ASTM E2465-13

(Test Method)Standard Test Method for Analysis of Ni-Base Alloys by Wavelength Dispersive X-Ray Fluorescence Spectrometry

Standard Test Method for Analysis of Ni-Base Alloys by Wavelength Dispersive X-Ray Fluorescence Spectrometry

SIGNIFICANCE AND USE

5.1 This procedure is suitable for manufacturing control and for verifying that the product meets specifications. It provides rapid, multi-element determinations with sufficient accuracy to assure product quality. The analytical performance data included may be used as a benchmark to determine if similar X-ray spectrometers provide equivalent precision and accuracy, or if the performance of a particular spectrometer has changed.

SCOPE

1.1 This test method covers the analysis of Ni-base alloys by wavelength dispersive X-ray Fluorescence Spectrometry for the determination of the following elements:

Element

Composition Range

Manganese

0.06 % to 1.6 %

Phosphorus

0.008 % to 0.015 %

Silicon

0.08 % to 0.6 %

Chromium

1.6 % to 22 %

Nickel

23 % to 77 %

Aluminum

0.20 % to 1.3 %

Molybdenum

0.03 % to 10 %

Copper

0.007 % to 2.5 %

Titanium

0.11 % to 3.0 %

Niobium

0.55 % to 5.3 %

Iron

0.17 % to 46 %

Tungsten

0.06 % to 0.50 %

Cobalt

0.04 % to 0.35 %

Note 1—Unless exceptions are noted, concentration ranges can be extended by the use of suitable reference materials. Once these element ranges are extended they must be verified by some experimental means. This could include but not limited to Gage Repeatability and Reproducibility studies and/or Inter-laboratory Round Robin studies. Once these studies are completed, they will satisfy the ISO 17025 requirements for capability.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2465 − 13

Standard Test Method for

Analysis of Ni-Base Alloys by Wavelength Dispersive X-Ray

1

Fluorescence Spectrometry

This standard is issued under the fixed designation E2465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

1.1 This test method covers the analysis of Ni-base alloys

E305 Practice for Establishing and Controlling Atomic

bywavelengthdispersiveX-rayFluorescenceSpectrometryfor

Emission Spectrochemical Analytical Curves

the determination of the following elements:

E1361 Guide for Correction of Interelement Effects in

Element Composition Range

X-Ray Spectrometric Analysis

Manganese 0.06 % to 1.6 %

Phosphorus 0.008 % to 0.015 % E1601 Practice for Conducting an Interlaboratory Study to

Silicon 0.08 % to 0.6 %

Evaluate the Performance of an Analytical Method

Chromium 1.6 % to 22 %

E1622 Practice for Correction of Spectral Line Overlap in

Nickel 23 % to 77 %

Aluminum 0.20 % to 1.3 % Wavelength-Dispersive X-Ray Spectrometry (Withdrawn

3

Molybdenum 0.03 % to 10 %

2006)

Copper 0.007 % to 2.5 %

2.2 Other Documents:

Titanium 0.11 % to 3.0 %

Niobium 0.55 % to 5.3 % ISO 17025 General requirements for the competence of

Iron 0.17 % to 46 %

testing and calibration laboratories

Tungsten 0.06 % to 0.50 %

4

2.3 U.S. Government Standards:

Cobalt 0.04 % to 0.35 %

10 CFR Part 19 Notices, Instructions and Reports to Work-

NOTE 1—Unless exceptions are noted, concentration ranges can be

ers: Inspection and Investigations

extended by the use of suitable reference materials. Once these element

10 CFR Part 20 Standards for Protection Against Radiation

ranges are extended they must be verified by some experimental means.

This could include but not limited to Gage Repeatability and Reproduc-

3. Terminology

ibility studies and/or Inter-laboratory Round Robin studies. Once these

studies are completed, they will satisfy the ISO 17025 requirements for

3.1 Definitions—For definitions of terms used in this test

capability.

method, refer to Terminology E135.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4. Summary of Test Method

standard.

4.1 Thetestspecimenisfinishedtoaclean,uniformsurface,

1.3 This standard does not purport to address all of the

then irradiated with an X-ray beam of high energy. The

safety concerns, if any, associated with its use. It is the

secondary X-rays produced are dispersed by means of crystals

responsibility of the user of this standard to establish appro-

and the intensities are measured by suitable detectors at

priate safety and health practices and to determine the

selected wavelengths. The outputs of the detectors in voltage

applicability of regulatory limitations prior to use.

pulsesarecounted.Radiationmeasurementsaremadebasedon

the time required to reach a fixed number of counts, or on the

2. Referenced Documents

total counts obtained for a fixed time (generally expressed in

2

counts or kilocounts per unit time).

2.1 ASTM Standards:

4.2 Concentrations of the elements are determined by relat-

ing the measured radiation of unknown specimens to analytical

1

This test method is under the jurisdiction of ASTM Committee E01 on

curves prepared with suitable reference materials. Either a

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.08 on Ni and Co and HighTemperatureAlloys. fixed-channel (simultaneous) spectrometer or a sequential

CurrenteditionapprovedJune1,2013.PublishedJuly2013.Originallyapproved

ε1

in 2006. Last previous edition approved in 2011 as E2465 – 11 . DOI: 10.1520/

3

E2465-13. The last approved version of this historical standard is referenced on

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from the U.S. Nuclear Regulatory Commission, Public Document

Standards volume information, refer to the standard’s Document Summary page on Room, One White Flint North, 11555 Rockville Pike, Rockville, MD 20852-2738,

the ASTM website. http://www.nrc.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

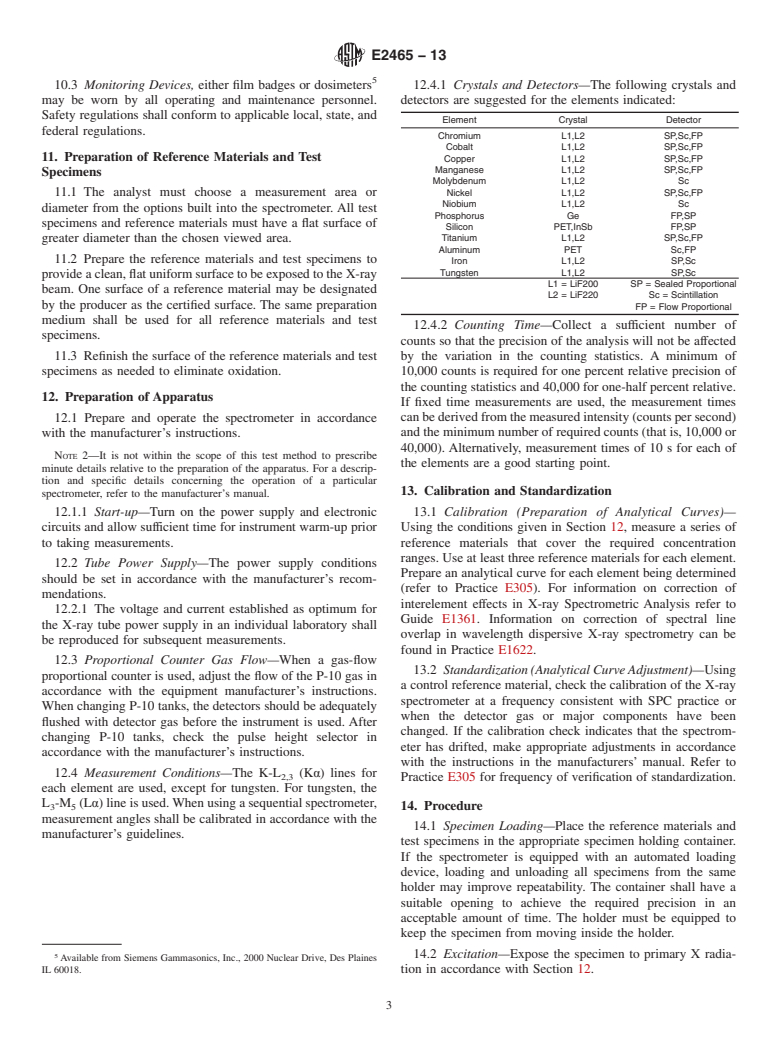

---------------------- Page: 1 ----------------------

E2465 − 13

spectrometer, or an instrument combining both fixed-channels maticpumpdownoftheopticalpath,andmaintainacontrolled

and one or more goniometers shall be used. pressure, usually 13 Pa (100 mm Hg)

...

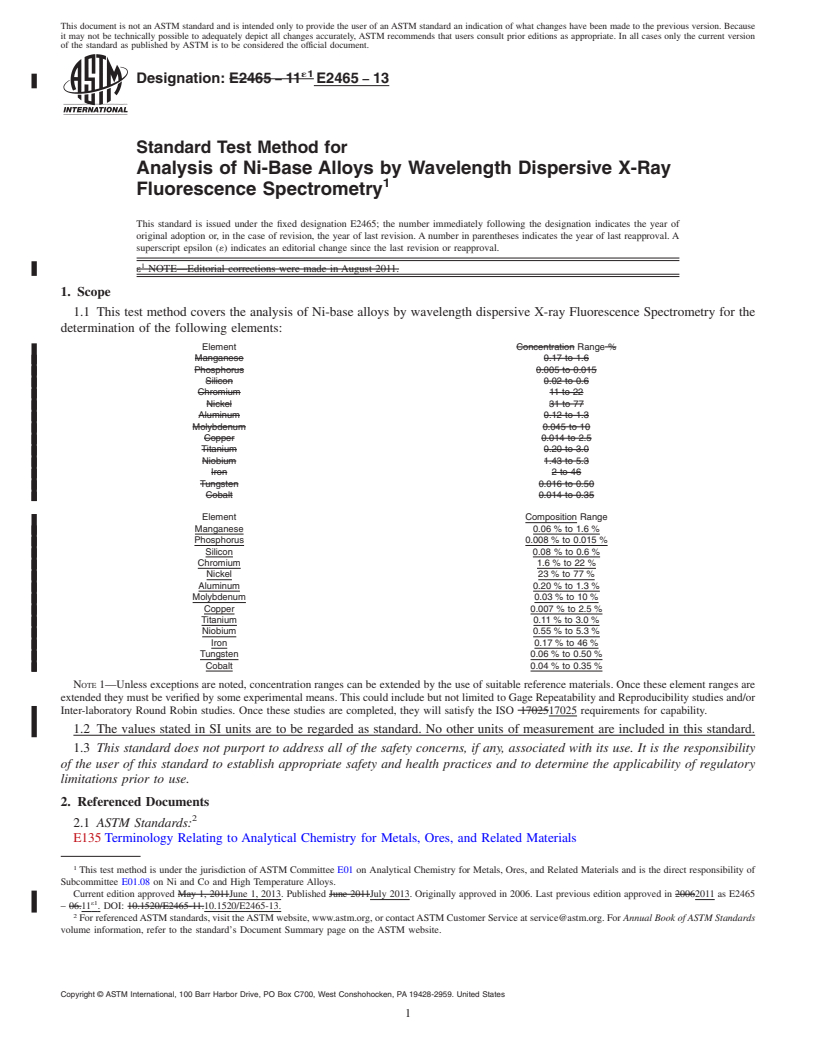

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E2465 − 11 E2465 − 13

Standard Test Method for

Analysis of Ni-Base Alloys by Wavelength Dispersive X-Ray

1

Fluorescence Spectrometry

This standard is issued under the fixed designation E2465; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial corrections were made in August 2011.

1. Scope

1.1 This test method covers the analysis of Ni-base alloys by wavelength dispersive X-ray Fluorescence Spectrometry for the

determination of the following elements:

Element Concentration Range %

Manganese 0.17 to 1.6

Phosphorus 0.005 to 0.015

Silicon 0.02 to 0.6

Chromium 11 to 22

Nickel 31 to 77

Aluminum 0.12 to 1.3

Molybdenum 0.045 to 10

Copper 0.014 to 2.5

Titanium 0.20 to 3.0

Niobium 1.43 to 5.3

Iron 2 to 46

Tungsten 0.016 to 0.50

Cobalt 0.014 to 0.35

Element Composition Range

Manganese 0.06 % to 1.6 %

Phosphorus 0.008 % to 0.015 %

Silicon 0.08 % to 0.6 %

Chromium 1.6 % to 22 %

Nickel 23 % to 77 %

Aluminum 0.20 % to 1.3 %

Molybdenum 0.03 % to 10 %

Copper 0.007 % to 2.5 %

Titanium 0.11 % to 3.0 %

Niobium 0.55 % to 5.3 %

Iron 0.17 % to 46 %

Tungsten 0.06 % to 0.50 %

Cobalt 0.04 % to 0.35 %

NOTE 1—Unless exceptions are noted, concentration ranges can be extended by the use of suitable reference materials. Once these element ranges are

extended they must be verified by some experimental means. This could include but not limited to Gage Repeatability and Reproducibility studies and/or

Inter-laboratory Round Robin studies. Once these studies are completed, they will satisfy the ISO 1702517025 requirements for capability.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.08 on Ni and Co and High Temperature Alloys.

Current edition approved May 1, 2011June 1, 2013. Published June 2011July 2013. Originally approved in 2006. Last previous edition approved in 20062011 as E2465

ε1

– 06.11 . DOI: 10.1520/E2465-11.10.1520/E2465-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2465 − 13

E305 Practice for Establishing and Controlling Atomic Emission Spectrochemical Analytical Curves

E1361 Guide for Correction of Interelement Effects in X-Ray Spectrometric Analysis

E1601 Practice for Conducting an Interlaboratory Study to Evaluate the Performance of an Analytical Method

3

E1622 Practice for Correction of Spectral Line Overlap in Wavelength-Dispersive X-Ray Spectrometry (Withdrawn 2006)

2.2 Other Documents:

ISO 17025 General requirements for the competence of testing and calibration laboratories

4

2.3 U.S. Government Standards:

10 CFR Part 19 Notices, Instructions and Reports to Workers: Inspection and Investigations

10 CFR Part 20 Standards for Protection Against Radiation

3. Terminology

3.1 For definitions of terms used in this test method, refer to Terminology .

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E135.

4. Summary of Test Method

4.1 The test specimen is finished to a clean, uniform surface, then irradiated with an X-ray beam of high energy. The secondary

X-rays produced are dispersed by means of crystals and the intensities are measured by suitable detectors at selected wavelengths.

The outputs of the detectors in voltage pulses are counted. Radiation measurements are made based on the time required to reach

a fixed number of counts

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.