ASTM E1479-99(2011)

(Practice)Standard Practice for Describing and Specifying Inductively-Coupled Plasma Atomic Emission Spectrometers

Standard Practice for Describing and Specifying Inductively-Coupled Plasma Atomic Emission Spectrometers

SIGNIFICANCE AND USE

This practice describes the essential components of an inductively-coupled plasma atomic emission spectrometer (ICP-AES). The components include excitation/radio-frequency generators, sample introduction systems, spectrometers, detectors, and signal processing and displays. This description allows the user or potential user to gain a cursory understanding of an ICP-AES system. This practice also provides a means for comparing and evaluating various systems, as well as understanding the capabilities and limitations of each instrument.

Training—The vendor should provide training in safety, basic theory of ICP spectrochemical analysis, operations of hardware and software, and routine maintenance for at least one operator. Training ideally should consist of the basic operation of the instrument at the time of installation, followed by an in-depth course one or two months later. Advanced courses are also offered at several of the important spectroscopy meetings that occur throughout the year as well as by independent training institutes. Furthermore, several independent consultants are available who can provide training, in most cases at the user's site.

SCOPE

1.1 This practice describes the components of an inductively-coupled plasma atomic emission spectrometer (ICP-AES) that are basic to its operation and to the quality of its performance. This practice identifies critical factors affecting accuracy, precision, and sensitivity. It is not the intent of this practice to specify component tolerances or performance criteria, since these are unique for each instrument. A prospective user should consult with the vendor before placing an order, to design a testing protocol to demonstrate that the instrument meets all anticipated needs.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety hazard statements are given in Section 13.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1479 − 99 (Reapproved 2011)

Standard Practice for

Describing and Specifying Inductively-Coupled Plasma

Atomic Emission Spectrometers

This standard is issued under the fixed designation E1479; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E416Practice for Planning and Safe Operation of a Spec-

trochemical Laboratory (Withdrawn 2005)

1.1 This practice describes the components of an

E520Practice for Describing Photomultiplier Detectors in

inductively-coupled plasma atomic emission spectrometer

Emission and Absorption Spectrometry

(ICP-AES) that are basic to its operation and to the quality of

its performance. This practice identifies critical factors affect-

3. Terminology

ing accuracy, precision, and sensitivity. It is not the intent of

3.1 Definitions—For terminology relating to emission

this practice to specify component tolerances or performance

spectrometry, refer to Terminology E135.

criteria, since these are unique for each instrument.Aprospec-

tive user should consult with the vendor before placing an

4. Summary of Practice

order, to design a testing protocol to demonstrate that the

4.1 AnICP-AESisaninstrumentusedtodetermineelemen-

instrument meets all anticipated needs.

talcomposition.Ittypicallyiscomprisedofseveralassemblies

1.2 The values stated in SI units are to be regarded as

including a radio-frequency (RF) generator, an impedance

standard. The values given in parentheses are for information

matchingnetwork(whererequired),aninductioncoil,aplasma

only.

torch,aplasmaignitorsystem,asampleintroductionsystem,a

1.3 This standard does not purport to address all of the

lightgatheringoptic,anentranceslitanddispersingelementto

safety concerns, if any, associated with its use. It is the

sample and isolate wavelengths of light emitted from the

responsibility of the user of this standard to establish appro-

plasma, one or more devices for converting the emitted light

priate safety and health practices and determine the applica-

into an electrical current or voltage, one or more analog

bility of regulatory limitations prior to use. Specific safety

preamplifiers,oneormoreanalog-to-digitalconverter(s),anda

hazard statements are given in Section 13.

dedicated computer with printer (see Fig. 1 ).

4.1.1 The sample is introduced into a high-temperature

2. Referenced Documents

(>6000K)plasmathatisformedfromtheionizationofthegas

2.1 ASTM Standards:

stream contained in the torch. The torch is inserted through

E135Terminology Relating to Analytical Chemistry for

metal tubing formed into a helix, which is called the load coil.

Metals, Ores, and Related Materials

EnergyisappliedtotheloadcoilbymeansofanRFgenerator.

E158Practice for Fundamental Calculations to Convert

4.1.2 Theterminductively-coupledreferstothefactthatthe

Intensities into Concentrations in Optical Emission Spec-

physical phenomenon of induction creates a plasma by trans-

trochemical Analysis (Withdrawn 2004)

ferringenergyfromtheloadcoiltothegasstreamthathasbeen

E172Practice for Describing and Specifying the Excitation

momentarilypreionizedbyahighvoltageignitorelectrodethat

SourceinEmissionSpectrochemicalAnalysis(Withdrawn

functions only during plasma ignition.

2001)

4.2 When material passes through the plasma, it is

vaporized,atomized,andmanyelementsarealmostcompletely

This practice is under the jurisdiction ofASTM Committee E01 on Analytical

ionized.Freeatomsandionsareexcitedbycollisionfromtheir

ChemistryforMetals,Ores,andRelatedMaterialsandisthedirectresponsibilityof

ground states. When the excited atoms or ions subsequently

Subcommittee E01.20 on Fundamental Practices.

decay to a lower energy state, they emit photons, some of

Current edition approved Nov. 15, 2011. Published June 2012. Originally

approved in 1992. Last previous edition approved in 2005 as E1479–99 (2005).

which pass through the entrance slit of a spectrometer. Each

DOI: 10.1520/E1479-99R11.

element emits a unique set of emission lines. Photons of a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

desired wavelength may be selected from the ultraviolet and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

visible spectra by means of a dispersing element.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org. Courtesy of PerkinElmer, Inc., 761 Main Ave., Norwalk, CT 06859.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1479 − 99 (2011)

FIG. 1 Components of Inductively Coupled Plasma

4.2.1 Instrumentsmaydetermineelementseithersimultane- This description allows the user or potential user to gain a

ously or sequentially. The output of the detector generally is cursory understanding of an ICP-AES system. This practice

directed to a preamplifier, an analog-to-digital converter, and a

also provides a means for comparing and evaluating various

computer which measures and stores a value proportional to

systems, as well as understanding the capabilities and limita-

the electrical current or voltage generated by the detector(s).

tions of each instrument.

Using blank and known calibration solutions, a calibration

5.2 Training—The vendor should provide training in safety,

curve is generated for each element of interest.

basic theory of ICP spectrochemical analysis, operations of

4.2.2 The computer compares the signals arising from the

hardware and software, and routine maintenance for at least

various elements in the sample to the appropriate calibration

one operator. Training ideally should consist of the basic

curve. The concentrations of more than 70 elements may be

operationoftheinstrumentatthetimeofinstallation,followed

determined.

by an in-depth course one or two months later. Advanced

4.3 Sensitivities (see 12.3) in a simple aqueous solution are

courses are also offered at several of the important spectros-

less than one part per million (ppm) for all of these elements,

copy meetings that occur throughout the year as well as by

generallylessthan10partsperbillion(ppb)formost,andmay

independent training institutes. Furthermore, several indepen-

even be below 1 ppb for some.

dent consultants are available who can provide training, in

4.3.1 Organic liquids may also be used as solvents yielding

most cases at the user’s site.

sensitivities that are within an order of magnitude of aqueous

limits for many common organic solvents. Some organic

6. Excitation/Radio Frequency Generators

solventsmayafforddetectionlimitssimilarorevensuperiorto

those obtained using aqueous solutions.

6.1 Excitation—A specimen is converted into an aerosol

4.3.2 Directsamplingofsolidmaterialshasbeenperformed

entrained in a stream of argon gas and transported through a

successfully by such techniques as spark or laser ablation and

high temperature plasma.The plasma produces excited neutral

slurry nebulization. However, these require greater care in the

atoms and excited ions. The photons emitted when excited

choiceofreferencematerialsandtheoperationofthesampling

atoms or ions return to their ground states or lower energy

devices. Solid materials, therefore, are usually dissolved prior

levelsaremeasuredandcomparedtoemissionsfromreference

to analysis.

materials of similar composition. For further details see Prac-

tice E172.

5. Significance and Use

6.2 Radio-Frequency Generator:

5.1 This practice describes the essential components of an

6.2.1 An RF generator is used to initiate and sustain the

inductively-coupled plasma atomic emission spectrometer

(ICP-AES). The components include excitation/radio- argon plasma. Commercial generators operate at 27.12 and

40.68 MHz since these frequencies are designated as clear

frequency generators, sample introduction systems,

spectrometers, detectors, and signal processing and displays. frequencies by U.S. Federal Communications Committee

E1479 − 99 (2011)

(FCC) regulations. Generators typically are capable of produc- 7. Sample Introduction

ing 1.0 to 2.0 kW for the 27.12 MHz generator and 1.0 to 2.3

7.1 The sample introduction system of an ICP instrument

kW for the 40.68 MHz system.

consists of a nebulizer, a spray chamber, and a torch.

6.2.2 Generators more powerful than 2.5 kW are of limited

7.2 Nebulizers:

practical analytical utility and are not commercially marketed

7.2.1 Samples generally are presented to the instrument as

with ICPspectrometers.The power requirements are related to

aqueous or organic solutions. A nebulizer is employed to

torch geometry and types of samples to be analyzed. Refer to

convertthesolutiontoanaerosolsuitablefortransportintothe

Practice E172 for details. More power (typically 1.5 to 2 kW

plasma where vaporization, atomization, excitation, and emis-

for a 27.12 MHz system utilizing a 20-mm outside diameter

sion occur.

torchand1.2to1.7kWfora40.68MHzgenerator)isrequired

7.2.2 Some nebulizers, designated as self-aspirating pneu-

for analyzing samples dissolved in organic solvents than is

matic nebulizers, operating on the Venturi principle, create a

needed for aqueous solutions (approximately 1.0 kW). Less

partial vacuum to force liquid up a capillary tube into the

powerisrequiredforsmalldiametertorches(forexample,650

nebulizer. Precision of operation may be improved if a peri-

to 750 W for a 13-mm outside diameter torch).

staltic pump controls the solution flow rate.

6.3 Load Coil:

7.2.3 Othernebulizersrequireanauxiliarydevice,suchasa

6.3.1 Acoilmadefromcopper(oranothermetaloranalloy

peristaltic pump, to drive solution to the nebulizer. Generally,

with similar electrical properties) is used to transmit power

pump-fed nebulizers are more tolerant of high levels of

from the generator to the plasma torch (see 7.6). A typical

dissolved solids and much less affected by suspended solids

designconsistsofatwo-tosix-turncoilofabout1-in.(25-mm)

and viscosity variations.

diameter, made from ⁄8-in. (3-mm) outside diameter and

7.2.4 If fluoride is present in solutions to be analyzed, it is

⁄16-in. (1.6-mm) inside diameter copper tubing (though larger

necessary to employ a nebulizer fabricated from hydrofluoric

tubing is used with two-turn coils). The tubing is fitted with

acid (HF)-resistant materials (see 7.4.1.). It is possible to use

ferrules or similar devices to provide a leak-free connection to

theHF-resistantnebulizerformostothertypesofsolutions,but

a coolant, either recirculated by a pump or fed from a

sensitivity and precision may be degraded. An HF-resistant

municipal water supply.Argon gas blown through the coil has

nebulizer may be more expensive to acquire and repair, and

been used to cool other load coils.

require greater operator proficiency and training than other

6.3.2 Thehighpowerconductedbythecoilcanleadtorapid

nebulizers.

oxidation, surface metal vaporization, RF arc-over and even

7.3 Self-Aspirating or Non-Pump-Fed Nebulizers:

melting if the coil is not cooled continuously.

7.3.1 Concentric Glass Nebulizers (CGN):

6.3.3 Asafety interlock must be included to turn off the RF

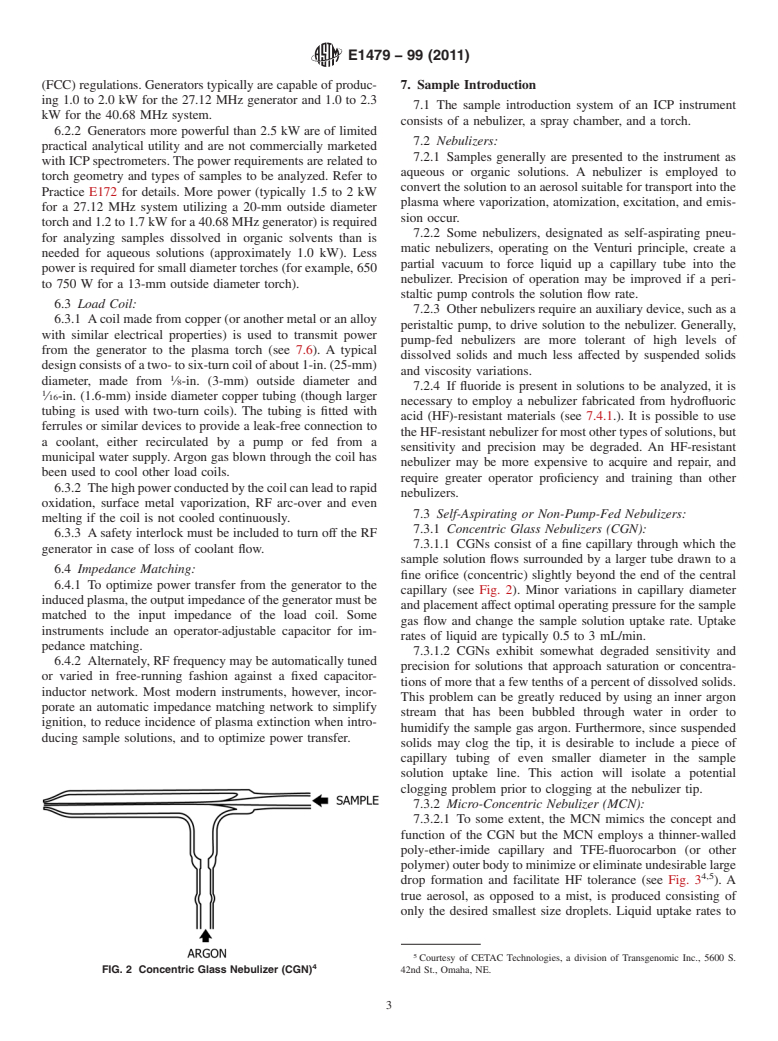

7.3.1.1 CGNs consist of a fine capillary through which the

generator in case of loss of coolant flow.

sample solution flows surrounded by a larger tube drawn to a

6.4 Impedance Matching:

fine orifice (concentric) slightly beyond the end of the central

6.4.1 To optimize power transfer from the generator to the

capillary (see Fig. 2). Minor variations in capillary diameter

inducedplasma,theoutputimpedanceofthegeneratormustbe

andplacementaffectoptimaloperatingpressureforthesample

matched to the input impedance of the load coil. Some

gas flow and change the sample solution uptake rate. Uptake

instruments include an operator-adjustable capacitor for im-

rates of liquid are typically 0.5 to 3 mL/min.

pedance matching.

7.3.1.2 CGNs exhibit somewhat degraded sensitivity and

6.4.2 Alternately,RFfrequencymaybeautomaticallytuned

precision for solutions that approach saturation or concentra-

or varied in free-running fashion against a fixed capacitor-

tionsofmorethatafewtenthsofapercentofdissolvedsolids.

inductor network. Most modern instruments, however, incor-

This problem can be greatly reduced by using an inner argon

porate an automatic impedance matching network to simplify

stream that has been bubbled through water in order to

ignition, to reduce incidence of plasma extinction when intro-

humidify the sample gas argon. Furthermore, since suspended

ducing sample solutions, and to optimize power transfer.

solids may clog the tip, it is desirable to include a piece of

capillary tubing of even smaller diameter in the sample

solution uptake line. This action will isolate a potential

clogging problem prior to clogging at the nebulizer tip.

7.3.2 Micro-Concentric Nebulizer (MCN):

7.3.2.1 To some extent, the MCN mimics the concept and

function of the CGN but the MCN employs a thinner-walled

poly-ether-imide capillary and TFE-fluorocarbon (or other

polymer)outerbodytominimizeoreliminateundesirablelarge

4,5

drop formation and facilitate HF tolerance (see Fig. 3 ). A

true aerosol, as opposed to a mist, is produced consisting of

only the desired smallest size droplets. Liquid uptake rates to

Courtesy of CETAC Technologies, a division of Transgenomic Inc., 5600 S.

FIG. 2 Concentric Glass Nebulizer (CGN) 42nd St., Omaha, NE.

E1479 − 99 (2011)

rates.Inaddition,micro-autosamplersthatarecompatiblewith

the MCN are available for the optimum handling of small

sample volumes.

7.3.3 Cross-Flow Nebulizer (CFN)—Consists of two capil-

laries held perpendicularly and with exit tips close together, as

shown in Fig. 4. This nebulizer is preadjusted by the manu-

facturer and is known as a fixed cross-flow nebulizer. It

requires little maintenance and is very durable. Problems with

high levels of dissolved and suspended solids are similar to

those of the concentric glass nebulizer.

7.4 Pump-Fed Pneumatic Nebulizers:

7.4.1 Grid Nebulizer—constructed from a fine-mesh screen

of acid and solvent resistant material, such as platinum,

mounted vertically in an inert housing. Sample solution is

4,5 pumped over the surface of the mesh. A high-velocity gas

FIG. 3 Micro-Concentric Nebulizer (MCN)

stream is directed through the openings in the screen, shearing

the liquid from the wetted surface.Afine mist is produced and

transported to the plasma.Asecond screen, parallel to the first

a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.