ASTM D6184-98(2005)

(Test Method)Standard Test Method for Oil Separation from Lubricating Grease (Conical Sieve Method) (Withdrawn 2014)

Standard Test Method for Oil Separation from Lubricating Grease (Conical Sieve Method) (Withdrawn 2014)

SIGNIFICANCE AND USE

When a lubricating grease separates oil, the residual material changes in consistency, which can affect the ability of the product to function as designed. Test results obtained with this procedure are intended to correlate with oil separation that occurs in 35-lb pails of grease during storage. They are not intended to predict oil separation tendencies of grease under dynamic service conditions.

Note 1—No quantitative relationship between results and oil separation in 35-lb pails has been developed.

This test method is used for specifications and quality control.

Note 2—No data have been developed to compare results between this test method and Test Method D 1742.

SCOPE

1.1 This test method covers the determination of the tendency of lubricating grease to separate oil at an elevated temperature. This test method shall be conducted at 100°C for 30 h unless other conditions are required by the grease specification.

1.2 This test method is not suitable for greases having a penetration (Test Methods D 217) greater than 340 (softer than NLGI No. 1 grade).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of the tendency of lubricating grease to separate oil at an elevated temperature. This test method shall be conducted at 100°C for 30 h unless other conditions are required by the grease specification.

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in July 2014 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6184 − 98(Reapproved 2005)

Standard Test Method for

Oil Separation from Lubricating Grease (Conical Sieve

1

Method)

This standard is issued under the fixed designation D6184; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

The conical sieve method for measuring leakage from lubricating grease (commonly known as the

cone bleed test) is virtually the same as Federal Test Method (FTM) 791C Method 321.3, Oil

Separation from Lubricating Grease (Static Technique). Despite the lack of a precision statement,

Method 321.3 has been used for many years in military and industrial grease specifications to

determine fluid separation tendencies. Test Method D6184 overcomes the deficiencies of Method

321.3. It reflects the procedures and precision determinations used in a cooperative study in

Subcommittee D02.G0 of Committee D02 and is intended to supersede the FTM method.

1. Scope D217 Test Methods for Cone Penetration of Lubricating

Grease

1.1 This test method covers the determination of the ten-

D1742 Test Method for Oil Separation from Lubricating

dency of lubricating grease to separate oil at an elevated

Grease During Storage

temperature. This test method shall be conducted at 100°C for

E437 Specification for Industrial Wire Cloth and Screens

30 h unless other conditions are required by the grease

(Square Opening Series) (Discontinued 2000) Replaced

specification.

3

by E 2016 (Withdrawn 2000)

1.2 This test method is not suitable for greases having a

2.2 Government Standard:

penetration (Test Methods D217) greater than 340 (softer than

Federal Test Method (FTM) 791C Method 321.3, Oil

NLGI No. 1 grade).

4

Separation from Lubricating Greases (Static Method)

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3. Terminology

standard.

3.1 Definitions:

1.4 This standard does not purport to address all the safety

3.1.1 lubricating grease, n—a semifluid to solid product of

concerns, if any, associated with its use. It is the responsibility

a dispersion of a thickener in a liquid lubricant.

of the user of this standard to establish appropriate safety

3.1.1.1 Discussion—The dispersion of the thickener forms a

practices and determine the applicability of regulatory limita-

two-phase system and immobilizes the liquid lubricant by

tions prior to use.

surface tension and other physical forces. Other ingredients

imparting special properties are often included. D217

2. Referenced Documents

3.1.2 oil separation, n—the appearance of a liquid fraction

2

2.1 ASTM Standards:

from an otherwise homogeneous lubricating composition.

D1742

3.1.3 thickener, n—in a lubricating grease, a substance

1

This test method is under the jurisdiction of ASTM Committee D02 on

composed of finely divided particles dispersed in a liquid

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

lubricant to form the product’s structure.

D02.G0.03 on Physical Tests

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1997. Last previous edition approved in 1998 as D6184 – 98. DOI:

10.1520/D6184-98R05.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6184 − 98 (2005)

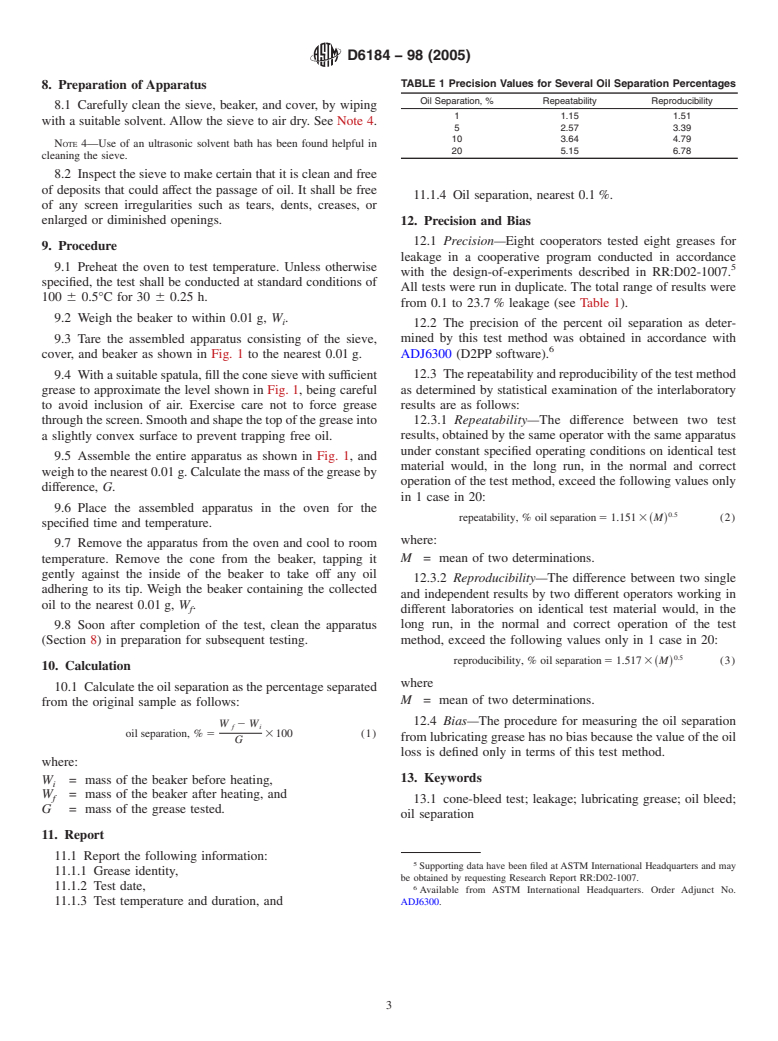

NOTE 1—Dimensions are provided in millimetres (with in./lb. units in parentheses) as follows:

A – 38.1 ± 0.3 (1.50 ± 0.01) radius

B – 27.0 ± 0.3 (1.06 ± 0.01) height

C – 70 (2.8) approximately (to fit beaker)

D – 9.7 ± 3.3 (0.38 ± 0.13) length

E – 100 (4) approximately

F – 36 (1.4) approximately

FIG. 1 Cone Fabrication and Test Setup

3.1.3.1 Discussion—The thickener can be fibers (such as 6. Apparatus

various metallic soaps) or plates or spheres (such as certain

6.1 Test Apparatus—The assembled apparatus consists of a

non-soap thickeners) which are insoluble or, at most, only very

cone-shaped sieve constructed of 60-mesh, corrosion-resistant

slightly soluble in the liquid lubricant. The general requ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.