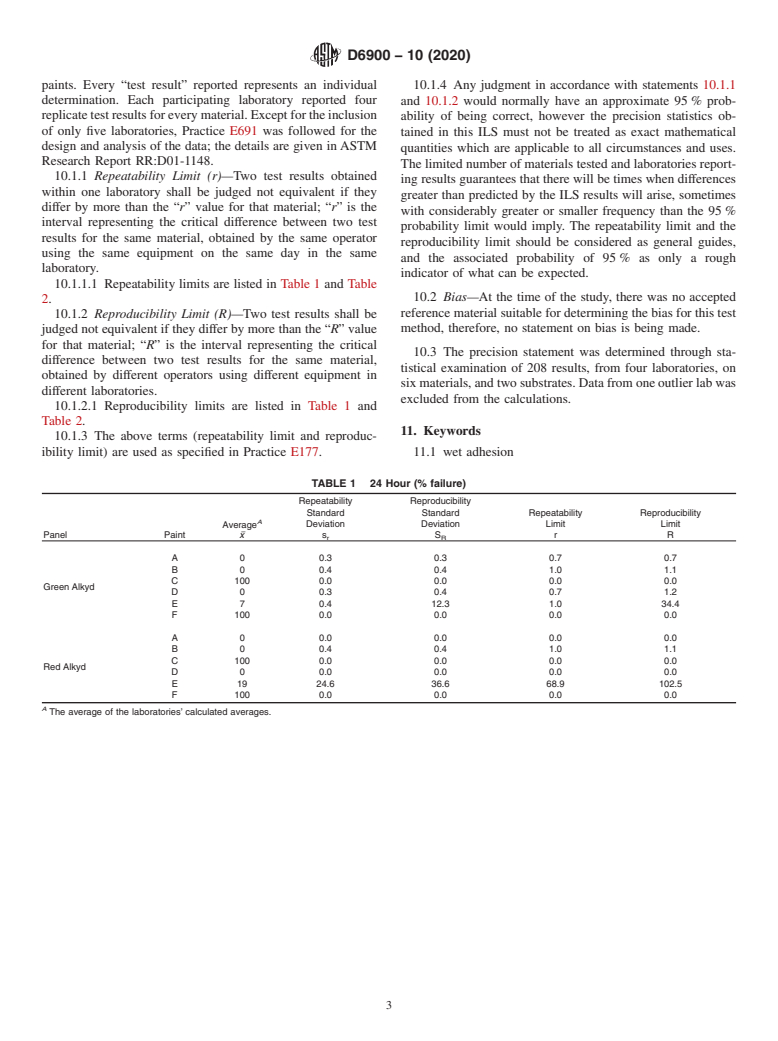

D6900 − 10 (2020)

6.5 Dow FilmApplicator,having7-mil(0.18-mm)clearance 8.2.2 Condition the panels for one week in the constant

by 5.2-in. (132-mm) width. applicator blade. temperature/humidity room as specified in Specification

D3924 or under other conditions agreed upon by buyer and

6.6 Single-edge Razor Blade, in safety holder.

seller.Shorterconditioningtimesmaybeusedifmorestringent

6.7 Metal Straight Edge (or appropriate guide).

measures of wet adhesion are needed, as in the case of

determining a coating’s “early” wet adhesion.

7. Reagents and Materials

NOTE 2—Since humidity and temperature both markedly influence the

7.1 A ready-mix deep-tint alkyd gloss enamel with a 60°

rateatwhichpaintdries,aconstanttemperature/humidityroomisstrongly

gloss of at least 65 as measured in accordance with Test

recommended in order to achieve reproducible results using this method.

Method D523 (or alkyd as agreed upon by the purchaser and

8.2.3 Condition, break in and rinse the scrub brush as

supplier).

specified in Test Methods D2486.

7.2 Plastic test panels as used in Test Methods D2486.

8.2.4 Using a metal straightedge or suitable guide, make

eighteen razor blade cuts, spaced 6.4 mm (0.25 in.) apart

8. Procedure

forminga6by10 array with a razor blade in the center of each

8.1 Preparation of the Alkyd Substrate Panels—Attach the paint (See Fig. 1.). Each cut should be made in one steady

motion with sufficient pressure to cut, but not tear the latex

plastic panel to the drawdown plate and drawdown the alkyd

gloss enamel lengthwise using a 7-mil clearance Dow appli- paint film. (Warning—Avoid cutting completely through the

alkyd enamel into the plastic substrate.)

cator. The time for application should be fairly slow—3 to 4 s

from end to end. The drawdown must be free of ridges, 8.2.5 Submerge each panel face-up for 30 min in a flat

container of ambient tap water, being careful not to bend the

holidays, specks, or other imperfections, which may affect

adhesion. substrate.

8.2.6 Removethepanelfromthewaterandquicklyexamine

8.1.1 Allow the alkyd gloss enamel to air-dry in a horizontal

position.Allowtocuretypicallyforaminimumofthreeweeks. the panel for blistering, per Test Method D714 (optional).

Immediatelysecurethepanelinthewashabilitytesterusingthe

Panels are to be used between three to six weeks from the date

of preparation. Wet adhesion with some latex paints may be gasketed frame accessory, ensuring that the array is in the path

of the brush. Place 20 mLof water in the path of the brush and

dramatically reduced if the alkyd is allowed to cure for more

than six weeks.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.