ASTM D1777-96(2007)

(Test Method)Standard Test Method for Thickness of Textile Materials

Standard Test Method for Thickness of Textile Materials

SCOPE

1.1 This test method covers the measurement of the thickness of most textile materials.

1.2 This test method applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, and pile fabrics. The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated. Instructions are provided for testing thickness, except as provided for in another standard such as listed in Section .

1.3 The values stated in SI units are to be regarded as the standard. The values stated in inch-pound may be approximate.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1777 – 96 (Reapproved 2007)

Standard Test Method for

1

Thickness of Textile Materials

This standard is issued under the fixed designation D1777; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope TEX-PAC

1.1 This test method covers the measurement of the thick-

3. Terminology

ness of most textile materials.

3.1 Definitions—For definitions of other textile terms used

1.2 This test method applies to most fabrics including

in this test method, see Terminology D123.

wovenfabrics,airbagfabrics,blankets,nappedfabrics,knitted

3.2 Definitions of Terms Specific to This Standard:

fabrics, layered fabrics, and pile fabrics. The fabrics may be

3.2.1 cross-machine direction, CD, n—the direction in the

untreated, heavily sized, coated, resin-treated, or otherwise

plane of the fabric perpendicular to the direction of manufac-

treated. Instructions are provided for testing thickness, except

ture.

as provided for in another standard such as listed in Section 2.

3.2.1.1 Discussion—This term is used to refer to the direc-

1.3 The values stated in SI units are to be regarded as the

tion analogous to coursewise or filling direction in knitted or

standard.Thevaluesstatedininch-poundmaybeapproximate.

woven fabrics, respectively.

1.4 This standard does not purport to address all of the

3.2.2 machine direction, MD, n—the direction in the plane

safety concerns, if any, associated with its use. It is the

of the fabric parallel to the direction of manufacture.

responsibility of the user of this standard to establish appro-

3.2.2.1 Discussion—This term is used to refer to the direc-

priate safety and health practices and determine the applica-

tion analogous to walewise or warp direction in knitted or

bility of regulatory limitations prior to use.

woven fabrics, respectively.

2. Referenced Documents 3.2.3 pressure, n—the force exerted to a surface per unit

2

area.

2.1 ASTM Standards:

3.2.3.1 Discussion—Pressure may be expressed in any ap-

D123 Terminology Relating to Textiles

propriate or specified units, such as pascals (Pa), newtons per

D1776 Practice for Conditioning and Testing Textiles

2

square metre (N/m ), or pounds-force per square inch (psi).

D2904 Practice for Interlaboratory Testing of a Textile Test

3.2.4 thickness, n—the distance between one surface of a

Method that Produces Normally Distributed Data

material and its opposite.

D2906 Practice for Statements on Precision and Bias for

3

3.2.4.1 Discussion—In textiles, thickness is the distance

Textiles

between the upper and lower surfaces of the material as

2.2 ASTM Adjuncts:

measuredunderaspecifiedpressure.Itisusuallydeterminedas

the distance between an anvil or base and a presser foot used

1 to apply the specified pressure.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

4. Summary of Test Method

General.

Current edition approved Jan. 1, 2007. Published January 2007. Originally

4.1 A specimen is placed on the base of a thickness gauge

approved in 1960. Discontinued in November 1995 and reinstated as D1777 – 96.

and a weighted presser foot lowered. The displacement be-

Lastpreviouseditionapprovedin2002asD1777 – 96(2002).DOI:10.1520/D1777-

96R07. tweenthebaseandthepresserfootismeasuredasthethickness

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of the specimen.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. A PC program on floppy disk for analyzing Committee D13 interlaboratory

3

1

Withdrawn. The last approved version of this historical standard is referenced data are available from ASTM Headquarters. For a 3 ⁄2-in. disk, request PCN:12-

1

on www.astm.org. 429040-18. For a 5 ⁄4-in. disk, request PCN:12-429041-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

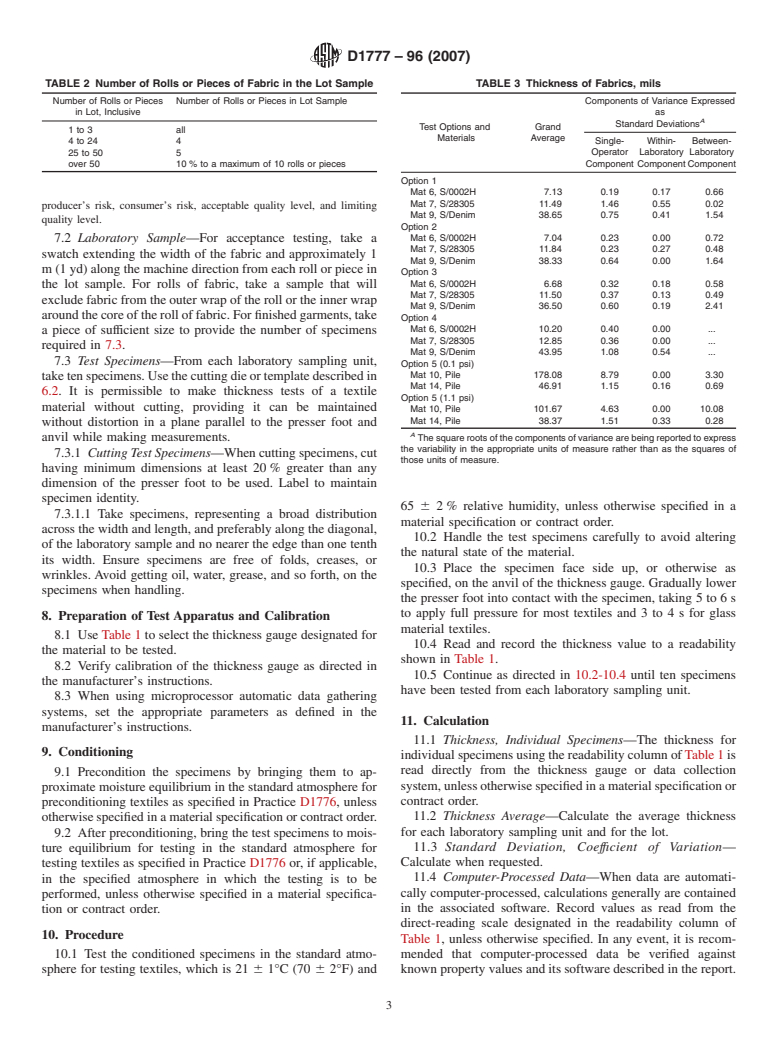

D1777 – 96 (2007)

5. Significance and Use shall take precedence over the directions described in this test

method, unless specifically provided for in that test method.

5.1 This test method is considered satisfactory for accep-

This test method is used in its entirety when no test method for

tance testing of commercial shipments since current estimates

measuring thickness is available for the specific material to be

of between-laboratory precision are acceptable, and this test

tested or unless otherwise specified in a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.