ASTM F1612-95(2005)

(Practice)Standard Practice for Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty Femoral Components with Torsion (Withdrawn 2011)

Standard Practice for Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty Femoral Components with Torsion (Withdrawn 2011)

SIGNIFICANCE AND USE

This practice can be used to describe the effects of materials, manufacturing, and design variables on the fatigue resistance of metallic stemmed femoral components subjected to cyclic loading for relatively large numbers of cycles. The recommended test assumes a worst case situation in which proximal support for the stem has been lost. It is also recognized that, for some materials, the environment has an effect on the response to cyclic loading (see 12.7). The test environment used and rationale for the choice of that environment should be described in the test report.

It is recognized that actual in vivo loading conditions are not constant amplitude. However, sufficient information is not available to create standard load spectrums for metallic stemmed femoral components. A simple periodic constant amplitude force is accordingly recommended.

SCOPE

1.1 This practice covers a method for the fatigue testing of metallic stemmed femoral components used in hip arthroplasty. The described method is intended to be used for evaluation in comparisons of various designs and materials used for stemmed femoral components used in the arthroplasty. This practice covers procedures for the performance of fatigue tests using (as a forcing function) a periodic constant amplitude force.

1.2 This practice applies primarily to one-piece prostheses and femoral stems with modular heads, with the head in place. Such prostheses should not have an anterior-posterior A-P bow or a medial-lateral M-L bow, and they should have a nearly straight section on the distal 50 mm of the stem. This practice may require modifications to accommodate other femoral stem designs.

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covers a method for the fatigue testing of metallic stemmed femoral components used in hip arthroplasty. The described method is intended to be used for evaluation in comparisons of various designs and materials used for stemmed femoral components used in the arthroplasty. This practice covers procedures for the performance of fatigue tests using (as a forcing function) a periodic constant amplitude force.

Formerly under the jurisdiction of Committee F04 on Medical and Surgical Materials and Devices, this practice was withdrawn in November 2011.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1612–95 (Reapproved 2005)

Standard Practice for

Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty

1

Femoral Components with Torsion

This standard is issued under the fixed designation F1612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1150 Definitions of Terms Relating to Fatigue

4

2.2 ISO Document:

1.1 This practice covers a method for the fatigue testing of

ISO 7206-3 (1988) Stem Test

metallicstemmedfemoralcomponentsusedinhiparthroplasty.

The described method is intended to be used for evaluation in

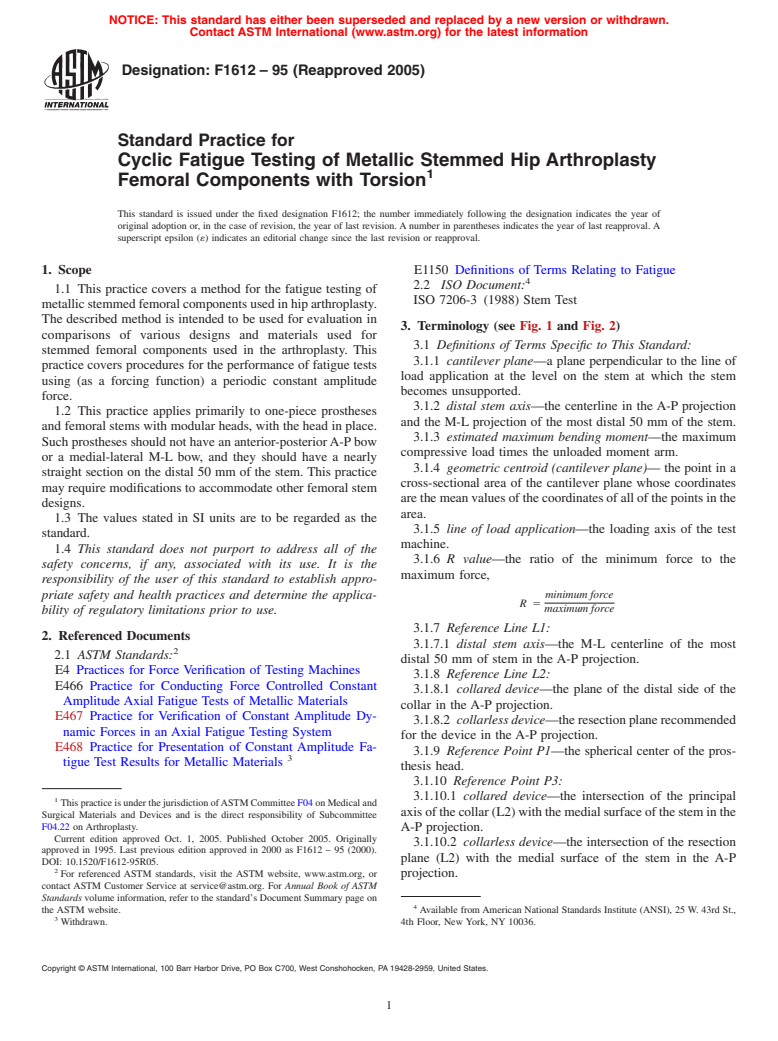

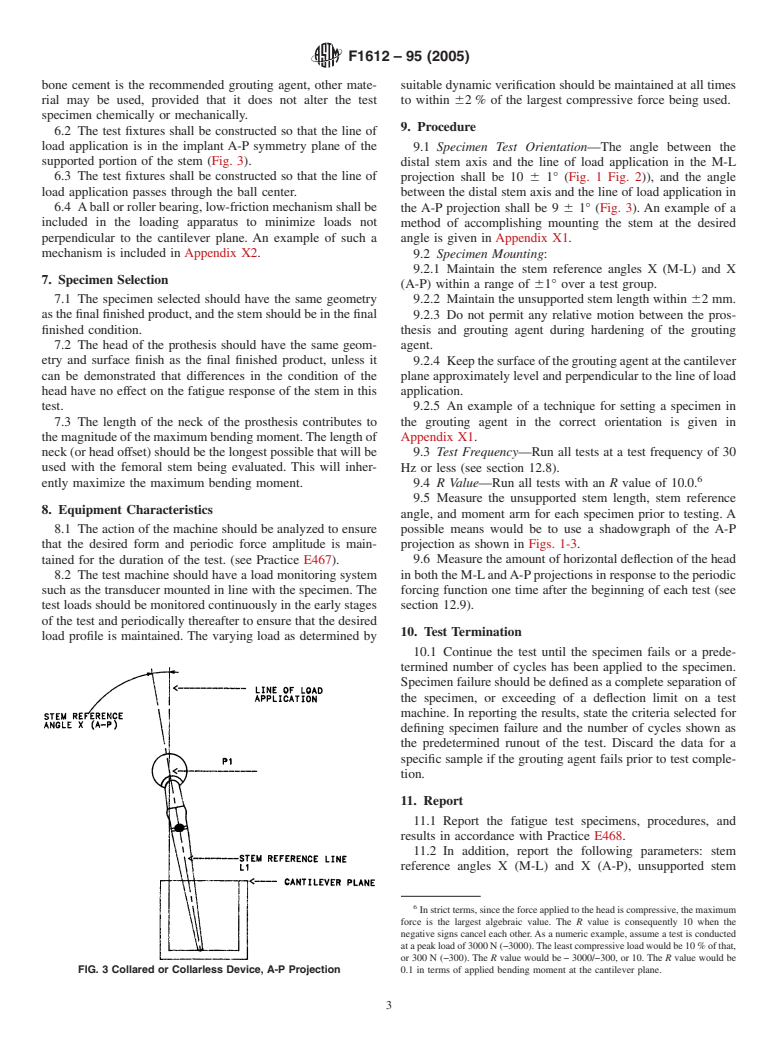

3. Terminology (see Fig. 1 and Fig. 2)

comparisons of various designs and materials used for

3.1 Definitions of Terms Specific to This Standard:

stemmed femoral components used in the arthroplasty. This

3.1.1 cantilever plane—a plane perpendicular to the line of

practice covers procedures for the performance of fatigue tests

load application at the level on the stem at which the stem

using (as a forcing function) a periodic constant amplitude

becomes unsupported.

force.

3.1.2 distal stem axis—the centerline in the A-P projection

1.2 This practice applies primarily to one-piece prostheses

and the M-L projection of the most distal 50 mm of the stem.

and femoral stems with modular heads, with the head in place.

3.1.3 estimated maximum bending moment—the maximum

Suchprosthesesshouldnothaveananterior-posteriorA-Pbow

compressive load times the unloaded moment arm.

or a medial-lateral M-L bow, and they should have a nearly

3.1.4 geometric centroid (cantilever plane)— the point in a

straight section on the distal 50 mm of the stem. This practice

cross-sectional area of the cantilever plane whose coordinates

mayrequiremodificationstoaccommodateotherfemoralstem

arethemeanvaluesofthecoordinatesofallofthepointsinthe

designs.

area.

1.3 The values stated in SI units are to be regarded as the

3.1.5 line of load application—the loading axis of the test

standard.

machine.

1.4 This standard does not purport to address all of the

3.1.6 R value—the ratio of the minimum force to the

safety concerns, if any, associated with its use. It is the

maximum force,

responsibility of the user of this standard to establish appro-

minimum force

priate safety and health practices and determine the applica-

R 5

maximum force

bility of regulatory limitations prior to use.

3.1.7 Reference Line L1:

2. Referenced Documents

3.1.7.1 distal stem axis—the M-L centerline of the most

2

2.1 ASTM Standards:

distal 50 mm of stem in the A-P projection.

E4 Practices for Force Verification of Testing Machines

3.1.8 Reference Line L2:

E466 Practice for Conducting Force Controlled Constant

3.1.8.1 collared device—the plane of the distal side of the

Amplitude Axial Fatigue Tests of Metallic Materials

collar in the A-P projection.

E467 Practice for Verification of Constant Amplitude Dy-

3.1.8.2 collarless device—theresectionplanerecommended

namic Forces in an Axial Fatigue Testing System

for the device in the A-P projection.

E468 Practice for Presentation of Constant Amplitude Fa-

3.1.9 Reference Point P1—the spherical center of the pros-

3

tigue Test Results for Metallic Materials

thesis head.

3.1.10 Reference Point P3:

3.1.10.1 collared device—the intersection of the principal

1

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland

axisofthecollar(L2)withthemedialsurfaceofthesteminthe

Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

A-P projection.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

3.1.10.2 collarless device—the intersection of the resection

approved in 1995. Last previous edition approved in 2000 as F1612 – 95 (2000).

plane (L2) with the medial surface of the stem in the A-P

DOI: 10.1520/F1612-95R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or projection.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

Withdrawn. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1612–95 (2005)

5

3.1.12 Reference Point P6 — the intersection of the canti-

lever plane with the medial surface of the stem in the A-P

projection.

3.1.13 stem reference angles—Since the distal stem axis is

obscurred by the grouting agent after preparation of the test

sample,the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.