ASTM F28-91(1997)

(Test Method)Standard Test Methods for Minority-Carrier Lifetime in Bulk Germanium and Silicon by Measurement of Photoconductivity Decay

Standard Test Methods for Minority-Carrier Lifetime in Bulk Germanium and Silicon by Measurement of Photoconductivity Decay

SCOPE

1.1 These test methods cover the measurement of minority carrier lifetime appropriate to carrier recombination processes in bulk specimens of extrinsic single-crystal germanium or silicon.

1.2 These test methods are based on the measurement of the decay of the specimen conductivity after generation of carriers with a light pulse. The following two test methods are described:

1.2.1 Test Method A -Pulsed Light Method, that is suitable for both silicon and germination.

1.2.2 Test Method B -Chopped Light Method, that is specific to silicon specimens with resistivity [>=]1 [omega][dot]cm.

1.3 Both test methods are nondestructive in the sense that the specimens can be used repeatedly to carry out the measurement, but these methods require special bar-shaped test specimens of size (see Table 1) and surface condition (lapped) that would be generally unsuitable for other applications.

1.4 The shortest measurable lifetime values are determined by the turn-off characteristics of the light source while the longest values are determined primarily by the size of the test specimen (see Table 2). Note 1-Minority carrier lifetime may also be deduced from the diffusion length as measured by the surface photovoltage (SPV) method made in accordance with Test Methods F391. The minority carrier lifetime is the square of the diffusion length divided by the minority carrier diffusion constant which can be calculated from the drift mobility. SPV measurements are sensitive primarily to the minority carriers; the contribution from majority carriers is minimized by the use of a surface depletion region. As a result lifetimes measured by the SPV method are often shorter than lifetimes measured by the photoconductivity decay (PCD) method because the photoconductivity can contain contributions from majority as well as minority carriers. In the absence of carrier trapping, both the SPV and PCD methods should yield the same values of lifetime (1) providing that the correct values of absorption coefficient are used for the SPV measurements and that the contributions from surface recombination are properly accounted for in the PCD measurement.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: F 28 – 91 (Reapproved 1997)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

Minority-Carrier Lifetime in Bulk Germanium and Silicon by

Measurement of Photoconductivity Decay

This standard is issued under the fixed designation F 28; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

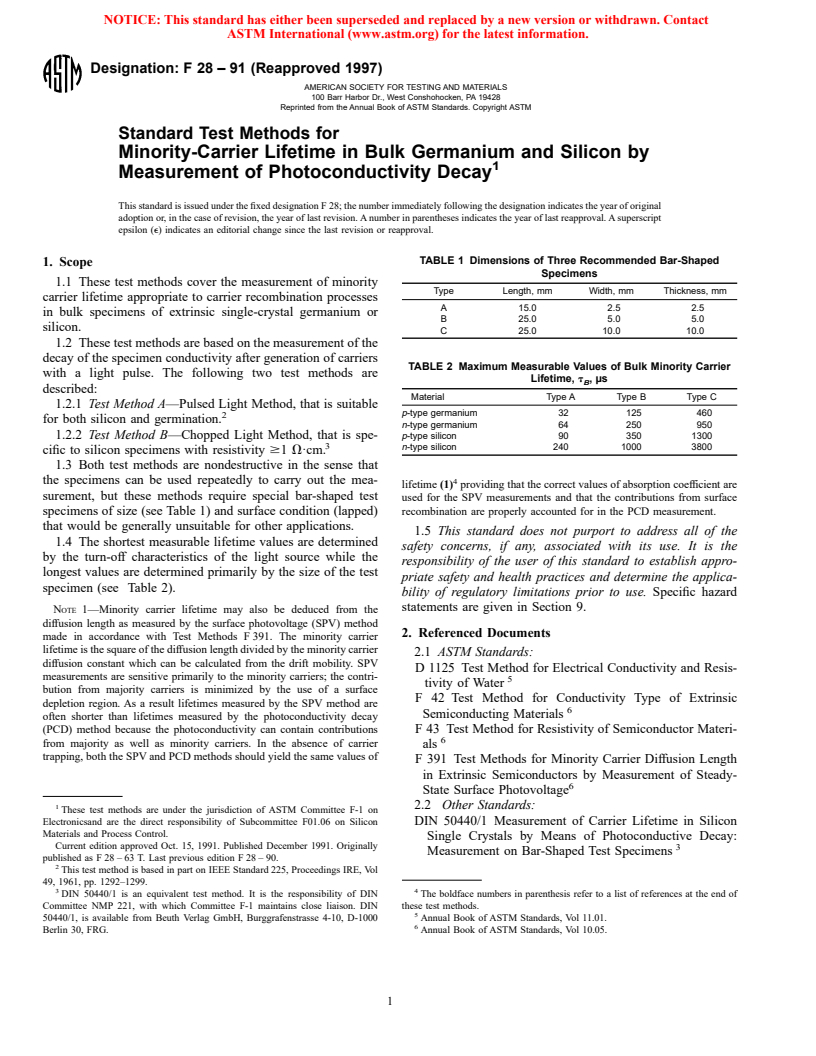

TABLE 1 Dimensions of Three Recommended Bar-Shaped

1. Scope

Specimens

1.1 These test methods cover the measurement of minority

Type Length, mm Width, mm Thickness, mm

carrier lifetime appropriate to carrier recombination processes

A 15.0 2.5 2.5

in bulk specimens of extrinsic single-crystal germanium or

B 25.0 5.0 5.0

silicon.

C 25.0 10.0 10.0

1.2 These test methods are based on the measurement of the

decay of the specimen conductivity after generation of carriers

TABLE 2 Maximum Measurable Values of Bulk Minority Carrier

with a light pulse. The following two test methods are

Lifetime, t ,μs

B

described:

Material Type A Type B Type C

1.2.1 Test Method A—Pulsed Light Method, that is suitable

p-type germanium 32 125 460

for both silicon and germination.

n-type germanium 64 250 950

1.2.2 Test Method B—Chopped Light Method, that is spe-

p-type silicon 90 350 1300

n-type silicon 240 1000 3800

cific to silicon specimens with resistivity $1 V·cm.

1.3 Both test methods are nondestructive in the sense that

the specimens can be used repeatedly to carry out the mea-

lifetime (1) providing that the correct values of absorption coefficient are

surement, but these methods require special bar-shaped test

used for the SPV measurements and that the contributions from surface

recombination are properly accounted for in the PCD measurement.

specimens of size (see Table 1) and surface condition (lapped)

that would be generally unsuitable for other applications.

1.5 This standard does not purport to address all of the

1.4 The shortest measurable lifetime values are determined

safety concerns, if any, associated with its use. It is the

by the turn-off characteristics of the light source while the

responsibility of the user of this standard to establish appro-

longest values are determined primarily by the size of the test

priate safety and health practices and determine the applica-

specimen (see Table 2).

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 9.

NOTE 1—Minority carrier lifetime may also be deduced from the

diffusion length as measured by the surface photovoltage (SPV) method

2. Referenced Documents

made in accordance with Test Methods F 391. The minority carrier

lifetime is the square of the diffusion length divided by the minority carrier

2.1 ASTM Standards:

diffusion constant which can be calculated from the drift mobility. SPV

D 1125 Test Method for Electrical Conductivity and Resis-

measurements are sensitive primarily to the minority carriers; the contri-

tivity of Water

bution from majority carriers is minimized by the use of a surface

F 42 Test Method for Conductivity Type of Extrinsic

depletion region. As a result lifetimes measured by the SPV method are

Semiconducting Materials

often shorter than lifetimes measured by the photoconductivity decay

(PCD) method because the photoconductivity can contain contributions F 43 Test Method for Resistivity of Semiconductor Materi-

from majority as well as minority carriers. In the absence of carrier

als

trapping, both the SPV and PCD methods should yield the same values of

F 391 Test Methods for Minority Carrier Diffusion Length

in Extrinsic Semiconductors by Measurement of Steady-

State Surface Photovoltage

1 2.2 Other Standards:

These test methods are under the jurisdiction of ASTM Committee F-1 on

DIN 50440/1 Measurement of Carrier Lifetime in Silicon

Electronicsand are the direct responsibility of Subcommittee F01.06 on Silicon

Materials and Process Control.

Single Crystals by Means of Photoconductive Decay:

Current edition approved Oct. 15, 1991. Published December 1991. Originally

Measurement on Bar-Shaped Test Specimens

published as F 28 – 63 T. Last previous edition F 28 – 90.

This test method is based in part on IEEE Standard 225, Proceedings IRE, Vol

49, 1961, pp. 1292–1299.

3 4

DIN 50440/1 is an equivalent test method. It is the responsibility of DIN The boldface numbers in parenthesis refer to a list of references at the end of

Committee NMP 221, with which Committee F-1 maintains close liaison. DIN these test methods.

50440/1, is available from Beuth Verlag GmbH, Burggrafenstrasse 4-10, D-1000 Annual Book of ASTM Standards, Vol 11.01.

Berlin 30, FRG. Annual Book of ASTM Standards, Vol 10.05.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

F28

IEEE Standard 225 Measurement of Minority-Carrier Life- 5.1.1 If the free carrier density is not too high, minority

time in Germanium and Silicon by the Method of Photo- carrier lifetime is controlled by such recombination centers;

conductive Decay however, since it does not distinguish the type of center

present, a measurement of minority carrier lifetime provides

3. Terminology

only a non-specific, qualitative test for metallic contamination

3.1 Definitions: in the material.

5.1.2 When present in sufficient quantity, free carriers con-

3.1.1 minority carrier lifetime— of a homogeneous semi-

conductor, the average time interval between the generation trol the lifetime; thus, these test methods do not provide a

reliable means for establishing the presence of recombination

and recombination of minority carriers.

3.2 Definitions of Terms Specific to This Standard: centers due to unwanted metallic or other non-dopant impuri-

ties when applied to silicon specimens with resistivity below 1

3.2.1 filament lifetime—the time constant, t , (in μs) of the

F

decay of the photoconductivity voltage, as defined by: V·cm.

5.2 Because special test specimens are required, it is not

D V5D V exp ~2t/t !

0 F

possible to perform this test directly on the material to be

where: employed for subsequent device or circuit fabrication. Further-

DV 5 the photoconductivity voltage (V),

more, the density of recombination centers in a crystal is not

DV 5 the peak or saturation value of the photoconductiv-

0 likely to be homogeneously distributed. Therefore, it is neces-

ity voltage ( V), and

sary to select samples carefully in order to ensure that the test

t 5 time (μs).

specimens are representative of the properties of the material

being evaluated.

4. Summary of Test Methods

5.3 These test methods are suitable for use in research,

4.1 Test Method A—By means of ohmic contacts at each

development, and process control applications; they are not

end, direct current is passed through a bar-shaped homoge-

suitable for acceptance testing of polished wafers since they

neous monocrystalline semiconductor specimen with lapped

cannot be performed on specimens with polished surfaces.

surfaces. The voltage drop across the specimen is observed on

6. Interferences

an oscilloscope. Excess carriers are created in the specimen for

6.1 Carrier trapping may be significant in silicon at room

a very brief time by a short pulse of light with energy near the

temperature and in germanium at lower temperatures. If

energy of the forbidden gap. An oscilloscope trace is triggered

trapping of either electrons or holes occurs in the specimen, the

by the light pulse and the time constant of the voltage decay

excess concentration of the other type of carrier remains high

following cessation of the light pulse is measured from the

for a relatively long period of time following cessation of the

oscilloscope trace. If the conductivity modulation of the

light pulse, contributing a long tail to the photoconductivity

specimen is very small, the observed voltage decay is equiva-

decay curve. Measurements made on this portion of the decay

lent to the decay of the photoinjected carriers. Thus the time

curve result in erroneously long time constants.

constant of the voltage decay is equal to the time constant of

6.1.1 Trapping can be identified by increases in the time

excess carrier decay. The minority carrier lifetime is deter-

constant as the measurement is made further and further along

mined from this time constant; trapping effects are eliminated

the decay curve.

and corrections are made for surface recombination and excess

6.1.2 Trapping in silicon may be eliminated by heating the

conductivity modulation, as required.

specimen to a temperature between 50 and 70°C or by flooding

4.2 Test Method B—This test method, that is specific to

the specimen with steady background light.

silicon, is similar to Test Method A except that the excess

6.1.3 The minority carrier lifetime should not be determined

carriers are generated by a chopped rather than a pulsed light

from a specimen in which trapping contributes more than 5 %

source. The wavelength of the light is specified to be between

to the total amplitude of the decay curve (Test Method A) or in

1.0 and 1.1 μm. In addition, it is required that low-injection-

which the decay curve is non-exponential (Test Method B).

level conditions are employed so that excess conductivity

6.2 The measurement is affected by surface recombination

modulation effects are avoided, special contacting procedures

effects, especially if small specimens are used. The specified

are given to ensure the formation of ohmic contacts, and signal

specimen preparation results in an infinite surface recombina-

conditioning may be employed before the oscilloscope. Cor-

tion velocity. Corrections for surface recombination for speci-

rection for surface recombination is required. Test specimens

mens with infinite surface recombination velocity and specific

that yield non-exponential signals under the conditions of the

recommended sizes are given in Table 3. A general formula for

test are deemed to be unsuitable for the measurement.

establishing the correction is also provided in the calculations

5. Significance and Use

section; use of this correction is especially important when the

ratio of the surface area to volume of the specimen is large.

5.1 Minority carrier lifetime is one of the essential charac-

−1

teristics of semiconductor materials. Many metallic impurities

TABLE 3 Surface Recombination Rate, R ,μs

s

form recombination centers in germanium and silicon; in many

Material Type A Type B Type C

cases, these recombination centers are deleterious to device

p-type germanium 0.03230 0.00813 0.00215

and circuit performance. In other cases, the recombination

n-type germanium 0.01575 0.00396 0.00105

p-type silicon 0.01120 0.00282 0.00075

characteristics must be carefully controlled to obtain the

n-type silicon 0.00420 0.00105 0.00028

desired device performance.

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

F28

6.2.1 If the correction for surface recombination is too large,

the accuracy of the minority carrier lifetime determination is

severely degraded. It is recommended that the corrections

applied to the observed decay time not exceed one-half of the

reciprocal of the observed value of decay time. Maximum bulk

lifetimes that can be determined on the standard bar-shaped

specimens are listed in Table 2.

6.3 The conductivity modulation in the specimen must be

very small if the observed decay, that is actually the decay of

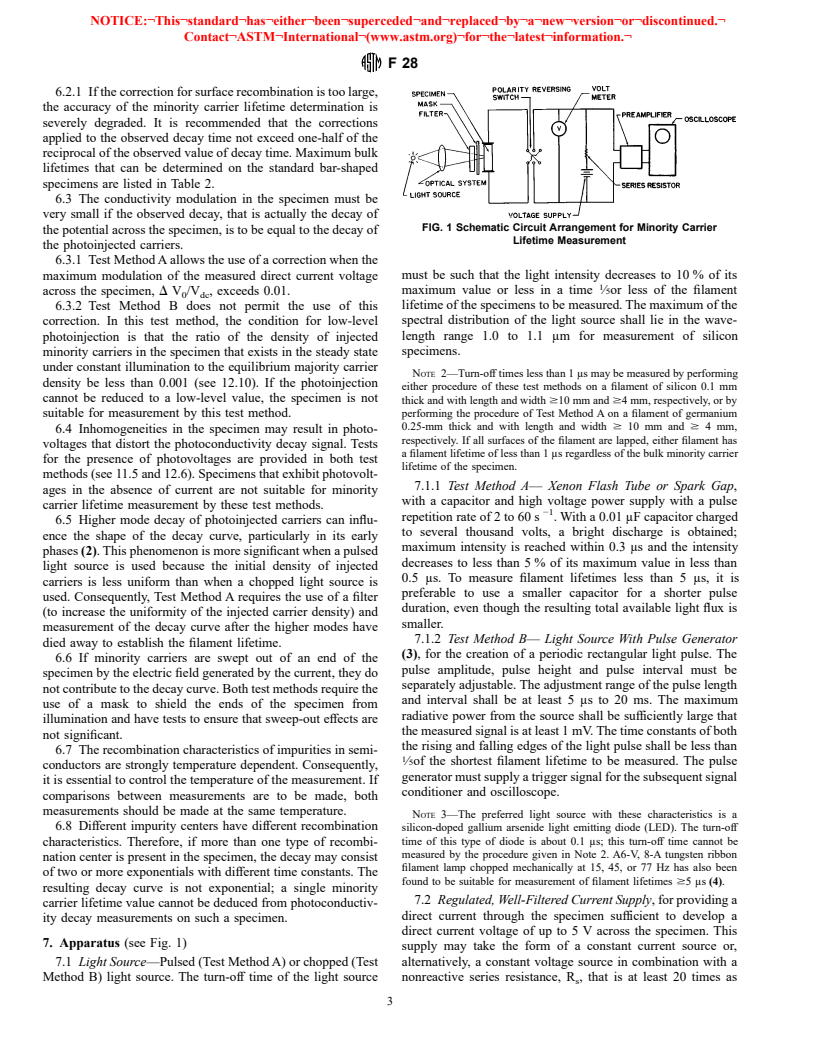

FIG. 1 Schematic Circuit Arrangement for Minority Carrier

the potential across the specimen, is to be equal to the decay of

Lifetime Measurement

the photoinjected carriers.

6.3.1 Test Method A allows the use of a correction when the

must be such that the light intensity decreases to 10 % of its

maximum modulation of the measured direct current voltage

maximum value or less in a time ⁄5or less of the filament

across the specimen, D V /V , exceeds 0.01.

0 dc

lifetime of the specimens to be measured. The maximum of the

6.3.2 Test Method B does not permit the use of this

spectral distribution of the light source shall lie in the wave-

correction. In this test method, the condition for low-level

length range 1.0 to 1.1 μm for measurement of silicon

photoinjection is that the ratio of the density of injected

specimens.

minority carriers in the specimen that exists in the steady state

under constant illumination to the equilibrium majority carrier

NOTE 2—Turn-off times less than 1 μs may be measured by performing

density be less than 0.001 (see 12.10). If the photoinjection

either procedure of these test methods on a filament of silicon 0.1 mm

cannot be reduced to a low-level value, the specimen is not

thick and with length and width $10 mm and $4 mm, respectively, or by

suitable for measurement by this test method. performing the procedure of Test Method A on a filament of germanium

0.25-mm thick and with length and width $ 10 mm and $ 4 mm,

6.4 Inhomogeneities in the specimen may result in photo-

respectively. If all surfaces of the filament are lapped, either filament has

voltages that distort the photoconductivity decay signal. Tests

a filament lifetime of less than 1 μs regardless of the bulk minority carrier

for the presence of photovoltages are provided in both test

lifetime of the specimen.

methods (see 11.5 and 12.6). Specimens that exhibit photovolt-

7.1.1 Test Method A— Xenon Flash Tube or Spark Gap,

ages in the absence of current are not suitable for minority

with a capacitor and high voltage power supply with a pulse

carrier lifetime measurement by these test methods.

−1

repetition rate of 2 to 60 s . With a 0.01 μF capacitor charged

6.5 Higher mode decay of photoinjected carriers can influ-

to several thousand volts, a bright discharge is obtained;

ence the shape of the decay curve, particularly in its early

maximum intensity is reached within 0.3 μs and the intensity

phases (2). This phenomenon is more significant when a pulsed

decreases to less than 5 % of its maximum value in less than

light source is used because the initial density of injected

0.5 μs. To measure filament lifetimes less than 5 μs, it is

carriers is less uniform than when a chopped light source is

preferable to use a smaller capacitor for a shorter pulse

used. Consequently, Test Method A requires the use of a filter

duration, even though the resulting total

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.