ASTM D1036-99(2017)

(Test Method)Standard Test Methods of Static Tests of Wood Poles

Standard Test Methods of Static Tests of Wood Poles

SIGNIFICANCE AND USE

4.1 Tests of wood poles are made to determine:

4.1.1 Data for use in establishing allowable stresses,

4.1.2 Data upon which to base economical pole line design,

4.1.3 Data on the strength properties of different species in pole sizes,

4.1.4 Data as to the influence of defects on the strength properties of poles,

4.1.5 Data as to the effect of preservatives and preservative treatments on the strength properties of poles, and

4.1.6 Data for correlating the strength properties of full-size poles with those of small clear specimens of the same species.

4.2 Treating procedures to which poles have been subjected may introduce variables that prohibit direct comparisons between different groups of data. Complete information on the treating techniques shall form a part of the test records.

SCOPE

1.1 These test methods cover determination of the bending strength and stiffness of wood poles. Knowledge of these properties is used in providing for reliable and economical design with poles of different species, size, or grade.

1.2 Two test methods are included: the cantilever test method and the machine test method.

1.3 Provision is also made for extracting small clear specimens from the butt section and determining static bending and compression parallel to grain strength values in accordance with Test Methods D143.

1.4 The procedures specified in these test methods apply to tests of either treated or untreated material.

1.5 The values stated in inch-pound units are to be regarded as the standard. SI values are given in parentheses and are provided for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1036 − 99 (Reapproved 2017)

Standard Test Methods of

Static Tests of Wood Poles

This standard is issued under the fixed designation D1036; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

One of the important factors involved in the design and economical use of poles for the support of

aerialcommunicationandpowerlinesisthevalueofthemaximumfiberstressforthedifferentspecies

of timber used for poles. In order to gain information on this characteristic, mechanical tests on pole

size specimens have been made by numerous investigators. These tests have been made in various

manners, such as the use of a testing machine, holding the pole butt horizontally in a crib and applying

the load at the tip, setting poles in the earth and applying the load at the tip, and so forth. The amount

of seasoning the test poles have received and the type of preservative treatment applied to the poles

are additional variables. The result is that it is difficult, if not impossible, to obtain sufficient

information pertaining to the various tests to permit accurate comparisons.

It is the purpose of these test methods to cover testing procedures in sufficient detail so that the

results of tests made in accordance with the test methods defined will be comparable. It is, of course,

not intended that using other test methods that may be better adapted to a particular investigation

should be discouraged. However, experience gained from tests of several hundred poles has indicated

the test methods specified are entirely practicable.

The data forms presented have been found to be convenient for recording the test data and for

making the calculations necessary for the proper analysis of the test results.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 These test methods cover determination of the bending

responsibility of the user of this standard to establish appro-

strength and stiffness of wood poles. Knowledge of these

priate safety, health, and environmental practices and deter-

properties is used in providing for reliable and economical

mine the applicability of regulatory limitations prior to use.

design with poles of different species, size, or grade.

1.7 This international standard was developed in accor-

1.2 Two test methods are included: the cantilever test

dance with internationally recognized principles on standard-

method and the machine test method.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.3 Provision is also made for extracting small clear speci-

mendations issued by the World Trade Organization Technical

mens from the butt section and determining static bending and

Barriers to Trade (TBT) Committee.

compression parallel to grain strength values in accordance

with Test Methods D143.

2. Referenced Documents

1.4 The procedures specified in these test methods apply to 2

2.1 ASTM Standards:

tests of either treated or untreated material.

D143 Test Methods for Small Clear Specimens of Timber

1.5 The values stated in inch-pound units are to be regarded D198 Test Methods of Static Tests of Lumber in Structural

as the standard. SI values are given in parentheses and are Sizes

provided for information only. 2.2 ANSI Standard:

O5.1 Specifications and Dimensions for Wood Poles

1 2

These test methods are under the jurisdiction of ASTM Committee D07 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Wood and are the direct responsibility of Subcommittee D07.04 on Pole and Pile contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2017. Published October 2017. Originally the ASTM website.

approved in 1949. Last previous edition approved in 2012 as D1036 – 99 (2012). Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/D1036-99R17. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1036 − 99 (2017)

3. Summary of Test Method

FIELD NOTES

Project No.

3.1 Major Tests:

Locality cut

3.1.1 In the cantilever test method, the pole is supported County

Slope . Elevation

securely from butt to ground line in a horizontal position, and

Undergrowth

a load is applied near the pole tip by means of a pulling line.

Crown

Soil

3.1.2 In the machine test method, the pole is supported near

Shipment No.

the butt and tip, and a load is applied at the ground line by the

Species

moving head of a mechanical testing machine.

Date cut

3.1.3 Determinations of age, rate of growth, moisture, and Seedling or sprout

How and when transported from woods

density are also made.

Age of tree in years

Treatment

3.2 Minor Tests:

Seasoning

3.2.1 Small clear specimens are taken from the butt section

Preservative retention

ofthetestedpolesforthedeterminationofstrengthvaluessuch

Age in service (if pole had been in service)

Age of pole since treatment

as static bending, compression parallel to grain, toughness,

Source of pole (supplier, region, and climate), if pole had been in service

compression perpendicular to grain, and hardness. The overall

Classification standard

objectives of the program will determine which of these tests

Condition of pole (decay, woodpecker holes, splits), if pole had been

in service

are desired.

8. Field Marking

4. Significance and Use

8.1 Each specimen shall be legibly marked on the butt with

4.1 Tests of wood poles are made to determine:

its length, class, and source of supply, in accordance with the

4.1.1 Data for use in establishing allowable stresses,

requirements ofANSI O5.1, using such symbols as may apply

4.1.2 Data upon which to base economical pole line design,

to each specimen.

4.1.3 Data on the strength properties of different species in

pole sizes,

CONDITIONING AND MEASURING OF SPECIMENS

4.1.4 Data as to the influence of defects on the strength

FOR TESTING

properties of poles,

4.1.5 Data as to the effect of preservatives and preservative

9. Conditioning

treatments on the strength properties of poles, and

9.1 Two basic procedures for conditioning and moisture

4.1.6 Data for correlating the strength properties of full-size

content are provided as follows:

poles with those of small clear specimens of the same species.

9.1.1 Test Method A, providing for air seasoning and butt

4.2 Treating procedures to which poles have been subjected soaking of poles prior to test.

may introduce variables that prohibit direct comparisons be- 9.1.2 Test Method B, providing for tests of poles in the

tween different groups of data. Complete information on the full-length green condition.

treating techniques shall form a part of the test records.

NOTE 2—Test Method A, providing for butt soaking of poles after

seasoning, has been used as a preconditioning test method when it is

COLLECTION OF MATERIAL

desired to provide tests simulating, as nearly as possible, actual field use

under certain climatic conditions.

5. Identification

Test Method B, providing for tests of poles in the green condition, has

been used where the stability of moisture-strength relationships thus

5.1 Thematerialfortestshallbeselectedbyonequalifiedto

established is particularly desired for comparison between species, grades,

identify the species.

and testing procedures, and for establishing relationship of strength

between full-size poles and that of small clear specimens taken from the

6. Number of Major Specimens

pole material.

6.1 For each species under investigation it is desirable that

10. Alternative Conditioning Requirements

a minimum of 50 specimens be selected for test. The poles

shall be carefully chosen as representative of the commercial

10.1 Test Method A—All poles tested shall be air-seasoned

product being supplied.

on skids at least 2 ft (600 mm) above the ground. Prior to

testing, the butt sections (from the groundline to the butt) shall

NOTE 1—Tests may be conducted to study the effect of some particular

besoakedinwaterinordertobringthemoisturecontentofthis

characteristic and in such cases the selection of test specimens shall be

made in such a manner as to ensure that the range of the characteristic section equal to or above the fiber saturation point. Butt

under study has been adequately sampled.

soaking shall be conducted in a manner to prevent decay and

withthepolesinaverticalposition.Moisturedeterminationsof

7. Field Notes

the butt section shall be made by means of increment borings.

7.1 Field notes fully describing the material shall be care-

The determinations shall be made by using the portions of the

fully made by the collector. These notes shall, so far as

borings nearest the pole surface with a length of boring equal

possible, supply data outlined as follows and shall be incorpo-

to one-half the pole radius.

rated into the test records:

D1036 − 99 (2017)

NOTE 3—For the purposes of these test methods, poles will be

STATIC BENDING TESTS OF POLES

considered air-seasoned when two successive determinations made one

Cantilever Test Method

week apart indicate the moisture content of the pole to have reached a

practically constant value at or below 22 %.

12. Apparatus

10.2 Test Method B—All poles to be tested shall be selected

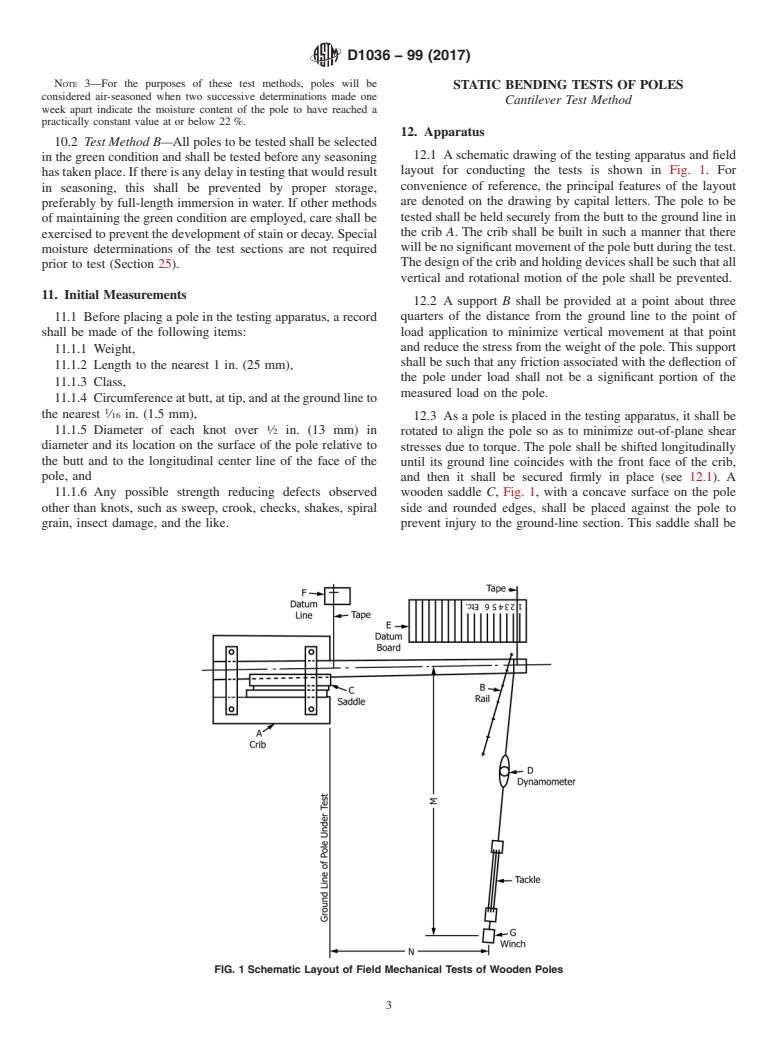

12.1 Aschematic drawing of the testing apparatus and field

in the green condition and shall be tested before any seasoning

layout for conducting the tests is shown in Fig. 1. For

hastakenplace.Ifthereisanydelayintestingthatwouldresult

convenience of reference, the principal features of the layout

in seasoning, this shall be prevented by proper storage,

are denoted on the drawing by capital letters. The pole to be

preferably by full-length immersion in water. If other methods

tested shall be held securely from the butt to the ground line in

of maintaining the green condition are employed, care shall be

the crib A. The crib shall be built in such a manner that there

exercised to prevent the development of stain or decay. Special

willbenosignificantmovementofthepolebuttduringthetest.

moisture determinations of the test sections are not required

Thedesignofthecribandholdingdevicesshallbesuchthatall

prior to test (Section 25).

vertical and rotational motion of the pole shall be prevented.

11. Initial Measurements

12.2 A support B shall be provided at a point about three

quarters of the distance from the ground line to the point of

11.1 Before placing a pole in the testing apparatus, a record

shall be made of the following items: load application to minimize vertical movement at that point

and reduce the stress from the weight of the pole. This support

11.1.1 Weight,

shall be such that any friction associated with the deflection of

11.1.2 Length to the nearest 1 in. (25 mm),

the pole under load shall not be a significant portion of the

11.1.3 Class,

measured load on the pole.

11.1.4 Circumferenceatbutt,attip,andatthegroundlineto

the nearest ⁄16 in. (1.5 mm),

12.3 As a pole is placed in the testing apparatus, it shall be

11.1.5 Diameter of each knot over ⁄2 in. (13 mm) in rotated to align the pole so as to minimize out-of-plane shear

diameter and its location on the surface of the pole relative to

stresses due to torque. The pole shall be shifted longitudinally

the butt and to the longitudinal center line of the face of the

until its ground line coincides with the front face of the crib,

pole, and

and then it shall be secured firmly in place (see 12.1). A

11.1.6 Any possible strength reducing defects observed wooden saddle C, Fig. 1, with a concave surface on the pole

other than knots, such as sweep, crook, checks, shakes, spiral side and rounded edges, shall be placed against the pole to

grain, insect damage, and the like. prevent injury to the ground-line section. This saddle shall be

FIG. 1 Schematic Layout of Field Mechanical Tests of Wooden Poles

D1036 − 99 (2017)

TABLE 1 Winch Positions

made of wood at least as soft as the pole under test and shall

have dimensions as shown in Fig. 2. Distance M from Distance N from

Pole Length, ft (m)

A A

Pole Axis, ft (m) Ground Line, ft (m)

13. Load 20 (6.1) 100 (30.5) 13.5 (4.1)

22 (6.7) 110 (33.5) 15.5 (4.7)

13.1 The load shall be applied at a point 2 ft (600 mm) from

25 (7.6) 125 (38.1) 17.5 (5.3)

30 (9.1) 150 (45.7) 22.0 (6.7)

the tip of the pole by a power winch, or other means of

35 (10.7) 175 (53.3) 26.5 (8.1)

sufficient capacity and capable of pulling at a constant rate of

40 (12.2) 200 (61.0) 31.0 (9.4)

speed. The pulling line shall be kept level between the winch

45 (13.7) 225 (68.6) 35.5 (10.8)

50 (15.2) 250 (76.2) 40.0 (12.2)

position and the point where load is applied to the pole. The

55 (16.8) 275 (83.8) 44.5 (13.6)

load shall be applied continuously until the pole fails, and at

60 (18.3) 300 (91.4) 49.0 (14.9)

such a rate of speed as to cause a deflection at the point of load

A

See Fig. 1 for location of distances M and N.

of N in./min (mm/min), as determined by the equation:

N 5 2πZL /3C (1)

t

type strain gages, suitably wrapped or housed for protection

where:

against shock when the pole breaks. This method permits

N = rate of deflection, in./min (mm/min),

remote reading of loads and minimizes the possibility of

Z = rate of fiber strain, in./in.·min (mm/mm·min) = 0.0010,

personal injury during test. Alternatively, where electric-type

the value specified in Test Methods D198,

straingagingequipmentisnotavailable,loadmaybemeasured

L = lever arm, in. (mm), and

by a dynamometer of suitable capacity, graduated in 50-lb

C = circumference at point of load application, in. (mm).

t

(200-N) divisions. Calibration of the dynamometer shall be

checked at frequent intervals during the tests. The load-

14. Pulling Line

measuringdeviceshallbesupportedonasledorcradlemoving

14.1 The pulling line shall be secured around the pole at the

on a suitable platform or level space.The sled or cradle and the

load point. The load measuring device shall be placed in series

surface on which it moves shall be such that the force required

with the pulling line and the line to the winch with a

to pull it shall not add mat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.