ASTM E1316-00

(Terminology)Standard Terminology for Nondestructive Examinations

Standard Terminology for Nondestructive Examinations

SCOPE

1.1 This standard defines the terminology used in the standards prepared by the E07 Committee on Nondestructive Testing. These nondestructive testing (NDT) methods include: acoustic emission, electromagnetic testing, gamma- and X-radiology, leak testing, liquid penetrant examination, magnetic particle examination, neutron radiology and gaging, ultrasonic examination, and other technical methods.

1.2 Section A defines terms that are common to multiple NDT methods, whereas, the subsequent sections define terms pertaining to specific NDT methods. An alphabetical list of the terms defined in this standard is given in Appendix X1, which also identifies the section in which each term is defined.

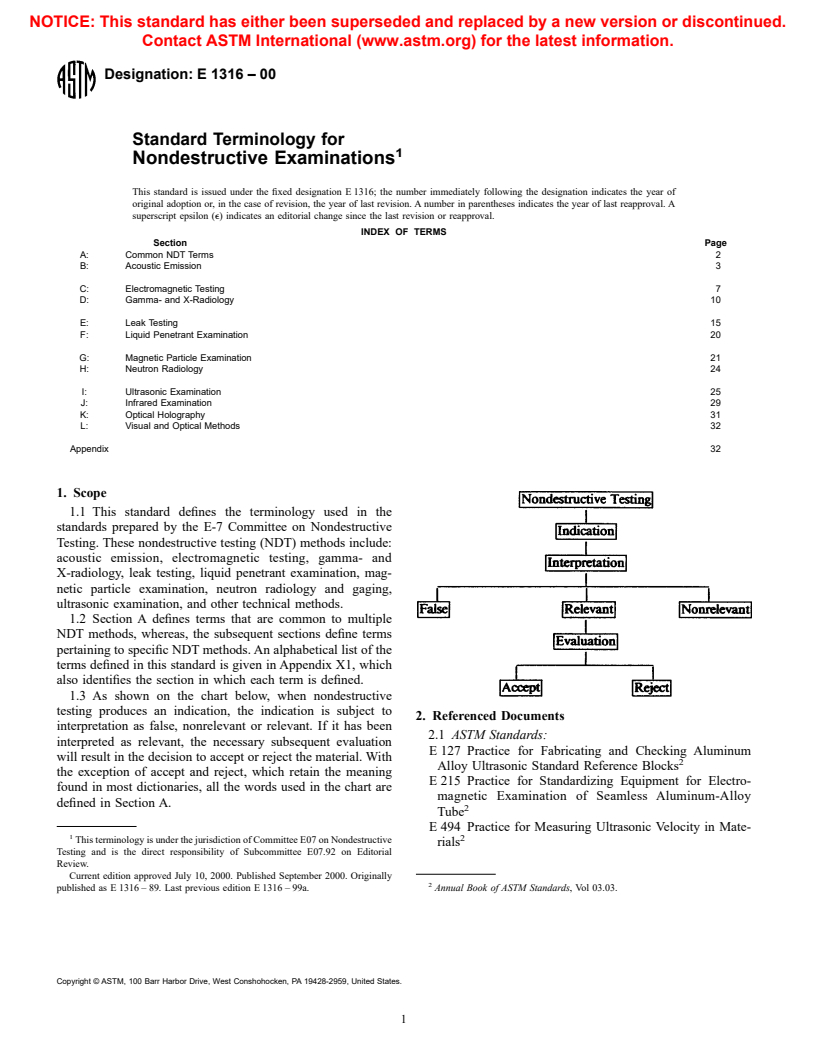

1.3 As shown on the chart below, when nondestructive testing produces an indication, the indication is subject to interpretation as false, nonrelevant or relevant. If it has been interpreted as relevant, the necessary subsequent evaluation will result in the decision to accept or reject the material. With the exception of accept and reject, which retain the meaning found in most dictionaries, all the words used in the chart are defined in Section A.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1316 – 00

Standard Terminology for

Nondestructive Examinations

This standard is issued under the fixed designation E 1316; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INDEX OF TERMS

Section Page

A: Common NDT Terms 2

B: Acoustic Emission 3

C: Electromagnetic Testing 7

D: Gamma- and X-Radiology 10

E: Leak Testing 15

F: Liquid Penetrant Examination 20

G: Magnetic Particle Examination 21

H: Neutron Radiology 24

I: Ultrasonic Examination 25

J: Infrared Examination 29

K: Optical Holography 31

L: Visual and Optical Methods 32

Appendix 32

1. Scope

1.1 This standard defines the terminology used in the

standards prepared by the E-7 Committee on Nondestructive

Testing. These nondestructive testing (NDT) methods include:

acoustic emission, electromagnetic testing, gamma- and

X-radiology, leak testing, liquid penetrant examination, mag-

netic particle examination, neutron radiology and gaging,

ultrasonic examination, and other technical methods.

1.2 Section A defines terms that are common to multiple

NDT methods, whereas, the subsequent sections define terms

pertaining to specific NDT methods. An alphabetical list of the

terms defined in this standard is given in Appendix X1, which

also identifies the section in which each term is defined.

1.3 As shown on the chart below, when nondestructive

testing produces an indication, the indication is subject to

2. Referenced Documents

interpretation as false, nonrelevant or relevant. If it has been

2.1 ASTM Standards:

interpreted as relevant, the necessary subsequent evaluation

E 127 Practice for Fabricating and Checking Aluminum

will result in the decision to accept or reject the material. With

Alloy Ultrasonic Standard Reference Blocks

the exception of accept and reject, which retain the meaning

E 215 Practice for Standardizing Equipment for Electro-

found in most dictionaries, all the words used in the chart are

magnetic Examination of Seamless Aluminum-Alloy

defined in Section A.

Tube

E 494 Practice for Measuring Ultrasonic Velocity in Mate-

This terminology is under the jurisdiction of Committee E07 on Nondestructive

rials

Testing and is the direct responsibility of Subcommittee E07.92 on Editorial

Review.

Current edition approved July 10, 2000. Published September 2000. Originally

published as E 1316 – 89. Last previous edition E 1316 – 99a. Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1316

E 566 Practice for Electromagnetic (Eddy-Current) Sorting Fiberlass Reinforced Plastic Resin (FRP) Tanks/Vessels

of Ferrous Metals

E 1118 Practice for Acoustic Emission Examination of Re-

E 664 Practice for Measurement of the Apparent Attenua-

inforced Thermosetting Resin Pipe (RTRP)

tion of Longitudinal Ultrasonic Waves by Immersion

E 1213 Test Method for Minimum Resolvable Temperature

Method

Difference for Thermal Imaging Systems

E 750 Practice for Characterizing Acoustic Emission Instru-

mentation

3. Significance and Use

E 804 Practice for Calibration of the Ultrasonic Test System

3.1 The terms found in this proposed standard are intended

by Extrapolation Between Flat-Bottom Hole Sizes

E 1033 Practice for Electromagnetic (Eddy-Current) Ex- to be used uniformly and consistently in all nondestructive

testing standards. The purpose of this standard is to promote a

amination of Type F-Continuously Welded (CW) Ferro-

magnetic Pipe and Tubing Above the Curie Temperature clear understanding and interpretation of the NDT standards in

E 1067 Practice for Acoustic Emission Examination of which they are used.

Section A: Common NDT Terms

The terms defined in Section A are the direct responsibility of Subcommittee E07.92, Editorial Review.

4. Terminology able by nondestructive testing and is not necessarily reject-

able.

acceptable quality level—the maximum percent defective or

flaw characterization, n—the process of quantifying the size,

the maximum number of units defective per hundred units

shape, orientation, location, growth, or other properties, of a

that, for the purpose of sampling test, can be considered

flaw based on NDT response.

satisfactory as a process average.

imperfection, n—a departure of a quality characteristic from

amorphous silicon (a-Si) X-ray detector, n—an amorphous

its intended condition.

silicon (a-Si) X-ray detector consists of a glass substrate

indication—the response or evidence from a nondestructive

with a matrix of photodiodes fabricated from amorphous

examination.

silicon and switches arranged in rows and columns upon it;

DISCUSSION—An indication is determined by interpretation to be

the photodiodes are activated by light photons emitted from

relevant, non-relevant, or false.

a scintillator which is activated by X rays and is usually in

close contact with the diode matrix. inspection, n—a procedure for viewing or observing visual

characteristics of a material or component in a careful,

calibration, instrument, n—the comparison of an instrument

critical manner.

with, or the adjustment of an instrument to, a known

reference(s) often traceable to the National Institute of

DISCUSSION—Examples include performance of a visual/optical in-

Standards and Technology (NIST). (See also standardiza-

spection, observing the results of a magnetic particle or liquid penetrant

tion, instrument.)

examination, or carefully observing a surface condition prior to

performing an ultrasonic or eddy-current examination. (From the same

defect, n—one or more flaws whose aggregate size, shape,

root word as “spectacle” or “spectator”.)

orientation, location, or properties do not meet specified

acceptance criteria and are rejectable.

interpretation—the determination of whether indications are

discontinuity, n—a lack of continuity or cohesion; an inten-

relevant or nonrelevant.

tional or unintentional interruption in the physical structure

interpretation, n—the determination of whether indications

or configuration of a material or component.

are relevant, nonrelevant, or false.

evaluation—a review, following interpretation of the indica- Nondestructive Testing (NDT), n—the development and

tions noted, to determine whether they meet specified application of technical methods to examine materials or

acceptance criteria. components in ways that do not impair future usefulness and

serviceability in order to detect, locate, measure and evaluate

examination, n—a procedure for determining a property (or

flaws; to assess integrity, properties and composition; and to

properties) or other conditions or characteristics of a material

measure geometrical characteristics.

or component by direct or indirect means.

Nondestructive Evaluation—see Nondestructive Testing.

DISCUSSION—Examples include utilization of X rays or ultrasonic

Nondestructive Examination—see Nondestructive Testing.

waves for the purpose of determining (directly or by calculation) flaw

Nondestructive Inspection—see Nondestructive Testing.

content, density, or (for ultra sound) modulus; or detection of flaws by

nonrelevant indication, n—an NDT indication that is caused

induction of eddy currents, observing thermal behavior, AE response,

by a condition or type of discontinuity that is not rejectable.

or utilization of magnetic particles or liquid penetrants.

False indications are non-relevant.

false indication, n—an NDT indication that is interpreted to be

relevant indication, n—an NDT indication that is caused by a

caused by a condition other than a discontinuity or imper-

condition or type of discontinuity that requires evaluation.

fection.

standardization, instrument, n—the adjustment of an instru-

flaw, n—an imperfection or discontinuity that may be detect- ment, prior to use, to an arbitrary reference value. (See also

E 1316

DISCUSSION—Examples include mechanical tests to determine

calibration, instrument.)

strength, hardness, or other property; determination of leakage (a leak

test, n—a procedure for determining a property or character-

test); or checking the performance (function) of a piece of equipment.

istic of a material or a component by direct measurement.

Section B: Acoustic Emission (E 750, E 1067, and E 1118)

The boldface designations in parentheses indicate the standards from which the terms in that section were derived.

The terms defined in Section B are the direct responsibility of Subcommittee E07.04 on Acoustic Emission Method.

acoustic emission (AE)—the class of phenomena whereby excursion exceeding threshold.

transient elastic waves are generated by the rapid release of array, n—a group of two or more AE sensors positioned on a

energy from localized sources within a material, or the structure for the purposes of detecting and locating sources.

transient waves so generated. Acoustic emission is the The sources would normally be within the array.

recommended term for general use. Other terms that have arrival time interval (Dt )—see interval, arrival time.

ij

been used in AE literature include (1) stress wave emission, attenuation, n—the decrease in AE amplitude per unit dis-

(2) microseismic activity, and (3) emission or acoustic tance, normally expressed in dB per unit length.

emission with other qualifying modifiers. average signal level, n—the rectified, time averaged AE

acoustic emission channel—see channel, acoustic emission. logarithmic signal, measured on the AE amplitude logarith-

acoustic emission count (emission count) (N)—see count, mic scale and reported in dB units (where 0 dB refers to

ae ae

acoustic emission. 1 μV at the preamplifier input).

acoustic emission count rate—see count rate, acoustic emis- burst emission—see emission, burst.

˙

sion (emission rate or count rate) (N). channel, acoustic emission—an assembly of a sensor, pream-

acoustic emission event—see event, acoustic emission. plifier or impedance matching transformer, filters secondary

amplifier or other instrumentation as needed, connecting

acoustic emission event energy—see energy, acoustic event.

acoustic emission sensor—see sensor, acoustic emission. cables, and dedector or processor.

acoustic emission signal amplitude—see signal amplitude,

NOTE 1—A channel for examining fiberglass reinforced plastic (FRP)

acoustic emission.

may utilize more than one sensor with associated electronics. Channels

acoustic emission signal (emission signal)—see signal, acous-

may be processed independently or in predetermined groups having

tic emission. similar sensitivity and frequency characteristics.

acoustic emission signature (signature)—see signature,

continuous emission— see emission, continuous.

acoustic emission.

count, acoustic emission (emission count) (N)—the number

acoustic emission transducer—see sensor, acoustic emission.

of times the acoustic emission signal exceeds a preset

acoustic emission waveguide—see waveguide, acoustic emis-

threshold during any selected portion of a test.

sion.

count, event (N )—the number obtained by counting each

e

acousto-ultrasonics (AU)—a nondestructive examination

discerned acoustic emission event once.

method that uses induced stress waves to detect and assess

count rate, acoustic emission (emission rate or count rate)

diffuse defect states, damage conditions, and variations of

˙

(N)—the time rate at which emission counts occur.

mechanical properties of a test structure. The AU method

count, ring-down—see count, acoustic emission, the preferred

combines aspects of acoustic emission (AE) signal analysis

term.

with ultrasonic materials characterization techniques.

couplant—a material used at the structure-to-sensor interface

adaptive location—source location by iterative use of simu-

to improve the transmission of acoustic energy across the

lated sources in combination with computed location.

interface during acoustic emission monitoring.

AE activity, n—the presence of acoustic emission during a

cumulative (acoustic emission) amplitude distribution F(V)—

test.

see distribution, amplitude, cumulative.

AE rms, n—the rectified, time averaged AE signal, measured

cumulative (acoustic emission) threshold crossing distribution

on a linear scale and reported in volts.

F (V)—see distribution, threshold crossing, cumulative.

t

AE signal duration—the time between AE signal start and AE

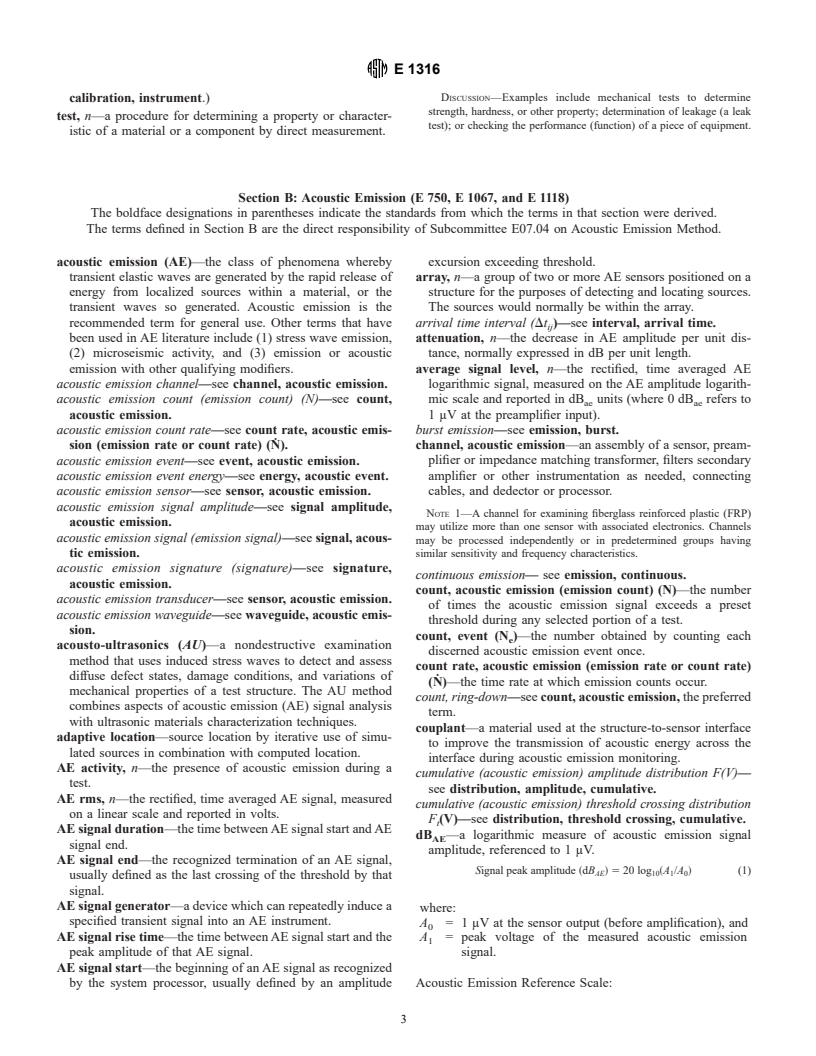

dB —a logarithmic measure of acoustic emission signal

AE

signal end.

amplitude, referenced to 1 μV.

AE signal end—the recognized termination of an AE signal,

Signal peak amplitude ~dB ! 5 20 log ~A /A ! (1)

AE 10 1 0

usually defined as the last crossing of the threshold by that

signal.

AE signal generator—a device which can repeatedly induce a

where:

specified transient signal into an AE instrument. A = 1 μV at the sensor output (before amplification), and

AE signal rise time—the time between AE signal start and the A = peak voltage of the measured acoustic emission

peak amplitude of that AE signal. signal.

AE signal start—the beginning of an AE signal as recognized

by the system processor, usually defined by an amplitude Acoustic Emission Reference Scale:

E 1316

the differential amplitude distribution, appropriate for loga-

dB Value Voltage at Sensor Output

AE

01μV

rithmically windowed data.

20 10 μV

dynamic range—the difference, in decibels, between the

40 100 μV

overload level and the minimum signal level (usually fixed

60 1 mV

80 10 mV

by one or more of the noise levels, low-level distortion,

100 100 mV

interference, or resolution level) in a system or sensor.

dead time—any interval during data acquisition when the

effective velocity, n—velocity calculated on the basis of arrival

instrument or system is unable to accept new data for any times and propagation distances determined by artificial AE

reason. (E 750)

generation; used for computed location.

differential (acoustic emission) amplitude distribution F(V)—

emission, burst—a qualitative description of the discrete

see distribution, differential (acoustic emission) ampli-

signal related to an individual emission event occurring

tude f(V).

within the material.

differential (acoustic emission) threshold crossing distribution

NOTE 2—Use of the term burst emission is recommended only for

f (V)—see distribution, differential (acoustic emission)

t

describing the qualitative appearance of emission signals. Fig. 1 shows an

threshold crossing.

oscilloscope trace of burst emission signals on a background of continuous

distribution, amplitude, cumulative (acoustic emission)

emission.

F(V)—the number of acoustic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.