ASTM F25-04

(Test Method)Standard Test Method for Sizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled Areas

Standard Test Method for Sizing and Counting Airborne Particulate Contamination in Cleanrooms and Other Dust-Controlled Areas

ABSTRACT

This test method covers the apparatus required, sampling methods, standard procedures and calculations, and test reports for counting and sizing airborne microparticulate matter, the sampling areas for which are specifically those with contamination levels typical of cleanrooms and dust-controlled areas. The test method is based on the microscopical examination of particles impinged upon a membrane filter with the aid of a vacuum. Sampling may be done in a cleanroom, clean zone, or other controlle areas, or in a duct or pipe, wherein the number of sampling points is proportional to the floor area of the enclosure to be checked. The apparatus and facilities required are typical of a laboratory for the study of macroparticle contamination. The operator must have adequate basic training in microscopy and the techniques of particle sizing and counting.

SCOPE

1.1 This test method covers counting and sizing airborne particulate matter 5 m and larger (macroparticles). The sampling areas are specifically those with contamination levels typical of cleanrooms and dust-controlled areas.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 25 – 04

Standard Test Method for

Sizing and Counting Airborne Particulate Contamination in

1

Cleanrooms and Other Dust-Controlled Areas

ThisstandardisissuedunderthefixeddesignationF 25;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Particulate Contamination of Air in Dust-Controlled

5

Spaces by Particle Count Method, August 1962

1.1 This test method covers counting and sizing airborne

particulate matter 5 µm and larger (macroparticles). The

3. Terminology

sampling areas are specifically those with contamination levels

3.1 Definitions:

typical of cleanrooms and dust-controlled areas.

3.1.1 airflow:

1.2 The values stated in SI units are to be regarded as the

3.1.1.1 unidirectional airflow—air flow which has a singu-

standard. The values given in parentheses are for information

lar direction of flow and may or may not contain uniform

only.

velocities of air flow along parallel lines.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 1—Formerly known as laminar airflow.

responsibility of the user of this standard to establish appro-

3.1.1.2 non-unidirectional airflow—air distribution where

priate safety and health practices and determine the applica-

the supply air entering the room mixes with the internal air by

bility of regulatory requirements prior to use.

means of induction.

3.1.2 critical pressure—for an orifice, with a constant up-

2. Referenced Documents

stream pressure, the downstream pressure at which the flow

2

2.1 ASTM Standards:

will not increase when the downstream pressure decreases.

F50 Practice for Continuous Sizing and Counting of Air-

3.1.3 critical pressure ratio—the ratio of the critical pres-

borne Particles in Dust-ControlledAreas and Clean Rooms

sure of an orifice to the entrance pressure.

Using Instruments Capable of Detecting Single Sub-

3.1.4 customer—organization, or the agent thereof, respon-

Micrometre and Larger Particles

sible for specifying the requirements of a cleanroom or clean

2.2 ISO Standard:

zone.

ISO 14644-1 Cleanrooms and Associated Controlled

3.1.5 fiber—particle having an aspect (length-to-width) ra-

3

Environments—Part 1: Classification of Air Cleanliness

tio of 10 or more.

2.3 IEST Document:

3.1.6 macroparticle—particle with an equivalent diameter

IEST-G-CC1003 Measurement of Airborne Macroparticles

greater than 5 µm.

4

(1999)

3.1.7 M descriptor—measured or specified concentration of

2.4 SAE Document:

macroparticles per cubic metre of air, expressed in terms of the

SAE AbstractARP-743, Procedure for the Determination of

equivalent diameter that is characteristic of the measurement

method used.

1

This test method is under the jurisdiction of ASTM Committee E21 on Space 3.1.7.1 Discussion—The M descriptor may be regarded as

Simulation andApplications of Space Technology and is the direct responsibility of

an upper limit for the averages at sampling locations (or as an

Subcommittee E21.05 on Contamination.

upper confidence limit, depending upon the number of sam-

Current edition approved Sept. 1, 2004. Published September 2004. Originally

pling locations used to characterize the cleanroom or clean

approved in 1963. Last previous edition approved in 1999 as F 25 – 68 (1999).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

zone). M descriptors cannot be used to define airborne particu-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

late cleanliness classes, but they may be quoted independently

Standards volume information, refer to the standard’s Document Summary page on

or in conjunction with airborne particulate cleanliness classes.

the ASTM website.

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

4 5

Available from Institute of Environmental Sciences and Technology (IEST), Available from Society of Automotive Engineers (SAE), 400 Commonwealth

5005 Newport Dr., Suite 506, Rolling Meadows, IL 60008-3841. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F25–04

apparatus and facilities required are typical of a laboratory for

the study of macroparticle contamination. The operator must

have adequate basic training in microscopy and the techniques

of particle sizing and counting.

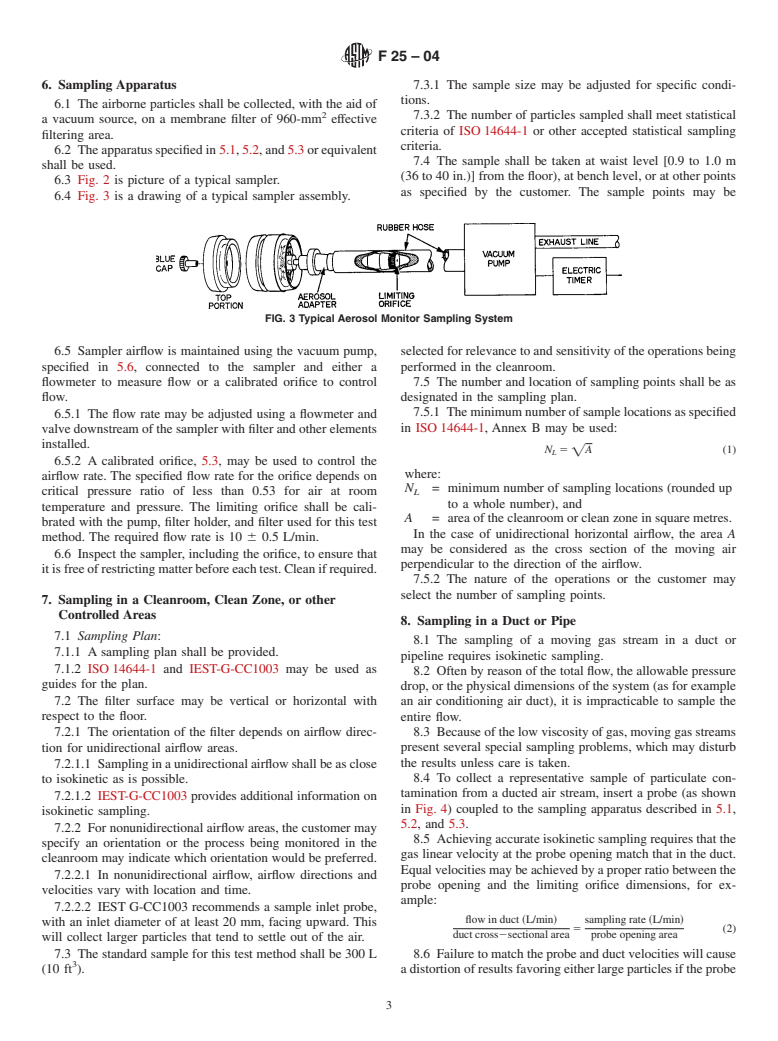

5. Apparatus

6

5.1 Filter Holder, aerosol open type having an effective

2

filtering area of 960 6 25 mm .

7

5.2 Adapter.

8

5.3 Flow-Limiting Orifice, 10 L/

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.