ASTM E2660-11

(Reference)Standard Digital Reference Images for Investment Steel Castings for Aerospace Applications

Standard Digital Reference Images for Investment Steel Castings for Aerospace Applications

SIGNIFICANCE AND USE

These digital reference images are intended for reference only, but are designed such that acceptance standards, which may be developed for particular requirements, can be specified in terms of these digital reference images. The illustrations are digital images of castings that were produced under conditions designed to develop the discontinuities.

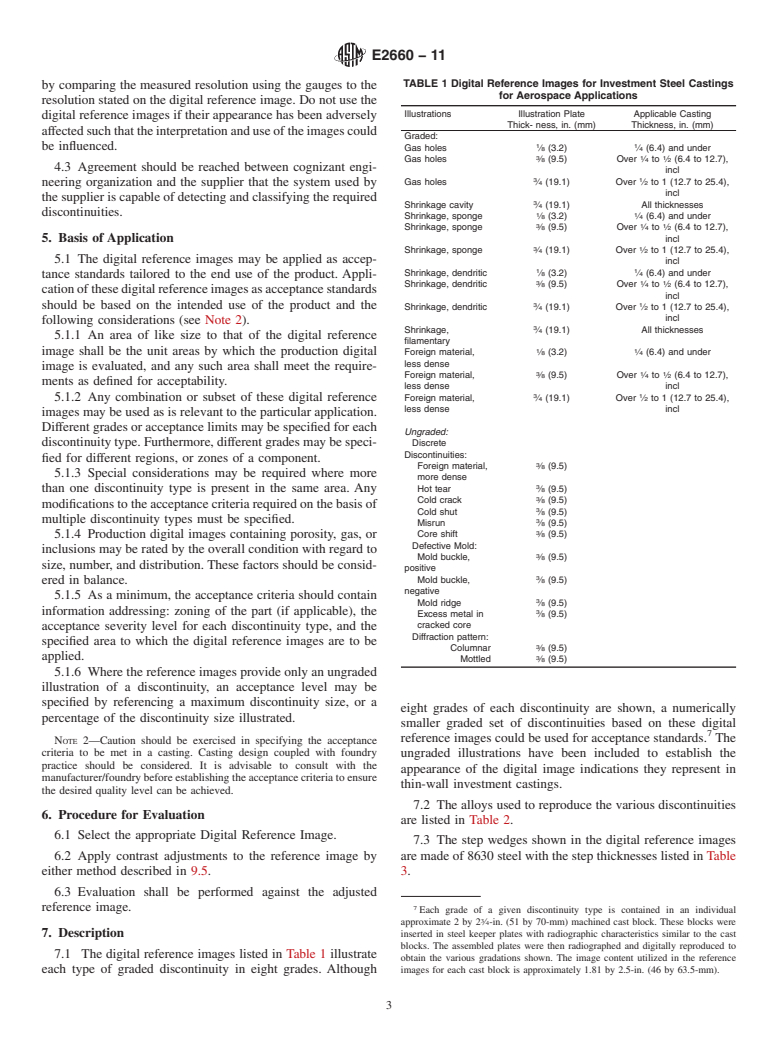

Graded Discontinuities:

Gas holes, sponge shrinkage, dendritic shrinkage, less dense foreign material

(1) The images of the 1/8-in (3.2-mm) castings are intended to be used in the thickness range up to and including ¼-in (6.3-mm). The images of the 3/8-in (9.5-mm) castings are intended to be used in the thickness range of over ¼-in (6.4-mm), up to and including ½-in (12.7-mm). The images of the ¾ -in (19.1-mm) castings are intended to be used in the thickness range of over ½-in (12.7-mm), up to and including 1-in. (25.4-mm).

Cavity Shrinkage, Filamentary Shrinkage:

(1) The images of the ¾-in (19.1-mm) castings are intended to be used in the thickness range up to and including 1-in. (25.4-mm).

Ungraded Discontinuities:

The images of the 3/8-in (9.5-mm) castings are intended to be used in the thickness range up to and including 1-in. (25.4-mm).

Image Deterioration—Many conditions can affect the appearance and functionality of digital reference images. For example, electrical interference, hardware incompatibilities, and corrupted files and drivers may affect their appearance. The Practice E2002 line pair gauges located in each digital reference image can be used as an aid to detect image deterioration by comparing the measured resolution using the gauges to the resolution stated on the digital reference image. Do not use the digital reference images if their appearance has been adversely affected such that the interpretation and use of the images could be influenced.

Agreement should be reached between cognizant engineering organization and the supplier that the system used by the supplier is cap...

SCOPE

1.1 The digital reference images provided in the adjunct to this standard illustrate various types and degrees of discontinuities occurring in thin-wall steel investment castings. Use of this standard for the specification or grading of castings requires procurement of the adjunct digital reference images which illustrate the discontinuity types and severity levels. They are intended to provide the following:

1.1.1 A guide enabling recognition of thin-wall steel casting discontinuities and their differentiation both as to type and degree through digital radiographic examination.

1.1.2 Example digital radiographic illustrations of discontinuities and a nomenclature for reference in acceptance standards, specifications and drawings.

1.2 Two illustration categories are covered as follows:

1.2.1 Graded—Six common discontinuity types each illustrated in eight degrees of progressively increasing severity.

1.2.2 Ungraded—Twelve single illustrations of additional discontinuity types and of patterns and imperfections not generally regarded as discontinuities.

1.3 The reference radiographs were developed for casting sections up to 1 in. (25.4 mm) in thickness.

1.4 All areas of this standard may be open to agreement between the cognizant engineering organization and the supplier, or specific direction from the cognizant engineering organization. These items should be addressed in the purchase order or the contract.

Note 1—The set of digital reference images consists of 16 digital files, software to load the desired format and specific instructions on the loading process. The 16 reference images illustrate eight grades of severity in six common discontinuity types and twelve ungraded discontinuities and contain an image of a step wedge and two duplex-wire gauges. Refer to Practice E2002 for wire pair details.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2660 − 11

Standard Digital Reference Images for

1

Investment Steel Castings for Aerospace Applications

This standard is issued under the fixed designation E2660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

to Practice E2002 for wire pair details.

1. Scope*

1.5 The values stated in inch-pound units are to be regarded

1.1 The digital reference images provided in the adjunct to

as standard. The values given in parentheses are mathematical

this standard illustrate various types and degrees of disconti-

2

conversions to SI units that are provided for information only

nuitiesoccurringinthin-wallsteelinvestmentcastings. Useof

and are not considered standard.

this standard for the specification or grading of castings

requires procurement of the adjunct digital reference images

1.6 These digital reference images are not intended to

which illustrate the discontinuity types and severity levels.

illustrate the types or degrees of discontinuities when perform-

They are intended to provide the following:

ing film radiography. If performing film radiography of thin-

1.1.1 Aguide enabling recognition of thin-wall steel casting

wall investment castings, refer to Reference Radiographs

discontinuities and their differentiation both as to type and

E192.

degree through digital radiographic examination.

1.7 This standard does not purport to address all of the

1.1.2 Example digital radiographic illustrations of disconti-

safety concerns, if any, associated with its use. It is the

nuities and a nomenclature for reference in acceptance

responsibility of the user of this standard to establish appro-

standards, specifications and drawings.

priate safety and health practices and determine the applica-

1.2 Two illustration categories are covered as follows:

bility of regulatory limitations prior to use.

1.2.1 Graded—Six common discontinuity types each illus-

1.8 Onlylicensedcopiesofthesoftwareandimagesshallbe

trated in eight degrees of progressively increasing severity.

utilized for production inspection. A copy of the ASTM/User

1.2.2 Ungraded—Twelve single illustrations of additional

license agreement shall be kept on file for audit purposes.

discontinuity types and of patterns and imperfections not

generally regarded as discontinuities. 2. Referenced Documents

3

1.3 The reference radiographs were developed for casting 2.1 ASTM Standards:

sections up to 1 in. (25.4 mm) in thickness. E94 Guide for Radiographic Examination

E192 Reference Radiographs of Investment Steel Castings

1.4 All areas of this standard may be open to agreement

for Aerospace Applications

between the cognizant engineering organization and the

E1025 Practice for Design, Manufacture, and Material

supplier, or specific direction from the cognizant engineering

Grouping Classification of Hole-Type Image Quality In-

organization. These items should be addressed in the purchase

dicators (IQI) Used for Radiology

order or the contract.

E1316 Terminology for Nondestructive Examinations

NOTE 1—The set of digital reference images consists of 16 digital files,

E1320 Reference Radiographs for Titanium Castings

softwaretoloadthedesiredformatandspecificinstructionsontheloading

E2002 Practice for Determining Total Image Unsharpness in

process. The 16 reference images illustrate eight grades of severity in six

Radiology

common discontinuity types and twelve ungraded discontinuities and

E2597 Practice for Manufacturing Characterization of Digi-

contain an image of a step wedge and two duplex-wire gauges. Available

from ASTM International Headquarters. Order number RRE2660. Refer

tal Detector Arrays

4

2.2 SMPTE Practice:

1 RP133 SMPTE Recommended Practice Specifications for

This standard is under the jurisdiction of ASTM Committee E07 on Nonde-

structive Testing and is the direct responsibility of Subcommittee E07.02 on

Medical Diagnostic Imaging test Pattern for Television

Reference Radiological Images.

Current edition approved Dec. 1, 2011. Published December 2011. Originally

approved in 2010. Last previous edition approved in 2010 as E2660 - 10.

3

DOI:10.1520/E2660-11. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

The digital reference images are considered to be applicable to all thin-wall contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

steel castings, requiring close tolerances.They may also be used for nickel-base and Standards volume information, refer to the standard’s Document Summary page on

cobalt-base cast alloys. Castings for which these images are applicable generally the ASTM website.

4

include those

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2660–10 Designation:E2660–11

Standard Digital Reference Images for

1

Investment Steel Castings for Aerospace Applications

This standard is issued under the fixed designation E2660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 The digital reference images provided in the adjunct to this standard illustrate various types and degrees of discontinuities

2

occurring in thin-wall steel investment castings. Use of this standard for the specification or grading of castings requires

procurement of the adjunct digital reference images which illustrate the discontinuity types and severity levels. They are intended

to provide the following:

1.1.1 Aguide enabling recognition of thin-wall steel casting discontinuities and their differentiation both as to type and degree

through digital radiographic examination.

1.1.2 Example digital radiographic illustrations of discontinuities and a nomenclature for reference in acceptance standards,

specifications and drawings.

1.2 Two illustration categories are covered as follows:

1.2.1 Graded—Six common discontinuity types each illustrated in eight degrees of progressively increasing severity.

1.2.2 Ungraded—Twelve single illustrations of additional discontinuity types and of patterns and imperfections not generally

regarded as discontinuities.

1.3 The reference radiographs were developed for casting sections up to 1 in. (25.4 mm) in thickness.

1.4 All areas of this standard may be open to agreement between the cognizant engineering organization and the supplier, or

specific direction from the cognizant engineering organization. These items should be addressed in the purchase order or the

contract.

NOTE 1—The set of digital reference images consists of 16 digital files, software to load the desired format and specific instructions on the loading

process. The 16 reference images illustrate eight grades of severity in six common discontinuity types and twelve ungraded discontinuities and contain

an image of a step wedge and two duplex-wire gauges. Available from ASTM International Headquarters. Order number RRE2660. Refer to Practice

E2002 for wire pair details.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 These digital reference images are not intended to illustrate the types or degrees of discontinuities when performing film

radiography. If performing film radiography of thin-wall investment castings, refer to Reference Radiographs E192.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.8 Only licensed copies of the software and images shall be utilized for production inspection. A copy of the ASTM/User

license agreement shall be kept on file for audit purposes.

2. Referenced Documents

3

2.1 ASTM Standards:

E94 Guide for Radiographic Examination

E192 Reference Radiographs of Investment Steel Castings for Aerospace Applications

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiology

1

This standard is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.02 on Reference

Radiological Images.

Current edition approved Jan. 1, 2010. Published February 2010.

Current edition approved Dec. 1, 2011. Published December 2011. Originally approved in 2010. Last previous edition approved in 2010 as E2660 - 10.

DOI:10.1520/E2660-11.

2

The digital reference images are considered to be applicable to all thin-wall steel castings, requiring close tolerances. They may also be used for nickel-base and

cobalt-base cast alloys. Castings for which these images are applicable generally include those made by the lost wax, frozen mercury, ceramicast or shell mold processes.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.