ASTM E1419/E1419M-15a

(Practice)Standard Practice for Examination of Seamless, Gas-Filled, Pressure Vessels Using Acoustic Emission

Standard Practice for Examination of Seamless, Gas-Filled, Pressure Vessels Using Acoustic Emission

SIGNIFICANCE AND USE

5.1 Because of safety considerations, regulatory agencies (for example, U.S. Department of Transportation) require periodic examinations of vessels used in transportation of industrial gases (see Section 49, Code of Federal Regulations). The AE examination has become accepted as an alternative to the common hydrostatic proof test. In the common hydrostatic test, volumetric expansion of vessels is measured.

5.2 An AE examination should not be performed for a period of one year after a common hydrostatic test. See Note 2.

Note 2: The Kaiser effect relates to decreased emission that is expected during a second pressurization. Common hydrostatic tests use a relatively high pressure (167 % of normal service pressure). (See Section 49, Code of Federal Regulations.) If an AE examination is performed too soon after such a pressurization, the AE results will be insensitive to a lower examination pressure (that is, the lower pressure that is associated with an AE examination).

5.3 Pressurization:

5.3.1 General practice in the gas industry is to use low pressurization rates. This practice promotes safety and reduces equipment investment. The AE examinations should be performed with pressurization rates that allow vessel deformation to be in equilibrium with the applied load. Typical current practice is to use rates that approximate 3.45 MPa/h [500 psi/h].

5.3.2 Gas compressors heat the pressurizing medium. After pressurization, vessel pressure may decay as gas temperature equilibrates with ambient conditions.

5.3.3 Emission from flaws is caused by flaw growth and secondary sources (for example, crack surface contact and contained mill scale). Secondary sources can produce emission throughout vessel pressurization.

5.3.4 When pressure within a vessel is low, and gas is the pressurizing medium, flow velocities are relatively high. Flowing gas (turbulence) and impact by entrained particles can produce measurable emission. Considering this, acquisition of AE d...

SCOPE

1.1 This practice provides guidelines for acoustic emission (AE) examinations of seamless pressure vessels (tubes) of the type used for distribution or storage of industrial gases.

1.2 This practice requires pressurization to a level greater than normal use. Pressurization medium may be gas or liquid.

1.3 This practice does not apply to vessels in cryogenic service.

1.4 The AE measurements are used to detect and locate emission sources. Other nondestructive test (NDT) methods must be used to evaluate the significance of AE sources. Procedures for other NDT techniques are beyond the scope of this practice. See Note 1.

Note 1: Shear wave, angle beam ultrasonic examination is commonly used to establish circumferential position and dimensions of flaws that produce AE. Time of Flight Diffraction (TOFD), ultrasonic examination is also commonly used for flaw sizing.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1419/E1419M − 15a

Standard Practice for

Examination of Seamless, Gas-Filled, Pressure Vessels

1

Using Acoustic Emission

ThisstandardisissuedunderthefixeddesignationE1419/E1419M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This practice provides guidelines for acoustic emission 2.1 ASTM Standards:

(AE) examinations of seamless pressure vessels (tubes) of the E543 Specification for Agencies Performing Nondestructive

type used for distribution or storage of industrial gases. Testing

E650 Guide for Mounting Piezoelectric Acoustic Emission

1.2 This practice requires pressurization to a level greater

Sensors

than normal use. Pressurization medium may be gas or liquid.

E976 GuideforDeterminingtheReproducibilityofAcoustic

1.3 This practice does not apply to vessels in cryogenic

Emission Sensor Response

service.

E1316 Terminology for Nondestructive Examinations

E2223 Practice for Examination of Seamless, Gas-Filled,

1.4 The AE measurements are used to detect and locate

emission sources. Other nondestructive test (NDT) methods Steel Pressure Vessels Using Angle Beam Ultrasonics

E2075 Practice for Verifying the Consistency of AE-Sensor

must be used to evaluate the significance of AE sources.

Procedures for other NDT techniques are beyond the scope of Response Using an Acrylic Rod

E2374 Guide for Acoustic Emission System Performance

this practice. See Note 1.

Verification

NOTE 1—Shear wave, angle beam ultrasonic examination is commonly

3

2.2 ASNT Standards:

used to establish circumferential position and dimensions of flaws that

Recommended Practice SNT-TC-1A for Nondestructive

produceAE.Time of Flight Diffraction (TOFD), ultrasonic examination is

also commonly used for flaw sizing. Testing Personnel Qualification and Certification

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

1.5 The values stated in either SI units or inch-pound units

cation of Nondestructive Testing Personnel

are to be regarded separately as standard. The values stated in

2.3 Code of Federal Regulations:

each system may not be exact equivalents; therefore, each

Section 49, Code of Federal Regulations, Hazardous Mate-

system shall be used independently of the other. Combining

rials Regulations of the Department of Transportation,

values from the two systems may result in non-conformance

4

Paragraphs 173.34, 173.301, 178.36, 178.37, and 178.45

with the standard.

5

2.4 Compressed Gas Association Standard:

1.6 This standard does not purport to address all of the

Pamphlet C-5 Service Life, Seamless High Pressure Cylin-

safety concerns, if any, associated with its use. It is the

ders

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bility of regulatory limitations prior to use. Specific precau-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tionary statements are given in Section 7.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

structive Testing and is the direct responsibility of Subcommittee E07.04 on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Acoustic Emission Method. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

Current edition approved Dec. 1, 2015. Published December 2015. Originally www.access.gpo.gov.

5

approved in 1991. Last previous edition approved in 2015 as E1419 – 15. DOI: Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

10.1520/E1419_E1419M-15A. Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

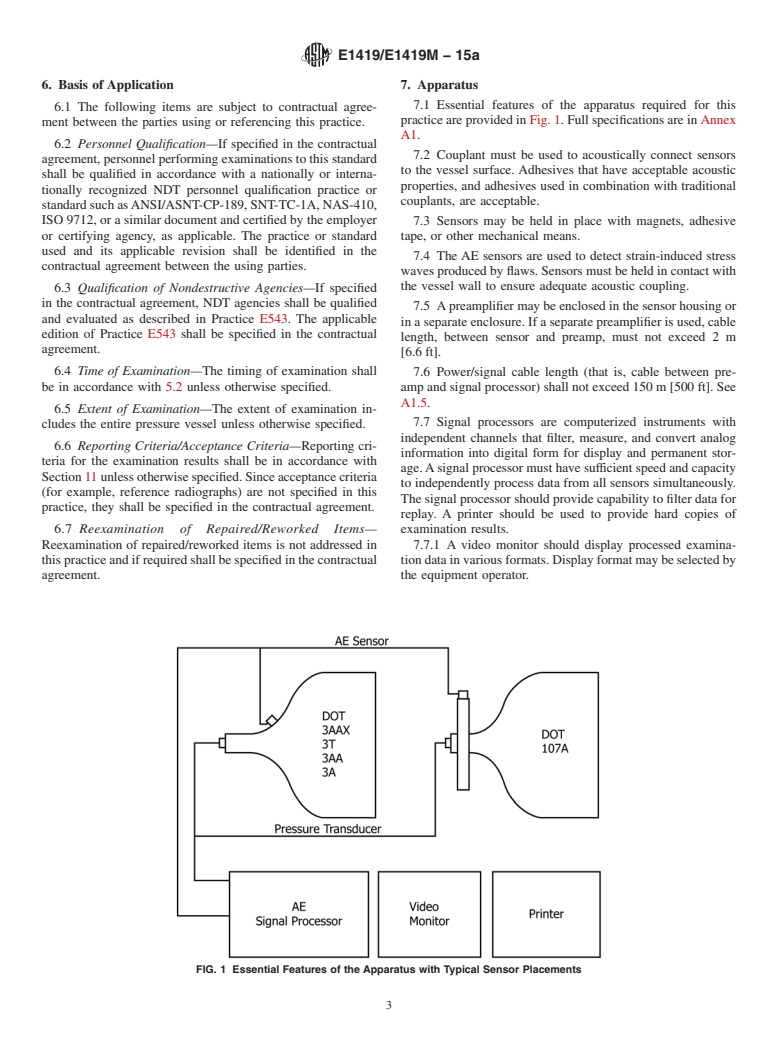

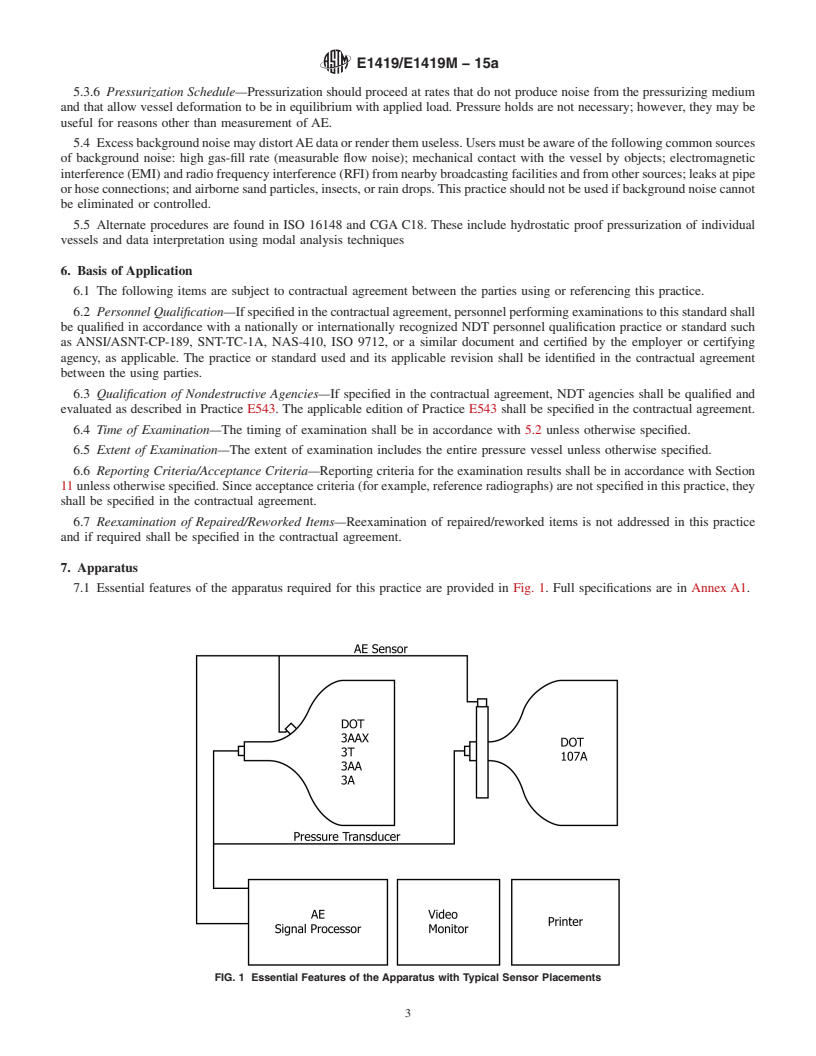

E1419/E1419M − 15a

CGA-C18 Methods for Acoustic Emission Requalification 5.2 An AE examination should not be performed for a

of Seamless Steel Compressed Gas Tubes period of one year after a common hydrostatic test. See Note 2.

2.5 AIA Document:

NOTE 2—The Kaiser effect relates to decreased emission that is

NAS-410 Certification and Qualification of Nondestructive

expected during a second pressurization. Common hydrostatic tests use a

6

Testing

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1419/E1419M − 15 E1419/E1419M − 15a

Standard Practice for

Examination of Seamless, Gas-Filled, Pressure Vessels

1

Using Acoustic Emission

This standard is issued under the fixed designation E1419/E1419M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice provides guidelines for acoustic emission (AE) examinations of seamless pressure vessels (tubes) of the type

used for distribution or storage of industrial gases.

1.2 This practice requires pressurization to a level greater than normal use. Pressurization medium may be gas or liquid.

1.3 This practice does not apply to vessels in cryogenic service.

1.4 The AE measurements are used to detect and locate emission sources. Other nondestructive test (NDT) methods must be

used to evaluate the significance of AE sources. Procedures for other NDT techniques are beyond the scope of this practice. See

Note 1.

NOTE 1—Shear wave, angle beam ultrasonic examination is commonly used to establish circumferential position and dimensions of flaws that produce

AE. Time of Flight Diffraction (TOFD), ultrasonic examination is also commonly used for flaw sizing.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E650 Guide for Mounting Piezoelectric Acoustic Emission Sensors

E976 Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

E1316 Terminology for Nondestructive Examinations

E2223 Practice for Examination of Seamless, Gas-Filled, Steel Pressure Vessels Using Angle Beam Ultrasonics

E2075 Practice for Verifying the Consistency of AE-Sensor Response Using an Acrylic Rod

E2374 Guide for Acoustic Emission System Performance Verification

3

2.2 ASNT Standards:

Recommended Practice SNT-TC-1A for Nondestructive Testing Personnel Qualification and Certification

ANSI/ASNT CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

2.3 Code of Federal Regulations:

Section 49, Code of Federal Regulations, Hazardous Materials Regulations of the Department of Transportation, Paragraphs

4

173.34, 173.301, 178.36, 178.37, and 178.45

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic Emission

Method.

Current edition approved June 1, 2015Dec. 1, 2015. Published July 2015December 2015. Originally approved in 1991. Last previous edition approved in 20092015 as

E1419 – 09.E1419 – 15. DOI: 10.1520/E1419_E1419M-15.10.1520/E1419_E1419M-15A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1419/E1419M − 15a

5

2.4 Compressed Gas Association Standard:

Pamphlet C-5 Service Life, Seamless High Pressure Cylinders

CGA-C18 Methods for Acoustic Emission Requalification of Seamless Steel Compressed Gas Tubes

2.5 AIA Document:

6

NAS-410 Certification and Qualification of Nondestructive Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.