ASTM D5628-10

(Test Method)Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass)

SIGNIFICANCE AND USE

Plastics are viscoelastic and therefore are likely to be sensitive to changes in velocity of the mass falling on their surfaces. However, the velocity of a free-falling object is a function of the square root of the drop height. A change of a factor of two in the drop height will cause a change of only 1.4 in velocity. Hagan et al (2) found that the mean-failure energy of sheeting was constant at drop heights between 0.30 and 1.4 m. This suggests that a constant mass-variable height method will give the same results as the constant height-variable mass technique. On the other hand, different materials respond differently to changes in the velocity of impact. Equivalence of these methods should not be taken for granted. While both constant-mass and constant-height techniques are permitted by these methods, the constant-height method should be used for those materials that are found to be rate-sensitive in the range of velocities encountered in falling-weight types of impact tests.

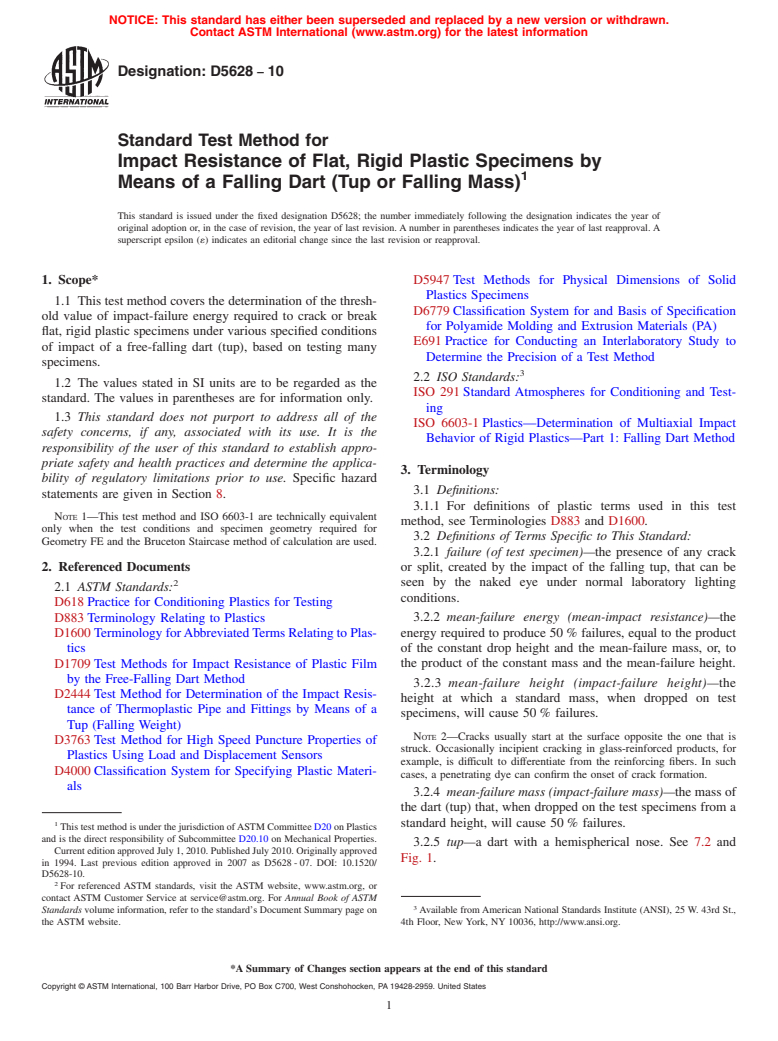

The test geometry FA causes a moderate level of stress concentration and can be used for most plastics.

Geometry FB causes a greater stress concentration and results in failure of tough or thick specimens that do not fail with Geometry FA (3). This approach can produce a punch shear failure on thick sheet. If that type of failure is undesirable, Geometry FC should be used. Geometry FB is suitable for research and development because of the smaller test area required.

The conical configuration of the 12.7-mm diameter tup used in Geometry FB minimizes problems with tup penetration and sticking in failed specimens of some ductile materials.

The test conditions of Geometry FC are the same as those of Test Method A of Test Method D1709. They have been used in specifications for extruded sheeting. A limitation of this geometry is that considerable material is required.

The test conditions of Geometry FD are the same as for Test Method D3763.

The test conditions of Geometry FE are the ...

SCOPE

1.1 This test method covers the determination of the threshold value of impact-failure energy required to crack or break flat, rigid plastic specimens under various specified conditions of impact of a free-falling dart (tup), based on testing many specimens.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

Note 1—This test method and ISO 6603-1 are technically equivalent only when the test conditions and specimen geometry required for Geometry FE and the Bruceton Staircase method of calculation are used.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5628 − 10

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimens by

1

Means of a Falling Dart (Tup or Falling Mass)

This standard is issued under the fixed designation D5628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D5947Test Methods for Physical Dimensions of Solid

Plastics Specimens

1.1 This test method covers the determination of the thresh-

D6779Classification System for and Basis of Specification

old value of impact-failure energy required to crack or break

for Polyamide Molding and Extrusion Materials (PA)

flat, rigid plastic specimens under various specified conditions

E691Practice for Conducting an Interlaboratory Study to

of impact of a free-falling dart (tup), based on testing many

Determine the Precision of a Test Method

specimens.

3

2.2 ISO Standards:

1.2 The values stated in SI units are to be regarded as the

ISO 291Standard Atmospheres for Conditioning and Test-

standard. The values in parentheses are for information only.

ing

1.3 This standard does not purport to address all of the

ISO 6603-1Plastics—Determination of Multiaxial Impact

safety concerns, if any, associated with its use. It is the

Behavior of Rigid Plastics—Part 1: Falling Dart Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use. Specific hazard

3.1 Definitions:

statements are given in Section 8.

3.1.1 For definitions of plastic terms used in this test

NOTE 1—This test method and ISO 6603-1 are technically equivalent

method, see Terminologies D883 and D1600.

only when the test conditions and specimen geometry required for

3.2 Definitions of Terms Specific to This Standard:

Geometry FE and the Bruceton Staircase method of calculation are used.

3.2.1 failure (of test specimen)—the presence of any crack

2. Referenced Documents or split, created by the impact of the falling tup, that can be

2

seen by the naked eye under normal laboratory lighting

2.1 ASTM Standards:

conditions.

D618Practice for Conditioning Plastics for Testing

D883Terminology Relating to Plastics 3.2.2 mean-failure energy (mean-impact resistance)—the

energy required to produce 50% failures, equal to the product

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics of the constant drop height and the mean-failure mass, or, to

the product of the constant mass and the mean-failure height.

D1709Test Methods for Impact Resistance of Plastic Film

by the Free-Falling Dart Method

3.2.3 mean-failure height (impact-failure height)—the

D2444Test Method for Determination of the Impact Resis-

height at which a standard mass, when dropped on test

tance of Thermoplastic Pipe and Fittings by Means of a

specimens, will cause 50% failures.

Tup (Falling Weight)

NOTE 2—Cracks usually start at the surface opposite the one that is

D3763Test Method for High Speed Puncture Properties of

struck. Occasionally incipient cracking in glass-reinforced products, for

Plastics Using Load and Displacement Sensors

example, is difficult to differentiate from the reinforcing fibers. In such

D4000Classification System for Specifying Plastic Materi-

cases, a penetrating dye can confirm the onset of crack formation.

als

3.2.4 mean-failure mass (impact-failure mass)—the mass of

the dart (tup) that, when dropped on the test specimens from a

1 standard height, will cause 50% failures.

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

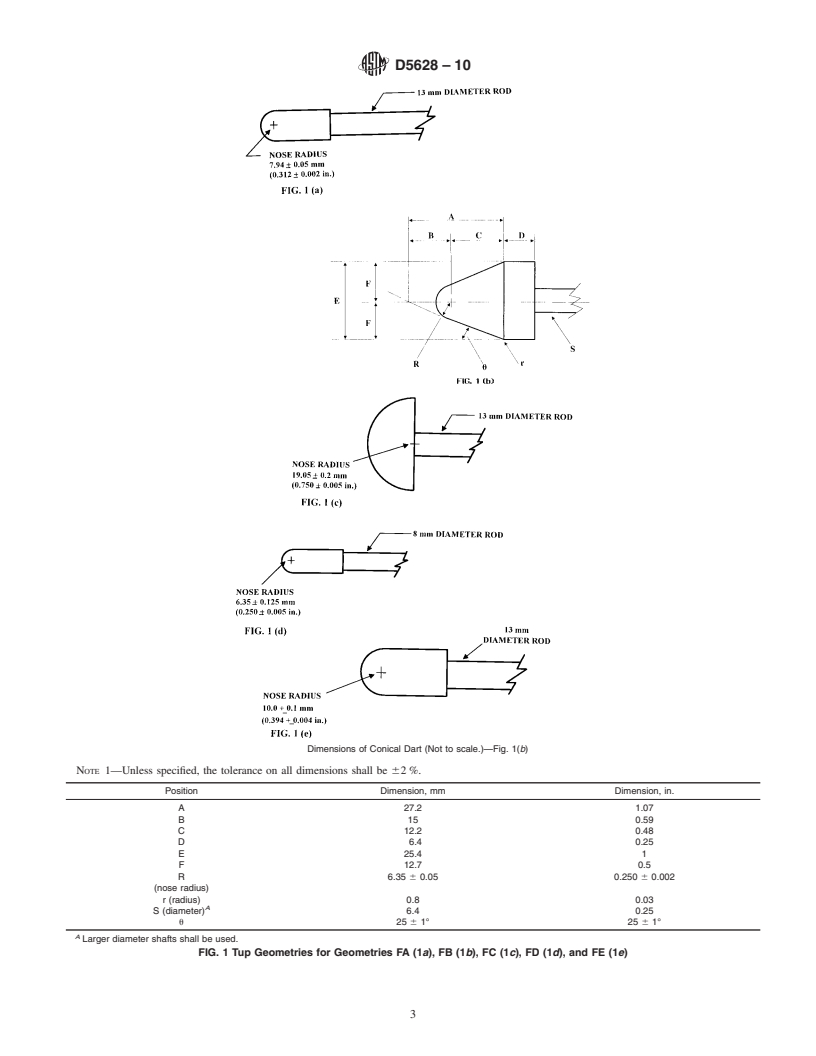

3.2.5 tup—a dart with a hemispherical nose. See 7.2 and

CurrenteditionapprovedJuly1,2010.PublishedJuly2010.Originallyapproved

Fig. 1.

in 1994. Last previous edition approved in 2007 as D5628-07. DOI: 10.1520/

D5628-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5628 − 10

Dimensions of Conical Dart (Not to scale.)—Fig. 1(b)

NOTE 1—Unless specified, the tolerance on all dimensions shall be 62%.

Position Dimension, mm Dimension, in.

A 27.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5628–07 Designation: D5628 – 10

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimens by

1

Means of a Falling Dart (Tup or Falling Mass)

This standard is issued under the fixed designation D5628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of the threshold value of impact-failure energy required to crack or break flat,

rigid plastic specimens under various specified conditions of impact of a free-falling dart (tup), based on testing many specimens.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazard statements are given in Section 8.

NOTE 1—ThistestmethodandISO6603-1aretechnicallyequivalentonlywhenthetestconditionsandspecimengeometryrequiredforGeometryFE

and the Bruceton Staircase method of calculation are used.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1709 Test Methods for Impact Resistance of Plastic Film by the Free-Falling Dart Method

D2444 TestMethodforDeterminationoftheImpactResistanceofThermoplasticPipeandFittingsbyMeansofaTup(Falling

Weight)

D3763 Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors

D4000 Classification System for Specifying Plastic Materials

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

D6779 Classification System for Polyamide Molding and Extrusion Materials (PA)

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ISO Standards:

ISO 291 Standard Atmospheres for Conditioning and Testing

ISO 6603-1 Plastics—Determination of Multiaxial Impact Behavior of Rigid Plastics—Part 1: Falling Dart Method

3. Terminology

3.1 Definitions:

3.1.1 For definitions of plastic terms used in this test method, see Terminologies D883 and D1600.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 failure (of test specimen)—the presence of any crack or split, created by the impact of the falling tup, that can be seen

by the naked eye under normal laboratory lighting conditions.

3.2.2 mean-failure energy (mean-impact resistance)—the energy required to produce 50% failures, equal to the product of the

constant drop height and the mean-failure mass, or, to the product of the constant mass and the mean-failure height.

3.2.3 mean-failure height (impact-failure height)—the height at which a standard mass, when dropped on test specimens, will

cause 50% failures.

NOTE 2—Cracks usually start at the surface opposite the one that is struck. Occasionally incipient cracking in glass-reinforced products, for example,

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved MarchJuly 1, 2007.2010. Published March 2007.July 2010. Originally approved in 1994. Last previous edition approved in 20062007 as

D5628-067. DOI: 10.1520/D5628-107.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5628 – 10

is difficult to differentiate from the reinforcing fibers. In such cases, a penetrating dye can confirm the onset of crack formation.

3.2.4 mean-failure mass (impact-failure mass)—the mass of the dart (tup) that, when dropped on the test specimens from a

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.