ASTM D2732-96

(Test Method)Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting

Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting

SCOPE

1.1 This test method covers determination of the degree of unrestrained linear thermal shrinkage at given specimen temperatures of plastic film and sheeting of 0.76 mm (0.030 in.) thickness or less. This test method does not cover shrinkage from loss of solvent in some materials.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- This document is similar in concept to ISO/DIS 11501, but it is unknown at this time whether both methods give comparable results.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2732 – 96

Standard Test Method for

Unrestrained Linear Thermal Shrinkage of Plastic Film

and Sheeting

This standard is issued under the fixed designation D 2732; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope stresses may be locked into the film which can be released by

heating. The temperature at which shrinkage will occur is

1.1 This test method covers determination of the degree of

related to the processing techniques employed to manufacture

unrestrained linear thermal shrinkage at given specimen tem-

the film and may also be related to a phase transition in the base

peratures of plastic film and sheeting of 0.76 mm (0.030 in.)

resin. The magnitude of the shrinkage will vary with the

thickness or less. This test method does not cover shrinkage

temperature of the film.

from loss of solvent in some materials.

4.2 Shrinkage of a particular material produced by a par-

1.2 This standard does not purport to address all of the

ticular process may be characterized by this test method by

safety concerns, if any, associated with its use. It is the

making measurements at several temperatures through the

responsibility of the user of this standard to establish appro-

shrinkage range of the material.

priate safety and health practices and determine the applica-

4.3 Following a characterization in a particular case, it is

bility of regulatory limitations prior to use.

usually sufficient thereafter to measure shrinkage at only one

NOTE 1—This document is similar in concept to ISO/DIS 11501, but it

selected temperature for purposes of process or quality control,

is unknown at this time whether both methods give comparable results.

or both.

2. Referenced Documents

5. Apparatus

2.1 ASTM Standards:

5.1 Constant-Temperature Liquid Bath, capable of control-

D 618 Practice for Conditioning Plastics for Testing

ling accurately to 60.5°C.

D 1204 Test Method for Linear Dimensional Changes of

5.1.1 The liquid for the bath should not plasticize or react

Nonrigid Thermoplastic Sheeting or Film at Elevated

with the specimens. Poly(ethylene glycol), glycerin, and water

Temperature

have been found to have wide applicability.

D 1898 Practice for Sampling of Plastics

5.2 Thermometer—ASTM Thermometer 1 C conforming to

E 1 Specification for ASTM Thermometers

the requirements as prescribed in Specification E 1.

5.3 Square Metal Stamp, 100 by 100 mm, with engraved

3. Terminology

arrow indicating machine direction of film and stamp pad and

3.1 Definitions:

ink. (The ink should not be soluble in the bath liquid.)

3.1.1 unrestrained linear thermal shrinkage (free shrink or

NOTE 2—A metal die or template (100 by 100 mm) can be used instead

shrinkage)—the irreversible and rapid reduction in linear

of the square metal stamp.

dimension in a specified direction occurring in film subjected

to elevated temperatures under conditions where nil or negli-

5.4 Free Shrink Holder—A holder designed for test of a

gible restraint to inhibit shrinkage is present. It is normally

single specimen, such as that shown in Fig. 1 and Fig. 2.

expressed as a percentage of the original dimension.

Alternatively, a holder such as that shown in Fig. 3 may be

used to immerse several specimens at a time. However, checks

4. Significance and Use

must be made to assure that contact among the specimens does

4.1 As a result of the manufacturing process, internal

not result in errors.

5.5 Ruler, graduated in millimetres.

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

6. Test Specimen

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

6.1 The test specimen shall consist of 100 by 100-mm

Current edition approved Sept. 10, 1996. Published February 1997. Originally

published as D 2732 – 68 T. Last previous edition D 2732 – 83 (1989)e .

samples.

This revision has incorporated an ISO equivalency statement, a revised precision

6.2 A minimum of two specimens is necessary for each test

and bias statement, keywords, and some of the note material has been included in

temperature.

the text.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2732

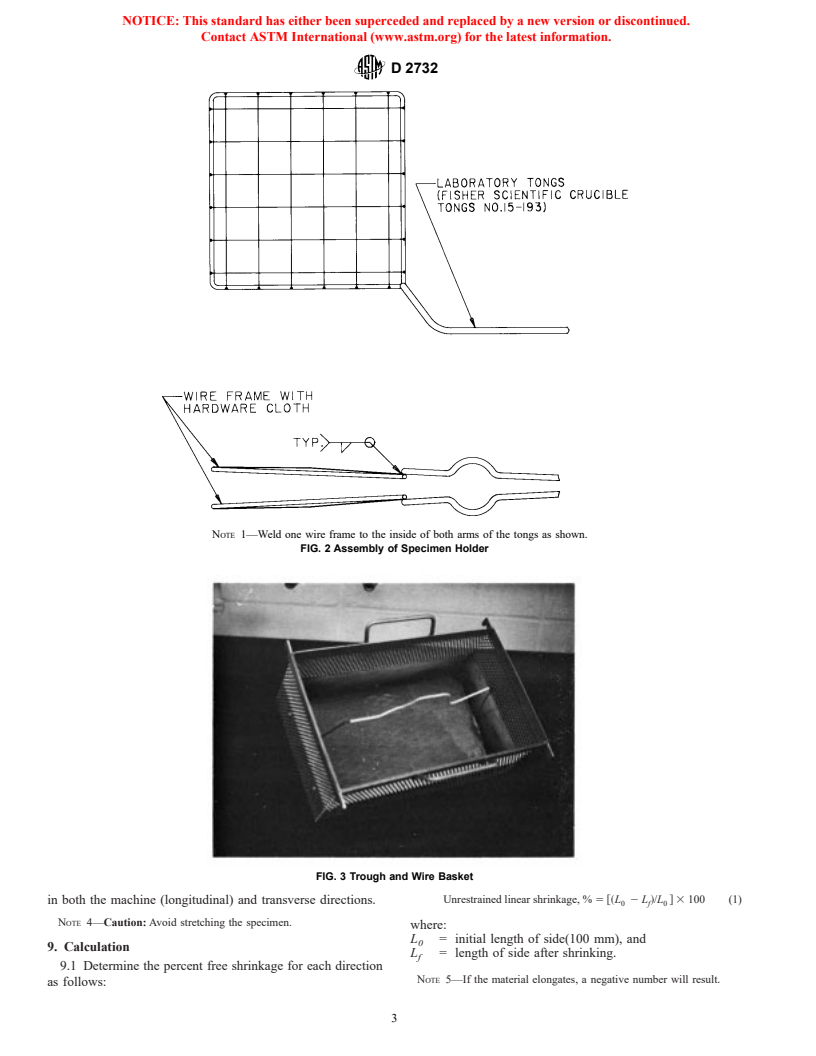

NOTE:

1 1

1. (A) Cut hardware cloth 6 ⁄8 by 6 ⁄8.

(B) Form a pocket in center of cloth.

(C) Weld cloth to frame as shown.

2. Two required for assembly.

FIG. 1 Construction of Top and Bottom Grid Retainers of Specimen Holder

6.3 The material shall be sampled in accordance with should restrain the specimen from floating in the bath medium

Practice D 1898. while allowing free circulation of the bath medium around the

specimen. Multiple specimens can be tested but care should be

7. Conditioning

exercised to prevent restraint between the specimens.

7.1 Conditioning—Condition the test specimens at 23 6

8.3 Observe and record the temperature of the bath before

2°C (73.4 6 3.6°F) and 50 6 5 % relat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.