ASTM D5456-99a

(Specification)Standard Specification for Evaluation of Structural Composite Lumber Products

Standard Specification for Evaluation of Structural Composite Lumber Products

SCOPE

1.1 This specification recognizes the complexity of structural glued products. Consequently, this specification includes both specific procedures and statements of intent that sampling and analysis must relate to the specific product.

1.2 This specification was developed in the light of currently manufactured products as defined in 3.2. Materials that do not conform to the definitions are beyond the scope of this specification. A brief discussion is found in Appendix X1.

1.3 Details of manufacturing procedures are beyond the scope of this specification.

Note 1—There is some potential for manufacturing variables to affect the properties of members that are loaded for sustained periods of time. Users of this specification are advised to consider the commentary on this topic, in Appendix X1.

1.4 This specification primarily considers end use in dry service conditions such as with most protected framing members, where the average equilibrium moisture content for solid-sawn lumber is less than 16 %. The conditioning environment of 6.3 is considered representative of such uses.

1.5 The performance of structural composite lumber is affected by wood species, wood element size and shape, adhesive and production parameters. Therefore, products produced by each individual manufacturer shall be evaluated to determine their product properties, regardless of the similarity in characteristics to products produced by other manufacturers. Where a manufacturer produces product in more than one facility, each production facility shall be evaluated independently. For additional production facilities, any revisions to the full qualification program in accordance with this specification shall be be approved by the independent qualifying agency.

1.6 This specification is intended to provide manufacturers, regulatory agencies, and end users with a means to evaluate a composite lumber product intended for use as a structural material.

1.7 This specification covers initial qualification sampling, mechanical and physical tests, analysis, and design value assignments. Requirements for a quality-control program and cumulative evaluations are included to ensure maintenance of allowable design values for the product.

1.8 This specification, or parts thereof, shall be applicable to structural composite lumber portions of manufactured structural components.

1.9 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5456 – 99a

Standard Specification for

Evaluation of Structural Composite Lumber Products

This standard is issued under the fixed designation D 5456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Structural composite lumber is intended for use as an engineering material for a variety of end-use

applications. The composition of the lumber varies by wood species, adhesive composition, wood

element size, shape, and arrangement. To provide the intended performance, composite lumber

products require: (1) an evaluation of the mechanical and physical properties and their response to

end-use environments, and (2) establishment of and conformance to standard performance specifica-

tions for quality.

Procedures contained in this specification are also to be used for establishing the design properties

and for checking the effectiveness of property assignment and quality assurance procedures.

The quality assurance sections in this specification are intended to serve as a basis for designing

quality-control programs specific to each product. The objective is to ensure that design values

established in the qualification process are maintained.

This specification is arranged as follows:

Section

Qualification Testing 5

Determination of Allowable Values 6

Independent Inspection 7

Quality Assurance 9

1. Scope ronment of 5.3 is considered representative of such uses.

1.5 The performance of structural composite lumber is

1.1 This specification recognizes the complexity of struc-

affected by wood species, wood element size and shape,

tural glued products. Consequently, this specification includes

adhesive and production parameters. Therefore, products pro-

both specific procedures and statements of intent that sampling

duced by each individual manufacturer shall be evaluated to

and analysis must relate to the specific product.

determine their product properties, regardless of the similarity

1.2 This specification was developed in the light of cur-

in characteristics to products produced by other manufacturers.

rently manufactured products as defined in 3.2. Materials that

Where a manufacturer produces product in more than one

do not conform to the definitions are beyond the scope of this

facility, each production facility shall be evaluated indepen-

specification. A brief discussion is found in Appendix X1.

dently. For additional production facilities, any revisions to the

1.3 Details of manufacturing procedures are beyond the

full qualification program in accordance with this specification

scope of this specification.

shall be be approved by the independent qualifying agency.

NOTE 1—There is some potential for manufacturing variables to affect

1.6 This specification is intended to provide manufacturers,

the properties of members that are loaded for sustained periods of time.

regulatory agencies, and end users with a means to evaluate a

Users of this specification are advised to consider the commentary on this

composite lumber product intended for use as a structural

topic, in Appendix X1.

material.

1.4 This specification primarily considers end use in dry

1.7 This specification covers initial qualification sampling,

service conditions such as with most protected framing mem-

mechanical and physical tests, analysis, and design value

bers, where the average equilibrium moisture content for

assignments. Requirements for a quality-control program and

solid-sawn lumber is less than 16 %. The conditioning envi-

cumulative evaluations are included to ensure maintenance of

allowable design values for the product.

1.8 This specification, or parts thereof, shall be applicable to

This specification is under the jurisdiction of ASTM Committee D-7 on Wood

and is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered

structural composite lumber portions of manufactured struc-

Wood Products.

tural components.

Current edition approved Oct. 10, 1999. Published December 1999. Originally

e1

1.9 The values stated in inch-pound units are to be regarded

published as D 5456 – 93. Last previous edition D 5456 – 99 .

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5456

as the standard. The SI units given in parentheses are for Under Direct-Voltage Stress

information only. D 4442 Test Methods for Direct Moisture Content Measure-

1.10 This standard does not purport to address all of the ment of Wood and Wood-Base Materials

safety concerns, if any, associated with its use. It is the D 4761 Test Methods for Mechanical Properties of Lumber

responsibility of the user of this standard to establish appro- and Wood-Base Structural Material

priate safety and health practices and determine the applica- D 4933 Guide for Moisture Conditioning of Wood and

bility of regulatory limitations prior to use. Wood-Base Materials

D 5055 Specification for Establishing and Monitoring

2. Referenced Documents

Structural Capacities of Prefabricated Wood I-Joists

2.1 ASTM Standards:

D 5457 Specification for Computing the Reference Resis-

C 177 Test Method for Steady-State Heat Flux Measure-

tance of Wood-Based Materials and Structural Connec-

ments and Thermal Transmission Properties by Means of

tions for Load and Resistance Factor Design

the Guarded-Hot-Plate Apparatus

D 5764 Test Method for Evaluating Dowel Bearing

C 355 Methods of Test for Water Vapor Transmission of 5

Strength of Wood and Wood-Based Products

Thick Materials Construction

E 84 Test Method for Surface Burning Characteristics of

C 384 Test Method for Impedance and Absorption of 9

Building Materials

Acoustical Materials by the Impedance Tube Method

E 119 Test Methods for Fire Tests of Building Construction

C 423 Test Method for Sound Absorption and Sound Ab- 9

and Materials

sorption Coefficients by the Reverberation Room Method

2.2 Canadian Standards:

D 7 Test Method for Sieve Analysis of Fine Aggregates

CAN3-O86-M84 Engineering Design in Wood (Working

D 9 Terminology Relating to Wood

Stress Design)

D 143 Method of Testing Small Clear Specimens of Tim- 10

CSA Standards for Wood Adhesives, O112 Series

ber

D 150 Test Methods for AC Loss Characteristics and Per- 3. Terminology

mittivity (Dielectric Constant) of Solid Electrical Insulat-

3.1 Definitions—Standard definitions of wood terms are

ing Materials

given in Terminology D 9.

D 198 Test Methods for Static Tests of Timbers in Structural

3.2 Definitions of Terms Specific to This Standard:

Sizes

3.2.1 laminated veneer lumber—a composite of wood ve-

D 245 Practice for Establishing Structural Grades and Re-

neer sheet elements with wood fibers primarily oriented along

lated Allowable Properties for Visually Graded Lumber

the length of the member. Veneer thickness shall not exceed

D 669 Test Method for Dissipation Factor and Permittivity

0.25 in. (6.4 mm).

Parallel With Laminations of Laminated Sheet and Plate

3.2.2 parallel strand lumber—a composite of wood strand

Materials

elements with wood fibers primarily oriented along the length

D 1666 Methods for Conducting Machining Tests of Wood

of the member. The least dimension of the strands shall not

and Wood-Base Materials

exceed 0.25 in. (6.4 mm) and the average length shall be a

D 1761 Method of Testing Mechanical Fasteners in Wood

minimum of 150 times the least dimension.

D 2132 Test Method for Dust-and-Fog Tracking and Ero-

3.2.3 structural composite lumber—in this specification,

sion Resistance of Electrical Insulating Materials

structural composite lumber (SCL) is either laminated veneer

D 2394 Method for Simulated Service Testing of Wood and

lumber (LVL) or parallel strand lumber (PSL). These materials

Wood-Base Finish Flooring

are intended for structural use and they shall be bonded with an

D 2395 Test Methods for Specific Gravity of Wood and

exterior adhesive, qualified in accordance with Specification

Wood-Base Materials

D 2559 or, in Canada, conforming to the appropriate section of

D 2559 Specification for Adhesives for Structural Lami-

CSA standards for wood adhesives.

nated Wood Products for Use Under Exterior (Wet Use)

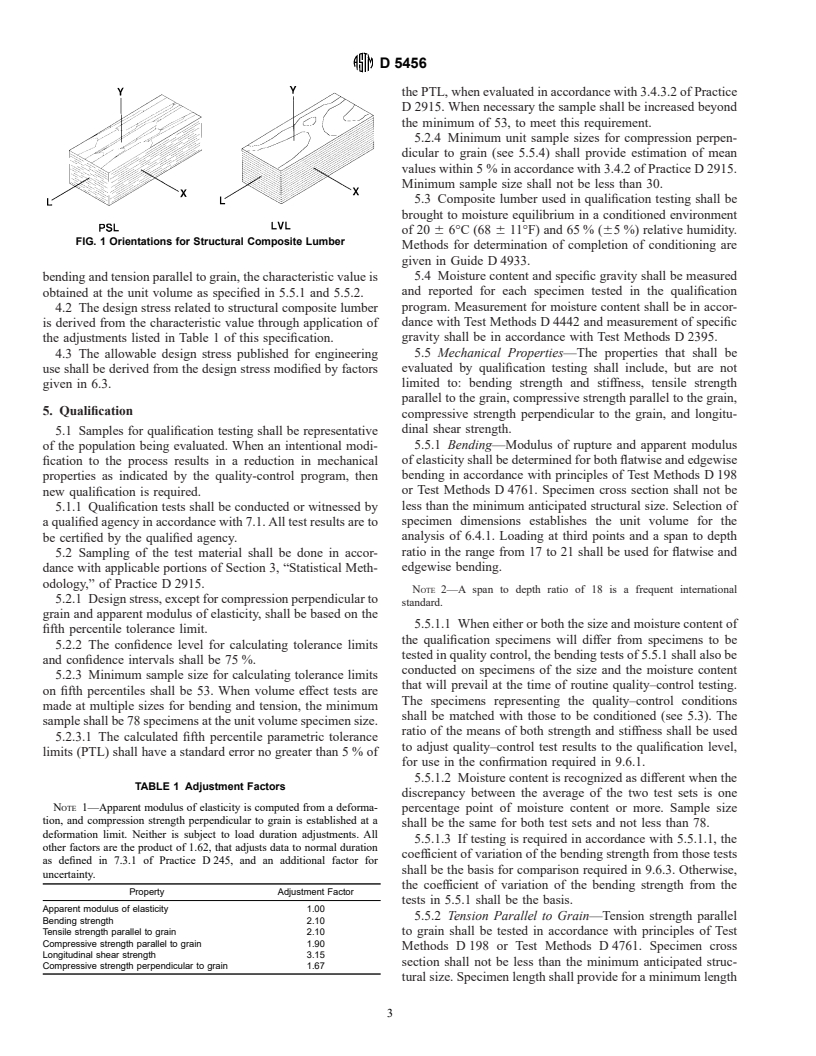

3.2.3.1 Discussion—Structural composite lumber has three

Exposure Conditions

mutually perpendicular directions of orientation (see Fig. 1):

D 2718 Test Method for Structural Panels in Planar Shear

L Direction—Parallel to the longitudinal direction of the member.

(Rolling Shear)

X Direction—Parallel to a surface of the member and normal to the L direction.

Y Direction—Normal to both L and X direction.

D 2915 Practice for Evaluating Allowable Properties for

Grades of Structural Lumber

In this specification, longitudinal shear means shear stress in

D 3201 Test Method for Hygroscopic Properties of Fire-

the L-X and L-Y planes. Planar shear is stress in the X-Y plane.

Retardant Wood and Wood-Base Products

4. Mechanical Properties

D 3755 Test Method for Dielectric Breakdown Voltage and

Dielectric Strength of Solid Electrical Insulating Materials

4.1 The characteristic value for structural composite lumber

is a statistic derived from test data as specified in 6.1. For

Annual Book of ASTM Standards, Vol 04.06.

Discontinued; see 1982 Annual Book of ASTM Standards, Part 18.

4 8

Discontinued; see 1937 Annual Book of ASTM Standards, Part 1. Annual Book of ASTM Standards, Vol 10.02.

5 9

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 04.07.

6 10

Annual Book of ASTM Standards, Vol 10.01. Available from Canadian Standards Association, 178 Rexdale Blvd., Rexdale,

Annual Book of ASTM Standards, Vol 15.06. Ontario, Canada M9W 1R3.

D 5456

the PTL, when evaluated in accordance with 3.4.3.2 of Practice

D 2915. When necessary the sample shall be increased beyond

the minimum of 53, to meet this requirement.

5.2.4 Minimum unit sample sizes for compression perpen-

dicular to grain (see 5.5.4) shall provide estimation of mean

values within 5 % in accordance with 3.4.2 of Practice D 2915.

Minimum sample size shall not be less than 30.

5.3 Composite lumber used in qualification testing shall be

brought to moisture equilibrium in a conditioned environment

of 20 6 6°C (68 6 11°F) and 65 % (65 %) relative humidity.

FIG. 1 Orientations for Structural Composite Lumber

Methods for determination of completion of conditioning are

given in Guide D 4933.

5.4 Moisture content and specific gravity shall be measured

bending and tension parallel to grain, the characteristic value is

and reported for each specimen tested in the qualification

obtained at the unit volume as specified in 5.5.1 and 5.5.2.

program. Measurement for moisture content shall be in accor-

4.2 The design stress related to structural composite lumber

dance with Test Methods D 4442 and measurement of specific

is derived from the characteristic value through application of

gravity shall be in accordance with Test Methods D 2395.

the adjustments listed in Table 1 of this specification.

5.5 Mechanical Properties—The properties that shall be

4.3 The allowable design stress published for engineering

evaluated by qualification testing shall include, but are not

use shall be derived from the design stress modified by factors

limited to: bending strength and stiffness, tensile strength

given in 6.3.

parallel to the grain, compressive strength parallel to the grain,

5. Qualification

compressive strength perpendicular to the grain, and longitu-

dinal shear strength.

5.1 Samples for qualification testing shall be representative

5.5.1 Bending—Modulus of rupture and apparent modulus

of the population being evaluated. When an intentional modi-

of elasticity shall be determined for both flatwise and edgewise

fication to the process results in a reduction in mechanical

bending in accordance with principles of Test Methods D 198

properties as indicated by the quality-control program, then

or Test Methods D 4761. Specimen cross section shall not be

new qualification is required.

less than the minimum anticipated structural size. Selection of

5.1.1 Qualification tests shall be conducted or witnessed by

specimen dimensions establishes the unit volume for the

a qualified agency in accordance with 7.1. All test results are to

analysis of 6.4.1. Loading at third points and a span to depth

be certified by the qualified agency.

ratio in the range from 17 to 21 shall be used for flatwise and

5.2 Sampling of the test material shall be done in accor-

edgewise bending.

dance with applicable portions of Section 3, “Statistical Meth-

odology,” of Practice D 2915.

NOTE 2—A span to depth ratio of 18 is a frequent international

5.2.1 Design stress, except for compression perpendicular to

standard.

grain and apparent modulus of elasticity, shall be based on the

5.5.1.1 When either or both the size and moisture content of

fifth percentile tolerance limit.

the qualification specimens will differ from specimens to be

5.2.2 The confidence level for calculating tolerance limits

tested in quality control, the bending tests of 5.5.1 shall also be

and confidence intervals shall be 75 %.

conducted on specimens of the size and the moisture content

5.2.3 Minimum sample size for calculating tolerance limits

that will prevail at the time of routine quality–control testing.

on fifth percentiles shall be 53. When volume effect tests are

The specimens representing the quality–control conditions

made at multiple sizes for bending and tension, the minimum

shall be matched with those to be conditioned (see 5.3). The

sample shall be 78 specimens at the unit volume specimen size.

ratio of the means of both strength and stiffness shall be used

5.2.3.1 The calculated fifth percentile parametric tolerance

to adjust quality–control test results to the qualification level,

limits (PTL) shall have a standard error no greater than 5 % of

for use in the confirmation required in 9.6.1.

5.5.1.2 Moisture content is recognized as different when the

TABLE 1 Adjustment Factors

discrepancy between the average of the two test sets is one

NOTE 1—Apparent modulus of elasticity is computed from a deforma-

percentage point of moisture content or more. Sample size

tion, and compression strength perpendicular to grain is established at a

shall be the same for both test sets and not less than 78.

deformation limit. Neither is subject to load duration adjustments. All

5.5.1.3 If testing is required in accordance with 5.5.1.1, the

other factors are the product of 1.62, that adjusts data to normal duration

coefficient of variation of the bending strength from those tests

as defined in 7.3.1 of Practice

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.