ASTM D7255-14

(Test Method)Standard Test Method for Abrasion Resistance of Leather (Rotary Platform, Abraser Method)

Standard Test Method for Abrasion Resistance of Leather (Rotary Platform, Abraser Method)

SIGNIFICANCE AND USE

5.1 The resistance of leather to abrasion, as measured on a testing machine in the laboratory, is generally only one of several factors contributing to wear performance or durability as experienced in the actual use of the material. While “abrasion resistance” (often stated in terms of the number of abrasion cycles) and “durability” are frequently related, the relationship varies with different end uses and different factors may be necessary in any calculation of predicted durability from specific abrasion data. This test method provides a comparative ranking of material performance, which can be used as an indication of relative end-use performance.

5.2 The resistance of leather to abrasion may be affected by factors including test conditions, type of abradant, pressure between the specimen and abradant, mounting or tension of the specimen, and type, kind, or amount of finishing materials.

5.3 Abrasion tests utilizing the rotary platform abraser may be subject to variation due to changes in the abradant during specific tests. Depending on abradant type and test specimen, the wheel surface may change (that is, become clogged) due to the pick up of finishing or other materials from test specimens and must be resurfaced at regularly defined intervals.

5.4 The measurement of the relative amount of abrasion may also be affected by the method of evaluation and may be influenced by the judgment of the operator.

SCOPE

1.1 This test method covers the determination of the abrasion resistance of leather using the rotary platform abraser.Note 1—This test method is similar but not equivalent to ISO 17076-1, and results should not be directly compared between the two methods.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7255 − 14

Standard Test Method for

Abrasion Resistance of Leather (Rotary Platform, Abraser

1

Method)

This standard is issued under the fixed designation D7255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 abrasion—the wearing away of any part of a material

by rubbing against another surface.

1.1 This test method covers the determination of the abra-

3.1.3 abrasion cycle—in abrasion testing, one or more

sion resistance of leather using the rotary platform abraser.

NOTE1—ThistestmethodissimilarbutnotequivalenttoISO17076-1, movements of the abradant across a material surface, or the

and results should not be directly compared between the two methods.

materialsurfaceacrosstheabradant,thatpermitsareturntoits

startingposition.Inthecaseoftherotaryplatformtestmethod,

1.2 The values stated in SI units are to be regarded as

it consists of one complete rotation of the specimen.

standard. No other units of measurement are included in this

standard.

3.1.4 durability—the ability to withstand deterioration or

wear out in use, including the effects of abrasion.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.5 resurface—the preparation of an abrasive wheel on a

responsibility of the user of this standard to establish appro-

resurfacing disk or diamond tool wheel refacer, prior to use in

priate safety and health practices and to determine the

testing.

applicability of regulatory limitations prior to use.

3.2 For definitions of other leather terms used in this test

method, refer to Terminology D1517.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Summary of Test Method

D1517Terminology Relating to Leather

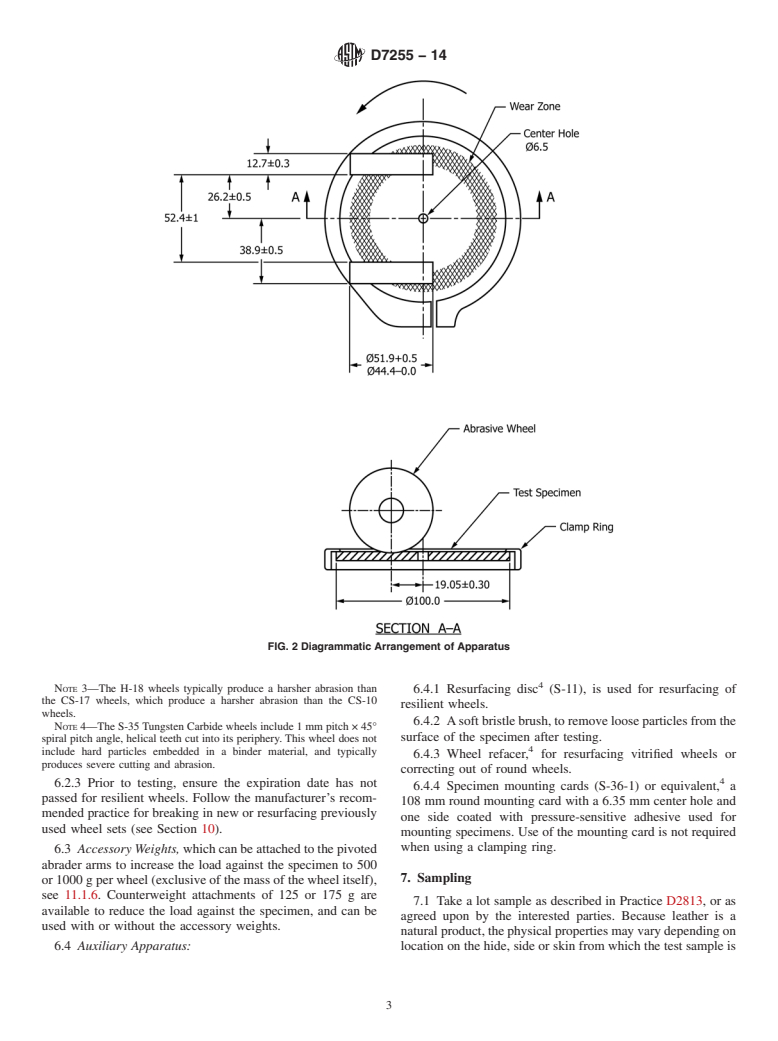

4.1 Aspecimenisabradedusingrotaryrubbingactionunder

D1610Practice for Conditioning Leather and Leather Prod-

controlled conditions of pressure and abrasive action. The test

ucts for Testing

specimen, mounted on a turntable platform, turns on a vertical

D2813Practice for Sampling Leather for Physical and

axis, against the sliding rotation of two abrading wheels. One

Chemical Tests

abrading wheel rubs the specimen outward toward the periph-

G195Guide for Conducting Wear Tests Using a Rotary

ery and the other, inward toward the center. The resulting

Platform Abraser

abrasion marks form a pattern of crossed arcs over an area of

3

2.2 Other Standards: 2

approximately 30 cm . Resistance to abrasion is evaluated by

ISO 17076-1Leather-Determination of abrasion resistance

visual inspection of damage to the specimen or change in

Part 1-Taber method

weight, as described in Section 14.

3. Terminology

5. Significance and Use

3.1 Definitions:

5.1 The resistance of leather to abrasion, as measured on a

3.1.1 abraser—aweartestinginstrument,alsoreferredtoas

testing machine in the laboratory, is generally only one of

a rotary platform tester or abrader.

several factors contributing to wear performance or durability

as experienced in the actual use of the material. While

“abrasion resistance” (often stated in terms of the number of

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD31onLeather

abrasion cycles) and “durability” are frequently related, the

and is the direct responsibility of Subcommittee D31.07 on Physical Properties.

relationship varies with different end uses and different factors

Current edition approved April 1, 2014. Published May 2014. Originally

ε1

approved in 2006. Last previous edition approved in 2006 as D7255-06 . DOI:

may be necessary in any calculation of predicted durability

10.1520/D7255-14.

from specific abrasion data. This test method provides a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

comparative ranking of material performance, which can be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on used as an indication of relative end-use performance.

the ASTM website.

3

5.2 The resistance of leather to abrasion may be affected by

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. factors including test conditions, type of abradant, pressure

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7255 − 14

betweenthespecimenandabradant,mountingortensionofthe 6.1.4 A vacuum suction system and vacuum pickup nozzle

specimen, and type, kind, or amount of finishing materials. to remo

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7255 − 06 D7255 − 14

Standard Test Method for

Abrasion Resistance of Leather (Rotary Platform, Double-

1

HeadAbraser Method)

This standard is issued under the fixed designation D7255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—In Note 2, the reference to H-19 was editorially corrected to H-18 in September 2006.

1. Scope

1.1 This test method covers the determination of the abrasion resistance of leather using the rotary platform, double-head tester

(RPDH).platform abraser.

NOTE 1—This test method is similar but not equivalent to ISO 17076-1, and results should not be directly compared between the two methods.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1517 Terminology Relating to Leather

D1610 Practice for Conditioning Leather and Leather Products for Testing

D2240 Test Method for Rubber Property—Durometer Hardness

D2813 Practice for Sampling Leather for Physical and Chemical Tests

G195 Guide for Conducting Wear Tests Using a Rotary Platform Abraser

3

2.2 Other Standards:

ISO 17076-1 Leather-Determination of abrasion resistance Part 1-Taber method

3. Terminology

3.1 Definitions:

3.1.1 abraser—a wear testing instrument, also referred to as a rotary platform, double head (RPDH) platform tester or abrader.

3.1.2 abrasion—the wearing away of any part of a material by rubbing against another surface.

3.1.3 abrasion cycle—in abrasion testing, one or more movements of the abradant across a material surface, or the material

surface across the abradant, that permits a return to its starting position. In the case of the rotary platform test method, it consists

of one complete rotation of the specimen.

3.1.4 durability—the ability to withstand deterioration or wear out in use, including the effects of abrasion.

3.1.5 resurface—the preparation of an abrasive wheel on a resurfacing disk or diamond tool wheel refacer, prior to use in testing.

3.2 For definitions of other leather terms used in this test method, refer to Terminology D1517.

4. Summary of Test Method

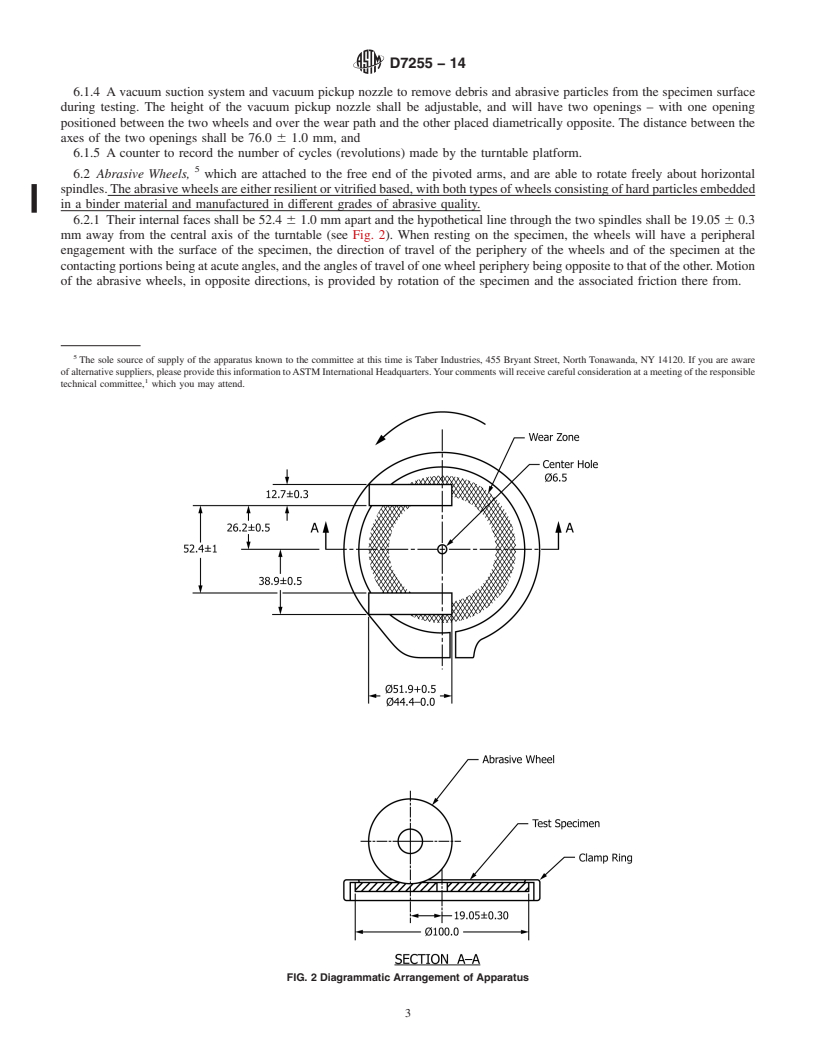

4.1 A specimen is abraded using rotary rubbing action under controlled conditions of pressure and abrasive action. The test

specimen, mounted on a turntable platform, turns on a vertical axis, against the sliding rotation of two abrading wheels. One

1

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.05D31.07 on UpholsteryPhysical

Properties.

ε1

Current edition approved April 1, 2006April 1, 2014. Published April 2006May 2014. Originally approved in 2006. Last previous edition approved in 2006 as D7255-06 .

DOI: 10.1520/D7255-06E01.10.1520/D7255-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7255 − 14

abrading wheel rubs the specimen outward toward the periphery and the other, inward toward the center. The resulting abrasion

2

marks form a pattern of crossed arcs over an area of approximately 30 cm . Resistance to abrasion is evaluated by visual inspection

of damage to the specimen or change in weight, as described in Section 14.

5. Significance and Use

5.1 The resistance of leather to abrasion, as measured on a testing machine in the laboratory, is generally only one of several

factors contributing to wear performance or durability as experienced in the actual use of the material. While “abrasion resistance”

(often stated in terms of the number of abrasion cycle

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.