ASTM D3803-91(2004)

(Test Method)Standard Test Method for Nuclear-Grade Activated Carbon

Standard Test Method for Nuclear-Grade Activated Carbon

SIGNIFICANCE AND USE

The results of this test method give a conservative estimate of the performance of nuclear-grade activated carbon used in all nuclear power plant HVAC systems for the removal of radioiodine.

SCOPE

1.1 This test method is a very stringent procedure for establishing the capability of new and used activated carbon to remove radio-labeled methyl iodide from air and gas streams. The single test method described is for application to both new and used carbons, and should give test results comparable to those obtained from similar tests required and performed throughout the world. The conditions employed were selected to approximate operating or accident conditions of a nuclear reactor which would severely reduce the performance of activated carbons. Increasing the temperature at which this test is performed generally increases the removal efficiency of the carbon by increasing the rate of chemical and physical absorption and isotopic exchange, that is, increasing the kinetics of the radioiodine removal mechanisms. Decreasing the relative humidity of the test generally increases the efficiency of methyl iodide removal by activated carbon. The water vapor competes with the methyl iodide for adsorption sites on the carbon, and as the amount of water vapor decreases with lower specified relative humidities, the easier it is for the methyl iodide to be adsorbed. Therefore, this test method is a very stringent test of nuclear-grade activated carbon because of the low temperature and high relative humidity specified. This test method is recommended for the qualification of new carbons and the quantification of the degradation of used carbons.

1.1.1 Guidance for testing new and used carbons using conditions different from this test method is offered in Annex A1.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3803 – 91 (Reapproved 2004)

Standard Test Method for

1

Nuclear-Grade Activated Carbon

This standard is issued under the fixed designation D 3803; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method is a very stringent procedure for 2.1 ASTM Standards:

establishing the capability of new and used activated carbon to D1193 Specification for Reagent Water

remove radio-labeled methyl iodide from air and gas streams. D2652 Terminology Relating to Activated Carbon

Thesingletestmethoddescribedisforapplicationtobothnew D2854 Test Method for Apparent Density of Activated

and used carbons, and should give test results comparable to Carbon

those obtained from similar tests required and performed E300 Practice for Sampling Industrial Chemicals

throughout the world. The conditions employed were selected E691 PracticeforConductinganInterlaboratoryTestStudy

to approximate operating or accident conditions of a nuclear to Determine Precision of a Test Method

reactor which would severely reduce the performance of 2.2 Code of Federal Regulations:

activatedcarbons.Increasingthetemperatureatwhichthistest CFR Title 49, Section 173.34, “Qualification, Maintenance,

3

is performed generally increases the removal efficiency of the and Use of Cylinders’’

carbon by increasing the rate of chemical and physical absorp- CFR Title 49, Part 178, Subpart C, “Specifications for

3

tion and isotopic exchange, that is, increasing the kinetics of Cylinders’’

the radioiodine removal mechanisms. Decreasing the relative 2.3 Military Standards:

humidityofthetestgenerallyincreasestheefficiencyofmethyl MIL-F-51068D Filter, Particulate High Efficiency, Fire Re-

4

iodideremovalbyactivatedcarbon.Thewatervaporcompetes sistant

with the methyl iodide for adsorption sites on the carbon, and MIL-F-51079A Filter, Medium Fire Resistant, High Effi-

4

as the amount of water vapor decreases with lower specified ciency

4

relative humidities, the easier it is for the methyl iodide to be MIL-STD-45662 Calibration Systems Requirements

adsorbed.Therefore, this test method is a very stringent test of 2.4 Other Standards:

nuclear-grade activated carbon because of the low temperature ANSI/ASME N45.2.6 Qualifications of Inspection, Exami-

5

and high relative humidity specified. This test method is nation, and Testing Personnel for Nuclear Power Plants

recommended for the qualification of new carbons and the

3. Terminology

quantification of the degradation of used carbons.

3.1 Definitions of Terms Specific to This Standard:

1.1.1 Guidance for testing new and used carbons using

conditions different from this test method is offered in Annex 3.1.1 counter effıciency (CE)—the fraction of the actual

number of disintegrations of a radioactive sample that is

A1.

1.2 This standard does not purport to address all of the recorded by a nuclear counter.

3.1.2 effıciency (E)—the percentage of the contaminant

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- removed from a gas stream by an adsorption bed; expressed

mathematically as E = 100 − P, where E and P are given in

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. percent.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Published by the General Service Administration, 18th and “F’’ St., N. W.,

1

This test method is under the jurisdiction of ASTM Committee D28 on Washington, DC 20405.

4

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Phase Evaluation Tests. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5

Current edition approved April 1, 2004. Published June 2004. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

approved in 1979. Last previous edition approved in 1998 as D3803–91 (1998). Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3803 – 91 (2004)

3.1.3 penetration (P)—the percentage of the contaminant separate units each capable of containing carbon to a depth of

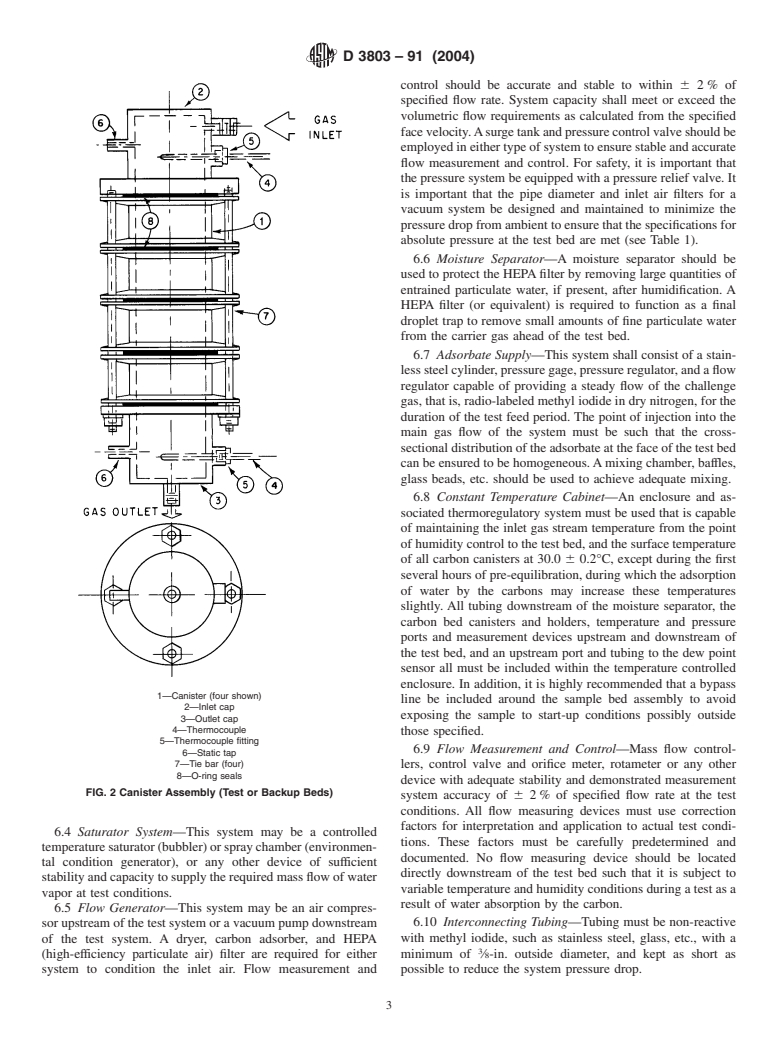

(CH I) which passes through the equilibrated test bed of 25 mm.Two backup canist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.