ASTM D143-94(2000)e1

(Test Method)Standard Test Methods for Small Clear Specimens of Timber

Standard Test Methods for Small Clear Specimens of Timber

SCOPE

1.1 These methods cover the determination of various strength and related properties of wood by testing small clear specimens.

1.1.1 These methods represent procedures for evaluating the different mechanical and physical properties, controlling factors such as specimen size, moisture content, temperature, and rate of loading.

1.1.2 Sampling and collection of material is discussed in Practice D5536. Sample data, computation sheets, and cards have been incorporated, which were of assistance to the investigator in systematizing records.

1.1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values are given in parentheses and are provided for information only. When a weight is prescribed, the basic inch-pound unit of weight (lbf) and the basic SI unit of mass (Kg) are cited.

1.2 The procedures for the various tests appear in the following order: SectionsPhotographs of Specimens5Control of Moisture Content and Temperature6Record of Heartwood and Sapwood7Static Bending8Compression Parallel to Grain9Impact Bending10Toughness11Compression Perpendicular to Grain12Hardness13Shear Parallel to Grain14Cleavage15Tension Parallel to Grain16Tension Perpendicular to Grain17Nail Withdrawal18Specific Gravity and Shrinkage in Volume19Radial and Tangential Shrinkage20Moisture Determination21Permissible Variations22Calibration23

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 143 – 94 (Reapproved 2000)

Standard Test Methods for

Small Clear Specimens of Timber

This standard is issued under the fixed designation D 143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Keywords were added in April 2000.

INTRODUCTION

The need to classify wood species by evaluating the physical and mechanical properties of small

clear specimens has always existed. Because of the great variety of species, variability of the material,

continually changing conditions of supply, many factors affecting test results, and ease of comparing

variables, the need will undoubtedly continue to exist.

In the preparation of these methods for testing small clear specimens, consideration was given both

to the desirability of adopting methods that would yield results comparable to those already available

and to the possibility of embodying such improvements as experience has shown desirable. In view

of the many thousands of tests made under a single comprehensive plan by the U.S. Forest Service,

the former Forest Products Laboratories of Canada (now Forintek Canada Corp.), and other similar

organizations, the methods naturally conform closely to the methods used by these institutions. These

methods are the outgrowth of a study of both American and European experience and methods. The

general adoption of these methods will tend toward a world-wide unification of results, permitting an

interchange and correlation of data, and establishing the basis for a cumulative body of fundamental

information on the timber species of the world.

Descriptionsofsomeofthestrengthtestsrefertoprimarymethodsandsecondarymethods.Primary

methods provide for specimens of 2 by 2-in. (50 by 50-mm) cross-section. This size of specimen has

been extensively used for the evaluation of various mechanical and physical properties of different

species of wood, and a large number of data based on this primary method have been obtained and

published.

The 2 by 2-in. (50 by 50-mm) size has the advantage in that it embraces a number of growth rings,

is less influenced by earlywood and latewood differences than smaller size specimens, and is large

enough to represent a considerable portion of the sampled material. It is advisable to use primary

method specimens wherever possible. There are circumstances, however, when it is difficult or

impossible to obtain clear specimens of 2 by 2-in. cross section having the required 30 in. (760 mm)

length for static bending tests. With the increasing incidence of smaller second growth trees, and the

desirability in certain situations to evaluate a material which is too small to providea2by 2-in.

cross-section, a secondary method which utilizesa1by 1-in. (25 by 25-mm) cross section has been

included. This cross section is established for compression parallel to grain and static bending tests,

while the 2 by 2-in. cross-section is retained for impact bending, compression perpendicular to grain,

hardness, shear parallel to grain, cleavage, and tension perpendicular to grain. Toughness and tension

parallel to grain are special tests using specimens of smaller cross section.

The user is cautioned that test results between two different sizes of specimens are not necessarily

directly comparable. Guidance on the effect of specimen size on a property being evaluated is beyond

the scope of these methods, and should be sought elsewhere.

Where the application, measurement, or recording of load and deflection can be accomplished using

electronic equipment and computerized apparatus, such devices are encouraged, providing they do not

lower the standard of accuracy and reliability available with basic mechanical equipment.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 143 – 94 (2000)

1. Scope D 4761 Test Method for Mechanical Properties of Lumber

and Wood-Base Structural Material

1.1 These methods cover the determination of various

D 5536 Practice for Sampling the Forest Trees for Determi-

strength and related properties of wood by testing small clear

nation of Clear Wood Properties

specimens.

E4 Practices for Force Verification of Testing Machines

1.1.1 Thesemethodsrepresentproceduresforevaluatingthe

different mechanical and physical properties, controlling fac-

3. Summary of Methods

tors such as specimen size, moisture content, temperature, and

3.1 The mechanical tests are static bending, compression

rate of loading.

parallel to grain, impact bending toughness, compression

1.1.2 Sampling and collection of material is discussed in

perpendicular to grain, hardness, shear parallel to grain (Note

Practice D 5536. Sample data, computation sheets, and cards

1), cleavage, tension parallel to grain, tension-perpendicular-

have been incorporated, which were of assistance to the

to-grain,andnail-withdrawaltests.Thesetestsmaybemadeon

investigator in systematizing records.

both green and air-dry material as specified in these methods.

1.1.3 The values stated in inch-pound units are to be

In addition, methods for evaluating such physical properties as

regarded as the standard. The SI values are given in parenthe-

specific gravity, shrinkage in volume, radial shrinkage, and

ses and are provided for information only. When a weight is

tangential shrinkage are presented.

prescribed, the basic inch-pound unit of weight (lbf) and the

basic SI unit of mass (Kg) are cited.

NOTE 1—The test for shearing strength perpendicular to the grain

1.2 The procedures for the various tests appear in the

(sometimes termed “vertical shear”) is not included as one of the principal

mechanical tests since in such a test the strength is limited by the shearing

following order:

resistance parallel to the grain.

Sections

Photographs of Specimens 5

4. Significance and Use

Control of Moisture Content and Temperature 6

Record of Heartwood and Sapwood 7

4.1 These methods cover tests on small clear specimens of

Static Bending 8

wood that are made to provide the following:

Compression Parallel to Grain 9

Impact Bending 10

4.1.1 Data for comparing the mechanical properties of

Toughness 11

various species,

Compression Perpendicular to Grain 12

4.1.2 Data for the establishment of correct strength func-

Hardness 13

Shear Parallel to Grain 14

tions, which in conjunction with results of tests of timbers in

Cleavage 15

structural sizes (see Methods D 198 and Test Method D 4761),

Tension Parallel to Grain 16

afford a basis for establishing allowable stresses, and

Tension Perpendicular to Grain 17

Nail Withdrawal 18

4.1.3 Data to determine the influence on the mechanical

Specific Gravity and Shrinkage in Volume 19

properties of such factors as density, locality of growth,

Radial and Tangential Shrinkage 20

position in cross section, height of timber in the tree, change of

Moisture Determination 21

Permissible Variations 22

properties with seasoning or treatment with chemicals, and

Calibration 23

change from sapwood to heartwood.

1.3 This standard does not purport to address all of the

5. Photographs of Specimens

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

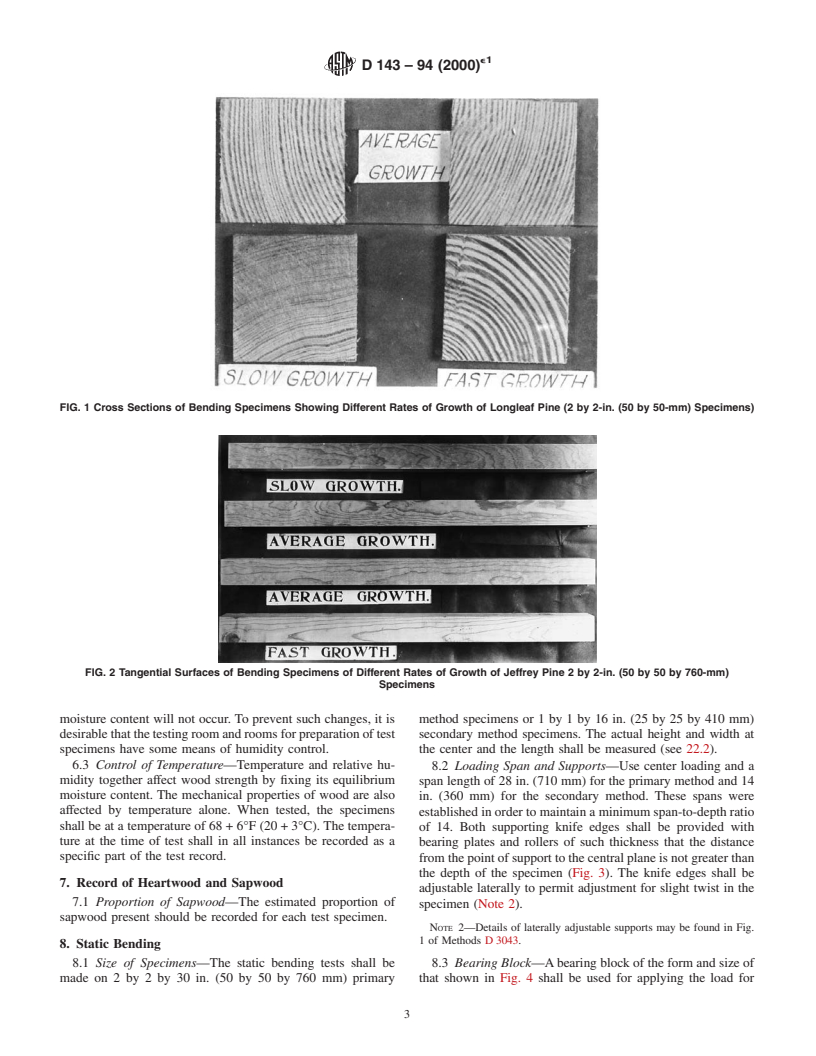

5.1 Four of the static bending specimens from each species

priate safety and health practices and determine the applica-

shall be selected for photographing, as follows: two average

bility of regulatory limitations prior to use.

growth, one fast growth, and one slow growth. These speci-

mens shall be photographed in cross section and on the radial

2. Referenced Documents andtangentialsurfaces.Fig.1isatypicalphotographofacross

section of 2 by 2-in. (50 by 50-mm) test specimens, and Fig. 2

2.1 ASTM Standards:

is the tangential surface of such specimens.

D 198 Methods for Static Tests of Timbers in Structural

Sizes

6. Control of Moisture Content and Temperature

D 2395 Test Methods for Specific Gravity of Wood and

6.1 Inrecognitionofthesignificantinfluenceoftemperature

Wood-Base Materials

and moisture content on the strength of wood, it is highly

D 3043 Methods of Testing Structural Panels in Flexure

desirable that these factors be controlled to ensure comparable

D 3500 Test Method for Structural Panels in Tension

test results.

D 4442 TestMethodsforDirectMoistureContentMeasure-

6.2 Control of Moisture Content—Specimens for the test in

ment of Wood and Wood-Base Materials

the air-dry condition shall be dried to approximately constant

weight before test. Should any changes in moisture content

occur during final preparation of specimens, the specimens

ThesemethodsareunderthejurisdictionofASTMCommitteeD7onWoodand

shall be reconditioned to constant weight before test. Tests

are the direct responsibility of Subcommittee D07.01 on FundamentalTest Methods

shall be carried out in such manner that large changes in

and Properties.

Current edition approved May 15, 1994. Published July 1994. Originally

published as D 143 – 22 T. Last previous edition D 143 – 83.

2 3

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 03.01.

e1

D 143 – 94 (2000)

FIG. 1 Cross Sections of Bending Specimens Showing Different Rates of Growth of Longleaf Pine (2 by 2-in. (50 by 50-mm) Specimens)

FIG. 2 Tangential Surfaces of Bending Specimens of Different Rates of Growth of Jeffrey Pine 2 by 2-in. (50 by 50 by 760-mm)

Specimens

moisture content will not occur. To prevent such changes, it is method specimens or 1 by 1 by 16 in. (25 by 25 by 410 mm)

desirablethatthetestingroomandroomsforpreparationoftest secondary method specimens. The actual height and width at

specimens have some means of humidity control. the center and the length shall be measured (see 22.2).

6.3 Control of Temperature—Temperature and relative hu-

8.2 Loading Span and Supports—Use center loading and a

midity together affect wood strength by fixing its equilibrium

span length of 28 in. (710 mm) for the primary method and 14

moisture content. The mechanical properties of wood are also

in. (360 mm) for the secondary method. These spans were

affected by temperature alone. When tested, the specimens

established in order to maintain a minimum span-to-depth ratio

shall be at a temperature of 68 + 6°F (20 + 3°C). The tempera-

of 14. Both supporting knife edges shall be provided with

ture at the time of test shall in all instances be recorded as a

bearing plates and rollers of such thickness that the distance

specific part of the test record.

from the point of support to the central plane is not greater than

the depth of the specimen (Fig. 3). The knife edges shall be

7. Record of Heartwood and Sapwood

adjustable laterally to permit adjustment for slight twist in the

7.1 Proportion of Sapwood—The estimated proportion of

specimen (Note 2).

sapwood present should be recorded for each test specimen.

NOTE 2—Details of laterally adjustable supports may be found in Fig.

1 of Methods D 3043.

8. Static Bending

8.1 Size of Specimens—The static bending tests shall be 8.3 Bearing Block—Abearing block of the form and size of

made on 2 by 2 by 30 in. (50 by 50 by 760 mm) primary that shown in Fig. 4 shall be used for applying the load for

e1

D 143 – 94 (2000)

FIG. 3 Static Bending Test Assembly Showing Method of Load Application, Specimen Supported on Rollers and Laterally Adjustable

Knife Edges, and Method of Measuring Deflection at Neutral Axis by Means of Yoke and Dial Attachment (Adjustable scale mounted on

loading head is used to measure increments of deformation beyond the dial capacity.)

method specimens, and at a rate of 0.05 in. (1.3 mm)/min for

secondary method specimens.

8.6 Load-Deflection Curves:

8.6.1 Load-deflection curves shall be recorded to or beyond

the maximum load for all static bending tests. The curves shall

be continued to a 6 in. (150 mm) deflection, or until the

specimen fails to support a load of 200 lbf (890 N) for primary

methodspecimensandtoa3in.(76mm)deflectionoruntilthe

specimenfailstosupportaloadof50lbf(220N)forsecondary

method specimens.

8.6.2 Deflections of the neutral plane at the center of the

length shall be taken with respect to points in the neutral plane

above the supports. Alternatively, deflection may be taken

relative to the tension surface at midspan. However, take care

to ensure that vertical displacements which may occur at the

reactions are accounted for.

8.6.3 Within the proportional limit, deflection readings shall

be taken to 0.001 in. (0.02 mm).After the proportional limit is

reached, less refinement is necessary in observing deflections,

butitisconvenienttoreadthembymeansofthedialgage(Fig.

3) until it reaches the limit of its capacity, normally approxi-

mately 1 in. (25 mm). Where deflections beyond 1 in. are

FIG. 4 Details of Bearing Block for Static Bending Tests

encountered, the deflections may be measured by means of the

scale mounted on the loading head (Fig. 3) and a wire mounted

at the neutral axis of the specimen of the side opposite the

primary method specimens. A block having a radius of 1 ⁄2 in.

yoke. Deflections are read to the nearest 0.01 in. (0.2 mm) at

(38 mm) for a chord length of not less than 2 in. (50 mm) shall

0.10 in. (2.5 mm) intervals and also after abrupt changes in

be used for secondary method specimens.

load.

8.4 Placement of Growth Rings—The specimen shall be

8.6.4 The load and deflection of first failure, the maximum

placed so that the load will be applied through the bearing

load, and points of sudden change shall be read and shown on

block to the tangential surface nearest the pith.

the curve sheet (Note 3) although they may not occur at one of

8.5 Speed of Testing—The load shall be applied continu-

the regular load or deflection increments.

ously throughout the test at a rate of motion of the movable

crosshead of 0.10 in. (2.5 mm)/min (see 22.3), for primary NOTE 3—See Fig. 5 for a sample static bending data sheet form.

e1

D 143 – 94 (2000)

FIG. 5 Sample Data Sheet for Static Bending Test

8.7 Description of Static Bending Failures—Static bending 9. Compression Parallel to Grain

(flexural) failures shall be classified in accordance with the

9.1 Size of Specimens—The compression-parallel-to-grain

appearance of the fractured surface and the manner in which

tests shall be made on 2 by 2 by 8 in. (50 by 50 by 200 mm)

the failure develops (F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.